Professional Documents

Culture Documents

Liziz Efb Long Fiber Project

Liziz Efb Long Fiber Project

Uploaded by

hepy85Copyright:

Available Formats

You might also like

- Green Composites PPTSDocument33 pagesGreen Composites PPTSShivansh ThakurNo ratings yet

- Comments On Detik Aturan SDN BHDDocument2 pagesComments On Detik Aturan SDN BHDAnonymous PfQcbJrIfNo ratings yet

- Steps To Process Palm Efb PelletDocument9 pagesSteps To Process Palm Efb PelletBahtiar YoganaNo ratings yet

- Steps To Process Palm Efb PelletDocument9 pagesSteps To Process Palm Efb PelletNata MiharjaNo ratings yet

- Steps To Process Palm Efb PelletDocument25 pagesSteps To Process Palm Efb PelletNata MiharjaNo ratings yet

- GEMCO Pellet Plant in Malaysia - Malaysian Oil Palm Biomass StudyDocument3 pagesGEMCO Pellet Plant in Malaysia - Malaysian Oil Palm Biomass StudyKelly ObrienNo ratings yet

- Chapter 3 Technical FeasibilityDocument88 pagesChapter 3 Technical FeasibilityAnissa Munira100% (2)

- ABSTRAK-Revisi2 (Inggris)Document1 pageABSTRAK-Revisi2 (Inggris)JESSICA WINARTONo ratings yet

- Enviromental Friendly Composites From Fibers of OilDocument3 pagesEnviromental Friendly Composites From Fibers of OilnnekaNo ratings yet

- Biomaterial From Oil Palm Waste: Properties, Characterization and ApplicationsDocument22 pagesBiomaterial From Oil Palm Waste: Properties, Characterization and Applicationsmuzikku1730No ratings yet

- Processing of Palm Oil Mill Wastes Based On Zero WDocument9 pagesProcessing of Palm Oil Mill Wastes Based On Zero WSatria MandalaNo ratings yet

- Pasi Rousu - Revenues From ResiduesDocument20 pagesPasi Rousu - Revenues From ResiduesAsia Clean Energy ForumNo ratings yet

- Biomass N Pellet ConferenceDocument24 pagesBiomass N Pellet ConferenceLai Mei EeNo ratings yet

- Utilization of Oil Palm Empty Fruit Bunches As Solid Materials'Document19 pagesUtilization of Oil Palm Empty Fruit Bunches As Solid Materials'ilayarasan100% (2)

- Coir Mat ProjectDocument18 pagesCoir Mat ProjectmadhusudhansNo ratings yet

- WPLACE 17 3.3.oil Palm Biomass Its Utilisation PotentialDocument46 pagesWPLACE 17 3.3.oil Palm Biomass Its Utilisation PotentialReca DewantoroNo ratings yet

- Efficientuseof Coconutanditsby ProductsDocument4 pagesEfficientuseof Coconutanditsby Productsshara juanilloNo ratings yet

- How To Enhancing of Iskandar Putri City To A World Class Local Authority?Document20 pagesHow To Enhancing of Iskandar Putri City To A World Class Local Authority?Muhamad Farizol Mohd JohanNo ratings yet

- Postharvest Fruit Detachmentin Oil Palm Buncheswith Ethephonand Ethylene Gas ApplicationDocument11 pagesPostharvest Fruit Detachmentin Oil Palm Buncheswith Ethephonand Ethylene Gas Applicationsiswanto99No ratings yet

- Energies 12 00420 v2 PDFDocument24 pagesEnergies 12 00420 v2 PDFKarolina DermawanNo ratings yet

- NCZ Report NRLDocument5 pagesNCZ Report NRLIzukanji KayoraNo ratings yet

- Abdul Khalil 2010Document18 pagesAbdul Khalil 2010Khawaja TaimoorNo ratings yet

- The Potential of Palm Oil Waste Biomass in Indonesia in 2020 and 2030Document10 pagesThe Potential of Palm Oil Waste Biomass in Indonesia in 2020 and 2030Putrika 02No ratings yet

- Banana Fibre Extracting ProjectDocument2 pagesBanana Fibre Extracting Projectmuthamil05No ratings yet

- Compost IEM Journal OoiDocument12 pagesCompost IEM Journal OoiJason OoiNo ratings yet

- Essay Palm Oil Waste ManagementDocument5 pagesEssay Palm Oil Waste ManagementAzim AdamNo ratings yet

- Proposal Mini Project Oil&FatDocument6 pagesProposal Mini Project Oil&FatFarihah EyfaNo ratings yet

- Introduction of Coir: Coir Industry in IndiaDocument25 pagesIntroduction of Coir: Coir Industry in IndiaMithun KiruthiNo ratings yet

- FarmcarbonisationmachineDocument20 pagesFarmcarbonisationmachineMarwin NavarreteNo ratings yet

- Efficient Use of Coconut and Its by ProductsDocument3 pagesEfficient Use of Coconut and Its by ProductsKIU PUBLICATION AND EXTENSIONNo ratings yet

- Tembec Biorefinery Ipw Final PDFDocument3 pagesTembec Biorefinery Ipw Final PDFChristian Chenchong ZhouNo ratings yet

- 4 Kemiri Sunan Is Alternative Fuel (Abstrak)Document2 pages4 Kemiri Sunan Is Alternative Fuel (Abstrak)jesi yardaniNo ratings yet

- Design and Development of A Scale Oil Palm Waste Shredder For Achieving Environmental SustainabilityDocument37 pagesDesign and Development of A Scale Oil Palm Waste Shredder For Achieving Environmental SustainabilityDuy HảiNo ratings yet

- MY172437ADocument17 pagesMY172437AGabrile ChiappoNo ratings yet

- Palm WasteDocument26 pagesPalm WasteTahirah Mohamed100% (1)

- Neem Coated Urea - A Step in Right DirectionDocument2 pagesNeem Coated Urea - A Step in Right DirectionDheeraj ShuklaNo ratings yet

- Marani Book Render1 CompDocument20 pagesMarani Book Render1 CompDEAD WUNo ratings yet

- Jurnal Teknologi: A Review of Palm Oil Biomass As A Feedstock For Syngas Fuel TechnologyDocument6 pagesJurnal Teknologi: A Review of Palm Oil Biomass As A Feedstock For Syngas Fuel TechnologyChong Ru YinNo ratings yet

- Empty Fruit Bunch Pellets For Biomass Fuels (PT Global Asia Bersama)Document5 pagesEmpty Fruit Bunch Pellets For Biomass Fuels (PT Global Asia Bersama)Muhamad FaisalNo ratings yet

- THERMACT-BIOSP Brochure ContentDocument1 pageTHERMACT-BIOSP Brochure Contentajeeit8No ratings yet

- DOST Bamboo S and T ProgramDocument12 pagesDOST Bamboo S and T ProgramJayson Ramirez SorianoNo ratings yet

- Lect7-Conversion of Soilless Culture Waste To Valuable ProductDocument33 pagesLect7-Conversion of Soilless Culture Waste To Valuable ProductAzammudin RifaeeNo ratings yet

- LEGOILDocument2 pagesLEGOILMaria Kaye LabayNo ratings yet

- Presentation Mida Biomass Conference 2015 MpobDocument28 pagesPresentation Mida Biomass Conference 2015 MpobZulkifli Zainal Rampak100% (1)

- IOP 2020 EFB Pulp and Paper Industry - CompressedDocument13 pagesIOP 2020 EFB Pulp and Paper Industry - CompressedSari Farah DinaNo ratings yet

- Hambali 2017 IOP Conf. Ser.: Earth Environ. Sci. 65 012050Document10 pagesHambali 2017 IOP Conf. Ser.: Earth Environ. Sci. 65 012050Ricky OktaNo ratings yet

- Biogas Production From Decanter Cake of Palm Oil Mill From South IndiaDocument4 pagesBiogas Production From Decanter Cake of Palm Oil Mill From South IndiaEditor IJTSRDNo ratings yet

- Has A Nudin 2015Document7 pagesHas A Nudin 2015windiastuti.elsaNo ratings yet

- Performance Evaluation of A Small Scale Palm Fruit PDFDocument6 pagesPerformance Evaluation of A Small Scale Palm Fruit PDFAliaNo ratings yet

- Biomaterials: The Potential For Bio-Isoprene: Commercial StatusDocument3 pagesBiomaterials: The Potential For Bio-Isoprene: Commercial StatusHari PurwitoNo ratings yet

- Biomass Pelletd From Plam Oil Mill WasteDocument12 pagesBiomass Pelletd From Plam Oil Mill WastereezNo ratings yet

- Bamboo ArticleDocument7 pagesBamboo ArticlekumaranprasadNo ratings yet

- Profile ReportDocument20 pagesProfile ReportAmol_Gunda_5727No ratings yet

- Spent Bleaching Earth Extraction FaqsDocument4 pagesSpent Bleaching Earth Extraction FaqsLalaine Russell SomoNo ratings yet

- (RRL - 1) Spent Bleaching Earth Extraction FAQSDocument4 pages(RRL - 1) Spent Bleaching Earth Extraction FAQSShania LoveresNo ratings yet

- A Value Chain For Coconut FiberDocument33 pagesA Value Chain For Coconut FiberpasebanjatiNo ratings yet

- Biodiesel Production101: Homebrew Edition: A Do It Yourself Guide to Produce Biodiesel on Your BackyardFrom EverandBiodiesel Production101: Homebrew Edition: A Do It Yourself Guide to Produce Biodiesel on Your BackyardNo ratings yet

Liziz Efb Long Fiber Project

Liziz Efb Long Fiber Project

Uploaded by

hepy85Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liziz Efb Long Fiber Project

Liziz Efb Long Fiber Project

Uploaded by

hepy85Copyright:

Available Formats

LIZIZ EFB LONG FIBER PROJECT

By Liziz Plantation Sdn Bhd

Liziz Palm Oil Mill has established in 2013. During first year of operation, Liziz Palm Oil

Mill has processed 181,000 mt of FFB. Since commissioning in February 2013, Liziz POM has

processed 396,000 mt of FFB.

EFB (Empty Fruit Bunch) is the by-product from crude palm oil mill which having low

economic value. Before latest application being developed, converting EFB to compost is

seems to be the only solution for most of the crude palm oil mill including in Liziz POM.

With average, Liziz POM has produced almost 40,000mt of Empty Fruit Bunches (EFB)

per year. At present, all EFBs at Liziz POM are being used for palm oil mulching at Lizizs Palm

Oil Estates. Apart from that, the EFBs are being dumped at EFB dumping site and 20% are

being sold to Third Party. Dumped EFBs are becoming major issues to environment and

managerial issues to Liziz POM.

Now EFB has more other application other than compost. The new application about

EFB is using the fibre nature of the EFB. There are researches about pressed and shredded

the EFB to get fibre for biomass boiler; gone through further cleaning process and extracting

long fibre for replacing coconut fibre for mattress; extracting Vitamin E from EFB Fibre.

The long EFB fibre has economic value that could be used as fibre mattress. Due to

more profitable income, we also seeing that Liziz Palm Oil Mill should also start investing in

this process to extract long fibre from EFB.

LIZIZ EFB LONG FIBER PROJECT

By Liziz Plantation Sdn Bhd

With the rising concerns over the detrimental effects due to deforestation, treebased fiber sources are becoming a scares commodity and its derivative products are being

labeled as non-environmental friendly. EFB fiber which are renewable and its processing

does not have an adverse effects on the environment, is becoming an attractive source of

fiber.

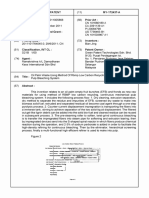

The Technology and Process Flow

The plant will consist of 1 unit EFB Press followed by 1 units of EFB Hammer Mill

which are installed continuously. The EFB is then fed into the Fiber Screen Drum to separate

the long from the short fibers. As a result, the short fiber will be sent to the disposal pit

before being used for boiler fuel and the long fiber will undergo the drying process at Single

Deck Steam Dryer before ending up at Dryed Fiber Baling Machine for baling and packaging.

You might also like

- Green Composites PPTSDocument33 pagesGreen Composites PPTSShivansh ThakurNo ratings yet

- Comments On Detik Aturan SDN BHDDocument2 pagesComments On Detik Aturan SDN BHDAnonymous PfQcbJrIfNo ratings yet

- Steps To Process Palm Efb PelletDocument9 pagesSteps To Process Palm Efb PelletBahtiar YoganaNo ratings yet

- Steps To Process Palm Efb PelletDocument9 pagesSteps To Process Palm Efb PelletNata MiharjaNo ratings yet

- Steps To Process Palm Efb PelletDocument25 pagesSteps To Process Palm Efb PelletNata MiharjaNo ratings yet

- GEMCO Pellet Plant in Malaysia - Malaysian Oil Palm Biomass StudyDocument3 pagesGEMCO Pellet Plant in Malaysia - Malaysian Oil Palm Biomass StudyKelly ObrienNo ratings yet

- Chapter 3 Technical FeasibilityDocument88 pagesChapter 3 Technical FeasibilityAnissa Munira100% (2)

- ABSTRAK-Revisi2 (Inggris)Document1 pageABSTRAK-Revisi2 (Inggris)JESSICA WINARTONo ratings yet

- Enviromental Friendly Composites From Fibers of OilDocument3 pagesEnviromental Friendly Composites From Fibers of OilnnekaNo ratings yet

- Biomaterial From Oil Palm Waste: Properties, Characterization and ApplicationsDocument22 pagesBiomaterial From Oil Palm Waste: Properties, Characterization and Applicationsmuzikku1730No ratings yet

- Processing of Palm Oil Mill Wastes Based On Zero WDocument9 pagesProcessing of Palm Oil Mill Wastes Based On Zero WSatria MandalaNo ratings yet

- Pasi Rousu - Revenues From ResiduesDocument20 pagesPasi Rousu - Revenues From ResiduesAsia Clean Energy ForumNo ratings yet

- Biomass N Pellet ConferenceDocument24 pagesBiomass N Pellet ConferenceLai Mei EeNo ratings yet

- Utilization of Oil Palm Empty Fruit Bunches As Solid Materials'Document19 pagesUtilization of Oil Palm Empty Fruit Bunches As Solid Materials'ilayarasan100% (2)

- Coir Mat ProjectDocument18 pagesCoir Mat ProjectmadhusudhansNo ratings yet

- WPLACE 17 3.3.oil Palm Biomass Its Utilisation PotentialDocument46 pagesWPLACE 17 3.3.oil Palm Biomass Its Utilisation PotentialReca DewantoroNo ratings yet

- Efficientuseof Coconutanditsby ProductsDocument4 pagesEfficientuseof Coconutanditsby Productsshara juanilloNo ratings yet

- How To Enhancing of Iskandar Putri City To A World Class Local Authority?Document20 pagesHow To Enhancing of Iskandar Putri City To A World Class Local Authority?Muhamad Farizol Mohd JohanNo ratings yet

- Postharvest Fruit Detachmentin Oil Palm Buncheswith Ethephonand Ethylene Gas ApplicationDocument11 pagesPostharvest Fruit Detachmentin Oil Palm Buncheswith Ethephonand Ethylene Gas Applicationsiswanto99No ratings yet

- Energies 12 00420 v2 PDFDocument24 pagesEnergies 12 00420 v2 PDFKarolina DermawanNo ratings yet

- NCZ Report NRLDocument5 pagesNCZ Report NRLIzukanji KayoraNo ratings yet

- Abdul Khalil 2010Document18 pagesAbdul Khalil 2010Khawaja TaimoorNo ratings yet

- The Potential of Palm Oil Waste Biomass in Indonesia in 2020 and 2030Document10 pagesThe Potential of Palm Oil Waste Biomass in Indonesia in 2020 and 2030Putrika 02No ratings yet

- Banana Fibre Extracting ProjectDocument2 pagesBanana Fibre Extracting Projectmuthamil05No ratings yet

- Compost IEM Journal OoiDocument12 pagesCompost IEM Journal OoiJason OoiNo ratings yet

- Essay Palm Oil Waste ManagementDocument5 pagesEssay Palm Oil Waste ManagementAzim AdamNo ratings yet

- Proposal Mini Project Oil&FatDocument6 pagesProposal Mini Project Oil&FatFarihah EyfaNo ratings yet

- Introduction of Coir: Coir Industry in IndiaDocument25 pagesIntroduction of Coir: Coir Industry in IndiaMithun KiruthiNo ratings yet

- FarmcarbonisationmachineDocument20 pagesFarmcarbonisationmachineMarwin NavarreteNo ratings yet

- Efficient Use of Coconut and Its by ProductsDocument3 pagesEfficient Use of Coconut and Its by ProductsKIU PUBLICATION AND EXTENSIONNo ratings yet

- Tembec Biorefinery Ipw Final PDFDocument3 pagesTembec Biorefinery Ipw Final PDFChristian Chenchong ZhouNo ratings yet

- 4 Kemiri Sunan Is Alternative Fuel (Abstrak)Document2 pages4 Kemiri Sunan Is Alternative Fuel (Abstrak)jesi yardaniNo ratings yet

- Design and Development of A Scale Oil Palm Waste Shredder For Achieving Environmental SustainabilityDocument37 pagesDesign and Development of A Scale Oil Palm Waste Shredder For Achieving Environmental SustainabilityDuy HảiNo ratings yet

- MY172437ADocument17 pagesMY172437AGabrile ChiappoNo ratings yet

- Palm WasteDocument26 pagesPalm WasteTahirah Mohamed100% (1)

- Neem Coated Urea - A Step in Right DirectionDocument2 pagesNeem Coated Urea - A Step in Right DirectionDheeraj ShuklaNo ratings yet

- Marani Book Render1 CompDocument20 pagesMarani Book Render1 CompDEAD WUNo ratings yet

- Jurnal Teknologi: A Review of Palm Oil Biomass As A Feedstock For Syngas Fuel TechnologyDocument6 pagesJurnal Teknologi: A Review of Palm Oil Biomass As A Feedstock For Syngas Fuel TechnologyChong Ru YinNo ratings yet

- Empty Fruit Bunch Pellets For Biomass Fuels (PT Global Asia Bersama)Document5 pagesEmpty Fruit Bunch Pellets For Biomass Fuels (PT Global Asia Bersama)Muhamad FaisalNo ratings yet

- THERMACT-BIOSP Brochure ContentDocument1 pageTHERMACT-BIOSP Brochure Contentajeeit8No ratings yet

- DOST Bamboo S and T ProgramDocument12 pagesDOST Bamboo S and T ProgramJayson Ramirez SorianoNo ratings yet

- Lect7-Conversion of Soilless Culture Waste To Valuable ProductDocument33 pagesLect7-Conversion of Soilless Culture Waste To Valuable ProductAzammudin RifaeeNo ratings yet

- LEGOILDocument2 pagesLEGOILMaria Kaye LabayNo ratings yet

- Presentation Mida Biomass Conference 2015 MpobDocument28 pagesPresentation Mida Biomass Conference 2015 MpobZulkifli Zainal Rampak100% (1)

- IOP 2020 EFB Pulp and Paper Industry - CompressedDocument13 pagesIOP 2020 EFB Pulp and Paper Industry - CompressedSari Farah DinaNo ratings yet

- Hambali 2017 IOP Conf. Ser.: Earth Environ. Sci. 65 012050Document10 pagesHambali 2017 IOP Conf. Ser.: Earth Environ. Sci. 65 012050Ricky OktaNo ratings yet

- Biogas Production From Decanter Cake of Palm Oil Mill From South IndiaDocument4 pagesBiogas Production From Decanter Cake of Palm Oil Mill From South IndiaEditor IJTSRDNo ratings yet

- Has A Nudin 2015Document7 pagesHas A Nudin 2015windiastuti.elsaNo ratings yet

- Performance Evaluation of A Small Scale Palm Fruit PDFDocument6 pagesPerformance Evaluation of A Small Scale Palm Fruit PDFAliaNo ratings yet

- Biomaterials: The Potential For Bio-Isoprene: Commercial StatusDocument3 pagesBiomaterials: The Potential For Bio-Isoprene: Commercial StatusHari PurwitoNo ratings yet

- Biomass Pelletd From Plam Oil Mill WasteDocument12 pagesBiomass Pelletd From Plam Oil Mill WastereezNo ratings yet

- Bamboo ArticleDocument7 pagesBamboo ArticlekumaranprasadNo ratings yet

- Profile ReportDocument20 pagesProfile ReportAmol_Gunda_5727No ratings yet

- Spent Bleaching Earth Extraction FaqsDocument4 pagesSpent Bleaching Earth Extraction FaqsLalaine Russell SomoNo ratings yet

- (RRL - 1) Spent Bleaching Earth Extraction FAQSDocument4 pages(RRL - 1) Spent Bleaching Earth Extraction FAQSShania LoveresNo ratings yet

- A Value Chain For Coconut FiberDocument33 pagesA Value Chain For Coconut FiberpasebanjatiNo ratings yet

- Biodiesel Production101: Homebrew Edition: A Do It Yourself Guide to Produce Biodiesel on Your BackyardFrom EverandBiodiesel Production101: Homebrew Edition: A Do It Yourself Guide to Produce Biodiesel on Your BackyardNo ratings yet