Professional Documents

Culture Documents

Met All A The Procedure

Met All A The Procedure

Uploaded by

Nguyen HauOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Met All A The Procedure

Met All A The Procedure

Uploaded by

Nguyen HauCopyright:

Available Formats

No.

DET ESWB-05-2-2

Authorised By: Manager ESWB

Title: Safe Work Procedure Template

Issue Date: May 2012

Last Reviewed: August 2015

Next Review Date: August 2017

Page Number: 1 of 2

DO NOT use this machine unless you have been trained in its safe use and operation.

Description of Work:

Using a metal working lathe.

Potential Hazards: Electrical hazard and exposed

moving parts with the potential to cause harm

through

entanglement,

impact

and

cutting,

pressurised content, noise, exposure to projectiles

and sharp objects.

Personal Protective Equipment (PPE) Required (Check the box for required PPE):

Gloves

Face Masks

Welding

Mask

Appropriate

Footwear

Hearing

Protection

Protective

Clothing

Safe Work Procedure Checklist:

1. PRE-Operation:

Task (e.g. Drawings, instructions, specifications etc.) is clearly understood.

Identify ON/OFF switch and emergency stop button and test any interlocking devises (if applicable).

Ensure chuck guard is in place.

Ensure outer spindle arm guard from the headstock is in place when length of material does not

protrude through headstock spindle.

Ensure the work piece has been suitably prepared for the lathe operation.

Check that the work piece is clamped tight in the chuck.

Ensure correct speed for machining process is selected.

Remove all tools from the bed, top and slides of the machine.

Remove the chuck key before starting the lathe.

2. Operation:

Start lathe and after reaching operating speed, gradually bring cutting tool into contact with work

piece.

Never leave the lathe running while unattended.

Where bar stock protrudes through headstock spindle, place barriers to ensure pedestrian safety.

Before making adjustments or measurements switch off and bring the lathe to a complete

standstill.

Do not attempt to slow/stop the chuck or revolving work by hand.

Do not let swarf build up on the tool or job. Stop the machine and remove it.

3. POST-Operation:

Switch off lathe before removing waste material or work piece from the lathe.

Competent Persons (The following persons are authorised to operate, supervise and test students on the equipment/process).

Name:

Title:

Contact Details:

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

No. DET ESWB-05-2-2

Authorised By: Manager ESWB

Title: Safe Work Procedure Template

Issue Date: May 2012

Last Reviewed: August 2015

Next Review Date: August 2017

Page Number: 2 of 2

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

You might also like

- HyPET Operator CourseDocument159 pagesHyPET Operator Coursemonterrubio_jl290940% (10)

- Ultimate Guide to Home Repair and Improvement, 3rd Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsFrom EverandUltimate Guide to Home Repair and Improvement, 3rd Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsNo ratings yet

- Volvo EW55B Compact Wheel Excavator Service Repair Manual PDFDocument21 pagesVolvo EW55B Compact Wheel Excavator Service Repair Manual PDFjfjkkskemmdm67% (3)

- CNC Milling Machine ProcedureDocument1 pageCNC Milling Machine ProcedureAmaliaAprina100% (1)

- Tyre Changer ProcedureDocument1 pageTyre Changer Procedurejealousmistress100% (4)

- Title: Safe Work Procedure Template: No. DET ESWB-05-2-2 Authorised By: Manager ESWBDocument1 pageTitle: Safe Work Procedure Template: No. DET ESWB-05-2-2 Authorised By: Manager ESWBBharat Patil100% (1)

- Sop Sheet Metal Shear Foot OperatedDocument2 pagesSop Sheet Metal Shear Foot OperatedBALAJI100% (1)

- Es6550c-6540-5540-6570-6560-5560 Toshiba Copier Service ManualDocument2,369 pagesEs6550c-6540-5540-6570-6560-5560 Toshiba Copier Service ManualDusty Lamp100% (6)

- Title: Safe Work Procedure TemplateDocument1 pageTitle: Safe Work Procedure TemplateBenouna FertNo ratings yet

- Metal Milling Mach ProcedureDocument2 pagesMetal Milling Mach ProcedureRemington SalayaNo ratings yet

- MetallatheprocedureDocument1 pageMetallatheprocedureSafety DeptNo ratings yet

- Title: Safe Work Procedure TemplateDocument2 pagesTitle: Safe Work Procedure TemplateEric RamseyNo ratings yet

- Scissor Lift ProcedureDocument2 pagesScissor Lift ProcedureAdhi LatifNo ratings yet

- MetalrollingprocedureDocument1 pageMetalrollingprocedureSyazwanzaim RiggingNo ratings yet

- HydraulicpressprocedureDocument1 pageHydraulicpressprocedureRohit SoniNo ratings yet

- Title: Safe Work Procedure TemplateDocument1 pageTitle: Safe Work Procedure TemplateChristian MakandeNo ratings yet

- Hydraulic Press ProcedureDocument2 pagesHydraulic Press ProcedureARMANNo ratings yet

- Air Compressor ProcedureDocument2 pagesAir Compressor ProcedurePerwez21No ratings yet

- Sop Sander Disc and Belt SanderDocument2 pagesSop Sander Disc and Belt Sanderaungmyat oo4079No ratings yet

- Chainsaw Fuel ProcedureDocument2 pagesChainsaw Fuel ProcedureJoshep Louis KahuanaNo ratings yet

- Sop Grinder Angle GrinderDocument2 pagesSop Grinder Angle Grindernur syamimiNo ratings yet

- Title: Safe Work Procedure Template: No. DET ESWB-05-2-2 Authorised By: Manager ESWBDocument1 pageTitle: Safe Work Procedure Template: No. DET ESWB-05-2-2 Authorised By: Manager ESWBKhaled ElsayedNo ratings yet

- CNC Milling Machine ProcedureDocument1 pageCNC Milling Machine ProcedureAbdullah AlolayanNo ratings yet

- SOP-Coil Winding MachinesDocument4 pagesSOP-Coil Winding MachinesRadhaKrishnan RNo ratings yet

- Sop Drill Electric HandDocument2 pagesSop Drill Electric HandLOCAL ExplorerNo ratings yet

- Arc Welder Risk MG T FormDocument9 pagesArc Welder Risk MG T FormMohd FikryNo ratings yet

- OME553 Industrial Safety Engineering: (Open Elective)Document47 pagesOME553 Industrial Safety Engineering: (Open Elective)Jana garan.s100% (1)

- LawnmowerprocedureDocument1 pageLawnmowerprocedureChristian MakandeNo ratings yet

- STD Template For SOPsDocument2 pagesSTD Template For SOPsHafiz HamzaNo ratings yet

- UntitledDocument2 pagesUntitledLIBANTE, Jason johnNo ratings yet

- Tractor ProcedureDocument1 pageTractor ProcedureDrew NeroNo ratings yet

- SOP MillingDocument2 pagesSOP MillingHehok HeheNo ratings yet

- BA - KPB 45 - 131150 - EngDocument41 pagesBA - KPB 45 - 131150 - EngGCNo ratings yet

- Safe Work Practices SWPDocument66 pagesSafe Work Practices SWPapi-317342021No ratings yet

- Fundamentals of Electrical & InstrumentationDocument80 pagesFundamentals of Electrical & InstrumentationSatya MakhijaNo ratings yet

- Technical Notice OMNI TRIACTLOCK 1Document22 pagesTechnical Notice OMNI TRIACTLOCK 1DistribuidorIBoolPedregalDeSantoDomingoNo ratings yet

- Powered Hand ToolsDocument12 pagesPowered Hand Toolssagar209No ratings yet

- Panther ManualDocument20 pagesPanther ManualBrian GalleyNo ratings yet

- Sop Welder TigDocument2 pagesSop Welder TigShahid Raza100% (1)

- 11B. Angle Grinder SafetyDocument2 pages11B. Angle Grinder SafetySantos RexNo ratings yet

- Metal TornoDocument6 pagesMetal TornoRicardo de OliveiraNo ratings yet

- Safety Rules and Regulations - For MechanicalWorkshop - Final9!10!17Document3 pagesSafety Rules and Regulations - For MechanicalWorkshop - Final9!10!17Raheel Neo AhmadNo ratings yet

- Shop Safety and Environmental CleanlinessDocument9 pagesShop Safety and Environmental CleanlinessrjkrtshNo ratings yet

- Makita Router 3601B - ManualDocument12 pagesMakita Router 3601B - ManualRomeo Echo TangoNo ratings yet

- Module 3 - Classification, Applications and Operations of MachinesDocument5 pagesModule 3 - Classification, Applications and Operations of MachinesIsmaeli KielNo ratings yet

- TVL - Ict - CSS: Quarter 2 - Module 2: Using Hand Tools (Uht)Document17 pagesTVL - Ict - CSS: Quarter 2 - Module 2: Using Hand Tools (Uht)anderson villalunaNo ratings yet

- Module 2Document38 pagesModule 2WilfNo ratings yet

- Technical Notice OMNI SCREWLOCK 1Document20 pagesTechnical Notice OMNI SCREWLOCK 1DistribuidorIBoolPedregalDeSantoDomingoNo ratings yet

- Equipment SOPDocument61 pagesEquipment SOPMyolwinooNo ratings yet

- AgempDocument7 pagesAgemppavan kumarNo ratings yet

- Manual Motor SM10GBDocument26 pagesManual Motor SM10GBtioinoNo ratings yet

- Physhaz 0Document3 pagesPhyshaz 0Toka MohamedNo ratings yet

- Department of Mechanical Engineering Name of SOP: Lathe Usage Room 207Document13 pagesDepartment of Mechanical Engineering Name of SOP: Lathe Usage Room 207Pinto CarlosNo ratings yet

- General Series Overhead Crane: User ManualDocument31 pagesGeneral Series Overhead Crane: User ManualjokoNo ratings yet

- Xerox PE16 Service ManualDocument138 pagesXerox PE16 Service ManualMargelatu SemintarNo ratings yet

- Image Quality Adjustment (Printing Function)Document282 pagesImage Quality Adjustment (Printing Function)Pham The TuNo ratings yet

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Thread Disk Report2Document1 pageThread Disk Report2Nguyen HauNo ratings yet

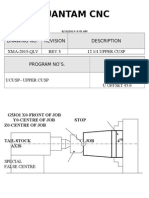

- Uppper Cusp Set-UpDocument3 pagesUppper Cusp Set-UpNguyen HauNo ratings yet

- Zeit BayDocument1 pageZeit BayNguyen HauNo ratings yet

- Hau Nguyen: Shaletech™ 2012 Keynote Speakers AnnouncedDocument3 pagesHau Nguyen: Shaletech™ 2012 Keynote Speakers AnnouncedNguyen HauNo ratings yet

- Tai Lieu Vong Bi NACHIDocument70 pagesTai Lieu Vong Bi NACHINguyen HauNo ratings yet

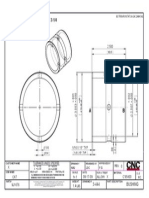

- Workpiece OD3.5" X ID1-7/8" X 3-1/4 Phôi ng89 X tr48 X 83mmDocument1 pageWorkpiece OD3.5" X ID1-7/8" X 3-1/4 Phôi ng89 X tr48 X 83mmNguyen HauNo ratings yet