Professional Documents

Culture Documents

60 GB

60 GB

Uploaded by

kuhn403825Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

60 GB

60 GB

Uploaded by

kuhn403825Copyright:

Available Formats

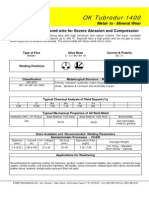

CORODUR 60

CLASSIFICATION:

DIN EN 14700

T Fe15

DIN 8555

MF 10-60-G

GENERAL CHARACTERISTICS:

High C- Cr- Nb- alloyed flux- cored wire electrode for high abrasive wear up to 550 C. The weld

deposit consists of chrome - and niobium carbides which are embedded into the matrix. The

deposit should be subjected to little impact stress. Weld metal is not machinable. Maximum deposit

should be limited to three layers and a thickness of 10 mm. Before overlaying sensitive base

materials and old previously hardfaced surfaces a buffering layer of CORODUR 200 K or 250 K is

recommended.

APPLICATION:

Mixer paddles, grinding rollers and grinding paths, wear plates, band transfers, chutes, hoppers,

cement and concrete pumps, excavator teeth, steel, coal, cement and mineral industry

TYPICAL ALL WELD METAL ANALYSIS ( % ):

C

Si

Mn

5,2

1,1

0,4

Cr

22,0

Nb

7,0

TYPICAL ALL WELD METAL MECHANICAL PROPERTIES:

Hardness: 61 - 63 HRc

PARAMETER:

Diameter

1,2

1,6

2,0

2,4

2,8

3,2

FORMS OF DELIVERY:

Coil "BS 300" = 15 kg

Voltage

18 - 27

20 - 27

22 - 26

24 - 27

25 - 28

26 - 30

Amps

140 - 240

160 - 280

220 - 300

260 - 340

320 - 440

350 - 520

Coil "BS 450" = 25 kg

Drums = 300 kg

OA = gasless, SA = Submerged Arc

Rev. 03-2010:1

Corodur Flldraht GmbH may change the characteristics of the wire without notice. Statements on composition and application are just for the appliers

information. Statements on mechanical properties always refer to the all-weld-metal according to valid standards. We recommend the applier to check our

products for their special application autonomously.

You might also like

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- PyroCarb 077Document1 pagePyroCarb 077Rana RandhirNo ratings yet

- Fisa Tehnica ROBODURDocument1 pageFisa Tehnica ROBODURdneprmt1No ratings yet

- Utp 75Document1 pageUtp 75mohamedNo ratings yet

- Category SMAW Stick Electrodes Type Applications: WC Cr3C2 Fe NBDocument1 pageCategory SMAW Stick Electrodes Type Applications: WC Cr3C2 Fe NBmohamedNo ratings yet

- Diffusion Hardfacing PlatesDocument8 pagesDiffusion Hardfacing Platesbalajiprasanna.kNo ratings yet

- Hard Facing Welding ElectrodesDocument3 pagesHard Facing Welding ElectrodesValli RajuNo ratings yet

- UTP 655 32 SpecSheetDocument1 pageUTP 655 32 SpecSheetFadi HasnNo ratings yet

- 2222XHDDocument1 page2222XHDmkpqNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- Weldability of Cr-Mo SteelsDocument20 pagesWeldability of Cr-Mo SteelsNitin Bajpai100% (2)

- Cu Ni FabricationDocument28 pagesCu Ni FabricationAli Varmazyar100% (1)

- CW CAT TABEL25!08!09 BewerkversieDocument46 pagesCW CAT TABEL25!08!09 BewerkversieAdeKusumahNo ratings yet

- CERTILAS EN Edition2023 320Document1 pageCERTILAS EN Edition2023 320Alireza KhodabandehNo ratings yet

- TDS 351do enDocument1 pageTDS 351do enMumkoNo ratings yet

- Stein-Megafil A 740 M: Seamless Flux Cored WireDocument1 pageStein-Megafil A 740 M: Seamless Flux Cored WireShijuNo ratings yet

- Alloy Data Sheet 6082Document1 pageAlloy Data Sheet 6082Prashant MalveNo ratings yet

- 56 GBDocument1 page56 GBJonathan DiazNo ratings yet

- Utp 63Document1 pageUtp 63Eileen TylerNo ratings yet

- Koco Koco Kocovvv Koco Koco Kocovv Koco KocoDocument0 pagesKoco Koco Kocovvv Koco Koco Kocovv Koco KocoSun SunNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationRudi SyamNo ratings yet

- Flux Cored Wires PDFDocument71 pagesFlux Cored Wires PDFCristian Camilo QuirogaNo ratings yet

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- Stellite 6 - ERCoCrADocument2 pagesStellite 6 - ERCoCrAtilakthakar1No ratings yet

- Utp BMCDocument1 pageUtp BMCSamanthaPereraNo ratings yet

- GMAW Welding ParametersDocument32 pagesGMAW Welding Parametersnarutothunderjet216No ratings yet

- OK Tubrodur 1400iDocument1 pageOK Tubrodur 1400icamelod555No ratings yet

- Welding WireDocument20 pagesWelding WirefoxmancementNo ratings yet

- Kiswel K-71TDocument1 pageKiswel K-71TArfan AnwarNo ratings yet

- Cobalarc 9EDocument1 pageCobalarc 9EDuy TânNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- Mild Steel Welding Electrodes: Salient FeaturesDocument16 pagesMild Steel Welding Electrodes: Salient FeaturesHandrea Hadi SaputraNo ratings yet

- Wire M10SDocument1 pageWire M10SCristian BoselliNo ratings yet

- Welding Consumables For Hydro Power StationsDocument16 pagesWelding Consumables For Hydro Power StationsMohamed FaragNo ratings yet

- Böhler Foxa7 Fox A 7Cn: DescriptionDocument1 pageBöhler Foxa7 Fox A 7Cn: Description2003vinayNo ratings yet

- Diamondspark 52 MC: Seamless Metal-Cored WireDocument2 pagesDiamondspark 52 MC: Seamless Metal-Cored WireDavid RodriguesNo ratings yet

- Spec - Ohe - Cat (Cu MG) 0120 (11 - 12 PDFDocument21 pagesSpec - Ohe - Cat (Cu MG) 0120 (11 - 12 PDFanuj sharmaNo ratings yet

- CHR707Document1 pageCHR707ImmalatulhusnaNo ratings yet

- 421 - Domex 700 MCDocument2 pages421 - Domex 700 MClalamed21No ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- مكونات نقط اللحام شامل بنط اللحامDocument2 pagesمكونات نقط اللحام شامل بنط اللحامdaha333No ratings yet

- Welding Manual For SP ElectrodeDocument72 pagesWelding Manual For SP Electrodehim123verNo ratings yet

- TS For 33kv Line Material PDFDocument27 pagesTS For 33kv Line Material PDFRamaKrishna ANo ratings yet

- Utp Ledurit 65Document1 pageUtp Ledurit 65Ulisses SilvaNo ratings yet

- Sandvik 2RE69: Austenitic Stainless SteelDocument4 pagesSandvik 2RE69: Austenitic Stainless SteelalexmontellNo ratings yet

- LH 104Document1 pageLH 104Sandeep gangulyNo ratings yet

- FC580 LeafletDocument1 pageFC580 Leafletkewatanil49No ratings yet

- Lastek 90 Ceweld - Croni 29-9 S - 2013-06-27Document1 pageLastek 90 Ceweld - Croni 29-9 S - 2013-06-27Niksa ZekicNo ratings yet

- HV 800Document1 pageHV 800rockyandianaNo ratings yet

- 570 950mpa High Tensile Strength SteelDocument32 pages570 950mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- Tenacito R: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageTenacito R: MMA Electrodes C-MN and Low-Alloy SteelsAnonymous hNpF6INo ratings yet

- WP I FCAW Sept 2010Document99 pagesWP I FCAW Sept 2010jhas988No ratings yet

- Abratec 6710 XHD: WeldingDocument2 pagesAbratec 6710 XHD: WeldingAravind rajNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Catalogo Speciali DisegnoDocument26 pagesCatalogo Speciali Disegnokuhn403825No ratings yet

- Microscopio MetallograficoDocument20 pagesMicroscopio Metallograficokuhn403825No ratings yet

- R DT EVO LF - Eng - TdsDocument2 pagesR DT EVO LF - Eng - Tdskuhn403825No ratings yet

- Industrial Series HDX ModelsDocument3 pagesIndustrial Series HDX Modelskuhn403825No ratings yet

- Encoder LIKA Catalogo GeneraleDocument24 pagesEncoder LIKA Catalogo Generalekuhn403825No ratings yet

- Flyer KV-Body28 English Single PagesDocument6 pagesFlyer KV-Body28 English Single Pageskuhn403825No ratings yet

- Primary Lithium BatteryDocument2 pagesPrimary Lithium Batterykuhn403825No ratings yet

- SK A 45-O: Description 1Document2 pagesSK A 45-O: Description 1kuhn403825No ratings yet

- SK 256-ODocument2 pagesSK 256-Okuhn403825No ratings yet

- Docol Case Hardening SteelDocument2 pagesDocol Case Hardening Steelkuhn403825No ratings yet

- Comparazione Grano Austenitico Tempra Calore Residuo - Forno A TappetoDocument1 pageComparazione Grano Austenitico Tempra Calore Residuo - Forno A Tappetokuhn403825No ratings yet

- Hardenable Boron SteelDocument8 pagesHardenable Boron Steelkuhn403825No ratings yet

- 27MnCrB5 Tempering ChartDocument1 page27MnCrB5 Tempering Chartkuhn403825No ratings yet