Professional Documents

Culture Documents

Bs 1400-Copper & Copper Alloys

Bs 1400-Copper & Copper Alloys

Uploaded by

dramiltCopyright:

Available Formats

You might also like

- ASTM B68 68A-Copper Full Hard Pipe STD PDFDocument12 pagesASTM B68 68A-Copper Full Hard Pipe STD PDFAsha ValandNo ratings yet

- Aisi 4140Document2 pagesAisi 4140Tirta BudiawanNo ratings yet

- HighTens EN25Document2 pagesHighTens EN25Annamali Thiayagarajan0% (1)

- Finite To InfiniteDocument1 pageFinite To InfinitedramiltNo ratings yet

- MSU Copper Casting Alloys 2011 PDFDocument10 pagesMSU Copper Casting Alloys 2011 PDFVahid SarfarazNo ratings yet

- RJR PMMTDocument16 pagesRJR PMMTArun PrasadNo ratings yet

- 1 7335Document5 pages1 7335stamatsNo ratings yet

- BS 3601Document3 pagesBS 3601nourlhudaNo ratings yet

- Estandares AstmDocument22 pagesEstandares AstmAgus HermantoNo ratings yet

- GB T 3077 - 1999 Specification of 40Cr Alloy SteelDocument1 pageGB T 3077 - 1999 Specification of 40Cr Alloy SteelĐình Sỹ TTPNo ratings yet

- Indian Standard - 2644Document8 pagesIndian Standard - 2644Biswajit DasNo ratings yet

- Chinese To DinDocument7 pagesChinese To Dindnageshm4n244No ratings yet

- GB T 699 1988 Quality Carbon Structural SteelsDocument17 pagesGB T 699 1988 Quality Carbon Structural SteelsPHUONGNo ratings yet

- Equivalent Grades of Gray IronDocument2 pagesEquivalent Grades of Gray Ironsujay13780100% (1)

- ErmetoDocument14 pagesErmetoJavier VespaNo ratings yet

- SN430-2 2006-12 SAP eDocument3 pagesSN430-2 2006-12 SAP eChristopher LloydNo ratings yet

- Hydrogen Cracking in Specialty Steels: Knolls Atomic Power Laboratory Schenectady, New YorkDocument23 pagesHydrogen Cracking in Specialty Steels: Knolls Atomic Power Laboratory Schenectady, New YorkNattapong PongbootNo ratings yet

- Din 17100Document4 pagesDin 17100Sheby SandyNo ratings yet

- DIN3015 - PART1 - Clamps Standard Series PDFDocument29 pagesDIN3015 - PART1 - Clamps Standard Series PDFSergio SacristanNo ratings yet

- Germany DIN Metals Standard NumbersDocument22 pagesGermany DIN Metals Standard NumbersTerastia Lera100% (1)

- Equivalent Grades of Cast IronsDocument2 pagesEquivalent Grades of Cast IronsVinh Do Thanh100% (1)

- ASTM Standards For Steel PlateDocument4 pagesASTM Standards For Steel Platefarmanali07No ratings yet

- Bs 980 1950 - Steel Tubes For Automobile PurposesDocument14 pagesBs 980 1950 - Steel Tubes For Automobile Purposesstuartj01No ratings yet

- Hexagon Head Screws With Metric Fine Pitch Thread - Product Grades Aandb (First Revision)Document15 pagesHexagon Head Screws With Metric Fine Pitch Thread - Product Grades Aandb (First Revision)kumar QANo ratings yet

- Sist en 13104 2009 A2 2014Document12 pagesSist en 13104 2009 A2 2014Юрий КостенкоNo ratings yet

- Caracteristicile BronzurilorDocument19 pagesCaracteristicile BronzurilorBorza DorinNo ratings yet

- 817M40 PDFDocument2 pages817M40 PDFSamir ChaudharyNo ratings yet

- ASTM Material Comparison TableDocument1 pageASTM Material Comparison Tabledhasdj100% (1)

- Din 3357-4-1981Document5 pagesDin 3357-4-1981олегNo ratings yet

- List of en Standards: SR No Code/Standard DescriptionDocument4 pagesList of en Standards: SR No Code/Standard DescriptionAnilNo ratings yet

- IS 1570 Part 5Document18 pagesIS 1570 Part 5Sheetal JindalNo ratings yet

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- Equivalent Grades of Gray Iron, Ductile Iron, SG Iron, Nodular Graphite IronDocument2 pagesEquivalent Grades of Gray Iron, Ductile Iron, SG Iron, Nodular Graphite IronBao Duy Nguyen100% (3)

- Aws A5Document5 pagesAws A5Omid BeygiNo ratings yet

- BS en 10250-3-2000Document17 pagesBS en 10250-3-2000Mansi BalduwaNo ratings yet

- C45 STD PDFDocument2 pagesC45 STD PDFJeetu GosaiNo ratings yet

- Cold Drawn Seamless Tube DIN 2391 C ST 37.4 NBKDocument3 pagesCold Drawn Seamless Tube DIN 2391 C ST 37.4 NBKtappannNo ratings yet

- Minfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Document3 pagesMinfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Biraj SahooNo ratings yet

- Is 2232 - Castle NutDocument18 pagesIs 2232 - Castle NutRajasekaran MuruganNo ratings yet

- Surface Vehicle StandardDocument7 pagesSurface Vehicle Standardwilian_coelho3309No ratings yet

- Geared Motor: Product ManualDocument178 pagesGeared Motor: Product Manualsanjibkrjana100% (1)

- BS en 15714-4Document28 pagesBS en 15714-4Thomas ValoNo ratings yet

- Din 1691 - 1985Document12 pagesDin 1691 - 1985a.n.87711990No ratings yet

- Gould Alloys Limited - Copper and Copper Alloys DEF STAN 02 838 NES838 Bar - 243Document2 pagesGould Alloys Limited - Copper and Copper Alloys DEF STAN 02 838 NES838 Bar - 243Gourav SharmaNo ratings yet

- BS 1503-1989Document35 pagesBS 1503-1989Олег Соловьев100% (1)

- En 10088 Steel NumberDocument3 pagesEn 10088 Steel Numberrvieira659No ratings yet

- Amendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationDocument3 pagesAmendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - Specificationbeshnu garanaikNo ratings yet

- Equivalent StandardsDocument1 pageEquivalent StandardsRamachandran RamNo ratings yet

- General Requirements For Steel Bars, Carbon and Alloy, Hot-WroughtDocument16 pagesGeneral Requirements For Steel Bars, Carbon and Alloy, Hot-Wroughtعصام السامرائيNo ratings yet

- Steel Forgings For Pressure PurposesDocument18 pagesSteel Forgings For Pressure PurposesnikolicjelenaNo ratings yet

- Din 2526Document1 pageDin 2526MartinsaikiNo ratings yet

- A270 PDFDocument5 pagesA270 PDFHansSarmientoNo ratings yet

- BS en 10059Document3 pagesBS en 10059Nilesh PatilNo ratings yet

- Specification: Hot Coiled Helical Springs Mainline Coaches, Emu and Freight Stock No. WD-01-HLS-94 (Rev.3)Document43 pagesSpecification: Hot Coiled Helical Springs Mainline Coaches, Emu and Freight Stock No. WD-01-HLS-94 (Rev.3)Anonymous PSNjTGUNo ratings yet

- 39NiCrMo3 PDFDocument2 pages39NiCrMo3 PDFAmy GriffinNo ratings yet

- MaterialsDocument4 pagesMaterialsSilvio VarricchioNo ratings yet

- Fitting ASTM A 197 PDFDocument4 pagesFitting ASTM A 197 PDFSusan Sue Berrospi Merino100% (1)

- Astm B575Document5 pagesAstm B575Jota JacquesNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4niladriprasadrNo ratings yet

- Utp Cast Iron GBDocument8 pagesUtp Cast Iron GBhrk100No ratings yet

- Copper and Copper Alloy Ingots and CastingsDocument2 pagesCopper and Copper Alloy Ingots and CastingspoopNo ratings yet

- P10 PDFDocument167 pagesP10 PDFdramiltNo ratings yet

- What Are LoadsDocument2 pagesWhat Are LoadsdramiltNo ratings yet

- Solid Finite Elements Through Three Decades: S&than&Document17 pagesSolid Finite Elements Through Three Decades: S&than&dramiltNo ratings yet

- (2008 Course) : S.E. (Mech.) (Ii Seni,) Examination, 2010 Strength of Machine ElementsDocument10 pages(2008 Course) : S.E. (Mech.) (Ii Seni,) Examination, 2010 Strength of Machine ElementsdramiltNo ratings yet

- Q7 PDFDocument3 pagesQ7 PDFdramiltNo ratings yet

- Q4Document15 pagesQ4dramiltNo ratings yet

- Finite Element Methods in EngineeringDocument1 pageFinite Element Methods in EngineeringdramiltNo ratings yet

- Q1Document12 pagesQ1dramiltNo ratings yet

- Grammar CBSE Class 4 WorksheetDocument6 pagesGrammar CBSE Class 4 WorksheetdramiltNo ratings yet

- Four Day Workshop On Practical Finite Element Analysis - Concepts & ApplicationsDocument2 pagesFour Day Workshop On Practical Finite Element Analysis - Concepts & ApplicationsdramiltNo ratings yet

- Safe Powder Coating Guideline: 7 EditionDocument16 pagesSafe Powder Coating Guideline: 7 EditiondramiltNo ratings yet

- Powder Coating ResinsDocument28 pagesPowder Coating Resinsdramilt100% (1)

- Thermal and Waterjet Cutting Processes PDFDocument5 pagesThermal and Waterjet Cutting Processes PDFdramiltNo ratings yet

- Gap Fills Exercise-5Document6 pagesGap Fills Exercise-5dramiltNo ratings yet

- Healthy Weight Loss PDFDocument5 pagesHealthy Weight Loss PDFdramiltNo ratings yet

Bs 1400-Copper & Copper Alloys

Bs 1400-Copper & Copper Alloys

Uploaded by

dramiltOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bs 1400-Copper & Copper Alloys

Bs 1400-Copper & Copper Alloys

Uploaded by

dramiltCopyright:

Available Formats

Copper and Copper Alloys

Conversion of Old BS into EN Material Designations

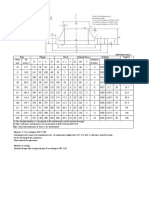

Table 5: Copper and Copper Alloy Ingots and Castings - Comparison of BS 1400 and EN 1982

Showing near equivalents where standardised in EN 1982 and original compositional symbols for guidance where no near equivalent is included.

See Table 7 for full details of compositions and properties.

EN Relevant Casting Processes and Designations (3)

Nearest Equivalent in Old

BS 1400 or BS 4577

EN or ISO Symbol for Castings (1)

EN Material Designation Number

for Castings (2)

GM

GS

GZ

GP

GC

Die Casting

Sand

Centrifugal

Pressure Die

Continuous

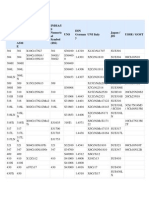

Copper and Copper-chromium (High Conductivity Coppers)

HCC1

Cu-C

CC040A

CC1-TF

CuCr1-C

CC140C

A4/1

G-CuNiP

A3/2

G-CuNi2Si

A3/1

G-CuCo2Be

A4/2

G-CuBe

Copper-zinc (Brasses)

DZR1

CuZn35Pb2Al-C

CC752S

DZR2

CuZn33Pb2Si-C

CC751S

CuZn37Pb2Ni1AlFe-C

CC753S

PCB1

G-CuZn40Pb

DCB1

CuZn38Al-C

CC767S

DCB2

G-CuZn37Sn

DCB3

CuZn39Pb1Al-C

CC754S

CuZn39Pb1AlB-C

CC755S

SCB1

G-CuZn25Pb3Sn2

SCB2

G-CuZn30Pb3

SCB3

CuZn33Pb2-C

CC750S

SCB4

G-CuZn36Sn

SCB5

G-CuZn10Sn

SCB6

CuZn15As-C

CC760S

CuZn16Si4-C

CC761S

CuZn32Al2Mn2Fe1-C

CC763S

CuZn34Mn3Al2Fe1-C

CC764S

HTB1

CuZn35Mn2Al1Fe1-C

CC765S

HTB2

G-CuZn36Al4FeMn

HTB3

CuZn25Al5Mn4Fe3-C

CC762S

CuZn37Al1-C

CC766S

Copper-tin (Gunmetals and Phosphor Bronzes)

CT1

CuSn10-C

CC480K

PB1

CuSn11P-C

CC481K

CuSn11Pb2-C

CC482K

PB2

CuSn12-C

CC483K

CT2

CuSn12Ni2-C

CC484K

PB4

G-CuSn10PbP

LPB1

G-CuSn7PbP

Copper-tin-lead (Gunmetals and Leaded Bronzes)

CC492K

CC493K

LG1

CuSn3Zn8Pb5-C

CC490K

LG2

CuSn5Zn5Pb5-C

CC491K

LG3

G-CuSn7Pb4Zn2

LG4

CuSn7Zn2Pb3-C

CuSn7Zn4Pb7-C

LB1

CuSn7Pb15-C

CC496K

LB2

CuSn10Pb10-C

CC495K

LB3

G-CuSn10Pb5

LB4

CuSn5Pb9-C

CC494K

LB5

CuSn5Pb20-C

CC497K

G1

G-CuSn10Zn2

G2

G-CuSn8Zn4Pb

G3

G-CuSn7Ni5Zn3

Copper-aluminium (Aluminium Bronzes)

-

CuAl9-C

CC330G

AB1

CuAl10Fe2-C

CC331G

CuAl10Ni3Fe2-C

CC332G

AB2

CuAl10Fe5Ni5-C

CC333G

CuAl11Fe6Ni6-C

CC334G

AB3

G-CuAl6Si2Fe

Copper-manganese-aluminium

CMA1

CuMn11Al8Fe3Ni3-C

CC212E

CMA2

G-CuMn13Al9Fe3Ni3

Copper-nickel (Cupro-nickels)

-

CuNi10Fe1Mn1-C

CC380H

CuNi30Fe1Mn1-C

CC381H

CN1

CuNi30Cr2FeMnSi-C

CC382H

CN2

CuNi30Fe1Mn1NbSi-C

CC383H

Notes:

(1) Symbol finishes with B for material in ingot form

(2) Number begins CB for material in ingot form

NB: Ingots are not specified for high conductivity coppers

(3) GM - permanent mould casting

GS - sand casting

GZ - centrifugal

GP - pressure die casting

GC - continuous casting

Method of casting affects properties significantly.

7

You might also like

- ASTM B68 68A-Copper Full Hard Pipe STD PDFDocument12 pagesASTM B68 68A-Copper Full Hard Pipe STD PDFAsha ValandNo ratings yet

- Aisi 4140Document2 pagesAisi 4140Tirta BudiawanNo ratings yet

- HighTens EN25Document2 pagesHighTens EN25Annamali Thiayagarajan0% (1)

- Finite To InfiniteDocument1 pageFinite To InfinitedramiltNo ratings yet

- MSU Copper Casting Alloys 2011 PDFDocument10 pagesMSU Copper Casting Alloys 2011 PDFVahid SarfarazNo ratings yet

- RJR PMMTDocument16 pagesRJR PMMTArun PrasadNo ratings yet

- 1 7335Document5 pages1 7335stamatsNo ratings yet

- BS 3601Document3 pagesBS 3601nourlhudaNo ratings yet

- Estandares AstmDocument22 pagesEstandares AstmAgus HermantoNo ratings yet

- GB T 3077 - 1999 Specification of 40Cr Alloy SteelDocument1 pageGB T 3077 - 1999 Specification of 40Cr Alloy SteelĐình Sỹ TTPNo ratings yet

- Indian Standard - 2644Document8 pagesIndian Standard - 2644Biswajit DasNo ratings yet

- Chinese To DinDocument7 pagesChinese To Dindnageshm4n244No ratings yet

- GB T 699 1988 Quality Carbon Structural SteelsDocument17 pagesGB T 699 1988 Quality Carbon Structural SteelsPHUONGNo ratings yet

- Equivalent Grades of Gray IronDocument2 pagesEquivalent Grades of Gray Ironsujay13780100% (1)

- ErmetoDocument14 pagesErmetoJavier VespaNo ratings yet

- SN430-2 2006-12 SAP eDocument3 pagesSN430-2 2006-12 SAP eChristopher LloydNo ratings yet

- Hydrogen Cracking in Specialty Steels: Knolls Atomic Power Laboratory Schenectady, New YorkDocument23 pagesHydrogen Cracking in Specialty Steels: Knolls Atomic Power Laboratory Schenectady, New YorkNattapong PongbootNo ratings yet

- Din 17100Document4 pagesDin 17100Sheby SandyNo ratings yet

- DIN3015 - PART1 - Clamps Standard Series PDFDocument29 pagesDIN3015 - PART1 - Clamps Standard Series PDFSergio SacristanNo ratings yet

- Germany DIN Metals Standard NumbersDocument22 pagesGermany DIN Metals Standard NumbersTerastia Lera100% (1)

- Equivalent Grades of Cast IronsDocument2 pagesEquivalent Grades of Cast IronsVinh Do Thanh100% (1)

- ASTM Standards For Steel PlateDocument4 pagesASTM Standards For Steel Platefarmanali07No ratings yet

- Bs 980 1950 - Steel Tubes For Automobile PurposesDocument14 pagesBs 980 1950 - Steel Tubes For Automobile Purposesstuartj01No ratings yet

- Hexagon Head Screws With Metric Fine Pitch Thread - Product Grades Aandb (First Revision)Document15 pagesHexagon Head Screws With Metric Fine Pitch Thread - Product Grades Aandb (First Revision)kumar QANo ratings yet

- Sist en 13104 2009 A2 2014Document12 pagesSist en 13104 2009 A2 2014Юрий КостенкоNo ratings yet

- Caracteristicile BronzurilorDocument19 pagesCaracteristicile BronzurilorBorza DorinNo ratings yet

- 817M40 PDFDocument2 pages817M40 PDFSamir ChaudharyNo ratings yet

- ASTM Material Comparison TableDocument1 pageASTM Material Comparison Tabledhasdj100% (1)

- Din 3357-4-1981Document5 pagesDin 3357-4-1981олегNo ratings yet

- List of en Standards: SR No Code/Standard DescriptionDocument4 pagesList of en Standards: SR No Code/Standard DescriptionAnilNo ratings yet

- IS 1570 Part 5Document18 pagesIS 1570 Part 5Sheetal JindalNo ratings yet

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- Equivalent Grades of Gray Iron, Ductile Iron, SG Iron, Nodular Graphite IronDocument2 pagesEquivalent Grades of Gray Iron, Ductile Iron, SG Iron, Nodular Graphite IronBao Duy Nguyen100% (3)

- Aws A5Document5 pagesAws A5Omid BeygiNo ratings yet

- BS en 10250-3-2000Document17 pagesBS en 10250-3-2000Mansi BalduwaNo ratings yet

- C45 STD PDFDocument2 pagesC45 STD PDFJeetu GosaiNo ratings yet

- Cold Drawn Seamless Tube DIN 2391 C ST 37.4 NBKDocument3 pagesCold Drawn Seamless Tube DIN 2391 C ST 37.4 NBKtappannNo ratings yet

- Minfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Document3 pagesMinfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Biraj SahooNo ratings yet

- Is 2232 - Castle NutDocument18 pagesIs 2232 - Castle NutRajasekaran MuruganNo ratings yet

- Surface Vehicle StandardDocument7 pagesSurface Vehicle Standardwilian_coelho3309No ratings yet

- Geared Motor: Product ManualDocument178 pagesGeared Motor: Product Manualsanjibkrjana100% (1)

- BS en 15714-4Document28 pagesBS en 15714-4Thomas ValoNo ratings yet

- Din 1691 - 1985Document12 pagesDin 1691 - 1985a.n.87711990No ratings yet

- Gould Alloys Limited - Copper and Copper Alloys DEF STAN 02 838 NES838 Bar - 243Document2 pagesGould Alloys Limited - Copper and Copper Alloys DEF STAN 02 838 NES838 Bar - 243Gourav SharmaNo ratings yet

- BS 1503-1989Document35 pagesBS 1503-1989Олег Соловьев100% (1)

- En 10088 Steel NumberDocument3 pagesEn 10088 Steel Numberrvieira659No ratings yet

- Amendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationDocument3 pagesAmendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - Specificationbeshnu garanaikNo ratings yet

- Equivalent StandardsDocument1 pageEquivalent StandardsRamachandran RamNo ratings yet

- General Requirements For Steel Bars, Carbon and Alloy, Hot-WroughtDocument16 pagesGeneral Requirements For Steel Bars, Carbon and Alloy, Hot-Wroughtعصام السامرائيNo ratings yet

- Steel Forgings For Pressure PurposesDocument18 pagesSteel Forgings For Pressure PurposesnikolicjelenaNo ratings yet

- Din 2526Document1 pageDin 2526MartinsaikiNo ratings yet

- A270 PDFDocument5 pagesA270 PDFHansSarmientoNo ratings yet

- BS en 10059Document3 pagesBS en 10059Nilesh PatilNo ratings yet

- Specification: Hot Coiled Helical Springs Mainline Coaches, Emu and Freight Stock No. WD-01-HLS-94 (Rev.3)Document43 pagesSpecification: Hot Coiled Helical Springs Mainline Coaches, Emu and Freight Stock No. WD-01-HLS-94 (Rev.3)Anonymous PSNjTGUNo ratings yet

- 39NiCrMo3 PDFDocument2 pages39NiCrMo3 PDFAmy GriffinNo ratings yet

- MaterialsDocument4 pagesMaterialsSilvio VarricchioNo ratings yet

- Fitting ASTM A 197 PDFDocument4 pagesFitting ASTM A 197 PDFSusan Sue Berrospi Merino100% (1)

- Astm B575Document5 pagesAstm B575Jota JacquesNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4niladriprasadrNo ratings yet

- Utp Cast Iron GBDocument8 pagesUtp Cast Iron GBhrk100No ratings yet

- Copper and Copper Alloy Ingots and CastingsDocument2 pagesCopper and Copper Alloy Ingots and CastingspoopNo ratings yet

- P10 PDFDocument167 pagesP10 PDFdramiltNo ratings yet

- What Are LoadsDocument2 pagesWhat Are LoadsdramiltNo ratings yet

- Solid Finite Elements Through Three Decades: S&than&Document17 pagesSolid Finite Elements Through Three Decades: S&than&dramiltNo ratings yet

- (2008 Course) : S.E. (Mech.) (Ii Seni,) Examination, 2010 Strength of Machine ElementsDocument10 pages(2008 Course) : S.E. (Mech.) (Ii Seni,) Examination, 2010 Strength of Machine ElementsdramiltNo ratings yet

- Q7 PDFDocument3 pagesQ7 PDFdramiltNo ratings yet

- Q4Document15 pagesQ4dramiltNo ratings yet

- Finite Element Methods in EngineeringDocument1 pageFinite Element Methods in EngineeringdramiltNo ratings yet

- Q1Document12 pagesQ1dramiltNo ratings yet

- Grammar CBSE Class 4 WorksheetDocument6 pagesGrammar CBSE Class 4 WorksheetdramiltNo ratings yet

- Four Day Workshop On Practical Finite Element Analysis - Concepts & ApplicationsDocument2 pagesFour Day Workshop On Practical Finite Element Analysis - Concepts & ApplicationsdramiltNo ratings yet

- Safe Powder Coating Guideline: 7 EditionDocument16 pagesSafe Powder Coating Guideline: 7 EditiondramiltNo ratings yet

- Powder Coating ResinsDocument28 pagesPowder Coating Resinsdramilt100% (1)

- Thermal and Waterjet Cutting Processes PDFDocument5 pagesThermal and Waterjet Cutting Processes PDFdramiltNo ratings yet

- Gap Fills Exercise-5Document6 pagesGap Fills Exercise-5dramiltNo ratings yet

- Healthy Weight Loss PDFDocument5 pagesHealthy Weight Loss PDFdramiltNo ratings yet