Professional Documents

Culture Documents

WM SD and PP Integration

WM SD and PP Integration

Uploaded by

RAMAKRISHNA.G0 ratings0% found this document useful (0 votes)

23 views2 pagessap wm pp and sd integration

Original Title

Wm Sd and Pp Integration

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsap wm pp and sd integration

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

23 views2 pagesWM SD and PP Integration

WM SD and PP Integration

Uploaded by

RAMAKRISHNA.Gsap wm pp and sd integration

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

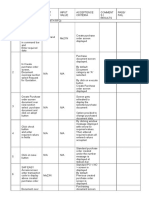

Refer the general scenario followed most commonly in WM,

A) IN MM At the time of good receipt MIGO

1.creation of transfer requirement takes place. Material Goes to Interim Storage

type (902)

2. Transfer order from TR is created ( we get destination storage type) -- In LT04 or

LT06

3. Confirmation of TO.(Put away completed )

In LT12

B) IN PP

1. Requirement we get from MD11,MD04,CO01.(staging , BOM Explosion etc.)

this time Generally TR, will be created Automatically( As per setting).

With LB10 TR to TO

TO will be confirmed in staging process.(Quantity of picked materials will be

reduced )

(Hear the raw material will be consumed. & TR for finished material will be created.)

With LB10 we can perform creation of TO.

TO for finished material will be confirmed when it will placed in the destination Bin.

Hear we will get the Finished good in the Unrestricted stock.

C)IN SD.

Creation of sale order: VA01

Creation of Outbound deliveryu2019s TO. VL01

TO confirmation after reaching to destination.LT03 then LT12 to confirm.

Dev.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Stock Watson 4E Exercisesolutions Chapter3 InstructorsDocument25 pagesStock Watson 4E Exercisesolutions Chapter3 InstructorsRodrigo PassosNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Customer Experience Book - How To Design, Measure and Improve Customer Experience in Your Business (PDFDrive)Document233 pagesThe Customer Experience Book - How To Design, Measure and Improve Customer Experience in Your Business (PDFDrive)Vera Pratiwi Goenfi100% (1)

- Purchase Order - Test ScriptDocument14 pagesPurchase Order - Test ScriptRAMAKRISHNA.GNo ratings yet

- Purchase Order - Test ScriptDocument14 pagesPurchase Order - Test ScriptRAMAKRISHNA.GNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CSS NC II Institutional AssessmentDocument3 pagesCSS NC II Institutional Assessmentdylan tikoyNo ratings yet

- Source List Test ScriptDocument5 pagesSource List Test ScriptRAMAKRISHNA.GNo ratings yet

- Purchase Requesition Test ScriptDocument14 pagesPurchase Requesition Test ScriptRAMAKRISHNA.GNo ratings yet

- Simple Method For Updating Progress in Primavera P6 - Ten Six ConsultingDocument10 pagesSimple Method For Updating Progress in Primavera P6 - Ten Six Consultingnwosu_dixonNo ratings yet

- AutoPilot Using Telegram - Over $200 DailyDocument6 pagesAutoPilot Using Telegram - Over $200 DailyRobert BillingtonNo ratings yet

- UB - Internal Purchase Order Process: SAP Postings in 4.6xDocument1 pageUB - Internal Purchase Order Process: SAP Postings in 4.6xRAMAKRISHNA.GNo ratings yet

- Debit Credit Memo in PoDocument2 pagesDebit Credit Memo in PoRAMAKRISHNA.GNo ratings yet

- Tips For Fast Message Determination SetupDocument12 pagesTips For Fast Message Determination SetupRAMAKRISHNA.GNo ratings yet

- Counters Sap PMDocument2 pagesCounters Sap PMRAMAKRISHNA.GNo ratings yet

- Val - Clases - DefinationDocument1 pageVal - Clases - DefinationRAMAKRISHNA.GNo ratings yet

- In SAP Easy Access Screen Enter T. CODE ME21N: All Maintained Data of PR COPIED in To PURCHASE ORDERDocument3 pagesIn SAP Easy Access Screen Enter T. CODE ME21N: All Maintained Data of PR COPIED in To PURCHASE ORDERRAMAKRISHNA.GNo ratings yet

- Production Resources ToolsDocument2 pagesProduction Resources ToolsRAMAKRISHNA.GNo ratings yet

- Break Down Maintenance S.NO Process Step Description Solution Description Performed BY Transaction Code RemarksDocument3 pagesBreak Down Maintenance S.NO Process Step Description Solution Description Performed BY Transaction Code RemarksRAMAKRISHNA.GNo ratings yet

- Bloking Bins in Ware House SapDocument3 pagesBloking Bins in Ware House SapRAMAKRISHNA.GNo ratings yet

- Batch Search StatergyDocument11 pagesBatch Search StatergyRAMAKRISHNA.GNo ratings yet

- WM and PP MM FlowDocument1 pageWM and PP MM FlowRAMAKRISHNA.GNo ratings yet

- Vendor Account Group For Relese StratergyDocument2 pagesVendor Account Group For Relese StratergyRAMAKRISHNA.GNo ratings yet

- GuillermoAG - Reading The ImageDocument15 pagesGuillermoAG - Reading The ImageAdrienne Villanueva100% (1)

- Instructions For Use: 1. To Ensure An Effective Molecular WeldDocument2 pagesInstructions For Use: 1. To Ensure An Effective Molecular WeldQuy RomNo ratings yet

- Comparative Study of Isolation Procedures For Essential Oils Hydro Distillation Versus Solvent ExtractionDocument2 pagesComparative Study of Isolation Procedures For Essential Oils Hydro Distillation Versus Solvent ExtractionmyrtaromNo ratings yet

- PagesfromICSSR Volume2 1stproofDocument25 pagesPagesfromICSSR Volume2 1stproofTechno GamingNo ratings yet

- What Is Tajweed - (PDFDrive)Document114 pagesWhat Is Tajweed - (PDFDrive)REYAZ HASSAN MIRNo ratings yet

- 536805502401 (1)Document30 pages536805502401 (1)kedarkNo ratings yet

- Slem Pc11ag Quarter1 Week8-SlmDocument22 pagesSlem Pc11ag Quarter1 Week8-SlmJuna Marie SuarezNo ratings yet

- Manual enDocument216 pagesManual enmosquidoNo ratings yet

- Home Remedies For PneumoniaDocument15 pagesHome Remedies For PneumoniaAljunBaetiongDiazNo ratings yet

- Ernst Gombrich - Power and Glory I (Ch. 21)Document11 pagesErnst Gombrich - Power and Glory I (Ch. 21)Kraftfeld100% (1)

- Central Nervous System StimulantsDocument6 pagesCentral Nervous System StimulantsNathalia CabalseNo ratings yet

- Oracle Enterprise Asset ManagementDocument4 pagesOracle Enterprise Asset ManagementMH.SezanNo ratings yet

- Design and Fabrication of Unmanned Arial Vehicle For Multi-Mission TasksDocument10 pagesDesign and Fabrication of Unmanned Arial Vehicle For Multi-Mission TasksTJPRC PublicationsNo ratings yet

- WCB Pumps-Lobe-MDL-0940 BRO USDocument8 pagesWCB Pumps-Lobe-MDL-0940 BRO USGrupo CruzNo ratings yet

- Adv RDBDocument7 pagesAdv RDBKunal ChaudhariNo ratings yet

- Case Study: Unsaturated Embankment Failure On Soft SoilsDocument10 pagesCase Study: Unsaturated Embankment Failure On Soft Soilsdbsurbf frhbsuvrNo ratings yet

- Audio Channel Layout Mapping Between Audio Formats PDFDocument5 pagesAudio Channel Layout Mapping Between Audio Formats PDFalvcardxNo ratings yet

- For ConsultationDocument11 pagesFor ConsultationClarisse PoliciosNo ratings yet

- Serge Morand, Boris R. Krasnov, D. Timothy J. Littlewood Parasite Diversity and Diversification Evolutionary Ecology Meets Phylogenetics PDFDocument508 pagesSerge Morand, Boris R. Krasnov, D. Timothy J. Littlewood Parasite Diversity and Diversification Evolutionary Ecology Meets Phylogenetics PDFIre rua100% (1)

- Rizals First Published Essay El Amor PatDocument23 pagesRizals First Published Essay El Amor PatNelly MesiasNo ratings yet

- Integration of New Literacies in The CurriculumDocument10 pagesIntegration of New Literacies in The CurriculumMariel Mae PolancosNo ratings yet

- Pinelands National ReserveDocument2 pagesPinelands National ReservesallyNo ratings yet

- Mikala Conway - Meal PlanDocument3 pagesMikala Conway - Meal Planmikala conwayNo ratings yet

- Coping Strategies, Optimism, and Life SatisfactionDocument12 pagesCoping Strategies, Optimism, and Life SatisfactionNurulAtiqahAbRajiNo ratings yet

- IOF Circular-Online RegistrationDocument2 pagesIOF Circular-Online Registration7A04Aditya MayankNo ratings yet