Professional Documents

Culture Documents

Coil Dimension Guidelines: Rows CH - Casing Height

Coil Dimension Guidelines: Rows CH - Casing Height

Uploaded by

tpqnd90gmailcomOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coil Dimension Guidelines: Rows CH - Casing Height

Coil Dimension Guidelines: Rows CH - Casing Height

Uploaded by

tpqnd90gmailcomCopyright:

Available Formats

P.O.

Box 410

Schofield, WI 54476

Phone: 715.359.6171

www.greenheck.com

Coil Dimension Guidelines

Rows

Horizontal rows of tubes in the fin pack

Chilled Water and DX Coils 1 to 12 rows

Hot Water Coils 1 to 12 rows

Steam Coils 1 to 2 rows

Condenser Coils 1 to 12 rows

FPI Fins Per Inch

1/2 OD tube coils 10 to 16 fins per inch

3/8 OD tube coils 10 to 20 fins per inch

5/8 OD tube coils 6 to 14 fins per inch

Standard fins are .006 die formed aluminum with

collared tube holes

Optional fins are .008 and .010 aluminum and .006

copper

Contact factory fin coatings

CH Casing Height

For coils with stackable flanges, casing height is

calculated as follows:

CH = SP1 + FH + SP2

(e.g. SP1 = 1.5, FL = 30, SP2 = 1.5) H = 33

For inverted flat casing, casing height is calculated as

CH = FH + 1/8

CL Casing Length

CL = EP1 + FL + EP2

CD = Casing Depth

Standard coil casing depths are as follows

Rows Deep

1

2

3

4

5

6

8

10

FH Fin Height

Fin heights are dictated by our tube patterns

For 5/8 tube coils, fin heights are available in increments

of 1.50

For 1/2" tube coils, fins are available in increments of

1.25

For 3/8 tube coils, fins are available in increments of

1.00

FL Fin Length

Fin length can be any size. Center supports (also called

tube supports) are required for every 50 of fin length. A

center support is sheet metal with tube holes used to support

the middle of the fin pack.

SP1, SP2 Sideplate Flanges

Standard flanges are typically 1 1/2 and stackable.

Minimum stackable flange is 1/2.

Inverted, flat sideplate flanges are typically 1 and

Casing Height (CH) is increased on both sides by the

1/16 thickness of the metal. (e.g. 9 Fin Height +

Inverted Flat Side Plates = 9 1/8 Casing Height)

Available casing materials are 16 gauge galvanized steel

and 16 gauge stainless steel.

NOTE: These dimensions were chosen to ensure that

headers remain inside the casing, however; modifications

can be made as long as:

CD > Fin Pack

Where CD is Casing Depth

Fin pack = (No. Rows)* (Centerline Distance between Rows)

Max

MAX is the dimension from the edge of the fin pack to

the outside of the return bend. A return bend is simply a

bent copper tube connecting two adjacent rows.

Minimum MAX dimension is 1.5

Typical MAX dimension is 2.25

Sometimes the flange, EP1 exceeds the MAX dimension. In

such a case, substitute the MAX dimension with EP1.

C Dimension

Contact Factory for other casing materials

FAQ: Why are top and bottom flanges called side plates?

ANSWER: When our coil builders are expanding the tubes

to the fins at the factory, the coil face lays flat on the table,

so the top and bottom flanges are actually viewed as side

plates.

EP1, EP2 End Plates (also called tube sheets)

Standard flanges are usually 1 1/2" and made of 16

gauge galvanized steel

16 gauge stainless steel end plates are also available

CD Dim

5

6-1/2

6-1/2

7-1/2

7-1/2

10

12

15

C is the dimension from the edge of the fin pack to the

outside of the header. For opposite end connection

coils, there would be two C dimensions C1 and C2.

Attached to the header are copper tubes or adapter

tubes which connect the coil tubes to the header.

Standard adapter tube lengths are 3 1/8 and 1 7/8.

(e.g. Coil has a 1 1/8 header with 3 1/8 adapter tubes

C = 1-1/8 + 3-1/8 = 4-3/8

NOTE: All double circuit coils to have a minimum adapter

tube length of 3 1/8.

OAL Overall Length

For same end connection coils, overall length is the

dimension from the edge of the return bends on one end

to the outside of the header on the other end.

OAL = MAX + FL + C

example: MAX = 2 + FL = 48 + C = 4 3/8 OAL = 54 5/8

For opposite end connection coils, overall length

measures from the outside of the header on one end to

the outside of the header on the opposite end.

OAL = C1 + FL + C2

ex: C1 = 3 1/8 + FL = 48 + C2 = 3 1/8 OAL = 54 1/4

Note that connection length L is not included in OAL

dimension.

Coil connections are typically copper or steel. Copper

connections can be made any length down to a certain

minimum.

Steel Connections have fixed lengths as shown in the

chart below.

Standard connection types for various Greenheck Coils :

Water and Steam Coils Copper MPT

connections (with option for Copper FPT, Copper

Sweat or Steel MPT connection).

DX Coils Supply connections are brass

distributors with removable type orifice and an

optional side port connection for hot gas bypass.

Suction headers have Copper SWEAT

connections.

Condenser and Heat Reclaim Coils Copper

SWEAT connections.

Typical Connection Lengths for Standard OD Connection

Sizes

Conn

Dia.

STD

MPT

L Dim.

2

2

3

3 1/4

3 1/2

3 1/2

4

3/4

1

1 1/4

1 1/2

2

2 1/2

3

STD

FPT

L Dim.

2

2 1/4

2 1/2

2 1/2

3

3 1/4

3 1/4

Absolute

Minimum

L Dim.

1 1/4

1 1/4

1 1/2

1 5/8

1 3/4

2

2

Connection Sizes-Header Diameters

1-4

4-8

8-16

Conn

3/4

1-1/4

1630

1-1/2

Connection locations may vary according to whether you are

replacing an existing coil or designing a new coil. For

Greenheck Coils, standard connection locations S and R

are determined from the centerline of the connection relative

to the top and bottom of the casing.

Typically, for Water Coils, Standard Steam, Direct

Expansion, and Condenser Coils

S or R = 1/2 (Conn size OD) + .5

(e.g. Conn Size = 2, S = 1.5)

3040

2

4075

2-1/2

E and F Connection Locations

E and F dimensions are determined from the centerline of

the connection relative to the sides of the casing. These

dimensions are probably the most mysterious of all coil

dimensions, for they are dependent on many factors

number of rows, tube pattern, header diameter, type of offset

adapters available, etc. The following schematic and

respective formulas should help in calculating E and F.

X = (No. Rows - 1) * (Distance

between Rows)

For 5/8" tube coils

distance between rows = 1.299

For 1/2" tube coils, distance

between rows = 1.082

For 3/8" tube coils, distance

between rows = 0.866

For 1 row coils E and F = 1/2 (CD) +/- (Offset Option)

For 2-12 row coils - E and F = 1/2 (CD X+ +/- (Offset

Option)

Note: Offset Option - Offset adapters are required if the

header diameter is greater than the dimension X.

As shown in the chart, standard MPT and FPT

connection diameters (ODs) range from to 3.

Contact factory for special connection sizes.

For water coils, connection sizes are typically sized

based on GPM of water.

GPM

S and R Connection Locations

Typically, for Steam Distribution Coils

S + 1/2 (Casing Height)

R + 1/2 (Conn Size OD) .5

L-Connection Length

1 Row Steam Dist. Coil = 2-5/8 OD Header, unless supply is

3 then header is 3 1/8

2 Row Steam Dist. Coil = 3-1/8 OD Header

Standard Offsets for Greenheck Coils

5/8 tube 0.75, 1.30, 2.05, 2.60

1/2 tube 1.08, 2.16

NOTE: All standard offset adapters are 3.25 long

75100

3

Greenheck Coils can provide special offset adapters if

required. For special offsets contact the factory.

For SWEAT connections and header diameters add, 1/8

to the standard connection size.

Header OD = Connection Size + 1/8

Sweat Connection = Connection Size + 1/8

(e.g. Coil with 1 MPT connections, header OD = 1 1/8

Exceptions: Non-Freeze Steam Distributing coils have fixed

header diameters regardless of connection size.

Coil Dimension Guidelines, Rev. 5, December 2008

Copyright Greenheck Fan Corporation

You might also like

- Honda - CBR - 125R - Maintenance - and - Service - Manual PDFDocument20 pagesHonda - CBR - 125R - Maintenance - and - Service - Manual PDFMar0% (1)

- FULL Download Ebook PDF Introduction To Business Third 3rd Edition by Julian e Gaspar PDF EbookDocument41 pagesFULL Download Ebook PDF Introduction To Business Third 3rd Edition by Julian e Gaspar PDF Ebookchristina.davis595100% (41)

- Piping NotesDocument11 pagesPiping NotesRavindra S. JivaniNo ratings yet

- MCQ CAG StandardsDocument11 pagesMCQ CAG StandardsAjay Singh PhogatNo ratings yet

- Coil Dimension Guidelines Capital Coil & AirDocument2 pagesCoil Dimension Guidelines Capital Coil & AirCarlos HoyosNo ratings yet

- Coil Dimension Guidelines: Rows CL - Casing Length CD Casing DepthDocument2 pagesCoil Dimension Guidelines: Rows CL - Casing Length CD Casing DepthkktayNo ratings yet

- How To Select Shell and Tube HEDocument10 pagesHow To Select Shell and Tube HEgigihpradana100% (1)

- Shell and Tube Heat ExchangerDocument34 pagesShell and Tube Heat ExchangerTamoor Tariq60% (5)

- Sthe SSDocument43 pagesSthe SSNathanianNo ratings yet

- Piping TheoryDocument20 pagesPiping Theorysonud4u100% (4)

- Heat Exchanger DesignDocument31 pagesHeat Exchanger DesignNestor C. camelloNo ratings yet

- HExchanger With ExampleDocument45 pagesHExchanger With ExampleSusanth SunilNo ratings yet

- Shell & Tube Heat ExchangersDocument14 pagesShell & Tube Heat ExchangersTPTL POLBAN 2013, broNo ratings yet

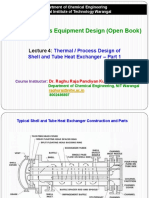

- CH352 CED Lecture 4Document19 pagesCH352 CED Lecture 4Abhishek UpadhyayulaNo ratings yet

- Heat Exchanger Design:: Dr. Chandra Mouli M.RDocument55 pagesHeat Exchanger Design:: Dr. Chandra Mouli M.RRayan HassanNo ratings yet

- 06+shell+and+tube+hx SDocument65 pages06+shell+and+tube+hx SMuhammad HaidiNo ratings yet

- Shell and TubeDocument66 pagesShell and TubeCachoNo ratings yet

- MT Coil Heat Ex BR 509Document6 pagesMT Coil Heat Ex BR 509Iin HarwiNo ratings yet

- 400 Shell and Tube Exchanger Design and Selection: Chevron Corporation 400-1 December 1989Document22 pages400 Shell and Tube Exchanger Design and Selection: Chevron Corporation 400-1 December 1989Esteban CastellanoNo ratings yet

- Heat Exchangers: S.SindhuDocument62 pagesHeat Exchangers: S.SindhuShivahari GopalakrishnanNo ratings yet

- Shell and TubeDocument66 pagesShell and TubeEdgar Enrique Diaz Marquina0% (1)

- Threaded Fittings General - Definition and Details - ASME B16.11 and ASME B1.20Document3 pagesThreaded Fittings General - Definition and Details - ASME B16.11 and ASME B1.20abhay_patil_22No ratings yet

- Shell & Tube Heat Exchanger DesignDocument87 pagesShell & Tube Heat Exchanger DesignankitmundharaNo ratings yet

- Stacked 2m Array Dipole PDFDocument6 pagesStacked 2m Array Dipole PDFWillowNo ratings yet

- 3.1 Heat ExchangersDocument76 pages3.1 Heat Exchangersraghu_iictNo ratings yet

- SHT ExchangerDocument55 pagesSHT ExchangerCc12 22tNo ratings yet

- PTSC MC-Piping Design Training-Basic Piping-LATESTDocument31 pagesPTSC MC-Piping Design Training-Basic Piping-LATESTNguyen Anh Tung50% (2)

- Basic Heat ExchangerDocument15 pagesBasic Heat Exchangeraw_aeNo ratings yet

- Pipes HandbookDocument13 pagesPipes HandbooksauroNo ratings yet

- Hydronic CoilsDocument16 pagesHydronic CoilsNdia2007No ratings yet

- Mechanical Design and Design CriteriaDocument32 pagesMechanical Design and Design CriteriaGhost RileyNo ratings yet

- Piping System Is Transportation System That Use To Flow The Fluid Either in The Form of A Liquid Phase or Gas Phase From One Place To Other PlaceDocument28 pagesPiping System Is Transportation System That Use To Flow The Fluid Either in The Form of A Liquid Phase or Gas Phase From One Place To Other Placerahult19No ratings yet

- Shell and Tube Heat Exchanger DesignDocument66 pagesShell and Tube Heat Exchanger DesignOmkar SutarNo ratings yet

- Shell and Tube Heat Exchangers DesignDocument27 pagesShell and Tube Heat Exchangers DesignAlëJaMürciaNo ratings yet

- Piping & Piping ComponentsDocument39 pagesPiping & Piping ComponentsRamesh mudunuri100% (1)

- Piping & Piping ComponentsDocument37 pagesPiping & Piping ComponentsRavindra S. JivaniNo ratings yet

- Heat ExchangersDocument8 pagesHeat ExchangersLiyan Fajar GintaraNo ratings yet

- ElbowDocument6 pagesElbowMohit BauskarNo ratings yet

- Pipe FittingsDocument40 pagesPipe FittingsLucky Jaswal100% (1)

- Shell and Tube Heat Exchanger DesignDocument25 pagesShell and Tube Heat Exchanger DesignSajid Ali100% (1)

- Piping Design (Revised)Document22 pagesPiping Design (Revised)Yash Patel100% (1)

- General PipingDocument42 pagesGeneral PipingSHANE MABUGAYNo ratings yet

- Presentation For Shell & Tub Heat ExchangerDocument33 pagesPresentation For Shell & Tub Heat ExchangerHoa Hoang PhuNo ratings yet

- 8 Design Considerations Double-Pipe Exchangers: The Wall Thickness Is Seen To Increase With The Schedule NumberDocument5 pages8 Design Considerations Double-Pipe Exchangers: The Wall Thickness Is Seen To Increase With The Schedule NumberMagdyNo ratings yet

- Water Coils, Chilled Water Coil, Hot Water Coils & Glycol CoilsDocument1 pageWater Coils, Chilled Water Coil, Hot Water Coils & Glycol CoilshlvijaykumarNo ratings yet

- Week8 Shell&TubeHEPart2Document56 pagesWeek8 Shell&TubeHEPart2Mochammad ReshaNo ratings yet

- Pipes, Fittings, Valves DrwaingsDocument187 pagesPipes, Fittings, Valves DrwaingsSyed FarhanNo ratings yet

- Tube Pipe FittingDocument36 pagesTube Pipe Fittingnbngoc012No ratings yet

- PDMSDocument39 pagesPDMSprathikNo ratings yet

- ACME MHX Condenser - PD Leaflet - 06.10 PDFDocument2 pagesACME MHX Condenser - PD Leaflet - 06.10 PDFhappale2002No ratings yet

- Pipe FittingsDocument10 pagesPipe Fittingssreelu100% (5)

- Piping ComponentsDocument39 pagesPiping Componentsbvenky991100% (1)

- PED 5 Heat ExchangersDocument74 pagesPED 5 Heat ExchangersDiogo EstevesNo ratings yet

- C 316SFeb2008Document2 pagesC 316SFeb2008Mano NegraNo ratings yet

- 1.10. Grades: Process Piping Fundamentals, Codes and Standards - Module 1Document5 pages1.10. Grades: Process Piping Fundamentals, Codes and Standards - Module 1Raakze MoviNo ratings yet

- Submarine Pipeline Hydraulic Design, Internal Pressure Design & Material SelectionDocument23 pagesSubmarine Pipeline Hydraulic Design, Internal Pressure Design & Material Selectionjiangqi75100% (1)

- Piping and Plumbing FittingDocument21 pagesPiping and Plumbing FittingC.yrillNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- WhatsNew in CodesmartDocument4 pagesWhatsNew in Codesmarttpqnd90gmailcomNo ratings yet

- Non-Isothermal Gas Absorption With Reversible Chemical ReactionDocument16 pagesNon-Isothermal Gas Absorption With Reversible Chemical Reactiontpqnd90gmailcomNo ratings yet

- New (Optimum) Layout Shell Side: B - Bonnet Bolted or Integral With Tubesheet E - One Pass Shell M - BonnetDocument1 pageNew (Optimum) Layout Shell Side: B - Bonnet Bolted or Integral With Tubesheet E - One Pass Shell M - Bonnettpqnd90gmailcomNo ratings yet

- CO Removal With 7M Monoethanolamine (MEA) - Aspen Plus Model For Base CaseDocument15 pagesCO Removal With 7M Monoethanolamine (MEA) - Aspen Plus Model For Base Casetpqnd90gmailcomNo ratings yet

- CO Removal With 7M Monoethanolamine (MEA) - Aspen Plus Model For Base CaseDocument15 pagesCO Removal With 7M Monoethanolamine (MEA) - Aspen Plus Model For Base Casetpqnd90gmailcomNo ratings yet

- A Computer Program For Excess Water Production Diagnosis Case Study - Heglig Oil Field - SudanDocument53 pagesA Computer Program For Excess Water Production Diagnosis Case Study - Heglig Oil Field - SudanOmernour1990100% (1)

- Packing Slip Template ExcelDocument15 pagesPacking Slip Template ExcelAlan Isai Valdez CastrejónNo ratings yet

- Loria Michelle Fernandes SWAT Analysis PresentationDocument11 pagesLoria Michelle Fernandes SWAT Analysis PresentationLoria FernandesNo ratings yet

- Power Station OverviewDocument11 pagesPower Station OverviewjamilNo ratings yet

- 09936550C AA Instrument Maintenance Checklist and LogDocument22 pages09936550C AA Instrument Maintenance Checklist and Logkariliz15No ratings yet

- Water Pollution SEDocument4 pagesWater Pollution SEaveri0% (1)

- JEE (Main + Advanced) : Leader Course (Score-I) & Enthusiast Course (Score-Ii)Document34 pagesJEE (Main + Advanced) : Leader Course (Score-I) & Enthusiast Course (Score-Ii)anwa1No ratings yet

- Q2 G8 Summative TestDocument9 pagesQ2 G8 Summative TestIrene FriasNo ratings yet

- S&TDocument4 pagesS&TMelmarmayneNo ratings yet

- C MIT Forum Supply Chain Risk Management Report 2013Document32 pagesC MIT Forum Supply Chain Risk Management Report 2013mustafaNo ratings yet

- DLP Eng9 Q3 W3Document5 pagesDLP Eng9 Q3 W3Jash BaldonNo ratings yet

- Aerospace Power System For A 1U Cubesat Built by SSU StudentsDocument1 pageAerospace Power System For A 1U Cubesat Built by SSU StudentsWes WatsonNo ratings yet

- Phrases & ClausesDocument9 pagesPhrases & ClausesMOHAMMED FURQAN BIN MUSTAFANo ratings yet

- Magnetic Levitation AbstractDocument6 pagesMagnetic Levitation Abstractkkkoundi0% (1)

- Exercise 2Document19 pagesExercise 2Jenn AguilarNo ratings yet

- Design and Finite Element Analysis of FRP LPG CylinderDocument2 pagesDesign and Finite Element Analysis of FRP LPG CylinderEric SamNo ratings yet

- Curriculum Map: Mapeh DepartmentDocument9 pagesCurriculum Map: Mapeh DepartmentArvenParafinaNo ratings yet

- Improvement of Mechanical Properties in Structural Steels by Development of Acicular Ferrite MicrostructuresDocument2 pagesImprovement of Mechanical Properties in Structural Steels by Development of Acicular Ferrite MicrostructuresevfratNo ratings yet

- Leice GS14 GPSDocument12 pagesLeice GS14 GPSbbutros_317684077No ratings yet

- Nuclear Engineering and Technology: Original ArticleDocument9 pagesNuclear Engineering and Technology: Original ArticleDiogo CoelhoNo ratings yet

- Behavioral Activation Worksheet Activity Log 1 1Document3 pagesBehavioral Activation Worksheet Activity Log 1 1Anca DobarleanuNo ratings yet

- 32-Bit Power Architecture MCU For Automotive General Purpose Applications - Chorus FamilyDocument139 pages32-Bit Power Architecture MCU For Automotive General Purpose Applications - Chorus FamilyEcus ElectronicsNo ratings yet

- IPURSE-2015 Proceedings Presented PapersDocument459 pagesIPURSE-2015 Proceedings Presented PapersWithanage WithanageNo ratings yet

- Quarter 1-Week 3 - Day 1.revisedDocument5 pagesQuarter 1-Week 3 - Day 1.revisedJigz FamulaganNo ratings yet

- Unit I: Introduction To Consumer Behavior (CB) - Importance, Scope, Need For Studying CB, Consumer Research ProcessDocument10 pagesUnit I: Introduction To Consumer Behavior (CB) - Importance, Scope, Need For Studying CB, Consumer Research ProcessGumber VidurNo ratings yet

- Job Stress QuestionnaireDocument2 pagesJob Stress QuestionnaireMake Image RealNo ratings yet

- SAP Script: Printing Layout Set Output Program ConfigurationDocument65 pagesSAP Script: Printing Layout Set Output Program Configurationplayboy117No ratings yet