Professional Documents

Culture Documents

Aircraft Maintenance Programme: S P Singh

Aircraft Maintenance Programme: S P Singh

Uploaded by

San Vill100%(1)100% found this document useful (1 vote)

9 views25 pagesaircrartmaintenance

Original Title

aircraftmaintenanceprogramme-110211200813-phpapp02

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentaircrartmaintenance

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

100%(1)100% found this document useful (1 vote)

9 views25 pagesAircraft Maintenance Programme: S P Singh

Aircraft Maintenance Programme: S P Singh

Uploaded by

San Villaircrartmaintenance

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 25

AIRCRAFT

MAINTENANCE

PROGRAMME

S P Singh

General

The MP is an important feature of the

airworthiness management process.

Ref. CAR M 302

Definition

Information

Control

Approval

component

Abbriviation

MPD : maintenance planning document

CMM : component maintenance manual

SB

: service bulletin

SIL

: service information letter

AMP : Aircraft Maintenance Programme

CAM : Continuing Airworthiness

Manager

Contains

1. what is maintenance

programme ?

2. Information for AMP

3. Approval of AMP

4. personnel

5. Component

6. AMP specialist

7. Optimization

Contains

8.Review

9.Task

10.Task card

11.Training

12.Responsibilities of CAM

13.Conclusion

Definition

What is a Maintenance Programme?

A Maintenance Programme is comprised of a

schedule of maintenance tasks with documented

management procedures which describe how

the scheduled maintenance will be managed.

The scheduled tasks are initially developed from

the TCH/STCH/OEM schedule recommendations

Each aircraft may require individual task

development as each aircraft service history

develops e.g. corrosion, repairs, modifications

Information

Information may come from a range of

documents

MPD

CMM

Repair approval instructions

SB, SIL

STC

Control of AMP

Provision for the control of Maintenance

Programme or Schedule Amendments is

contained in Part M.A.302 Maintenance

Programme Approval by Sub part G

organisation (see also appendix 1 to AMC

M.A.302)

Approval of AMP

Approval may be issued to Sub Part G approved

organisation with approved procedures in CAME

Approval may be used for control of In House

Programmes / Schedules

Contracted Operators

Ultimate Responsibility for effectiveness of

Programme / Schedule (Part M.A.301) remains

with operator

Personnel

Nominated Post holder to liaise with

dgca and manage control of Programme

In-House

Sufficient numbers of trained and

competent personnel with knowledge of

Reliability Centred Maintenance

MSG Analysis and MRB Procedures (as

applicable)

AMP component

Type Certification Requirements

Aircraft or System or Component (Type)

Organisation Procedures relating to

Schedule or Programme Amendment

Control

Requirements applicable to control of

Schedules / Programmes including

Powerplant and Structures Programmes

AMP specialist

The MP is an important feature of the

airworthiness management process.

In order to manage the MP the operator

will need to employ specialists related to

Systems

Weight Control

Power plant

Structures

Maintenance Programme Management

Reliability Programme management

The role of the specialists

Assessment of ICAW SB, SIL, MPD, AD,

CMM

Continuing Review of fleet performance

reliability, MP effectiveness, ASR/MOR,

strip reports, check findings, function

check reports, corrosion findings

Planning

MOR

Action/follow up to MOR/ASR/SDR

Raise Engineering Orders as necessary

The role of the specialists-cont.

Liaison with TCH/OEM/DGCA

Liaison with operations

Liaison/oversight of service providers e.g.

maintenance, ground operations

Review of operator technical instructions

MEL/ADD rates

Trend monitoring reports

Preparation of work scopes esp.

Powerplant

specialists require

In order to fulfill the function associated

with maintenance programme

management the specialists require

Specialised technical

training/qualifications

Familiarity with the TCH procedures

Knowledge of MP management processes

organisation structure

There is no idealised organisation structure for

the management of maintenance programmes

the organisation should have the following

features

Independent Quality Audit

Sufficient numbers of qualified specialists

Appropriate level of management

Reporting lines within the airworthiness

management structure

Applicable and effective procedures to ensure

appropriate liaison and decision making

Optimization

Optimization could result in the following changes

to the Scheduled Maintenance Programme;

Change to compliance interval category (FH, FC,

Calendar, Check etc)

Escalation or reduction of compliance interval

Revision of task or process (insp, CK, FC, OPC,

CM, OC, HT etc)

Revision of accomplishment instructions

Deletion of Task or Process

Revision of work scope

Addition of tasks

Optimization

Procedures to be adopted Reliability Monitoring

(Part M.A.302 (d) AMC M.A.302 (d))

Task escalation and adjustment

SB Policy, Review and Assessment

MP / MS Review and Revision

Independent Quality Audit

Component Equipment & Structures In- Service

Programme Review

Programme Rules

Review

Maintenance Procedures effectiveness

Review and Amendment

MPD Review and Assessment

Quality Audit

Variation Procedures

Operator / Maintenance Liaison

Sub-Contractor and Supplier Evaluation

Training

Reliability Procedure

Reliability Procedures - Reliability review

must additionally take account of

Maintenance Standards

Operating Rules

Aircraft Age

SB / Mod. Standard

Utilisation

Maintenance Procedures

Task

The scheduled maintenance tasks are

often transcribed on to Task Cards

The task cards are then used by the

maintenance supplier to control the

maintenance at the point of delivery

hangar, line etc.

Task Card

The task card contains the Inspection

Standard General Visual Inspection

The definition of General Visual

Inspection is in the MPD programme rules

not on the task card!

Task Card

Task Card Development Process In

accordance with approved procedures

subject to independent audit

ensure traceability in each case

Ensure that any additional data e.g.

inspection standards are included

Responsibility of the CAM

It is the responsibility of the operator

CAM to ensure that the inspection

standards are advised to the

maintenance supplier the task card will

not do this

It is the responsibility of the maintenance

supplier to ensure that the Inspectors are

suitably trained in the inspection

standards

In conclusion:

A maintenance programme is a combination of

management procedures as well as scheduled

maintenance tasks

In order to be applicable and effective a

maintenance programme requires an

integrated organisational structure and

qualified personnel to manage the scheduled

maintenance

The management process is of primary

importance what is scheduled is meaningless

without the management process

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cessna 152 Electrical SystemDocument5 pagesCessna 152 Electrical SystemManish MishraNo ratings yet

- BU1 Technical ManualDocument16 pagesBU1 Technical ManualkevinjonescomNo ratings yet

- HAND TOOL For EASA/CAR - 66 EXAMINATIONDocument201 pagesHAND TOOL For EASA/CAR - 66 EXAMINATIONManish Mishra100% (1)

- VorDocument11 pagesVorManish MishraNo ratings yet

- Dgca Feb 2014 - Paper 2Document8 pagesDgca Feb 2014 - Paper 2Manish MishraNo ratings yet

- B 757 General Familiarisation in MaintenanceDocument167 pagesB 757 General Familiarisation in MaintenanceManish Mishra100% (8)

- DG ShippingDocument76 pagesDG ShippingManish MishraNo ratings yet

- C152 Training Manual SAMPLE 16aug2011Document34 pagesC152 Training Manual SAMPLE 16aug2011Arturo Canalda100% (1)

- BiteDocument2 pagesBiteManish MishraNo ratings yet

- Aircrfat Battery: BY M.K. MishraDocument2 pagesAircrfat Battery: BY M.K. MishraManish MishraNo ratings yet

- Eelectronic SensetiveDocument12 pagesEelectronic SensetiveManish MishraNo ratings yet

- Solve The Problems: (1 Marks)Document7 pagesSolve The Problems: (1 Marks)Govin RocketzNo ratings yet

- CHE 110A Problem Set No. 2: Smith, Van Ness, Abbott, 2.3, Page 56Document2 pagesCHE 110A Problem Set No. 2: Smith, Van Ness, Abbott, 2.3, Page 56Karthika SNo ratings yet

- Pistons To JetsDocument41 pagesPistons To JetsRon Downey100% (2)

- Test Bank For Clinical Nursing Skills 8th Edition SmithDocument7 pagesTest Bank For Clinical Nursing Skills 8th Edition Smithnoumenalskall0wewNo ratings yet

- Rollarc 400Document48 pagesRollarc 400m khNo ratings yet

- The Development of Self-Regulation Across Early ChildhoodDocument37 pagesThe Development of Self-Regulation Across Early ChildhoodvickyreyeslucanoNo ratings yet

- TRA2 - User ManualDocument40 pagesTRA2 - User ManualvaultedroomNo ratings yet

- The Relationship Between Dimensions of Love, Personality, and Relationship LengthDocument11 pagesThe Relationship Between Dimensions of Love, Personality, and Relationship LengthjuaromerNo ratings yet

- Textbook - Thermal Physics PopleDocument26 pagesTextbook - Thermal Physics PoplecowsarechillNo ratings yet

- Risk Assessment On Temperature and Relative Humidity Deviation During On-Going Stability StudiesDocument2 pagesRisk Assessment On Temperature and Relative Humidity Deviation During On-Going Stability StudiesAAAAAAAAAAAAAAAAAAAA ANo ratings yet

- SK 135 SR 3Document327 pagesSK 135 SR 3Trung Cuong100% (1)

- Solution of Assignment 5Document5 pagesSolution of Assignment 5Reza Borah100% (1)

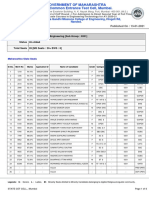

- 2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedDocument8 pages2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedAjit DeshmukhNo ratings yet

- R Reference Manual Volume 1Document736 pagesR Reference Manual Volume 1PH1628No ratings yet

- On Arushi Murder CaseDocument8 pagesOn Arushi Murder Case0000No ratings yet

- The Spirit of Jugaad / Bricolage For Enhanced Corporate EntrepreneurshipDocument20 pagesThe Spirit of Jugaad / Bricolage For Enhanced Corporate EntrepreneurshippanditpreachesNo ratings yet

- Physics Lab Heat and HumidityDocument3 pagesPhysics Lab Heat and HumidityLAUREN YAPNo ratings yet

- Work Inspection Checklist: Project DetailsDocument1 pageWork Inspection Checklist: Project Detailsmark lester caluzaNo ratings yet

- Front Wheel Assy. DrumDocument2 pagesFront Wheel Assy. DrumSoroj BiswasNo ratings yet

- Anggaran ElektronikaDocument12 pagesAnggaran ElektronikaSeptian IswanjayaNo ratings yet

- RRLsDocument6 pagesRRLsRobot RobotNo ratings yet

- Earth Dams Foundation & Earth Material InvestigationDocument111 pagesEarth Dams Foundation & Earth Material Investigationmustafurade1No ratings yet

- 14 Sept Quiz Chapter 1 SoalanDocument5 pages14 Sept Quiz Chapter 1 SoalanLukman MansorNo ratings yet

- Soal Quizziz Buat Sendiri Kelas Xii TTG News ItemDocument6 pagesSoal Quizziz Buat Sendiri Kelas Xii TTG News ItemJorus RukuNo ratings yet

- Proposal Nur Azizah 2315059 R1Document34 pagesProposal Nur Azizah 2315059 R1zizieNo ratings yet

- 12B TB Book PDF-1 PDFDocument113 pages12B TB Book PDF-1 PDFامل العودة طالب100% (1)

- Volume AdministrationDocument264 pagesVolume AdministrationeviyipyipNo ratings yet

- Sharp Edge OrificeDocument2 pagesSharp Edge Orificeleo.caguimbal6433No ratings yet

- LISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsDocument6 pagesLISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsLeandro González De CeccoNo ratings yet