Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

15 viewsInst Book 639en

Inst Book 639en

Uploaded by

Andika Reza Psewing machine manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- EnglishDocument4 pagesEnglishAndika Reza PNo ratings yet

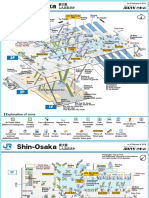

- Kyoto-Osaka: Sightseeing Pass (Greater KURAMA & KIBUNE Area)Document1 pageKyoto-Osaka: Sightseeing Pass (Greater KURAMA & KIBUNE Area)Andika Reza PNo ratings yet

- KATALOG PART Supra X 125 Pgm-FiDocument89 pagesKATALOG PART Supra X 125 Pgm-FiAndika Reza P100% (1)

- To Tokyo To Kyoto: East GateDocument2 pagesTo Tokyo To Kyoto: East GateAndika Reza PNo ratings yet

- Audiologist Tip SheetDocument1 pageAudiologist Tip SheetAndika Reza PNo ratings yet

Inst Book 639en

Inst Book 639en

Uploaded by

Andika Reza P0 ratings0% found this document useful (0 votes)

15 views8 pagessewing machine manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsewing machine manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

15 views8 pagesInst Book 639en

Inst Book 639en

Uploaded by

Andika Reza Psewing machine manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 8

OPERATING INSTRUCTION

For your safety.

Always tum off the power and unplug from the outlet.

When leaving the machine unattended.

When attaching or removing parts.

When cleaning the machine.

When the electric current is shut off,

2. During operation, keep an eye on sewing area.

Do not touch moving parts such as the Thread take-

up lever, Hand wheel, Needle.

1_Names of parts

Before sewing

|. Clean the machine with soft cloth to prevent oil and

dust from the machine.

Do not use thinner, benzine, etc. for cleaning.

.. Do not use the machine except as described in these

instructions.

@® Thread guide

@ Thread take-up lever

@ Tension dial unit

@ Extension table

© Presser foot lever

© Reverse lever

@ Patter selector dial |

® Hand wheel

@® Bobbin winder stopper

@ Bobbin winder spindle

@ Bobbin winder thread

guide

@ Spool pin

2 Free Arm sewing

3 Standard accessories

Slide the Extension table along

the Free Arm inserting tab into

For Free Arm sewing, slide the

Extension table to the left and

remove.

— To replace Extension table.

Extension table

the slot,

Accessory kit,

Standard accessories located

inside the Extension table.

Standard accessories

are in vinyl bag

Bobbins

cD Needles

a

Seam ripper

Felt Buttonnole foot

0

4 Power Connection

5 Speed Control

a plug

aN, Machine

a

Power outlet

Q Machine socket

@® Insert the Power plug into the Power Outlet.

© Insert the Machine plug into the Machine socket.

* Pull out the Power plug when the Machine is not in use.

120V Model

240V Model

The Foot Control regulates sewing speed.

To increase speed, press down with foot.

To decrease speed, release foot pressure.

6 Adjust the Presser foot lever

7_Needle removal and replacement

t

r 7 Prosser foot ever

The Presser foot lever raises and lowers the Presser

foot.

You can raise it about 1/4” higher than normal up

position,

This helps when removing the Foot or when sewing

thick material

Pin.

Tighten

Hg

: Loosen

(To remove the Needle) |) (To replace the Needie)

Loosen the Needle } Insert new Needle into

| clamp screw by tumingit | the Needle clamp with

| toward you. flat side away from you.

Remove the Needle by

pulling it downward.

Push the Needle up as

far as it will go.

Tighten the Needle

clamp screw firmly with

the Screw driver.

@ Tum the Bulb clockwise to

replace.

8 Sewing light 9 Spool pin

Face plato

< To replace Bulb

Set scrow @ Loosen the Set screw and Felt

remove the Face plate by

swinging it to the direction of ‘Spool pin

Bulb arrow.

@ Tur Bulb counterclockwise The Spool pin holds the spool of the thread for feeding

to remove. into the Machine.

To use, turn the Spool pin to the back.

10 Removal and replacement the Bobbin case

Open

Open the Hook cover. place

Lift the Latch and pull out the Bobbin case. jook race.

Raise the Needle by turing the Hand — When inserting the Bobbin case,

wheel toward you. place the Finger into the recess of the

11_ Winding the Bobbin

@ Pull the handwhee! out to the right.

@ Pull the thread from the spool and draw it around the thread guides.

@ Draw the thread through one of the holes in the bobbin from inside to outside, put

the bobbin on the bobbin winder spindle and push to right.

@ Hold the free end of the thread in your hand and depress the foot control,

® Stop the machine when it has made a few turns. Cut the thread close to the hole in

the bobbin . Depress the foot control again.

‘When the bobbin is fully wound, push the bobbin winder spindle to the left and cut

the thread.

@© Push the handwheel in.

Note: When you move the bobbin winder spindle, do not operate your sewing

machine,

@O® -

OS we

LO xe

:

@

12 Threading the Bobbin case

Bobbin case

Thread ‘oa

° >

™

ia | A

Bobbi ON

. @ Draw the Thread under the

® Place the Bobbin into the @ Pullthe Thread into the Bobbin Tension spring and into the

Bobbin case. case slot. Delivery eye.

Make sure the Thread unwinds Pull out about 10 om (4 inches)

in direction of ARROW. of the Thread.

13 Threading the Machine

Thread

guide

Plate

‘Thread take-up

lever “——~ Needle bar |

thread guide

—needle

Raise the Thread Take-up lever to its highest position by turning the Hand Wheel toward you.

Raise the Presser foot.

@ Place the Spool on the Spool pin as shown, with the thread coming from the front of the Spool.

@ Draw the thread around the Thread guide as shown.

@® Draw the thread around the Thread guide plate as shown.

@ Pull the thread up, then through the Thread take-up lever from right to left.

© Draw the thread and slip it into the Needle bar thread guide.

@© Thread the Needle eye from front to back. Pull out about 10 cm (4 inches) of the thread,

14 Drawing up the Bobbin thread

Bobbin thread

Bobbin thread

@ Raise the Presser foot while @ Turn the Hand wheel with @ Pull both threads to the back

holding the Needle thread your right hand until the of the Machine under the

lightly with your left hand. Needle thread picks up the Presser foot.

Bobbin thread.

OPERATING INSTRUCTION:

The symbol 0" of a switch indicates the “of” position of a switch,

“For appliances with a polarized plug (one blade wider than the other)

To reduce the tisk of electric shock, this plug is intended to fit in a polarized outlet

only one way,

I the plug does not ft fully in the outlet, reverse the plug.

fit til does not fit, contact a qualified electrician to instal the proper outlet,

Do not madly the plug in any way.

"Foot Controller Model YC-482J or TUC-180 for use with Sewing Machine Model 639

(For USA. Marker Only)

15 Stitch selection

16 Reverse lever

Setting mark 4,

Nes fabric.

2. Tum the Dial

1d stitch pattern is at

the Setting mark.

Do not turn the dial while the

Needle is in the material.

(The Needle may break.)

| $332495

des

HOG |

Raise the Needle above the

until

the

As long as you keep the Reverse lever

depressed, the Machine sews backwards.

17 Straight stitch sewing

Machine setting

Stitch

|

1

to

18 28 4

Thread tension dial

256

\g

z

4)

Before sewing

Raise the Presser foot and position the fabric next

to a stitching guide line on the Needle plate.

Lower the Needle into the fabric.

Lower the Presser foot and smooth the threads

toward the back.

Depress the Foot control

* To fasten the beginning of a seam, press the Reverse

lever and sew several reverse stitches.

To change sewing direction

Stop the Machine and turn the Hand

wheel toward you to bring the

Needle down into the fabric.

Raise the Presser foot.

Pivot the fabric around the Needle to

change sewing direction as shown.

Seam ends, thread cutting

To fasten seam ends, press the

Reverse lever and sew several

stitches.

Raise the Presser foot and

remove the fabric, drawing the

threads to the back.

Thread gutting groove,

Cut the threads end by inserting

them in the Thread cutting

groove as shown.

18 Zigzag stitching and Overcasting

Machine setting

132

Thread tension dial

|

This type of stitch is used to

prevent fabrics from fraying at

the edges.

* Before the actual sewing, try sewing with a piece of

similar fabric to find the correct thread tension.

To obtain better Zigzag

stitches, the upper tension

should be slightly weaker

than normal. The upper

thread appear slightly on the

wrong side of the fabric.

19 Tricot stitch

Machine setting

suten

3

Ss

Thread tension dial

Place the fabric under the Presser foot so that the edge

is just inside the right side of the Presser foot.

Guide the work so the right-hand stitches fall at the

edge of the fabric

20 Sewing Buttonholes

Machine setting

ae Sich selec Neel or

| st suri

| 7 b- a—a— P seam eo

i

reese

/ ess

| XK

\

| @ bbe teed ®° © 6@ ®

* Make a test Buttonhole using the same fabric and interfacing as the actual garment.

Buttonhole foot

@ Raise the Needle and set the Stitch ©) Raise the Needle and set the Stitch

selector dial to [fi selector dial tof]

Slide both threads to the left. Sew 5 stitches of Bartacks and raise

Lower the Needle into the garment the Needle from the fabric.

where the Buttonhole is to start, and () Raise the Presser foot, remove the

Changing the Presser lower the Buttonhole foot. fabric from the Machine and cut the

foot ® Sew down the left side stopping at the sewing threads

7 bottom mark(B). (Leave 10 cm fortifying)

5 @ Raise the Needle and set the Stitch @ Insert a Pin at the end ot the Button

selector dial to ). hole, as shown, then cut the opening

J Sew 5 stitches of bartack and stop the with a Seam ripper.

Machine. Take care not to cut the stitches.

@ Raise the Needle and turn the Stitch

selector dial to

Loosen the thumb screw Sew up the right side of the Buttonhole,

and Teplace the presser stop the Machine when you are directly

* A

(eek an the thumb sero Opps the fst sich on hole hand

Sewing Corded Buttonholes © With the Buttonhole foot raised, hook the filler cord

‘on the Spur on the back of the Foot.

Bring the ends toward you under the Foot until they

clear the front end.

Hook the cord ends into the Forks on the front of

the Foot to hold them tight.

@ Lower the Needle into the fabric where the

Buttonhole will start and lower the Foot. Sew as you

would a normal buttonhole (See above).

@ Pull the left end of the filler cord to tighten it, and cut.

21. Blind hemming:

Machine setting

Stitch

43

Ht

Wrong side

of fab

04-07 em

w

Wrong side

olfabvie

Right side

offabric

Thread tension dial @ Fold up the fabric as @ Lower the Foot, (3) Spread the fabric flat

x illustrated. stitching slowly for with the right side facing

better control so that the up.

2 Zigzag stitches fall on

the Hem allowance and

pierce the soft fold.

22 Shell tuck

Machine setting

Stitch

ead tron da

\A

é

ts

Place the folded edge along the slot on the Foot.

The Needle should fall off the edge of the fabric

on the right forming a Tuck.

23 Balancing Needle thread

Correct thread tension for

Straight stitches

tension

The Needle thread is too tight.

Decrease Tension

ee

The Needle thread is too loose.

—,>

—

Setting mark

Increase Tension

=),

Setting mark

* In general, Fine threads and Needle are used

for sewing thin fabrics, and Thicker threads

and Needle are used with Heavy fabrics.

Always test Thread and Needle size on a

small piece of fabric which will be used for

actual sewing.

24 Matching Fabric, Thread and Needle Types.

Fabric Thread | Needle

Crepe de Chine, | Fine Silk +9

Fine | Voile, Lawn Fine Cotton tn

Organdy, Georgette. | Fine Synthetic.

Cotton, Pique, 50 Silk 1

Normal | Serg 50-80 Cotton Na

Perc 50-60 Synthetic,

Denim, Tweed, 60 Silk "4

Heavy | Gabardine, 40-50 Cotton ne

Coating 40-50 Synthetic,

* Use the same Thread for Needle and Bobbin.

* When sewing Stretch, very Fine Fabrics and

Synthetic, use a Blue Tip Needle.

CARE OF YOUR MACHINE

25 Cleaning the Feed dog

—screns

Ae. are

© Clean out dust and lint clogging

@ Remove the Needle and the Presser foot. on the Feed dog teeth with a

@® Remove the Needle plate screws and remove the Needle brush.

plate. ® Replace the Needle plate.

26 Dismantling and Assembling Hook race

f

| Bobbin case Hook race ring Shuttle hook

er

@ Raise the Needle to its highest @) Open the Hook race holders @) Clean the Hook race with a

Hook race holders

position and open the Hook and remove the Hook race ring Brush and a Soft dry cloth.

cover. Open the Bobbin case and Shuttle hook. ® Clean the Shuttle hook.

latch and pull the Bobbin out

© Replace all parts by following

of the Machine.

directions in reverse.

27 Trouble shooting

Problem Cause [setting

1. The Needle thread isnot treaded propor See Not

2 The Nowsle tread tension 00 gt Seon 23

The Noodle tread breaks. | 5. The Needles bot or bunt SeeNo.7

The Needles incorrectly inserted. Seco.

5. The thread is either too heavy or too fine for the Needle. See No. 24

1. The Bobbin treads not veaded propery inthe Bobbin case SeeNo.t2

‘he Bobbin thread breaks. | 2 The Bobbin cae tension sping et sean sto Sort See Note

5: Lin has cotocted nthe Bovbin case, See No. 26

1. The Nesdle is neoveaty inserted, Se0No7

the Needle beat 2 The Senses daltacbeontumedvteheNeedewasinthe | See Ho.15

3. The Needle is too fine for the fabric being sewn. ‘See No. 24

1. The Needle is incorrectly inserted or bent. ‘See No.7

2, The Needle andlor Teed sn sutable forthe material being sewn. | SeeNo 24

Skipping stitches 3. A Blue tip needle is not being used when sewing Stretch, very Fine ‘See No. 24

faonce, Synthetes

4. The Noodle treed le not headed propery SeeNo.19

, 1. The Needle thead tension or Bobbin head tension is oo tight) ‘| See No. 23

‘Seam puckering 2. The Needle and/or Bobbin thread are not threaded properly. See No. 12, 13

‘ones form 1. The Needle tveadtecion ito loose SeeNo 23

Stitches form loops 2, The Nowsle i eer too heavy oro fine forthe thread See. 2

3, The Noodle endfor Bobbi teed are nt teaded propery. Beene 13

‘The cloth is not feeding. | 1. The Feed dog is packed with lint. ‘See No. 25

The Machine does not 1. The Feed dog or Shuttle hook area is packed with lint. See No. 25, 26

work (Noise, Slow speed). | 2. The Shuttle hook needs to be oiled. ‘See No. 26

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- EnglishDocument4 pagesEnglishAndika Reza PNo ratings yet

- Kyoto-Osaka: Sightseeing Pass (Greater KURAMA & KIBUNE Area)Document1 pageKyoto-Osaka: Sightseeing Pass (Greater KURAMA & KIBUNE Area)Andika Reza PNo ratings yet

- KATALOG PART Supra X 125 Pgm-FiDocument89 pagesKATALOG PART Supra X 125 Pgm-FiAndika Reza P100% (1)

- To Tokyo To Kyoto: East GateDocument2 pagesTo Tokyo To Kyoto: East GateAndika Reza PNo ratings yet

- Audiologist Tip SheetDocument1 pageAudiologist Tip SheetAndika Reza PNo ratings yet