Professional Documents

Culture Documents

29 Ug Sjadat PTFI

29 Ug Sjadat PTFI

Uploaded by

Ridwan KotoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

29 Ug Sjadat PTFI

29 Ug Sjadat PTFI

Uploaded by

Ridwan KotoCopyright:

Available Formats

PROSIDING TPT XXI PERHAPI 2012

Application Uniformity Index in Draw Control Practices to Reduce

Damage at the Production Level of Block Cave Mine PT Freeport

Indonesia

E. WIDIJANTO1, S. NUGRAHA2, and A. SJADAT3

1

Civil Geotech & Regional Hydrology-PTFI

2,3

Underground Geotech-PTFI

ABSTRACT

PT Freeport Indonesia operates a copper-gold mine located in the province of Papua,

Indonesia about 3,500 km east of Jakarta. Current ore production from the project is about

200,000 tonnes per day (tpd) of which about 2.5 ktpd from Big Gossans stope mine, 50 ktpd

come from the DOZ Block Cave and the rest is mined from the Grasberg Open Pit. Currently

two new underground mines under development are the Grasberg Block Cave and Deep Mill

Level Zone to ultimately replace surface mine operation with underground.

The stability of the production level in block or panel caving drives production performance

of the mine. It is critical to ensure stability of the panels and reduce the damage to support

efficient and productive mine. Damage of the panels which lead to the heavy damage or panel

closure contribute to the lower productivity, additional repair and re-support program, also

instability at the adjacent area for the future. Draw or mucking performance is one of critical

factor which contribute to the stability of production level in a block or panel cave.

Significant correlation between draw behavior and displacement rate at DOZ (Deep Ore

Zone) mine, and showed relationship as the draw rate increases, the displacement decreases

and vice versa also empirical draw rate recommendations have been determined. The best

practical application is to have uniform and continuous mucking surrounding draw points. To

quantify and elaborate relationship between draw behavior with displacement, uniformity

index which have been applied for draw control practices at South America Mines are utilized

to do further analysis.

This paper outlines some works to determine relation of draw performance and damage of the

production level which represented by displacement, consequences of non-uniform and

discontinuous drawing at block or panel cave mines, and the effort of the team to implement

practical application to reduce the hazard of instability at production level also to achieve its

desired production target.

Keywords: stope mine, block cave, panel cave, stability, damage, draw performance, draw

behavior, uniform mucking, continuous mucking, displacement, uniformity index

INTRODUCTION

PT Freeport Indonesia operates a copper and gold mining complex in the Erstberg Mining

District of the Sudirman Mountains in the province of Papua, Indonesia at elevations from

3000 to 4500 metres above sea level (Figure 1). The topography is extremely rugged and

rainfall in the mine area averages 5500 mm per year.

Current operations in the district include the Grasberg open pit (150,000 tpd ore), the DOZ

panel cave mine (50,000 tpd ore), and Big Gossan stope mine (2,500 tpd ore). The DOZ

block cave is the third panel cave in the Erstberg East Skarn System (EESS) after the Gunung

Bijih Timur (GBT) Mine and the Intermediate Ore Zone (IOZ) Mine (Figure 2). The GBT

287

block cave was in operation from 1980 to 1993 and produced about 60 million tonnes of ore.

The IOZ block cave was started in 1994 and produced over 50 million tons of ore till 2003.

The DOZ block cave started production in 2000 and by the end of 2011 will produce more

than 160 million tonnes. The future DMLZ mine (Deep Mill Level Zone) underneath current

DOZ mine will be on production in 2015.

Figure 1 Location of PTFIs mining operations

The stability of the production level in block or panel caving drives production performance

of the mine. It is critical to ensure stability of the panels and reduce the damage to support

efficient and productive mine. Damage of the panel which leads to the heavy damage or panel

closure contributes to the lower productivity, additional repair and re-support program, also

instability at the adjacent area for the future.

Figure 2 - Ertsberg East Skarn System (EESS) complex

288

The damage of the panel normally due to poor ground, geological features, abutment stress

from the undercut, strain burst, and non-uniform and discontinuous mucking or drawing.

Uniform and continuous mucking or drawing in the block caving is essential to reduce high

deformation or displacement, also damage reduction in the extraction level. The challenge is

how to maintain uniform and continuous mucking for long period with available resources

and some production constraints (i.e. limited equipment, panel damage, wet muck, etc.).

GEOLOGY & GEOTECHNICAL CONDITION

The key lithologies consist of skarn assemblages locally intruded by variably altered Erstberg

Diorite; the later forms the footwall while forsterite skarn, magnetite-forsterite skarn,

magnetite and DOZ Breccia (locally known as HALO High Altered Locally Ore) and marble

are in the hanging wall (Coutts et al., 1999).

Figure 3 - Geology Complex in DOZ Mine

Much of the bedding has been preserved in the skarn deposits and within the hanging wall

marble. There has been movement observed along these bedding planes as small scale faults

which indicate normal left lateral movement, which are cut by NE-SW and NW-SE-trending

faults. Although diorite has healed most structures, there are prominent joint sets cutting the

diorite and skarn, with as many as four sets observed.

Ground conditions within the EESS system are highly variable. Within zones of good to very

good ground conditions there are elongated zones of very poor ground conditions

characterized by low strength, low core recovery and low RQD values. The values of the

Uniaxial Compressive Strength (UCS), Rock Quality Designation (RQD), Rock Mass Rating

(RMR) classification, together with percentage from each rock type are summarized in Table

1.

289

Table 1 . Geotechnical classification and its distribution in the DOZ (Widijanto et al., 2006)

Rock Type

UCS (MPa)

RQD (%)

RMR Class

Percentage (%)

DOZ Breccia

22.3

40

Very poor

9.57

Marble-Sandstone

22.3

65

Poor

1.20

Forsterite Skarn

127.3

84

Good

20.58

Fors-Mag Skarn

56.88

67

Fair

16.26

Magnetite Skarn

97.5

71

Good

1.87

Diorite

111

80

Good

49.99

Other

0.52

DRAW CONTROL CONTRIBUTION IN PANEL STABILITY

Draw control is defined as the practice of controlling the tonnages drawn from individual

drawpoints with the object of minimizing overall dilution and maintaining the planned ore

grade sent to the plant, ensuring maximum ore recovery, avoiding damaging load

concentration on the extraction horizon, and avoiding the creation of conditions that could

lead to air blasts, mud rushes, etc. (Laubscher, 2000).

Refer to Laubscher (2000) that appropriate draw control can avoid damage due to load

concentration on the extraction horizon. Load concentration on the extraction horizon can be

observed through its displacement and damage progress. So it is critical to maintain draw

control in the extraction level to avoid high displacement or extensive damage progress.

Figure 4 Cracks at the rib as one of indicator of excessive load at the extraction level

In line with Laubscher, at DOZ Mine, the relation between damage as of displacement result

with mucking or drawing as follow:

Draw rate increases, the displacement decreases, and vice versa (Rachmad & Widijanto,

2002).

290

Mucking rate increases, the displacement decreases. At consistent mucking rate, a consistent

convergence is observed, and differential draw induces high convergence (Febrian, Yudanto,

& Rubio, 2004)

The empirical criteria established for the draw rate recommendation, for convergence rate <

0.8 mm/day no change in draw order, for convergence rate 0.8-2.0 mm/day increase

draw rate by 2-3 buckets/shift up to a maximum of 10 buckets/shift, and for convergence

rate > 2.0 mm/day increase draw rate by 4-6 buckets/shift up to a maximum of 17 buckets

per shift (Sahupala & Annavarapu, 2007).

Figure 5 Draw rate versus displacement and damage class

It is obvious that continuous mucking or drawing in the block caving is essential to reduce

high displacement, also to reduce damage in the extraction level (as shown in figure 5).

UNIFORMITY INDEX

The uniformity index is introduced and results of back analysis are presented to show relation

between draw and interaction, as well as a methodology to asses and evaluate interactive

layout designs (Susaeta, 2004).

Where:

UI : Uniformity Index

: Number of inactive draw points in the draw point vicinity

: Factor of normalization, equal to 99/89

tp : Tonnage extracted from draw point p (see figure 4) under analysis, in a specific period

of time

ti : Tonnage extracted from draw point i belonging to draw point p vicinity in the same period

of time

291

tmax : Maximum tonnage extracted in the vicinity of draw point p, in the same period of time

tmin : Minimum tonnage extracted in the vicinity of draw point p, in the same period of time

n : Number of draw points belonging to the vicinity of draw point p

Figure 4 Plan view draw point interaction

The first integer part (), that indicates the number of inactive draw points in the vicinity, in

other words draw points without movement during the considered period of time. Then as

grows draw is less uniform.

Figure 5 - Uniformity Index Example Matrix (Susaeta, 2004)

The second part of equation above will be called Specific Index of Uniformity, it is a decimal

number between 0 and 1, and indicates the uniformity of draw among the active draw points

for the selected period of time or in the other word 0 means completely uniform draw and 1

means completely isolated draw

DATA ANALYSIS

To test uniformity index (UI) as assessment tool to review drawing performance or behavior,

there are some steps of work as shown in figure below.

292

DATA COLLECTION

For

SIGNIFICANT

CONVERGENCE (SC)

DETERMINE

POTENTIAL CAUSE

OF SC

SELECT SC

RELATED

MUCKING

UI

CALCULATION

DATA ANALYSIS

RESULT

Figure 6 Flow of works

From 283 selected significant convergence events ( 1mm/day) at DOZ mine during 2010.

The contributor of these events associated with close draw point or no mucking activities

(41.3%), decreasing mucking (24.7%) and abutment stress (33.9%). This data shows that

mucking or drawing activities is the main contributor of significant convergence events in the

extraction level (66%).

There is a significant correlation between drawing and displacement rate, and showed

relationship as the draw increases, the displacement decreases and vice versa (Rachmad &

Widijanto, 2002).

Some test trials utilizing uniformity index (UI) show that as higher UI, the chance for having

significant displacement higher as well and vice versa. Higher UI means higher number of

inactive or close draw point and higher non-uniform production among surrounding draw

points. Test trial for different shift scenarios (1 to 9 shift calculations) show the same trend

that high displacement (significant convergence) occurred at higher uniformity index.

Figure 9 Most of significant convergence at its higher uniformity index

APPLICATION IN THE FIELD

It is obvious as a number of inactive draw point gets higher possibility for having significant

convergence event (significant displacement) is higher as well. For extreme comparison if 1

inactive draw point only, the possibility of having significant convergence is only 10% of data

population compare to the almost 100% significant convergence events from 9 inactive or

close draw points scenario.

That figure also provide practical guidance to allow maximum 3 inactive or close draw points

to avoid significant convergence event which cause damage in the extraction level. Three

inactive or close draw points give 30% in average of significant convergence events.

293

It is believed that as long the non-uniform and discontinuous mucking happen as the

significant convergence event increases. Figure 12 shows the percentage of cumulative

significant convergence occurs between 4-5 shifts period (at 3 inactive draw points scenario).

In other word, the condition without non-uniform and discontinuous mucking still can be

allowed for 5 shifts period.

Figure 70 Most of significant convergence at its higher uniformity index

Figure 8 The change trend happen at 4-5 shifts period for 3 inactive draw point scenario

CONCLUSION

Significant convergence displacement is associated with close draw points means no

mucking activities- (41%), abutment stress (34%), and decreasing mucking (25%). Mucking

or drawing activity is main contributor of significant convergence events in extraction level

(66%)

294

Uniformity index (UI) can be utilized to assess and evaluate how uniform drawing activities

in each draw point.

Number of inactive or close drawpoints correlates with significant convergence or

displacement. Statistically 3 (three) inactive drawpoints cover 26-32% of significant

convergence events for 1 up to 9 shifts scenarios. Three (3) draw points can be as a

maximum inactive draw points application to avoid potential significant convergence events

due to drawing activities.

From time perspective (for 3 inactive draw points scenario), the critical change of additional

significant convergence events happen from 4 to 5 shifts uniformity index calculation, in

other word 5 shifts can be utilized as maximum recommended time without any drawing or

mucking of draw point (for damage avoidance)

Uniform and continuous drawing is essential to reduce significant displacement (damage

reduction) however it is quite difficult to be executed in the field due some resources and

production constraints, so quantification of maximum number of inactive or close draw

points and critical time constraint will provide technical judgments for tactical production

strategy.

ACKNOWLEDGEMENTS

The authors would like to thank the management of PT. Freeport Indonesia for permission to

publish this paper. The contributions made by underground personnel, especially DOZ

geotechnical engineers to this paper are gratefully acknowledged.

REFERENCES

Coutts B.P. et al., Geology of the Deep Ore Zone, Erstberg East Skarn System, Irian Jaya,

AusIMM PACRIM Conference, Bali Indonesia (1999).

Laubscher, D, A Practical Manual on Block Caving, International Caving Study (1997-2000),

Brisbane Australia (2000).

Rachmad, L. and Widijanto, E. ,Application of Convergence Monitoring at PT. Freeport

Indonesia Deep Ore Zone Mine, 5th North American Rock Mechanics Symposium and 17th

Tunneling Association of Canada Conference, Sudbury Canada (2002).

Febrian I et al. , Application of convergence monitoring to manage induced stress by mining

activities at PT Freeport Indonesia Deep Ore Zone Mine, MassMin 2004, Santiago Chile

(2004)

Susaeta, A., Theory of gravity flow (part2), MassMin 2004, Santiago Chile (2004).

Widijanto E. et al., Geotechnical Challenges in the DOZ Block Cave Mine, Rock Mechanics

in Underground Construction ISRM International Symposium 2006, Singapore (2006).

Sahupala H. & Annavarapu S. Assessment of pillar damage at the extraction level in the deep

ore zone (DOZ) mine, PT Freeport Indonesia, 1st Int. Symposium on Block and Sub-Level

Caving, Cape Town South Africa (2007)

Widijanto E. & Nugraha S, Uniformity Index for Draw Control Practices DOZ Mine,

Internal Memorandum PT Freeport Indonesia (2012).

Widijanto E et al., Optimizing draw control practices to reduce damage at the production

level of block cave mine PT Freeport Indonesia, 10th International Symposium on Earth

Science and Technology 2012, Bandung Indonesia (September 2012).

You might also like

- UNSW MINE3310 Rock MechanicsDocument215 pagesUNSW MINE3310 Rock MechanicsBikesh ShresthaNo ratings yet

- Technical Manual (Part A) Tatuus-Msv 023: Release 1.03 (27/02/2023)Document80 pagesTechnical Manual (Part A) Tatuus-Msv 023: Release 1.03 (27/02/2023)Nelson Piquet Souto Maior100% (1)

- Groningen Motivational Letter 3.11Document1 pageGroningen Motivational Letter 3.11way heavnNo ratings yet

- 4.1.8 Long Term Geomechanical Stability AnalysisDocument139 pages4.1.8 Long Term Geomechanical Stability Analysisboper dantoNo ratings yet

- Planning For Narrow Vein Mines: G GemellDocument4 pagesPlanning For Narrow Vein Mines: G GemellBendigo BanksNo ratings yet

- MassMin2012 - PT Freeport Indonesia - Transitioning To 240,000 TPD From Underground MiningDocument9 pagesMassMin2012 - PT Freeport Indonesia - Transitioning To 240,000 TPD From Underground MiningÁALNo ratings yet

- Lessons Learned in Cave Mining El Teniente PDFDocument13 pagesLessons Learned in Cave Mining El Teniente PDFAle Reveco FloresNo ratings yet

- 01 - Mine Geotechnics - Supandi - IntroductionDocument43 pages01 - Mine Geotechnics - Supandi - IntroductionN Kusuma WardhanaNo ratings yet

- Exercises - N2 - UBC Mining Method SelectionDocument12 pagesExercises - N2 - UBC Mining Method SelectionLuis_Escriba_CNo ratings yet

- CyanideDocument193 pagesCyanideEutimio ChiNo ratings yet

- Full Scale Near Field Flow Behaviour at The Ridgeway Deeps Block Cave MineDocument10 pagesFull Scale Near Field Flow Behaviour at The Ridgeway Deeps Block Cave MineandresmaureiravNo ratings yet

- Draw Points OkokDocument151 pagesDraw Points OkokBasago Minas Lo MejorNo ratings yet

- Rose and Hungr 2007Document13 pagesRose and Hungr 2007Carles CousoNo ratings yet

- Frieda Copper and Gold ProjectDocument26 pagesFrieda Copper and Gold ProjectAdrian Lantapi100% (1)

- Block CavingDocument5 pagesBlock CavingDiego Arturo Rojas AlfaroNo ratings yet

- Geologi Regional Papua (English)Document16 pagesGeologi Regional Papua (English)Eko Johan Taruk Allo100% (1)

- Long Hole ProceduresDocument16 pagesLong Hole ProceduresJimmy Junior Blas VenegasNo ratings yet

- 1998.minimizing Dilution in Open Stope Mining With A Focus On Stope Design and Narrow Vein Longhole Blasting. Thesis. Clark PDFDocument357 pages1998.minimizing Dilution in Open Stope Mining With A Focus On Stope Design and Narrow Vein Longhole Blasting. Thesis. Clark PDFRichard PaulNo ratings yet

- NSW Code of Practice Strata Control in Undergound Coal Mines PDFDocument102 pagesNSW Code of Practice Strata Control in Undergound Coal Mines PDFKorchak JohnNo ratings yet

- Teknik Q SistemDocument48 pagesTeknik Q SistemZola1stNo ratings yet

- Guidelines For Use of The Scaled Span Method PDFDocument34 pagesGuidelines For Use of The Scaled Span Method PDFpedroNo ratings yet

- 23 Failure Criteria For Rocks PDFDocument20 pages23 Failure Criteria For Rocks PDFVu ThuygiangNo ratings yet

- Drilling Rate Prediction of An Open Pit Mine Using The Rock Mass Drillability IndexDocument15 pagesDrilling Rate Prediction of An Open Pit Mine Using The Rock Mass Drillability IndexmycdrhelpNo ratings yet

- State of The Art - LaubscherDocument21 pagesState of The Art - LaubscherAndres Condore VásquezNo ratings yet

- 03 - Best Practices For Geotechnical Planning & Design in Open Pit Mining OperationsDocument31 pages03 - Best Practices For Geotechnical Planning & Design in Open Pit Mining OperationsIvan MarianNo ratings yet

- Rock Mass Blastability Dependence On RocDocument12 pagesRock Mass Blastability Dependence On Rocbinod2500No ratings yet

- RQD After 20 Years Deere 1989Document101 pagesRQD After 20 Years Deere 1989Johan Van Staveren100% (1)

- Sublevel Caving (SME Mining Engineering Handbook) - RNADocument17 pagesSublevel Caving (SME Mining Engineering Handbook) - RNARisman N. AriestNo ratings yet

- Determination of Drilling Rate Index Based On RockDocument10 pagesDetermination of Drilling Rate Index Based On RockGeo Khader AbdulNo ratings yet

- Icg17 Soq Ungd 04 PDFDocument32 pagesIcg17 Soq Ungd 04 PDFpedroNo ratings yet

- Shotcrete Pakalnis PDFDocument9 pagesShotcrete Pakalnis PDFAlejandro VidalNo ratings yet

- Sainsbury Et Al 2015 Open Stope SimulationDocument17 pagesSainsbury Et Al 2015 Open Stope SimulationIoannis VazaiosNo ratings yet

- Mogalakwena Case Study - para Capítulo 1Document16 pagesMogalakwena Case Study - para Capítulo 1Alexandre Justino NhanombeNo ratings yet

- Fragmentation and Its Impact On Downstream ProcessingDocument4 pagesFragmentation and Its Impact On Downstream Processingalvaroaac4No ratings yet

- Northparkes E26 Lift 2 Block Cave - A Case StudyDocument10 pagesNorthparkes E26 Lift 2 Block Cave - A Case StudyEduardo MenaNo ratings yet

- Module 6 - HUMAN Practices - Mining For Human ExtractionDocument22 pagesModule 6 - HUMAN Practices - Mining For Human ExtractionCarlos TuazonNo ratings yet

- Geomembrane and Pipe Design Issues in Deeper Heap Leach PadsDocument13 pagesGeomembrane and Pipe Design Issues in Deeper Heap Leach PadsdreamerangelNo ratings yet

- A Holistic Approach To Mine PlanningDocument11 pagesA Holistic Approach To Mine PlanningLucide Ingele100% (1)

- PPV Mining BlastDocument11 pagesPPV Mining Blastفردوس سليمانNo ratings yet

- Teknik PeledakanDocument43 pagesTeknik PeledakanandikaNo ratings yet

- Back Analysis in Rock Engineering 16 17Document2 pagesBack Analysis in Rock Engineering 16 17Ambarr SutantiNo ratings yet

- Appendix E13 - UG Mitchell PFS 31MAY2012 PDFDocument247 pagesAppendix E13 - UG Mitchell PFS 31MAY2012 PDFAlfaro RoblesNo ratings yet

- Field Practice Guidelines For Blasting Seismographs 2015 PDFDocument11 pagesField Practice Guidelines For Blasting Seismographs 2015 PDFAlexMurguiaUrbina100% (1)

- Geology - Paralic Coal From Mukah, Sarawak PDFDocument19 pagesGeology - Paralic Coal From Mukah, Sarawak PDFrafiz91100% (1)

- Debris Flow PDFDocument12 pagesDebris Flow PDFAntonio Castillo RualesNo ratings yet

- 07 - Golder AssociatesDocument8 pages07 - Golder AssociatesFerdiyan100% (1)

- IAMGOLD Geotech Logging 20071101 PrintDocument42 pagesIAMGOLD Geotech Logging 20071101 PrintJoseph Mofat100% (1)

- 3DS 2017 GEO Surpac 5tips and Tricks Ebook Vol 1 PDFDocument13 pages3DS 2017 GEO Surpac 5tips and Tricks Ebook Vol 1 PDFAbush Desta100% (1)

- Seminar Nasional Geomekanika IIIDocument326 pagesSeminar Nasional Geomekanika IIIOlivinNo ratings yet

- 2011 USRM Cave Mining-Back To The Basics - MossDocument79 pages2011 USRM Cave Mining-Back To The Basics - MossgertvanhoutNo ratings yet

- Guidlines For Use of The Scaled Span Method For Surface Crown Pillar Stability AssessmentDocument34 pagesGuidlines For Use of The Scaled Span Method For Surface Crown Pillar Stability AssessmentSajjad AnwarNo ratings yet

- Proceeding ICG2015Document357 pagesProceeding ICG2015Fatoni AdyahyaNo ratings yet

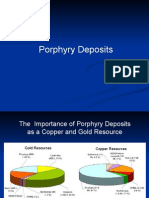

- Porphyry DepositsDocument43 pagesPorphyry DepositsVictor Valdivia100% (2)

- Methods For Design & Sability Ug ExcavationDocument67 pagesMethods For Design & Sability Ug Excavationbishal pradhanNo ratings yet

- Alpha & Beta 3 5 PlungeDocument2 pagesAlpha & Beta 3 5 PlungeGodfrey MakiwaNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Fragblast: International Journal For Blasting and FragmentationDocument20 pagesFragblast: International Journal For Blasting and FragmentationPatricio CisternasNo ratings yet

- Wall Control by Blasting Optimization Fragblast10 Delhi2012Document10 pagesWall Control by Blasting Optimization Fragblast10 Delhi2012Diego Araya HernándezNo ratings yet

- Evaluation of Formation Damage Models On Effective WellboreDocument12 pagesEvaluation of Formation Damage Models On Effective WellboreEbube OrisaNo ratings yet

- NDX KumarDocument11 pagesNDX KumarDr-Jitendra VaishNo ratings yet

- The Application of GRP and Thin Spray Liner Support Products in A Typical Block Cave Mining Method To Enhance Safety and ProductivityDocument10 pagesThe Application of GRP and Thin Spray Liner Support Products in A Typical Block Cave Mining Method To Enhance Safety and ProductivityMark EdowaiNo ratings yet

- 8 Mine To Mill Cost Analysis Kanchibotla and ValeryDocument16 pages8 Mine To Mill Cost Analysis Kanchibotla and ValeryWillan Villanueva Bolaños0% (1)

- Goodie Bag Hut 48Document4 pagesGoodie Bag Hut 48Ridwan KotoNo ratings yet

- Abstract Thesis Geert de Jong Abstract Thesis Jeroen DijkstraDocument4 pagesAbstract Thesis Geert de Jong Abstract Thesis Jeroen DijkstraRidwan KotoNo ratings yet

- 1 Eksplorasi Geoffrey de Jong PTFI Prosiding FixDocument7 pages1 Eksplorasi Geoffrey de Jong PTFI Prosiding FixRidwan KotoNo ratings yet

- 109 HeadshotDocument2 pages109 HeadshotRidwan KotoNo ratings yet

- Gary D. Holt: Onc, HNCDocument23 pagesGary D. Holt: Onc, HNCRidwan KotoNo ratings yet

- Disk No. Label Comments BootDocument1 pageDisk No. Label Comments BootDavid HiddingsNo ratings yet

- Microbial Physiology in The Genomic Era: A Revolutionary TaleDocument21 pagesMicrobial Physiology in The Genomic Era: A Revolutionary TaleLiona PatriciaNo ratings yet

- Pakistan Exams BC Bank AccountsDocument4 pagesPakistan Exams BC Bank AccountskhulsanNo ratings yet

- List of Goosebumps BooksDocument10 pagesList of Goosebumps Booksapi-398384077No ratings yet

- Entrepreneurship Summative Test Q1Document3 pagesEntrepreneurship Summative Test Q1urhenNo ratings yet

- Wine Enthusiast - May 2014Document124 pagesWine Enthusiast - May 2014Johanna Shin100% (1)

- Pressform Refractory PRINT Brochure PDFDocument44 pagesPressform Refractory PRINT Brochure PDFravikumarangNo ratings yet

- Chapter 5 Steam and Gas TurbinesDocument64 pagesChapter 5 Steam and Gas TurbinesKeba Del Ray100% (2)

- Policy For Take-Back ProgramDocument16 pagesPolicy For Take-Back ProgramShaswat SrivastavaNo ratings yet

- Examining The Relationship BetDocument24 pagesExamining The Relationship BetMariaNo ratings yet

- 1468 Water Soluble Salts Bresle Method Iso 8509Document2 pages1468 Water Soluble Salts Bresle Method Iso 8509osgamNo ratings yet

- Steel Body - Lever Hoists: A e B A e B A e BDocument1 pageSteel Body - Lever Hoists: A e B A e B A e BtylerlhsmithNo ratings yet

- Lesson 11 Payroll Calculation SolutionDocument6 pagesLesson 11 Payroll Calculation SolutionashrithssNo ratings yet

- ED486 Trailblazer 330 DieselDocument6 pagesED486 Trailblazer 330 DieselGV CamposNo ratings yet

- Confirmation For Booking ID # 843643049Document1 pageConfirmation For Booking ID # 843643049cindy brigitaNo ratings yet

- Workstationst Modbus® Instruction Guide: Gei-100696EDocument41 pagesWorkstationst Modbus® Instruction Guide: Gei-100696EЕсет ДаулетжанNo ratings yet

- Clarkson Lumber Case QuestionsDocument2 pagesClarkson Lumber Case QuestionsJeffery KaoNo ratings yet

- 05 Inventory ManagementDocument47 pages05 Inventory ManagementjackNo ratings yet

- Fractal Audio fm3 Omg9 ManualDocument7 pagesFractal Audio fm3 Omg9 Manualenezio vieiraNo ratings yet

- MBA Interviews (Undergraduation Questions)Document14 pagesMBA Interviews (Undergraduation Questions)anshshah1310No ratings yet

- 5 Practical Use Cases Sankey DiagramDocument5 pages5 Practical Use Cases Sankey DiagramRaviNo ratings yet

- Vendor ListDocument3 pagesVendor ListJohn Son GNo ratings yet

- Pattern Recognition: Zhiming Liu, Chengjun LiuDocument9 pagesPattern Recognition: Zhiming Liu, Chengjun LiuSabha NayaghamNo ratings yet

- Megohmmeter: User ManualDocument60 pagesMegohmmeter: User ManualFlavia LimaNo ratings yet

- Juhani Pallasmaa Complete MonographDocument52 pagesJuhani Pallasmaa Complete MonographYang Yu100% (1)

- PQR Amp WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR Amp WPQ Standard Testing Parameter WorksheetvinodNo ratings yet

- Guía Express TOEFL iBTDocument21 pagesGuía Express TOEFL iBTJordan Raji JrLcNo ratings yet

- Basic Modules of Instruction Agriculture NC IIDocument13 pagesBasic Modules of Instruction Agriculture NC IIMEAMALLORCANo ratings yet