Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

15 viewsPackaging of Banana Fruits

Packaging of Banana Fruits

Uploaded by

Joe Josephpackaging of banana fruits

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pineapple & Banana ExpansionDocument12 pagesPineapple & Banana Expansionnestor0% (2)

- JellyDocument2 pagesJellyJoe JosephNo ratings yet

- Tri Blender TheoryDocument6 pagesTri Blender TheoryPiero Sanguineti AcevedoNo ratings yet

- The Non-Beginner's Guide To Syncing Data With Rsync PDFDocument7 pagesThe Non-Beginner's Guide To Syncing Data With Rsync PDFJoe JosephNo ratings yet

- New Syllabus of B.tech (Dairy Tech)Document50 pagesNew Syllabus of B.tech (Dairy Tech)Joe JosephNo ratings yet

- Desktop HP 6000 Pro DisassemblyDocument9 pagesDesktop HP 6000 Pro DisassemblyJoe JosephNo ratings yet

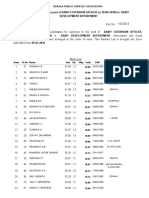

- Main List: Ranked List For The Post of DAIRY EXTENSION OFFICER On 19240-34500 in DAIRY Development DepartmentDocument4 pagesMain List: Ranked List For The Post of DAIRY EXTENSION OFFICER On 19240-34500 in DAIRY Development DepartmentJoe JosephNo ratings yet

- SlaughteringDocument69 pagesSlaughteringJoe JosephNo ratings yet

- Lemon Grass DistillateDocument9 pagesLemon Grass DistillateJoe Joseph100% (1)

- Rsync (Remote Sync) - 10 Practical Examples of Rsync Command in LinuxDocument13 pagesRsync (Remote Sync) - 10 Practical Examples of Rsync Command in LinuxJoe Joseph100% (1)

- 1 Second Challenge ListDocument5 pages1 Second Challenge ListsyeretematejetNo ratings yet

- Davao Del Norte Davao Del Sur & OccidentalDocument1 pageDavao Del Norte Davao Del Sur & OccidentalEricka Shane R. LabillesNo ratings yet

- Banana Wiki - Google SearchDocument2 pagesBanana Wiki - Google SearchShobhit GajbhiyeNo ratings yet

- Illustrated Guide To The Identification of Banana Varieties in The South PacificDocument45 pagesIllustrated Guide To The Identification of Banana Varieties in The South PacificNeville and Emma WalkerNo ratings yet

- United Brands V Commission (1978) ECR 207Document103 pagesUnited Brands V Commission (1978) ECR 207KELVIN A JOHNNo ratings yet

- Sub County RecoveryDocument32 pagesSub County RecoveryAllanNo ratings yet

- Banana Imports 1 On 1Document4 pagesBanana Imports 1 On 1keithNo ratings yet

- Banana: Jump To Navigation Jump To Search Musa (Genus) Cooking Banana Banana (Disambiguation)Document30 pagesBanana: Jump To Navigation Jump To Search Musa (Genus) Cooking Banana Banana (Disambiguation)shwepyi tharNo ratings yet

- OP+01+DRAF+ARTIKEL+19 1+AN+Eka+Vanisa+ArsyadDocument8 pagesOP+01+DRAF+ARTIKEL+19 1+AN+Eka+Vanisa+Arsyaddeviayuanggraini1No ratings yet

- Varieties and Production of Bananas in The PhilippinesDocument29 pagesVarieties and Production of Bananas in The PhilippinesMeow YoongiNo ratings yet

- Ultimo Movimiento I/B Actual Visit O/B Actual Visit O/B Actual Carrier Name Numero de Unidad Booking NumberDocument32 pagesUltimo Movimiento I/B Actual Visit O/B Actual Visit O/B Actual Carrier Name Numero de Unidad Booking NumberithanchukyNo ratings yet

- Soal PTS Akm 9Document4 pagesSoal PTS Akm 9Dwik Buk'e RaraNo ratings yet

- Yellow BananaDocument1 pageYellow BananaGabriela VitanNo ratings yet

- 38351-Article Text-154092-2-10-20211110Document12 pages38351-Article Text-154092-2-10-20211110Andika Yuli HeryantoNo ratings yet

- The United Fruit CompanyDocument1 pageThe United Fruit CompanyAlyanna JovidoNo ratings yet

- Artikel - Yuni Hidayati (J1A014138)Document12 pagesArtikel - Yuni Hidayati (J1A014138)Ardy Steve VayNo ratings yet

- Banana Improvement Imperatives - The Case For Asia: Ramon V. ValmayorDocument7 pagesBanana Improvement Imperatives - The Case For Asia: Ramon V. Valmayormji makNo ratings yet

- Banana Reports PDFDocument60 pagesBanana Reports PDFHammad HanifNo ratings yet

- Banana Plantain OverviewDocument27 pagesBanana Plantain Overviewkeith118No ratings yet

- PH B. Inggris 2 Bab 1Document2 pagesPH B. Inggris 2 Bab 1Siti SaidahNo ratings yet

- Engineering Consultant in AUHDocument11 pagesEngineering Consultant in AUHShameem JazirNo ratings yet

- BYENDA Mutuga Bienfait: BstractDocument11 pagesBYENDA Mutuga Bienfait: BstractPuta 1.47No ratings yet

- 2015 PisangDocument14 pages2015 PisangRikaNo ratings yet

- Master Data Cavendish OCADocument14 pagesMaster Data Cavendish OCAHabib FirdausNo ratings yet

- 500 Backlinks For 5 Keywords 1Document34 pages500 Backlinks For 5 Keywords 1Amir AliNo ratings yet

- LakatanDocument1 pageLakatankurt pro100% (1)

- Analisis Saluran Distribusi Pada Volume Penjualan Di Home Industri Keripik Pisang Miroso Kecamatan BangkoDocument8 pagesAnalisis Saluran Distribusi Pada Volume Penjualan Di Home Industri Keripik Pisang Miroso Kecamatan Bangkojuliandre pratamaNo ratings yet

- Philippine Banana Industry RoadmapDocument190 pagesPhilippine Banana Industry RoadmapSnype GomitNo ratings yet

- Musa Varieties ListDocument42 pagesMusa Varieties ListRas KhemanuNo ratings yet

Packaging of Banana Fruits

Packaging of Banana Fruits

Uploaded by

Joe Joseph0 ratings0% found this document useful (0 votes)

15 views5 pagespackaging of banana fruits

Original Title

packaging of banana fruits

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpackaging of banana fruits

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

15 views5 pagesPackaging of Banana Fruits

Packaging of Banana Fruits

Uploaded by

Joe Josephpackaging of banana fruits

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 5

NATIONAL DAIRY RESEARCH INSTITUTE | 19 July to 8 August, 2013

Centre of Advanced Faculty Training in Dairy Processing

Migration of Additives from Plastic Packaging

Materials into Dairy Products

P. Narender Raju’ and Ashish Kumar Singh”

‘Scientist, “Senior Scientist,

Dairy Technology Division, National Dairy Research Insitute, Karnal

Email pnr.ndri@gmail.com

INTRODUCTION

Pure resins are rarely processed into final products without the addition of selected compounds,

called additives that are incorporated during the process of extrusion and molding of a plastic

resin or applied externally on the formed material. Resins without additives are sometimes

called as barefoot resins. Compounding is the process of uniformly mixing the additives into the

resin, to make a homogenous material. It starts with dry mixing and usually ends with an

extruder producing pellets. A blend, by definition, is formed from two or more polymer resins

which have been mixed together. Concentrate of additive dispersed in a polymer are termed as

master batch. Blending of the master batch with the barefoot resin to achieve the desired

additive concentration is called letting down. The number and amount of additives incorporated

in a resin vary with resin type and application. The presence of additives in packaging

applications raises the question of additive migration. Most additives diffuse within the polymer

and often tend to migrate to the surface of the material. When a packaged product is indirect

contact with a compounded polymer, there may be a transfer of the additive to the product.

Excessive intake of such additives has been shown to be toxic. The present article briefly

covers the plastics additives and commonly found migrants in dairy products.

ADDITIVES USED IN PLASTICS

There are a variety of reasons for the use of additives in a resin including (a) to improve the

processing conditions, (b) to improve or increase the resin's stability to oxidation, (c) to obtain

better impact resistance, (d) to increase or decrease hardness, (0) to control surface tension, (f)

to facilitate extrusion and melting, (g) to control blocking, (h) to reduce cost, and () to increase

flame resistance. In general, a number of additives are commonly incorporated into plastics

used for packaging applications. However, they may be classified based on their functional

property into antioxidants, heat stabilizers, UV stabilizers, antiblocking agents, plasticizers, slip

agents, anti-slip agents, lubricants, mould release agents, anti-fogging agents, colourants, anti-

static agents, nucleating agents, fillers and reinforcements. Some of the important are briefly

described below:

Antioxidants

Polymeric materials chemically deteriorate during fabrication, processing and storage due to a

series of complex chemical oxidation reactions with atmospheric oxygen. The major result is (a)

chain scission, which can yield a significant decrease in molecular weight and/or (b)

crosslinking, which increases molecular weight and affects flow properties. To prevent the

damage to the polymer caused by the oxidative degradation, chemical additives called

antioxidants are incorporated into the polymer. Two main types of antioxidants are available

commercially, primary and secondary antioxidants. Primary antioxidants work by removing free

radical species while secondary antioxidants work by interfering with the formation of free

radicals. In packaging, polyethylene (PE), polypropylene (PP) and high impact polystyrene

(HIPS) account for the majority of the market for antioxidants. Irganox’™ (phenolic antioxidant),

Ingafos™ (phosphate antioxidant), butylated hydroxyl toluene (BHT), a-tocopherol, etc. are

commonly used as antioxidants in plastics processing.

Heat stabilizers

They are used to prevent degradation of polymers when they are exposed to heat especially

during processing. For most polymers, oxidation is primary mode of reaction and hence,

Innovative approaches in processing and packaging of milk and milk products

antioxidants function effectively as heat stabilizers. For a few sensitive polymers such as

polyvinyl chloride (PVC), other forms of reactions are important such as dehydrochlorination

yielding hydrochloric acid and resulting in formation of double bond in the main polymer chain.

This reaction imparts a visible colour to PVC, first yellow, then amber, reddish, brown and finally

black. Organometallic compounds, salts derived from lead, cadmium, barium, zinc and tin,

epoxides and phosphites are most common heat stabilizers used,

UV light stabilizers

UV radiation from outdoor light and »-radiation used for sterilization can cause photo-oxidation

in PS, PP, PVC and other polymers. High energetic UV photons can be captured by a polymeric

chain resulting in the breaking of covalent bonds and production of free radicals. Changes in

colour, loss of flexibility and gloss and lower molecular weight are some of the effects that can

be produced photo-oxidation. There are three types of UV light stabilizers. Those which absorb

the harmful UV radiation and emit harmless radiation of larger wavelength and lower energy

(UV absorbers), e.g. hydrobenzophenone, those which bring the excited polymeric chain from a

higher level of energy to a stable state by absorbing the energy (UV quenchers), 0.9.

organosalts of nickel, and free radical scavengers which accepts free radicals and prevents

them from reacting with other polymer molecules, e.g. hindered amine light stabilizers (HALS)

Plasticizers

These are the substances that are incorporated into a rigid plastic to increase its flexibility,

workability and extensibility. By reducing the glass transition temperature (T,) and increasing

chain lubricity, they also improve processing and extrusion characteristics, reduce the minimum,

required processing temperature, reduce hardness and improve low temperature flexibility. Not

all plastics require the use of plasticizer, but for certain plastics, such as PVC, the use of an

appropriate plasticizer for the desired end use is essential. Without plasticizer, PVC is a semi-

crystalline, brittle polymer that is difficult to process. At lower concentrations the plasticizer

helps to reduce processing temperatures and helps to minimize the thermal degradation of the

polymer. At higher concentrations, besides improving processing conditions, plasticizer reduces

hardness and increases flexibility of the final product. The polar nature of PVC gives it a high

affinity for plasticizers and therefore, PVC accounts for more than 80% of the total use of

plasticizers. Most plasticizers are liquids at room temperatures and have high boiling points and

low vapour pressure, so that they are not easily lost from the plastic during processing. The

most common plasticizers are the phthalates and among them diethylhexyl phthalate is the

most widely used, For food packaging films, only legally approved plasticizers can be used,

Most often, an adipate plasticizer, normally di-(2-ethylhexyl) adipate combined with epoxidized

soybean oil is used

Colorants

Colorants give an opaque appearance that can contribute to light protection of a packaged

product and also influence consumers purchasing considerations. Hundreds of different

colorants are used in plastics packaging industry. Three major categories of colorants are used

in plastics viz, dyes, organic pigments and inorganic pigments. Inorganic pigments are widely

used in plastics industry as they are less expensive, more opaque and more stable to high

‘temperatures and have less tendency to migrate. However, most of them are extremely toxic

since they are oxides of heavy metals such as chromium, lead, cadmium or nickel

PLASTICS AND CHEMICAL MIGRATION

Food packaging has the prime function to protect food from contamination unti it is consumed

and to help keep the food fresh, but it also fulfils other requirements, such as to convey

information about the food stuff and present it in an appealing manner. Plastics are able to fulfil

a wide range of functional requirements and offer unparalleled advantages compared to other

materials. However, it is also important that the food contact material is inert and does not

contaminate the food stuff through migration or transfer of substances used in its manufacture

Food may interact with packaging materials and this may change the initial mechanical and

barrier properties as well as safety of the product. The interaction may be classified into three

phenomena: migration, permeation and sorption. Migration of potentially toxic substances from

NATIONAL DAIRY RESEARCH INSTITUTE | 19 July to 8 August, 2013

Centre of Advanced Faculty Training in Dairy Processing

Packaging material to contact phase is also a major concem in the selection and use of

materials for food packaging because of the possible effect upon human health.

There are two types of migration viz. global and specific migration. Global migration refers to

total transfer i.e. the quantity of all substances migrating from the package into the packaged

food while specific migration related to the transfer of one or more identifiable substances that is,

a constituent of the packaging material. The main factors that control the migration are:

i. Diffusion process of migrants: Migration of chemical substances is a diffusion process

subject to both kinetic and thermodynamic control and can be described by diffusion

mathematics derived from Fick's Law. The mathematics describe the diffusion process

as a function of time, temperature, thickness of the material, amount of chemical in the

material, partition coefficient and distribution coefficient. The kinetic dimension of

migration dictates how fast the process of migration occurs. The thermodynamic

dimension dictates how extensively the transfer of substances will be when migration is

finished i.e. when the system is at equilibrium,

Cp @2Cp

a PX Ge

dCs als

ae 8 Ge

where, D, and Ds are diffusion coefficients (diffusivity) of migrant in the polymer (m? s")

and food phases (m’ s"), respectively; Cp and Cs are concentrations of migrants in

the polymer and food phase, respectively; x is the space coordinates measured

normal to the polymer-food interface (m) and tis the time (s).

ii, Composition of packaging material: The packaging material is the source of any

chemical migration. The extent of any migration depends on the concentration of the

chemical in the packaging. if a substance is not present in a packaging material then it

cannot migrate. if a substance is present in the packaging then, other things remaining

equal, migration levels will be higher if the concentration in the packaging is increased

and vice versa.

il, The nature and extent of contact: This depends on the physical properties of the food

and the size and shape of the pack. Further, if a chemical that may migrate is located in

one layer of the packaging material but is separated from the food by an intervening

layer, then this barrier layer may retard or prevent migration from occurring.

iv. Nature of the food: If the packaging is not compatible with a given type of food then

there can be a strong interaction leading to an accelerated release of chemical

substances. Examples are the interaction of fats and oils with certain plastics that leads

to swelling of the plastic and leaching of substances from that plastic.

v. Temperature of contact: The migration of chemicals is like virtually all chemical and

physical processes in that it is accelerated by heat. So migration will occur faster if the

temperature is raised

vi. The duration of contact: Materials suitable for short duration contact may not be

suitable for longer service times. The kinetics of migration is first-order in that the extent

of migration increases according to the square-root of the time of contact: M xt".

vil, Mobility of the chemicals in the packaging material: The mobility of a chemical in the

packaging material depends on the size and shape of the molecule, any interaction it

experiences with the material, and the intrinsic resistance to mass transfer that the

material presents. It is assumed thal the chemical is compatible with the material. If the

chemical is not compatible then it could “bloom” to the surface and give enhanced

migration. Permeable materials such as plastics, rubbers and elastomers offer some

limited resistance to migration but this can not only ocour from the surface but also from

the interior of the material, The resistance to mass transfer depends on structure,

density, crystallinity, etc, of the material.

NATIONAL DAIRY RESEARCH INSTITUTE | 19 July to 8 August, 2013

Innovative approaches in processing and packaging of milk and milk products

DETERMINATION OF OVERALL MIGRATION OF CONSTITUENTS OF PLASTICS

The Bureau of Indian Standards has laid down standard procedure for determining the overall

migration of constituents of plastics materials and articles intended to come in contact with

foodstuffs (IS 9845: 1998). The standard is applicable for determination of overall migration of

constituents of single or multi-layered heat sealable films, single homogenous non-sealable

films, finished containers and closures for sealing as lids in the finished form, preformed or

converted form. The determination is to be carried out by using stimulants as given in Table 1

for different foods categorized in Table 2. The maximum extraction value of the material shall

not exceed 10 mg/dm? or 60 mg/kg.

Table 1. Recommended stimulants for determination of migration in to food stuffs

Sr.No. | Stimulant Description

1 ‘A__| Distiled water or water of equivalent quality

2 B__| Sper cent acetic acid (w/v) in aqueous solution (using stimulant A)

3 c 710 per cent ethanol (viv) in aqueous solution for food stuffs having

alcohol less than 10 per cent (viv) (using the stimulant ‘A’

4 Cc 50 per cent ethanol (viv) in aqueous solution for food stuffs having

alcohol more than 50 per cent (viv) (using the stimulant ‘A’)

5 D__| mheptane (freshly distilled)

6 E*___ | Rectified olive oil or mixture of synthetic triglycerides or sun flower oll

*"Slmulant © suggested by EEC for fatly foods fe nat considered al present as the methodology of estimation isnot

yet developed.

Table 2. Stimulating solvents for different food products

Sr.No. | Type Description Examples ‘Stimulants

1 |_| Aqueous, non-acidic Honey, mineral water, skimmed A

foods (pH > 5) without fat_| milk, rasogolla, murabba, yeast

paste, ote,

2 1 Aqueous, non-acidic Fruit juices, squashes, jams, 8

foods (pH < 5) without fat | jelies, carbonated beverages,

sauces, RTS beverages, soups,

lemonade, vinegar, etc.

3 Ti _ | Alcoholic beverages:

i. Alcohol concentration | Beer and some pharmaceutical c

less than 10 per cent | syrups

ii, Alcohol concentration | Wine, brandy, whiskey, arrack ce

above 10 per cent and other alcoholic drinks

a TV] Oils, fats and processed | Vegetable oils, ghee, vanaspati, D

dry foods with surface fat | cocoa butter, lard, spice powder,

oF Volatile oil snacks and savoury, chocolate,

caramels, malted foods, egg

powder, fried and roasted nuts,

tea, coffee powder, etc.

5 V_ | Non-acidic foods (pH>5) | Butter, bread, pastry, cakes, ‘Rand D

‘or high fat and having —_| shrikhand, milk-based sweets,

high moisture content —_| ice-cream, moist and fatty

confectionery products

6 Vi_| Acidic foods (pH<5)or | Pickles, ketchup, cheese, curd, | BS andD

high fat and having high | fresh and processed meat and

moisture content fish products, sauces having fat,

frozen foods, mayonnaise, etc.

7 Vil_| Dry processed foods Cereals and pulses, dehydrated | No end test

without fat vegetable and fruits, dried yeast,

com flakes, salt, sugar, milled

products, barley powder, oats,

vermicelli, spaghetti, ete,

NATIONAL DAIRY RESEARCH INSTITUTE | 19 July to 8 August, 2013

NATIONAL DAIRY RESEARCH INSTITUTE | 19 July to 8 August, 2013

& Centre of Advanced Faculty Training in Dairy Processing

MIGRATION OF ADDITIVES INTO DAIRY PRODUCTS

PVC films are commonly used as “cling” films for wrapping fresh fruits, vegetables, poultry

meat, red meat and cheeses at retail level. As mentioned earlier, PVC is almost always

processed with plasticizers such as adipates and pthalates. Goulas et al. (2000) studied the

migration of d-(2-ethylhexy) adipate (DEHA) plasticizer from food grade polyvinyl chlorde film used to

wrap three different types of cheeses (Kefalotyri, Edam and Fela), It was reported that after 240 h of

contact, under refrigeration, the migration of DEHA was approximately 345.4 mg/kg (189

mg/dm) for Kefalotyri, 222.5 mg/kg (12.2 mg/dm?) for Edam and 133.9 mg/kg (7.3 mg/dm’) for

Feta indicating that the loss of DEHA from the PVC film into the three cheese types was 37.8,

24.3 and 14.6 per cent, respectively.

‘The migration kinetics of diphenylbutadiene (OPBD) from low density poly ethylene (LDPE) film

(444 um) into whole milk powder (WMP), skim milk powder (SMP), toast with fat, wheat flour,

honey and rice was studied by Silva et al. (2009). It was reported that migration of DPBD was

highest in WMP followed by toast with fat, flour and rice and it was negligible in honey and

SMP. It was concluded that fat content greatly affects the migration of DPBD in dry foods.

CONCLUSION

‘Although all the plastic resins do not require additives for processing into packaging materials,

additives aid in improving processability, functional properties and also aesthetics. Dairy

products depending on their composition and intended shelf life interact with packaging

materials differently. Hence, there is a need to choose appropriate packaging material so that

the overall migration of migrants would be within the limits prescribed.

SUGGESTED READINGS

1S 9845 (1998). Determination of the overall migration of constituents of plastics materials and articles

Intended to come in contact with foodstuffs-method of analysis. Bureau of Indian Standards, New

Delhi

Goulas, A.E., Anifantaki, K.l,, Koliouis, D.G, and Kontominas, M.G, (2000), Migration of di-(2-ethythexyl)

acipate plasticizer from food grade polyvinyl chloride film into hard and soft cheeses. Journal of Dairy

Soience, 83: 1712-1718,

Siva, AS., Freire, J.M.C., Sendon, R., Franz, R. and Losada, P.P. (2009). Migration and diffusion of

diphenylbutadiene from packages into foods. Journal of Agriculture and Food Chemistry, 87:10225-

10230.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pineapple & Banana ExpansionDocument12 pagesPineapple & Banana Expansionnestor0% (2)

- JellyDocument2 pagesJellyJoe JosephNo ratings yet

- Tri Blender TheoryDocument6 pagesTri Blender TheoryPiero Sanguineti AcevedoNo ratings yet

- The Non-Beginner's Guide To Syncing Data With Rsync PDFDocument7 pagesThe Non-Beginner's Guide To Syncing Data With Rsync PDFJoe JosephNo ratings yet

- New Syllabus of B.tech (Dairy Tech)Document50 pagesNew Syllabus of B.tech (Dairy Tech)Joe JosephNo ratings yet

- Desktop HP 6000 Pro DisassemblyDocument9 pagesDesktop HP 6000 Pro DisassemblyJoe JosephNo ratings yet

- Main List: Ranked List For The Post of DAIRY EXTENSION OFFICER On 19240-34500 in DAIRY Development DepartmentDocument4 pagesMain List: Ranked List For The Post of DAIRY EXTENSION OFFICER On 19240-34500 in DAIRY Development DepartmentJoe JosephNo ratings yet

- SlaughteringDocument69 pagesSlaughteringJoe JosephNo ratings yet

- Lemon Grass DistillateDocument9 pagesLemon Grass DistillateJoe Joseph100% (1)

- Rsync (Remote Sync) - 10 Practical Examples of Rsync Command in LinuxDocument13 pagesRsync (Remote Sync) - 10 Practical Examples of Rsync Command in LinuxJoe Joseph100% (1)

- 1 Second Challenge ListDocument5 pages1 Second Challenge ListsyeretematejetNo ratings yet

- Davao Del Norte Davao Del Sur & OccidentalDocument1 pageDavao Del Norte Davao Del Sur & OccidentalEricka Shane R. LabillesNo ratings yet

- Banana Wiki - Google SearchDocument2 pagesBanana Wiki - Google SearchShobhit GajbhiyeNo ratings yet

- Illustrated Guide To The Identification of Banana Varieties in The South PacificDocument45 pagesIllustrated Guide To The Identification of Banana Varieties in The South PacificNeville and Emma WalkerNo ratings yet

- United Brands V Commission (1978) ECR 207Document103 pagesUnited Brands V Commission (1978) ECR 207KELVIN A JOHNNo ratings yet

- Sub County RecoveryDocument32 pagesSub County RecoveryAllanNo ratings yet

- Banana Imports 1 On 1Document4 pagesBanana Imports 1 On 1keithNo ratings yet

- Banana: Jump To Navigation Jump To Search Musa (Genus) Cooking Banana Banana (Disambiguation)Document30 pagesBanana: Jump To Navigation Jump To Search Musa (Genus) Cooking Banana Banana (Disambiguation)shwepyi tharNo ratings yet

- OP+01+DRAF+ARTIKEL+19 1+AN+Eka+Vanisa+ArsyadDocument8 pagesOP+01+DRAF+ARTIKEL+19 1+AN+Eka+Vanisa+Arsyaddeviayuanggraini1No ratings yet

- Varieties and Production of Bananas in The PhilippinesDocument29 pagesVarieties and Production of Bananas in The PhilippinesMeow YoongiNo ratings yet

- Ultimo Movimiento I/B Actual Visit O/B Actual Visit O/B Actual Carrier Name Numero de Unidad Booking NumberDocument32 pagesUltimo Movimiento I/B Actual Visit O/B Actual Visit O/B Actual Carrier Name Numero de Unidad Booking NumberithanchukyNo ratings yet

- Soal PTS Akm 9Document4 pagesSoal PTS Akm 9Dwik Buk'e RaraNo ratings yet

- Yellow BananaDocument1 pageYellow BananaGabriela VitanNo ratings yet

- 38351-Article Text-154092-2-10-20211110Document12 pages38351-Article Text-154092-2-10-20211110Andika Yuli HeryantoNo ratings yet

- The United Fruit CompanyDocument1 pageThe United Fruit CompanyAlyanna JovidoNo ratings yet

- Artikel - Yuni Hidayati (J1A014138)Document12 pagesArtikel - Yuni Hidayati (J1A014138)Ardy Steve VayNo ratings yet

- Banana Improvement Imperatives - The Case For Asia: Ramon V. ValmayorDocument7 pagesBanana Improvement Imperatives - The Case For Asia: Ramon V. Valmayormji makNo ratings yet

- Banana Reports PDFDocument60 pagesBanana Reports PDFHammad HanifNo ratings yet

- Banana Plantain OverviewDocument27 pagesBanana Plantain Overviewkeith118No ratings yet

- PH B. Inggris 2 Bab 1Document2 pagesPH B. Inggris 2 Bab 1Siti SaidahNo ratings yet

- Engineering Consultant in AUHDocument11 pagesEngineering Consultant in AUHShameem JazirNo ratings yet

- BYENDA Mutuga Bienfait: BstractDocument11 pagesBYENDA Mutuga Bienfait: BstractPuta 1.47No ratings yet

- 2015 PisangDocument14 pages2015 PisangRikaNo ratings yet

- Master Data Cavendish OCADocument14 pagesMaster Data Cavendish OCAHabib FirdausNo ratings yet

- 500 Backlinks For 5 Keywords 1Document34 pages500 Backlinks For 5 Keywords 1Amir AliNo ratings yet

- LakatanDocument1 pageLakatankurt pro100% (1)

- Analisis Saluran Distribusi Pada Volume Penjualan Di Home Industri Keripik Pisang Miroso Kecamatan BangkoDocument8 pagesAnalisis Saluran Distribusi Pada Volume Penjualan Di Home Industri Keripik Pisang Miroso Kecamatan Bangkojuliandre pratamaNo ratings yet

- Philippine Banana Industry RoadmapDocument190 pagesPhilippine Banana Industry RoadmapSnype GomitNo ratings yet

- Musa Varieties ListDocument42 pagesMusa Varieties ListRas KhemanuNo ratings yet