Professional Documents

Culture Documents

DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)

DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)

Uploaded by

Johann ZabaletaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)

DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)

Uploaded by

Johann ZabaletaCopyright:

Available Formats

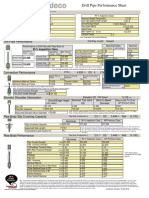

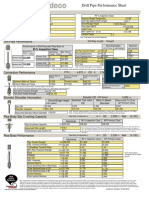

Drill Pipe Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

Drill Pipe Configuration

Pipe Body OD

Pipe Body Wall Thickness

Pipe Body Grade

Drill Pipe Length

Connection

Tool Joint OD

Tool Joint ID

Pin Tong

Box Tong

(in)

(in)

(in)

(in)

(in)

(in)

80 % Inspection Class

Nominal Weight Designation

14.00

(ft) 31.7

Drill Pipe Approximate Length

(in) 3/32 Raised

SmoothEdge Height

(psi) 120,000

Tool Joint SMYS

Upset Type

IU

(in) 4.188

Max Upset OD (DTE)

Friction Factor

1.0

4.000

0.330

G-105

Range2

XT39

4.875

2.563

10

15

Note: Tong space may include hardfacing.

Drill-Pipe Length

Drill Pipe Performance

Best Estimates

Performance of Drill Pipe with Pipe Body at

(without Coating)

80 % Inspection Class

Applied Make-up

Torque

Max Tension

Operational

Torque (ft-lbs)

(lbs)

(ft-lbs)

Maximum MUT

22,200

Minimum MUT

18,500

Tension Only

Combined Loading

Tension Only

Combined Loading

0

20,600

313,900

184,900

0

16,400

313,900

240,200

Drill Pipe Adjusted Weight

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

16.38

0.25

(Bbls/ft) 0.0060

(gal/ft) 0.43

(Bbls/ft) 0.0103

(in) 2.438

XT39

4.875

Applied Make-up

Tension at Shoulder

Torque

Separation

(ft-lbs)

22,200

18,500

(ft-lbs)

(lbs)

Tensile Limited

677,200

SmoothEdge Height

(in)

(lbs)

3/32 Raised

5.062

631,200

Assumed Elevator Bore Diameter

15.80

0.24

0.0057

0.44

0.0105

(lbs/ft)

0.43

0.0101

(lbs)

OD X

(in)

2.563

Tension at Connection

Yield

(lbs)

640,100

724,100

ID

(in)

120,000

(psi)

Tool Joint Dimensions

Balanced OD

(in)

Minimum Tool Joint OD for API

(in)

Premium Class

Minimum Tool Joint OD for

Counterbore

(in)

4.992

4.653

4.653

37,000

724,100

Elevator Shoulder Information

Box OD

Elevator Capacity

(least accurate)

(gal/ft)

Note: The maximum make-up torque should be applied when possible.

Note: To maximize connection operational tensile, a MUT (T4) = 19,800 (ft-lbs) should be applied.

Tool Joint Torsional Strength

Tool Joint Tensile Strength

Nominal

(with Coating)

Note: Oil field barrel equals 42 US gallons.

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

Connection Performance

Maximum Make-up Torque

Minimum Make-up Torque

Range2

(in)

Elevator OD 3/32 Raised

Nominal Tool Joint

Worn to Bevel

OD

Diameter

Worn to Min TJ OD for

API Premium Class

4.875

470,100

4.653

287,200

Pipe Body Slip Crushing Capacity

Pipe Body Configuration

Nominal

Assumed Slip Length

Transverse Load Factor (K)

(lbs)

(in)

Pipe Body Performance

300,400

(ft-lbs)

(ft-lbs)

(psi)

(psi)

(in)

(in)

(in)

(in^2)

(in^2)

(in^2)

(in^3)

(in^3)

4 (in) OD

80 % Inspection Class

238,200

Pipe Body Configuration

(lbs)

0.330 (in) Wall

G-105 )

API Premium Class

238,200

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe

Fail in the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference

only. Slip crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in

slips, drill pipe OD and wall variation, and other factors. Consult with the slip manufacturer for additional

information.

16.5

4.2

Nominal

Pipe Tensile Strength

Pipe Torsional Strength

TJ/PipeBody Torsional Ratio

80% Pipe Torsional Strength

Burst

Collapse

Pipe OD

Wall Thickness

Nominal Pipe ID

Cross Sectional Area of Pipe Body

Cross Sectional Area of OD

Cross Sectional Area of ID

Section Modulus

Polar Section Modulus

(in)

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

4.281

Slip Crushing Capacity

4.786

395,700

5.062

399,500

32,600

1.13

26,100

15,159

15,896

4.000

0.330

3.340

3.805

12.566

8.762

3.229

6.458

4 (in) OD

80 % Inspection Class

313,900

25,500

1.45

20,400

13,860

11,622

3.868

0.264

3.340

2.989

11.751

8.762

2.523

5.046

0.330 (in) Wall

G-105 )

API Premium Class

313,900

25,500

1.45

20,400

13,860

11,622

3.868

0.264

3.340

2.989

11.751

8.762

2.523

5.046

Note: Nominal Burst

calculated at 87.5% RBW

per API.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear

conditions (remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance

ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to

the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback

Customer Created 02-03-2014

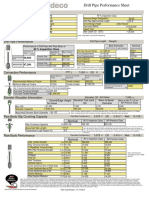

Operational Limits of Drill Pipe

Connection

Pipe Body

XT39

80 % Inspection Class

Tool Joint OD

(in)

4.875

Tool Joint ID

Pipe Body OD

(in)

Wall Thickness (in) 0.330

(in)

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 22,200

Operational Assembly

Torque

Max Tension

(ft-lbs)

0

1,100

2,200

3,300

4,300

5,400

6,500

7,600

8,700

9,800

10,800

11,900

13,000

14,100

15,200

16,300

17,300

18,400

19,500

20,600

(lbs)

313,900

313,600

312,700

311,200

309,400

306,700

303,500

299,600

295,000

289,700

284,300

277,500

269,900

261,400

251,900

241,200

230,400

217,100

202,000

184,900

Pipe Body Grade

Minimum Make-up Torque = 18,500

(ft-lbs)

Operationa Assembly

l Torque

Max Tension

(ft-lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(lbs)

(lbs)

313,900

313,900

677,200

313,900

640,100

313,600

640,100

900

313,700

313,700

677,200

640,100

1,700

313,200

313,200

677,200

677,200

311,200

640,100

2,600

312,200

312,200

309,400

640,100

3,500

310,900

310,900

677,200

306,700

640,100

4,300

309,400

309,400

677,200

303,500

640,100

5,200

307,200

307,200

677,200

640,100

6,000

305,000

305,000

677,200

640,100

6,900

302,100

302,100

677,200

640,100

7,800

298,800

298,800

677,200

677,200

299,600

295,000

289,700

284,300

640,100

8,600

295,400

295,400

277,500

640,100

9,500

291,200

291,200

677,200

269,900

640,100

10,400

286,500

286,500

677,200

261,400

640,100

11,200

281,900

281,900

677,200

640,100

12,100

276,200

276,200

677,200

640,100

12,900

270,600

270,600

677,200

263,800

263,800

677,200

677,200

251,900

241,200

230,400

13,800

640,100

217,100

640,100

14,700

256,300

256,300

202,000

640,100

15,500

249,100

249,100

677,200

184,900

640,100

16,400

240,200

240,200

677,200

Operational drilling torque is limited by the Make-up Torque.

(ft-lbs)

Connection

Max Tension

312,700

G-105

Combined Loading for Drill Pipe at

Connection Max

Pipe Body

Max Tension Tension

(lbs)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

2.563

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

18,500

18,900

19,300

19,700

20,100

20,600

21,000

21,400

21,800

22,200

Connection Max

Tension

(lbs)

677,200

691,900

706,500

721,100

712,900

695,600

681,700

667,800

653,900

640,100

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

Connection Wear Table

Connection

XT39

Tool Joint OD

Connection

Wear

Tool

Joint OD

New OD

(in)

4.875

4.855

4.835

4.814

4.794

4.774

4.754

4.734

4.714

4.693

4.673

4.653

Worn OD

(in)

4.875

Tool Joint ID

(in)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

2.563

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

37,000

36,300

35,700

35,100

34,400

33,800

33,200

32,600

32,000

31,300

30,700

30,100

22,200

21,800

21,400

21,000

20,700

20,300

19,900

19,500

19,200

18,800

18,400

18,100

(ft-lbs)

Connection Max

Tension

Min MUT

(lbs)

(lbs)

(ft-lbs)

640,100

651,400

662,700

673,800

681,400

683,000

676,200

668,900

658,000

634,300

606,700

582,800

18,500

677,200

18,200

668,800

17,900

660,400

17,500

648,500

17,200

640,000

16,900

622,900

16,600

599,100

16,300

575,700

16,000

552,800

15,700

529,700

15,400

507,800

15,100

486,200

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

Pipe Body OD

80 % Inspection Class

Pipe Body Torque

(in)

Wall Thickness (in) 0.330

Pipe Body Grade

G-105

2,300

4,600

6,900

9,300

11,600

13,900

16,200

18,500

20,800

23,200

25,400

312,600

308,700

302,100

292,200

279,400

263,000

242,200

215,800

181,200

129,600

23,900

(ft-lbs)

Pipe Body Max

313,900

Tension

(lbs)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

02-03-2014

You might also like

- Agar Corporation Instruction Manual FORDocument77 pagesAgar Corporation Instruction Manual FORAnand SasidharanNo ratings yet

- Halliburton Icruise Technology (With Modification)Document2 pagesHalliburton Icruise Technology (With Modification)Zakaria Ghrissi aloui0% (1)

- Drawing Bug BlowerDocument1 pageDrawing Bug BlowerahnafNo ratings yet

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocument15 pagesPiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNo ratings yet

- Force Feed Lubricator Pump: PrimingDocument2 pagesForce Feed Lubricator Pump: Priminggustavofx21No ratings yet

- 2M Tek Torq Tek ZIIDocument1 page2M Tek Torq Tek ZIIamghardjillali_449230% (1)

- HOSS ProductDescriptionDocument6 pagesHOSS ProductDescriptionmath62210No ratings yet

- TSH Ip 53.0064 - 01Document4 pagesTSH Ip 53.0064 - 01Cong Bui100% (1)

- TSH-IP-00.0077 - 02 Evaluation of ImperfectionsDocument8 pagesTSH-IP-00.0077 - 02 Evaluation of ImperfectionsCong BuiNo ratings yet

- 1847 A Duplex Piston Pump Mud PumpDocument2 pages1847 A Duplex Piston Pump Mud PumpÆmanuel J SilvaNo ratings yet

- Here: Drilling Data Handbook PDFDocument2 pagesHere: Drilling Data Handbook PDFعماد الدين بن عبودNo ratings yet

- 65500e Hydro-Form CentralizersDocument2 pages65500e Hydro-Form CentralizersNavin KumarNo ratings yet

- PZH (PZ-8) Pump Parts List AF 19002011Document25 pagesPZH (PZ-8) Pump Parts List AF 19002011mantilla7No ratings yet

- Mud Gas Separator Calculation PDFDocument16 pagesMud Gas Separator Calculation PDFGusti Ryandi Arief100% (1)

- 07-01 MafDocument5 pages07-01 MafJuan Roberto López BetanzosNo ratings yet

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringDocument19 pagesSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13No ratings yet

- FMC, SJ Petro TripleStep Swivel Joint, Chiksan Longsweep Swivel JointsDocument4 pagesFMC, SJ Petro TripleStep Swivel Joint, Chiksan Longsweep Swivel JointsAlice Mi100% (1)

- Air Accumulator Operation ManualDocument5 pagesAir Accumulator Operation ManualYasir AbdooNo ratings yet

- Normas APIDocument3 pagesNormas APIJose BarcoNo ratings yet

- Desgaste de BrocasDocument2 pagesDesgaste de Brocasjuliantobop181No ratings yet

- TSH Ip 53.0070 - 01Document4 pagesTSH Ip 53.0070 - 01Cong BuiNo ratings yet

- Halliburton Latam 2009Document17 pagesHalliburton Latam 2009juanmmjcNo ratings yet

- Blast Joint/Flow Coupling: Document # RevisionDocument1 pageBlast Joint/Flow Coupling: Document # RevisionfelipeNo ratings yet

- Bomba Series 100Document4 pagesBomba Series 100Edwing William Salhuana MendozaNo ratings yet

- Tech Manual: Tech-5.12 10K Eh Dual Combi InvDocument22 pagesTech Manual: Tech-5.12 10K Eh Dual Combi InvRiski KurniawanNo ratings yet

- Kunkletabla Seleccion PSVDocument12 pagesKunkletabla Seleccion PSVedwinmenaNo ratings yet

- 160 HR1GJMRS 8168Document1 page160 HR1GJMRS 8168Balkis FatihaNo ratings yet

- JFE CasingDocument40 pagesJFE CasingezrawongNo ratings yet

- Maintenance Interval Schedule c15 MCW PDFDocument3 pagesMaintenance Interval Schedule c15 MCW PDFVictor NunezNo ratings yet

- 5'' 19.5 - G105 NC50 6.625-3.25Document1 page5'' 19.5 - G105 NC50 6.625-3.25Hamza LahbibenNo ratings yet

- Mckissick RJ Style Drilling BlocksDocument1 pageMckissick RJ Style Drilling BlocksRichard EVNo ratings yet

- Properties of Ss410Document5 pagesProperties of Ss410gregkilatonNo ratings yet

- Mantenimece and Operation F-1000Document89 pagesMantenimece and Operation F-1000cesar moraNo ratings yet

- Spe 102658 MS PDFDocument8 pagesSpe 102658 MS PDFxavierNo ratings yet

- Deadline AnchorDocument1 pageDeadline AnchorVijay KotiNo ratings yet

- TSH Ip 53.0067 - 01Document4 pagesTSH Ip 53.0067 - 01Cong BuiNo ratings yet

- API Monogram Products: SelectDocument4 pagesAPI Monogram Products: SelectvsantenrNo ratings yet

- Petrotrim Services General Product Catalog, API-6A EquipmentDocument12 pagesPetrotrim Services General Product Catalog, API-6A EquipmentPetrotrim ServicesNo ratings yet

- 731 AaDocument101 pages731 AaasdasdNo ratings yet

- ZJ70/4500DB RIG 钻机: Parts ListDocument3 pagesZJ70/4500DB RIG 钻机: Parts Listwaleed50% (2)

- Float Valve Recess DimensionsDocument1 pageFloat Valve Recess DimensionsQuality controllerNo ratings yet

- Specifications:: 1. Traveling Block (YG-150)Document6 pagesSpecifications:: 1. Traveling Block (YG-150)Dewantoro HarisNo ratings yet

- 使用说明书Operation ManualDocument84 pages使用说明书Operation ManualMohamed el attarNo ratings yet

- Hydro Pneumatic 1 Inch FNPT Inlet and OutletDocument2 pagesHydro Pneumatic 1 Inch FNPT Inlet and Outletjuan olarteNo ratings yet

- Gate Valve API 6ADocument4 pagesGate Valve API 6ARicardo Paz SoldanNo ratings yet

- Lavadora Secadora LG WD15EGS6 PDFDocument100 pagesLavadora Secadora LG WD15EGS6 PDFK-Search100% (1)

- Api RP 53 SPE 23900 de La IADC - SPE (BOP) EspañolDocument16 pagesApi RP 53 SPE 23900 de La IADC - SPE (BOP) EspañolLucas MaldonadoNo ratings yet

- Chapter 2 - Casing, Tubing and Line Pipe.Document74 pagesChapter 2 - Casing, Tubing and Line Pipe.Franklyn Frank100% (2)

- ABS Fire and Safety Features For MODU - Part5Document40 pagesABS Fire and Safety Features For MODU - Part5Eyoma Etim100% (1)

- Testing Requirements of API 5CRA - Rev2Document2 pagesTesting Requirements of API 5CRA - Rev2ganis supriadiNo ratings yet

- Grasa para Tuberia Bestolife 2000Document4 pagesGrasa para Tuberia Bestolife 2000Haiber BurgosNo ratings yet

- 02 TL-SH32-0001 Hydraulic Stage Cementing ToolDocument7 pages02 TL-SH32-0001 Hydraulic Stage Cementing ToolMaria ArdilaNo ratings yet

- GEB22A-NC Electric MotorDocument153 pagesGEB22A-NC Electric Motorerminhusagic2308No ratings yet

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocument3 pagesDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Инженер Луис А. ГарсиаNo ratings yet

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Garcia C L AlbertoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- Mnemonics - Tool & CurveDocument47 pagesMnemonics - Tool & CurveJohann ZabaletaNo ratings yet

- 6 Chemical FloodingDocument73 pages6 Chemical FloodingJohann ZabaletaNo ratings yet

- Hydrostatic Pressure CalculationDocument2 pagesHydrostatic Pressure CalculationJohann ZabaletaNo ratings yet

- List of Comparative and Superlative AdjectivesDocument3 pagesList of Comparative and Superlative AdjectivesJohann ZabaletaNo ratings yet