Professional Documents

Culture Documents

Hyprotech Tel) 02-3453-3144 Fax) 02-3453-9772 E-Mail) Gcyeo@aeat - Co.kr

Hyprotech Tel) 02-3453-3144 Fax) 02-3453-9772 E-Mail) Gcyeo@aeat - Co.kr

Uploaded by

최승원Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hyprotech Tel) 02-3453-3144 Fax) 02-3453-9772 E-Mail) Gcyeo@aeat - Co.kr

Hyprotech Tel) 02-3453-3144 Fax) 02-3453-9772 E-Mail) Gcyeo@aeat - Co.kr

Uploaded by

최승원Copyright:

Available Formats

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

/ / 2016-03-10 14:32

HYPROTECH

Tel) 02-3453-3144

Fax) 02-3453-9772

E-Mail) gcyeo@aeat.co.kr

or gcyeo@software.aeat.com

- 193 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

.

.

1.

2

.

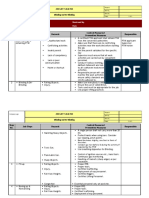

1. Double Pipe Type

2. Shell & Tube Type

3. Plate and Frame Type

4. Plate Fin Type

5. Air Cooled Type

6. Cooling Tower Type

7. Furnace Type

. Shell & Tube

1.

2.

Mechanism

. Thermal Rating

1. Thermal Rating

2.

3. Thermal Rating

4.

5.

6.

.

Program

1. HTFS ( Heat Transfer Fluid Service)

2. HTRI ( Heat Transfer Research Inc.)

3. STX/ACX

4. THERMECH

5. B-JAC

/ / 2016-03-10 14:32

- 194 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

.

(Heat Exchanger)

(Equipment)

(Process Fluid)

,

(Chemical Plant)

(Refinery Plant)

,

.

,

.

, 2

, 3

Shell & Tube

, 5

Thermal Design

, 6

. 7

Shell & Tube Type

.

HTFS.TASC

Tube

Shell &

.

1.

(Conductive Heat Transfer),

(Convective Heat Transfer),

(Radiative Heat Transfer)

,

(Phase Change)

Transfer)

.

.

Tool

/ / 2016-03-10 14:32

(Mass

,

,

Tools

Pilot

.

- 195 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

COLD

HOT

1.1

(Conductive Heat Transfer)

(Solid),

(Static Fluid)

.

Flux

/ / 2016-03-10 14:32

Heat

w

yw

Thot

(Thot Tcold )

Tcold

Thermal

Conductivity

Thermal Conductivity

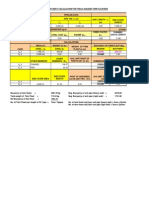

Material

Unit (W/m K)

Stainless Steel

15

Copper

390

Aluminium

208

Carbon Steel

50

Gases

0.02 0.3

Liquids

0.03 0.7

Ploystyrene Foam

0.03

Pipe Lagging

0.092

1.2

yw

(Convective Heat Transfer)

,

(Boundary Layer)

Heat Flux

- 196 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

/ / 2016-03-10 14:32

Film

/

.

(Stream Heat Transfer Coefficient)

h(Film Coefficient)

Bulk Fluid

.

q

(Tbulk Tw )

Reality

Tbulk

q (Tbulk Tw )

Tw

= f(

) = f(Re, Pr)

Film Model

Re = V D / ,

Inertial Force(V2) / Viscous Force(V / D)

Pr = Cp / k ,

Diffusivity of Momentum(/) / Diffusivity of Heat (k/Cp)

(Stream Heat Transfer Coefficient)

Fluid

(W/m2K)

State

Water

Single Phase

Water

Boiling < 5 Bar

Steam

Condensing 1 Bar

Organic

Single Phase 0.5 2.5 cp

750 1500

Organic

Boiling 0.5 2.5 cp

1000 3500

Organic

Condensing 0.5 2.5 cp

1500 4000

Gas

1 Bar

80 125

Gas

10 Bar

250 400

1.3

5000 7500

3000 10000

(Radiative Heat Transfer)

.

.

- 197 -

10000 15000

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

/ / 2016-03-10 14:32

= (T4 - T04)

Q / A

Stephan's constant, 5.67 x 108 W/(m2 K4)

(Furnace)

.

2.

2.1

( U ; Overall Heat Transfer Coefficient)

,

.

.

dQ

= U ( T hot - T cold )

dA

Q = UATLM

Q = mCp(Tin - Tout)

Property

,

U

(Turbulent Flow)

U

1

=

=

cold

1

cold

yw

w

+rcold +

1

hot

yw

w

+rhot +

Clean

1

hot

Fouling

Thot

Clean

Clean

- 198 -

Tcold

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

Fouling

Calculated

Service

.

.

LMTD(Logarithmic

Mean Temperature Difference ; TLM)

Heat Flux

TLM

/ / 2016-03-10 14:32

.

-

(

Counter-Current Flow

TLM

T1 t2 T2 t1

T t

ln 1 2

T2 t1

t2

T2

t1

Enthalpy

(

(

T1

Temp

1

=

H

H1

H2

+

+)

TLM1 T LM2

H

TLM

H

Enthalpy

- Non Counter-Current Flow

T1

Temp

T2

T = FT TLM

t2

t1

FT(F-Factor)

,

.

LMTD

Pilot

Rigorous

2.2 Fouling factor

.

- 199 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

Fouling Layer

- Sedimentation

- Crystallization / Inverse Solubility

- Corrosion

- Polymerization

- Thermal Degradation

- Biological

Fouling Layer

Fouling Factor

Cleaning

Fouling

Flow

,

Fluid Stream

r, m2K/W

0.0001

Treated Cooling Water below 50

0.0002

Treated Cooling Water above 50

0.0003

Steam (Oil Free)

/ / 2016-03-10 14:32

Distribution

Fouling Factor

Sea Water below 50

Untreated Water

.

.

Fluid Stream

Fuel Oil

Crude Oil

0.0005 Refrigerant Liquid

r, m2K/W

0.0008

0.0003

0.0010

0.0002

0.0008

Compressed Air

0.0003

0.0001

Natural Gas

0.0002

- 200 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

.

1. Double Pipe Type

Shell & Tube Type

.

,

Extended Fin

(Longitudinal Fin)

6m

Double Pipe

.

-

Counter-Current Flow

Service

- Modular

(Hair-Fin

Tube

Pipe

2. Shell & Tube Type

85%

,

Heat Exchanger Manufacturers Association)

Thermal Design

/ / 2016-03-10 14:32

TEMA(Tubular

Detail

Mechanical Design

- 201 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

/ / 2016-03-10 14:32

3. Plate and Frame Type

Shell & Tube Heat Exchanger

.

.

,

.

Shell & Tube

.

- Thermal Efficiency

-

- Maintenance

.

.(Cleaning

- Fouling

- Leakage

-

.

.

.

- 202 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

4. Plate Fin Type

Air Separation,

Cryogenic, LNG, LPG,

Ethylene, Ammonia

, Plate

& Frame

Plate & Frame Type

Plate Fin Type

/ / 2016-03-10 14:32

Stream

.

- 203 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

Stainless Steel

- Fouling

Cleaning

5. Air Cooled Type

Tube

Tube

. Tube

Fan

Fin Tube

Fan

.

Forced Draft

Induced Draft Type

Forced Draft Type

Induced Draft Type

Top

Motor/Fan

Fan

Tube Bundle

Bundle Inlet

/ / 2016-03-10 14:32

Cooling

Turbulent

Bundle Inlet

- 204 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

6. Cooling Tower Type

,

.

Cooling Tower

(Cooling Water, Air)

Cooling Water

Cooling Water

.

- Packing

-

Shell

(

- Induced

Loss

Forced Driven Fan

Air

.

.

7. Furnace Type

.

Radiant Section

Convection Section

/ / 2016-03-10 14:32

. Radiant Section

, Convection Section

Heat Flux

Radiant Section

.

SOx, NOx

.

- 205 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

SUMMARY COMPARISON OF HEAT EXCHANGER TYPES

Type

Air cooled

Maximum

Temp.

Fluid

Pressure,

Range

Limitation

bar(abs)

Process Side

Process Side

Ambient to Few

500

600

Brazed Plate 16

Double Pipe

Plate &

Frame

Plate Fin

Printed

Circuit

Must be

-195 200 Compatible

w/ Braze

Shell : 300

-100 600 Few

Tube : 1400

Limited by

-25 175 Gasket,

Normal : 25

not for

Special

Special : 40

-40 200 Normal for

Gases

90

Al : -200 Low fouling

But Size

150

Many Limits

Dependent SS : 600 w/ Al

1000

Range for

Single

2

Unit, m

Minimum T

Temperature Approach

Maximum

Efficiency

0.8

1 10

0.95

0.25 200

0.9

1 2500

0.95

1 10000

(Including

Fin Area)

0.1

0.98

0.1

0.98

10 1000

0.9

1 10000

(Type

Dependent)

0.95

1000

Thot,out - Tcold,out).

- 206 -

T*,

10

Counter-current

(

Minimum

5 350

(Based on

Bare Tube

OD)

-200 800 Low Fouling 1

-25 600

Shell &

Shell : 300 Lower w/

Few

Tube

Tube : 1400 Special

Steels

Welded Plate Differential Depends on Few

Covers

30 60

Type and

Some Types

Range of

Total w/

Material

Need Clean

Types

Shell : 300 -200 650 Fluids

/ / 2016-03-10 14:32

Size

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

. Shell & Tube

Shell & Tube Type

,

TEMA (Tubular Exchanger

Manufacturers Association)

1968

. TEMA

Shell & Tube

ASME Pressure

Vessel Code

1988

Shell & Tube

Head, Shell, Rear 3

.

, TEMA

Double Pipe

.

Kern

,

6

,

Tight

Vibration

Vibration Checking

. Kern

Tube Side

Shell

Side

1.

1.1 Shell

Shell

Shell

/ / 2016-03-10 14:32

E Shell

Horizontal Thermosyphone

G

K Shell

. E Shell

Reboiler

J

, Shell

F Shell

.

- 207 -

H

X Shell

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

TEMA

Front Head

A Type(Dirty

)

Type

B Type(Clean

Fluid

, B Type

. C

N Type

C Type

Shell

/ / 2016-03-10 14:32

Fluid

. D Type

.

Rear Head

Fixed tube Sheet(L, M, N)

Floating Tube Sheet(P, S, T, W)

- 208 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

35 Bar)

Shell

Expansion Joint

Fixed Tube Sheet

Bundle

U Tube

Shell

- 6 12

Standard Pipe

- 14 24

Standard Pipe

(ID

19mm

)

- 24

50mm

3000mm

, Shell

1.2 Tube

Tube

Size(0.25 2)

, Tube

Pitch

Tube

1.25 1.5

.

Pipe

Tube

Tube

Pipe

(

)

BWG

Tube

Schedule No.

8, 10, 12, 14, 16, 20

Tube

Tube

/ / 2016-03-10 14:32

6m, 12m

Pass

F-Factor(FT)

Tube

.

Tube

- 209 -

Pattern

Pattern

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

45o, 90o

Shell

.

30o, 60o

Tube

30o, 60o

Shell

Triangular - 30o

Square - 90o

Rotated Triangular - 60o

Rotated Square - 45o

1-1/4 31.750 16, 14, 12, 10

in.

0.312

0.375

0.500

0.531

0.625

0.656

0.688

0.781

0.812

0.875

0.938

1.000

1.062

1.125

1.250

1.312

1.375

1.562

mm

7.938

9.525

12.700

13.494

15.875

16.669

17.462

19.844

20.638

22.225

23.813

25.400

26.988

28.575

31.750

33.338

34.925

39.688

Pitch

Ratio

1.250

1.500

1.330

1.420

1.250

1.310

1.380

1.250

1.300

1.400

1.250

1.330

1.420

1.500

1.250

1.312

1.375

1.250

1-1/2 38.100 16, 14, 12, 10

2 50.800 13, 11

1.875 47.625

2.500 63.500

1.250

1.250

OD

in.

BWG

mm

1/4

6.350 27, 24, 22

3/8

9.525 22, 20, 18

1/2 12.700 20, 18

5/8 15.875 20, 18, 16

3/4 19.050

20, 18, 16,

14, 12

1 25.400 18, 16, 14, 12

/ / 2016-03-10 14:32

Pitch

- 210 -

BWG

24

0.559

22

0.711

20

0.889

18

1.245

16

1.651

14

2.108

12

2.769

10

3.404

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

1.3 Baffle

Baffle

Cross Baffle

Longitudinal Baffle

Shell

.

F, G, H Shell

Baffle

Single Segment, Double

Segment, Triple Segment, Rod Baffle,

Single segment

Disc-Doughnut, Helical/Spiral

.

Cross Flow

, Shell

Double segment

h

Baffle Cut (%) = h/Ds x 100

Tube

Baffle

Shell

Window Region

Ds

Ds

NTIW(No Tube In Window)

.

Baffle

Nozzle

.

Shell Side Condenser

Vertical

Bypass

Baffle Cut

Spacing

Horizontal

15%(NTIW

10%) 45%

50mm 1500mm(Tube

Baffle

1.4

Shell

Inlet Nozzle

Momentum

Impingement Plate

Vapor Belt

Velocity Head(v2)

.

lb/ft s

Tube

500 lb/ft s

1500

.

Sealing Strip

Shell

Shell Clearance

, Dummy Tube

Pass

/ / 2016-03-10 14:32

Pass Partition

Bypass

Tube

.

- 211 -

Tube

Shell

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

1 : Cross Flow

2 : Bypass

1

1 3

3 : Inline Pass Partition

4 : Window Flow

5 : Tube/Baffle Leakage

6 : Shell/Baffle Leakage

2.

Mechanism

Mechanism

.

2.1 Vertical Tube

Boiling

Vertical Thermosyphone Reboiler

.

Column

Static Head

Static Head

.

Vapor Fraction

Liquid

Surface

Return

0.2(0.1 0.5)

Two-phase

Condensate

Temperature, T

Steam

Ts

Liquid

2.2 Horizontal Tube

Liquid bulk

temperature

Distance z

Boiling

Mechanism

Region

/ / 2016-03-10 14:32

Wall temperature

Tw

- 212 -

, Boiling

Flow

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

Tube

Wet

2.3 Horizontal Shell

Boiling

Horizontal Thermosyphone

,

Kettle Reboiler

Mechanism

.

Pool Boiling

Single phase vapour

Steam

Weir

Tube Bundle

Separation

Region

Liquid level

Circulation

Support Plates

Condensate

2.4 Shell

Tube bundle

Condensing

Process Fluid

Shear Force

Gravity Flow

Gravity

. Horizontal

Baffle

Horizontal

Notch

/ / 2016-03-10 14:32

.

.

- 213 -

Vertical

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

2.5 Falling Film Evaporator

Falling Film Evaporator

,

.

Wall

- Residence Time

- Static Head

.(

- Liquid

Distribution

.

Film Breakdown

- Counter-Current Flow

-

Flooding

Multi-Component Effect

Reboiler

.

Kettle

Vertical

Horizontal

Thermosyphone Thermosyphone

Good

Good

Dirty Fluid

Poor

Hight Limited

Good

Poor

Good

Piping

Good

Good

Poor

Good

Poor

Good

Vacuum

/ / 2016-03-10 14:32

- 214 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

. Thermal Rating

/ / 2016-03-10 14:32

1. Thermal Rating

Thermal Rating

,

U, P,

.

(2

- Shell Diameter

- Tube OD,

- Tube

Pass Partition

- Baffle Data(

, Cut %, Longitudinal Baffle)

- Sealing Strip, Dummy Tube

- Nozzle

Impingement Plate

2.

.

.

.

,

Stress

Stress

.

Tube

,

,

- 215 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

/ / 2016-03-10 14:32

, Lifting, Service Capability

, Tube

3. Thermal Rating

- Heat Duty

- Fluid

-

(Density, Specific Heat Capacity, Viscosity, Thermal

Conductivity, Surface Tension)

- Fouling Factor

-

Heat Flux

- Shell Diameter

- Tube Dimension

-

Code

Standard

4.

Shell

Tube Bundle(Fixed Tube Sheet, Floating Head, U Tube Bundle)

(Tube

Shell

Thermal Expansion

Tolerance

- 216 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

5.

Rule

- Fixed Tube Sheet

- Floating Head/Sheet :

Leak

- U-Tube/Bundle

:

Bending

Erosion

.

- Kettle Type

: Tube Bundle

.

- Double Pipe

- Pipe/Open Coil

.

,

.

- Plate and Frame

- Spiral

: Turbulence

Corrosion

: Cooling Water

: Fouling

Tube Side

Tube Side

Tube Side

- Capital Cost : High Alloy

Tube Side

- Operating Cost :

Shell Side

Tube Side

Shell Side

Dirty, Fouling Material

High Volumetric Fluid

High Temp./Press.

Clean/Non-Fouling Material

Corrosive/Flammable/Poisonous Fluid

Required Expansive Material

/ / 2016-03-10 14:32

- 217 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

6.

Overall Heat Transfer Rate

Individual Heat Transfer Coefficients/Resistances

Fluid Velocity

Pressure Drop

Area Ratio Between Required and Actual

Vibration and Demage Analysis

Metal Temperature of Shell and Tube

Surface Temperature of the Tube

Circulation Rate/Velocity Head for Thermosyphone Reboiler

/ / 2016-03-10 14:32

- 218 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

Program

,

.

HTFS

Module, HTRI Module, STX/ACX, THERMECH, B-JAC

.

1. HTFS ( Heat Transfer Fluid Service)

HTFS

AEAT(Atomic Energy Authority Technology Plc.)

1967

.

.

Software

AEAT

Hyprotech

Simulator

Process

.

1.1

HTRI

HTRI

Plate Fin

.

1.2

Membership

Module

License

. Membership

HTFS

License

,

/ / 2016-03-10 14:32

. Membership

.

License

Licensing

HTFS.TASC

(HTFS.MECHX)

Option

Option

1500

.

- 219 -

Component

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

- HTFS.TASC

Shell & Tube Type Heat Exchanger Design, Rating and

Simulation Package including Thermosyphone.

- HTFS.ACOL

Air Cooled (Crossflow) Type Heat Exchanger Design

and Simulation Package.

- HTFS.MUSE

Plate Fin Type Heat Exchanger Design and Simulation

Package including Thermosyphone.

HTFS.FIHR

Fired Heater and Furnaces Type Heat Exchanger

Simulation and Rating package.

- HTFS.APLE

Plate Type Heat Exchanger Design, Rating and

Simulation Package

- HTFS.PIPE

Hydraulic Calculation Package for the Unbranched

Pipeline Network.

- HTFS.MECHX Mechanical Design Package for the Shell & Tube

Type Heat Exchanger.

2. HTRI ( Heat Transfer Research Inc.)

HTRI

1962

/ / 2016-03-10 14:32

11

.

HTFS

HTFS Module

HTFS

HTRI

.

2.1

Shell & Tube, Air Cooled, Plate Type

.

.

2.2

HTFS

Membership

- 220 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

.

- CST

Shell & Tube Type Heat Exchanger Design, Rating and

Simulation Package including Thermosyphone.(ST, RTF, RKH

)

- ACE

Air Cooled (Cross-Flow) Type Heat Exchanger Design and

Simulation Package.

FH

Fired Heater and Furnaces Type Heat Exchanger Simulation and

Rating package.

- PHE

Plate Type Heat Exchanger Design, Rating and Simulation

Package.

3. STX/ACX

HTC(Heat Transfer Consultants)

HTFS

HTFS

STX

1976

Module

Shell & Tube Type, ACX

Air Cooled Type

HTFS, HTRI Module

4. THERMECH

Lumus

(Lumus Heat Transfer Systems, LTHS)

Tube

/ / 2016-03-10 14:32

Shell &

HTFS.TASC

.

Thermosyphone

TEMA

Shell & Tube

.

Code

- 221 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

/ / 2016-03-10 14:32

5. B-JAC

B-JAC

(B-JAC Computer Service)

1970

ASPEN

.

TEMA

Shell & Tube

Air Cooled, Fired Heater

.

- 222 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

HTFS.TASC

.

HTFS.TASC

Mode(

Design

), Checking Mode(

Rating

), Simulation Mode(

Output

Input

Mode

Kettle Type

- HTFS.TASC

Thermosyphone, Evaporator,

HTFS.TASC

TEMA

Shell & Tube

Windows

, OLE(Object

Linking and Embedding)

.

HTRI

HYSYS

CST Module

File

Simulator

Program

ASCII

- TEMA Specification Sheet

-

Input/Output

Setting Plan

- Costing Package

Mechanical Design Tool

1500

Option

Component

.

Option

.

HTFS.TASC

Shell &

Tube Type

/ / 2016-03-10 14:32

- Heater/Cooler

- General Shell & Tube(Condenser, Reboiler)

- Vertical & Horizontal Thermosyphone

- Kettle Type Reboiler

- Falling Film Evaporator

- Double Pipe / Multiple Hairpin

MEK Distillation Column

.

- 223 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

2001

Product

MEK

Purification

Property

Data

HYSYS

Simulation

HYSYS

HTFS.TASC

OLE

Condenser

Data

HTFS.TASC

Property

HTFS.TASC

Design Mode

Module

.

Minimum Area

(Default)

/ / 2016-03-10 14:32

HTFS.TASC

Option

Minimum Cost

Minimum Cost

.

Minimum Cost

Base

Tuning

- 224 -

APCPCWM_4828539:WP_0000008WP_000000

APCPCWM_4828539:WP_0000008WP_0000008

/ / 2016-03-10 14:32

- 225 -

You might also like

- JSA Blinding and de Blinding PDF FreeDocument3 pagesJSA Blinding and de Blinding PDF Free최승원No ratings yet

- Energy Isolation ProcedureDocument33 pagesEnergy Isolation Procedure최승원No ratings yet

- Refinery Process: Application Solutions GuideDocument168 pagesRefinery Process: Application Solutions Guide최승원No ratings yet

- BOC Cylinder and Gas IdentificationDocument2 pagesBOC Cylinder and Gas IdentificationJun Xian WaiNo ratings yet

- Design of SlabsDocument42 pagesDesign of SlabsMuralidargouda BhagavantagoudarNo ratings yet

- Orientation CalculationDocument3 pagesOrientation CalculationSalman Khan100% (1)

- Composite Floor Beam Design-BDocument23 pagesComposite Floor Beam Design-BIhab SorourNo ratings yet

- Cycle of Absorption MachineDocument4 pagesCycle of Absorption MachineMajid Sattar100% (1)

- Api 600 CatalogueDocument32 pagesApi 600 CatalogueJairo Javier Díaz MontenegroNo ratings yet

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 pagesFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNo ratings yet

- James Walker Metaflex SGIR - SPG Revision 0 (2009!05!11)Document1 pageJames Walker Metaflex SGIR - SPG Revision 0 (2009!05!11)Dieter BuysseNo ratings yet

- BS Hinges 2Document22 pagesBS Hinges 2Peter MohabNo ratings yet

- Welding Symbols On DrawingsDocument4 pagesWelding Symbols On DrawingsDomineering94No ratings yet

- Appendix ADocument25 pagesAppendix ALUIGI ARENANo ratings yet

- Etd 02 01Document7 pagesEtd 02 01mkashkooli_scribdNo ratings yet

- Pressure Loss CharacteristicsDocument6 pagesPressure Loss CharacteristicsMarilucia Copque100% (1)

- Parcial CodeDocument114 pagesParcial CodeLuciano LeiteNo ratings yet

- IBC 2022 Exhibition Standards Book 01 FinalDocument202 pagesIBC 2022 Exhibition Standards Book 01 FinalR BettaNo ratings yet

- Vessel Data Sheet Process Specification Sheet FormDocument1 pageVessel Data Sheet Process Specification Sheet FormunitedmanticoreNo ratings yet

- Self Cleaning FilterDocument3 pagesSelf Cleaning FilterswisticatedNo ratings yet

- Tech ProposalDocument44 pagesTech ProposalnickcruzltdNo ratings yet

- Buckling Check: Material DataDocument28 pagesBuckling Check: Material Datading liuNo ratings yet

- Pressure Vessel & Heat Exchanger Design TrainingDocument15 pagesPressure Vessel & Heat Exchanger Design TrainingMukeshChopraNo ratings yet

- BS EN 12542 - 2010 LPG Equipment and Accessories. Static Welded Steel Cylindrical Tanks, Serially Produced For The Storage of Liqu - Libgen - LiDocument66 pagesBS EN 12542 - 2010 LPG Equipment and Accessories. Static Welded Steel Cylindrical Tanks, Serially Produced For The Storage of Liqu - Libgen - LiRinnoNo ratings yet

- FERRYNDODocument29 pagesFERRYNDONovie100% (1)

- ANZ-DS-E-5016 HV Surge DiverterDocument17 pagesANZ-DS-E-5016 HV Surge Divertermika cabelloNo ratings yet

- IP (Ingress Protection) Standards PDFDocument1 pageIP (Ingress Protection) Standards PDFzineddine sofieneNo ratings yet

- The Principle of Temperature Calculation: Rolling LibraryDocument2 pagesThe Principle of Temperature Calculation: Rolling LibrarycguillermosmNo ratings yet

- Strength Calculation ARTDocument34 pagesStrength Calculation ARTdenstar silalahiNo ratings yet

- IS.5216 1982part2Document27 pagesIS.5216 1982part2Mahendra SuryavanshiNo ratings yet

- Curriculum VitaeDocument3 pagesCurriculum VitaeAbdallah El Amine SoufiNo ratings yet

- 0001y01091 en PDFDocument1 page0001y01091 en PDFvivekpattniNo ratings yet

- Calculation Sheet For 700mm SQ Metal FloatersDocument3 pagesCalculation Sheet For 700mm SQ Metal FloatersAdagharaNo ratings yet

- Astm D3294 PtefDocument6 pagesAstm D3294 PtefIsabella RomeroNo ratings yet

- Brighton Spec ASME 80-10 2017 PDFDocument1 pageBrighton Spec ASME 80-10 2017 PDFSuhas JadhavNo ratings yet

- Thermal Calculation of Heat Exchangers With Simplified Consideration of Axial Wall Heat ConductionDocument7 pagesThermal Calculation of Heat Exchangers With Simplified Consideration of Axial Wall Heat ConductionA.M.P.P. GUNARATHNANo ratings yet

- Heat Excganger Detail DesignDocument45 pagesHeat Excganger Detail Designoverlord5555No ratings yet

- Advanced Series PLASTIC Pumps: Advance Your ProcessDocument23 pagesAdvanced Series PLASTIC Pumps: Advance Your ProcesskokifpNo ratings yet

- CV - Omid KhodadadfarDocument4 pagesCV - Omid KhodadadfarGurvir SinghNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Technical Data Sheet For UEA-01,02 CentrífugoDocument13 pagesTechnical Data Sheet For UEA-01,02 Centrífugocarmen hernandezNo ratings yet

- RP 105Document8 pagesRP 105ChrisBurnettNo ratings yet

- CP Design OD (In) OD (MM) Length Area (m2)Document1 pageCP Design OD (In) OD (MM) Length Area (m2)mtuanlatoi9704No ratings yet

- Simplified Torsion Analysis For Steel Beams: Simple Span Beam With Eccentric Concentrated Load Applied at MidspanDocument4 pagesSimplified Torsion Analysis For Steel Beams: Simple Span Beam With Eccentric Concentrated Load Applied at MidspanIhab El AghouryNo ratings yet

- Bolt Length CalculationDocument1 pageBolt Length Calculationridho ziskaNo ratings yet

- Guidelines For Sizing of Restriction Orifice For Single-Phase Fluids With PDFDocument8 pagesGuidelines For Sizing of Restriction Orifice For Single-Phase Fluids With PDFEPTCO LHDNo ratings yet

- Weight CalculationDocument1 pageWeight CalculationOmil RastogiNo ratings yet

- Joint Efficiency - EDocument6 pagesJoint Efficiency - EPaul NeedhamNo ratings yet

- HVAC - Units & Ducting & AccessoriesDocument23 pagesHVAC - Units & Ducting & Accessoriesวรศิษฐ์ อ๋องNo ratings yet

- TK-02 Supported Roof - Calculo Soporte TechoDocument5 pagesTK-02 Supported Roof - Calculo Soporte Techojoaquin torrano veraNo ratings yet

- Maz 0027 Man VCF 0038 ManualDocument147 pagesMaz 0027 Man VCF 0038 ManualFilipe AreasNo ratings yet

- UKCADocument3 pagesUKCAaltafkhan hameedNo ratings yet

- AWS A5.12: Material Safety Data Sheet (MSDS)Document3 pagesAWS A5.12: Material Safety Data Sheet (MSDS)Mani VannanNo ratings yet

- Anchor Steel Supports-LoadsDocument3 pagesAnchor Steel Supports-LoadsНемања КараклајићNo ratings yet

- SteelSpan MADDocument6 pagesSteelSpan MADAnonymous pD2ymRUguNo ratings yet

- Indian Minerals Yearbook 2019: 58 EditionDocument33 pagesIndian Minerals Yearbook 2019: 58 EditionmodoyioNo ratings yet

- 12 Air Venting in Hydraulic System PDFDocument5 pages12 Air Venting in Hydraulic System PDFnarimeneNo ratings yet

- DWS1160 - Design, Manufacture, Supply and Installation of PVC Pressure PipesDocument26 pagesDWS1160 - Design, Manufacture, Supply and Installation of PVC Pressure PipesleeNo ratings yet

- Cyclone SeperatorDocument2 pagesCyclone SeperatorVaibhav JainNo ratings yet

- Gas Dispersion Guidance Notes Nov19Document43 pagesGas Dispersion Guidance Notes Nov19Ben SundarNo ratings yet

- Design of Loose Type Flanges-Lap Joint-2Document12 pagesDesign of Loose Type Flanges-Lap Joint-2Jose BijoyNo ratings yet

- Welding Procedure Specification SampleDocument5 pagesWelding Procedure Specification SampleAdiNo ratings yet

- TLP291 4 PDFDocument14 pagesTLP291 4 PDFBruno SilvaNo ratings yet

- Design of Coupling Enclosures by Michael M. CalistratDocument8 pagesDesign of Coupling Enclosures by Michael M. Calistrat최승원No ratings yet

- Polymershapes MitsubishiChemicalAdvancedMaterials MCM-NA Abradable Labrinth-Seal WebDocument2 pagesPolymershapes MitsubishiChemicalAdvancedMaterials MCM-NA Abradable Labrinth-Seal Web최승원No ratings yet

- Coupling GuardsDocument10 pagesCoupling Guards최승원No ratings yet

- HSP 201Document16 pagesHSP 201최승원No ratings yet

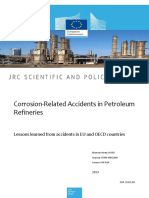

- TR 01 CorrosionRefineriesDocument104 pagesTR 01 CorrosionRefineries최승원100% (1)

- Fired Heater Tube Fretting. - Boiler and Pressure Vessel Engineering - Eng-TipsDocument2 pagesFired Heater Tube Fretting. - Boiler and Pressure Vessel Engineering - Eng-Tips최승원No ratings yet

- ISI7Document42 pagesISI7최승원No ratings yet

- 4 Rules of Fired Heater OperationDocument17 pages4 Rules of Fired Heater Operation최승원No ratings yet

- Transportation of Hydrogen Gas in Existing Carbon Steel PipelinesDocument26 pagesTransportation of Hydrogen Gas in Existing Carbon Steel Pipelines최승원No ratings yet

- Investigation and Repair of Heat Exchanger FlangeDocument12 pagesInvestigation and Repair of Heat Exchanger Flange최승원No ratings yet

- Acid Salt Corrosion in A Hydrotreatment Plant of A Petroleum RefineryDocument8 pagesAcid Salt Corrosion in A Hydrotreatment Plant of A Petroleum Refinery최승원No ratings yet

- Supplementary Specification To NORSOK M-004 Insulation For Piping and EquipmentDocument44 pagesSupplementary Specification To NORSOK M-004 Insulation For Piping and Equipment최승원100% (1)

- Removable Reusable Blanket Insulation: Engineering Reusable Solutions For A Sustainable PlanetDocument6 pagesRemovable Reusable Blanket Insulation: Engineering Reusable Solutions For A Sustainable Planet최승원No ratings yet

- Line Blinding/Blanking Options: Increase Safety, Save Time, Costs and Increase EfficiencyDocument22 pagesLine Blinding/Blanking Options: Increase Safety, Save Time, Costs and Increase Efficiency최승원No ratings yet

- Orrosion Nder Nsulation: AtiphonDocument49 pagesOrrosion Nder Nsulation: Atiphon최승원No ratings yet

- A Review On Boiler Depositionfoulage Prevention AnDocument7 pagesA Review On Boiler Depositionfoulage Prevention An최승원No ratings yet

- Loop-Seal ProblemsDocument1 pageLoop-Seal Problems최승원No ratings yet

- Attachment 7.2: Page 386 of 557Document1 pageAttachment 7.2: Page 386 of 557최승원No ratings yet

- A Circulating Fluidized Bed Boiler ControlDocument3 pagesA Circulating Fluidized Bed Boiler Control최승원No ratings yet

- App 2020Document479 pagesApp 2020최승원No ratings yet

- Problematic Processes For Hot TappingDocument2 pagesProblematic Processes For Hot Tapping최승원No ratings yet

- Installing BlindsDocument1 pageInstalling Blinds최승원No ratings yet

- Stress Relaxation High-Temperature Service LimitDocument1 pageStress Relaxation High-Temperature Service Limit최승원No ratings yet

- Bolting Material Specifications - PIPING HANDBOOKDocument1 pageBolting Material Specifications - PIPING HANDBOOK최승원No ratings yet