Professional Documents

Culture Documents

Light Crimp

Light Crimp

Uploaded by

Alejandro PerezCopyright:

Available Formats

You might also like

- Method Statement - Cable Joint LVDocument4 pagesMethod Statement - Cable Joint LVanuraj arackal67% (6)

- AT520JK Users ManualDocument15 pagesAT520JK Users ManualgerezairNo ratings yet

- Bosch Aftertreatment DEF Controller ConnectorDocument4 pagesBosch Aftertreatment DEF Controller ConnectorO mecanicoNo ratings yet

- Service Manual (AT) - J Transmission (AT)Document16 pagesService Manual (AT) - J Transmission (AT)Николай КирилловNo ratings yet

- Boomerang PDFDocument16 pagesBoomerang PDFYusuf SarikayaNo ratings yet

- Conector LC Light Crimp - ManualDocument8 pagesConector LC Light Crimp - ManualTirso W. RodríguezNo ratings yet

- Fi - SCST Multimode Singlemode Connector - II PDFDocument4 pagesFi - SCST Multimode Singlemode Connector - II PDFmirkofedorNo ratings yet

- Fibra Optica - RS DataSheetDocument8 pagesFibra Optica - RS DataSheetAlex MoralesNo ratings yet

- Instruction C02 78.3Document4 pagesInstruction C02 78.3ВиталийКрутиковNo ratings yet

- Assembly Instructions For Cable Gland: 755 32R4: Connection SolutionsDocument4 pagesAssembly Instructions For Cable Gland: 755 32R4: Connection Solutionspvalverdea2014No ratings yet

- Psiipro Coil Connector Assy v3Document3 pagesPsiipro Coil Connector Assy v3reza yousefiNo ratings yet

- DT436 500 Sq. MM PDFDocument3 pagesDT436 500 Sq. MM PDFHamedObaidNo ratings yet

- Troubleshooting Manual, TS2712EN 04Document82 pagesTroubleshooting Manual, TS2712EN 04thibierozNo ratings yet

- Fi Xlr8 Mechanical Splice Fiber Connector IIDocument8 pagesFi Xlr8 Mechanical Splice Fiber Connector IIguideoNo ratings yet

- Cable Termination - Installation Instructions - 755LR - IsDocument5 pagesCable Termination - Installation Instructions - 755LR - Isvladimir_71No ratings yet

- Fibrlok Optical Fiber Splicing System: InstructionsDocument12 pagesFibrlok Optical Fiber Splicing System: InstructionsJohn Amiel LegaspiNo ratings yet

- 2100d Installation GuideDocument20 pages2100d Installation GuideJazz TubaNo ratings yet

- OPGW Splicing GuidelineDocument18 pagesOPGW Splicing Guidelinedc12dc100% (1)

- 2178CL-S Series F/O Splice Case: InstructionDocument13 pages2178CL-S Series F/O Splice Case: InstructionHữu Khánh NguyễnNo ratings yet

- Mid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFDocument12 pagesMid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFMehdi SHNo ratings yet

- 3M Fibrlok II 2539 InstrDocument4 pages3M Fibrlok II 2539 InstrjoseNo ratings yet

- Qt-Iii: Cold Shrink Silicone Rubber TerminationDocument10 pagesQt-Iii: Cold Shrink Silicone Rubber TerminationHJNo ratings yet

- 15kV PM Joints - Straight - KSU - 500-500sq - MMDocument8 pages15kV PM Joints - Straight - KSU - 500-500sq - MMabd elmohsen saedNo ratings yet

- BH138-Instruction Manual L-13 Blanik (Ok07.09.13) Ok - 29Document22 pagesBH138-Instruction Manual L-13 Blanik (Ok07.09.13) Ok - 29Catalin CiocarlanNo ratings yet

- Esd 4873 Au 5 - 09 PDFDocument13 pagesEsd 4873 Au 5 - 09 PDFGeorge IstrateNo ratings yet

- Irvine Tutor 40Document16 pagesIrvine Tutor 40IvanadoNo ratings yet

- Installation Protek Pipe Shoe 04 2018Document1 pageInstallation Protek Pipe Shoe 04 2018Sabuj SaikiaNo ratings yet

- Desktop Printer Service ManualDocument58 pagesDesktop Printer Service ManualMiguel Angel Lasso CastañoNo ratings yet

- Feeder System Installation Procedure - MOPDocument19 pagesFeeder System Installation Procedure - MOPSandeep singh100% (1)

- Matrix Infinity 2Document2 pagesMatrix Infinity 2marianotavaresNo ratings yet

- Fiber Optic Cable TerminationDocument16 pagesFiber Optic Cable TerminationStephenNo ratings yet

- Application Note 058: Connector MaintenanceDocument6 pagesApplication Note 058: Connector Maintenanceosto72No ratings yet

- Fireball Ignition PDFDocument14 pagesFireball Ignition PDFLucian LeonteNo ratings yet

- Technical Service BulletinDocument5 pagesTechnical Service BulletinMiguel AlmoraNo ratings yet

- Twisted Pair Wiring SchemesDocument9 pagesTwisted Pair Wiring SchemesPedroNo ratings yet

- Installation Instructions UTERMKIT Mk3Document4 pagesInstallation Instructions UTERMKIT Mk3aleloc2000No ratings yet

- Eclipse Matrix Blend Installation GuideDocument3 pagesEclipse Matrix Blend Installation GuideMichael KingNo ratings yet

- Connector Modular Plug Amp Tyco XXX 8p8c Rj45 Shielded c6 XXX XXX Emt AssemblyDocument9 pagesConnector Modular Plug Amp Tyco XXX 8p8c Rj45 Shielded c6 XXX XXX Emt AssemblyarifNo ratings yet

- PEAK Sidewall Cutter Data ManualDocument13 pagesPEAK Sidewall Cutter Data ManualRizky WahyuNo ratings yet

- Firecharger Installation ADocument10 pagesFirecharger Installation AAugmotorsNo ratings yet

- Introduction and Installation of FICDocument19 pagesIntroduction and Installation of FICbanigx0xNo ratings yet

- YHT-Installation - Dome Closure CV10-24Document8 pagesYHT-Installation - Dome Closure CV10-24juan joseNo ratings yet

- Fiber Optics Splicing Procedures: Your Source To Fiber Optics, Industrial Datacomm & Fieldbus Products-Solutions-ServicesDocument7 pagesFiber Optics Splicing Procedures: Your Source To Fiber Optics, Industrial Datacomm & Fieldbus Products-Solutions-ServicesHafis Aikal AmranNo ratings yet

- Esd 4872 Au 5 09 PDFDocument10 pagesEsd 4872 Au 5 09 PDFGuler RahimNo ratings yet

- Multiplex Minimag Model RC Airplane Manual M13209Document18 pagesMultiplex Minimag Model RC Airplane Manual M13209Anett ÁrvaiNo ratings yet

- Ig Gabions May 2015Document2 pagesIg Gabions May 2015LynxNo ratings yet

- 15kV Indoor Termination - KSU - 500sq - MMDocument6 pages15kV Indoor Termination - KSU - 500sq - MMabd elmohsen saedNo ratings yet

- Nipple Attachment-OM 151029Document1 pageNipple Attachment-OM 151029W MoralesNo ratings yet

- Splicing/changing Cable: Service InformationDocument8 pagesSplicing/changing Cable: Service InformationSmolovic SrdjanNo ratings yet

- Sealey SMS2008Document3 pagesSealey SMS2008cabuloNo ratings yet

- Connector MaintenanceDocument6 pagesConnector MaintenanceZain MalikNo ratings yet

- Elastimold Compact I JointDocument6 pagesElastimold Compact I Jointwerawatb819No ratings yet

- PNJHY-0001-82-02 (Fast SC - 0.25&0.9) PDFDocument2 pagesPNJHY-0001-82-02 (Fast SC - 0.25&0.9) PDFLêViệtLongNo ratings yet

- Antenna Feeder System InstallationDocument24 pagesAntenna Feeder System InstallationAbdul RahimNo ratings yet

- Activity Performance Worksheet: Computer TechnologyDocument14 pagesActivity Performance Worksheet: Computer TechnologyJefferson CanalejaNo ratings yet

- Pioneer Deh 2100ub 2110ub 2120ubDocument113 pagesPioneer Deh 2100ub 2110ub 2120ubJeki27No ratings yet

- Terminal Con Copa 3M Cold Shrink QT-III 769X-S-4 KitsDocument20 pagesTerminal Con Copa 3M Cold Shrink QT-III 769X-S-4 KitsEnrique G.No ratings yet

- Scotchcast Power Cable Tap Splice Kit 90-B1: InstructionsDocument8 pagesScotchcast Power Cable Tap Splice Kit 90-B1: InstructionsWanessa SuárezNo ratings yet

- Sehs9065 Deutsch CeDocument11 pagesSehs9065 Deutsch CeAlvaro arceNo ratings yet

- Wired Chinese Knot, Wire Jewelry Tutorial: Layer Coiled Crystal Pearls EarringsFrom EverandWired Chinese Knot, Wire Jewelry Tutorial: Layer Coiled Crystal Pearls EarringsRating: 1 out of 5 stars1/5 (1)

- Parachute Cord Craft: Quick & Simple Instructions for 22 Cool ProjectsFrom EverandParachute Cord Craft: Quick & Simple Instructions for 22 Cool ProjectsRating: 4 out of 5 stars4/5 (1)

- Dura. Grout: Non-Shrink Cementitious GroutDocument2 pagesDura. Grout: Non-Shrink Cementitious GroutANILNo ratings yet

- Aqualung - Titan - 1st - Stage - Service - Manual 2Document24 pagesAqualung - Titan - 1st - Stage - Service - Manual 2jmartinezNo ratings yet

- FFDVFDocument1 pageFFDVFshamirNo ratings yet

- Duraplate 8200Document4 pagesDuraplate 8200Carlos VillacrizNo ratings yet

- LMR 400 PDFDocument4 pagesLMR 400 PDFviktor220378No ratings yet

- Propylene Glycol - Market DataDocument3 pagesPropylene Glycol - Market DataSavannah Yonita CNo ratings yet

- ASME Section X InterpretationsDocument6 pagesASME Section X InterpretationsAnonymous UoHUagNo ratings yet

- Is 11218 1984Document5 pagesIs 11218 1984Ahmed HossamNo ratings yet

- Arisa Mandir IDocument20 pagesArisa Mandir IAnanda Tis'aNo ratings yet

- SEN KoreaDocument46 pagesSEN KoreasawwahwahNo ratings yet

- CAP2 - TRiiAGE Tools For Clariion Log Analysis - ENDocument16 pagesCAP2 - TRiiAGE Tools For Clariion Log Analysis - ENakuma27No ratings yet

- Glassheim MostDocument31 pagesGlassheim MostOskari TarkkaNo ratings yet

- Service ManualDocument45 pagesService ManualStoneAge1No ratings yet

- Trinidad Lake Modified Asphalt: Standard Specification ForDocument2 pagesTrinidad Lake Modified Asphalt: Standard Specification ForAhmedNo ratings yet

- Project Report: Traning AND Development Hero Honda CompanyDocument70 pagesProject Report: Traning AND Development Hero Honda CompanySurender Dhuran PrajapatNo ratings yet

- Inspection PT - AekDocument2 pagesInspection PT - AekMemo BongNo ratings yet

- Ser-59 Syspro MangalamDocument2 pagesSer-59 Syspro MangalamMicheal BuckNo ratings yet

- Mechanical and Chemical Weathering PDFDocument47 pagesMechanical and Chemical Weathering PDFYlla JovillanoNo ratings yet

- Pengaruh Laju Erosi Terhadap Umur PipaDocument6 pagesPengaruh Laju Erosi Terhadap Umur PipaDede Si Engghe SurenggheNo ratings yet

- DC Inverter VRF Air Conditioning SystemsDocument35 pagesDC Inverter VRF Air Conditioning SystemsTudor SorbanNo ratings yet

- Praj and Dedini Join Hands in BrazilDocument2 pagesPraj and Dedini Join Hands in BrazilindtnNo ratings yet

- Nayara Carin Report 10-Apr-2024Document3 pagesNayara Carin Report 10-Apr-2024amitk397115No ratings yet

- SPADA Soal Ujian Semester TK 1 EC D3 Sem 1 TA 2020 2021 (11) - Converted - by - AbcdpdfDocument3 pagesSPADA Soal Ujian Semester TK 1 EC D3 Sem 1 TA 2020 2021 (11) - Converted - by - AbcdpdfAlwin Arrahman NasutionNo ratings yet

- Astrophysics XIS 6545Document2 pagesAstrophysics XIS 6545Linchys_880% (1)

- Designing AV Automation For The Mediasite Rich Media RecorderDocument26 pagesDesigning AV Automation For The Mediasite Rich Media RecorderjohnemeryisiNo ratings yet

- Tractor Caterpillar d7r Renr5627 Renr5627 P Esquema HidraulicoDocument32 pagesTractor Caterpillar d7r Renr5627 Renr5627 P Esquema HidraulicoRuberli RJNo ratings yet

- En Safe Load GuidelinesDocument46 pagesEn Safe Load GuidelinesCEIT LogisticaNo ratings yet

- Sika Rokkon RB: Non Explosive Demolition AgentDocument2 pagesSika Rokkon RB: Non Explosive Demolition AgentIsnan Luthfi100% (1)

- K K K Automotive Training Center FacebookDocument1 pageK K K Automotive Training Center Facebookkyaw boNo ratings yet

Light Crimp

Light Crimp

Uploaded by

Alejandro PerezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Light Crimp

Light Crimp

Uploaded by

Alejandro PerezCopyright:

Available Formats

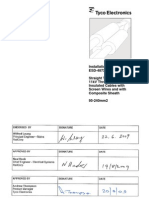

Instruction Sheet

LightCrimp* Plus SC Simplex

408-4471

Connector Kits 492643-[ ], 1278079-[ ],

1588291-[ ], and 1693276-1

10 FEB 05

Rev F

Strain Relief

Inner

Crimp

Eyelet

Eyelet

Bare Buffer

Plunger

Boot

Dust Cap

Connector

Assembly

Ferrule

Dust Cap

Small

Clear

Tubing

Connector

Housing

Tubing

Connectors are shipped with dust caps installed onto the

connector. Keep dust caps in place until ready for assembly.

Figure 1

1. INTRODUCTION

Connector Kits 492643[ ] (62.5/125 mm), 1278079[ ]

(50/125 mm), and 1588291[ ] (50/125 mm) are

designed for use with 125mm multimode glass fiber

optic cable. Connector Kit 16932761 is designed for

use with 125mm singlemode fiber. All of these kits

can be used with any of the following media except

where indicated.

5.1.

900- m Bare Buffered Fiber

5.2.

250- m Coated Fiber

5.3.

2.5- to 3.0-mm Loose Jacketed Cable

"Use for multimode fiber only.

"DO NOT use with singlemode fiber.

"Any jacketed cable used with SC connectors must

allow for the axial movement of the buffered fiber in

the jacket which occurs when the connector is mated

to another connector or device. Certain cable

constructions do not allow axial movement and are

not suitable for use with SC connectors. Refer to

Inspection Specification 1291496 for a method of

determining whether a given cable construction

allows axial movement (result of the buffer pull test

should measure less than 2 lbf).

5.4.

5.5.

NOTE

Reasons for reissue of this instruction sheet are

provided in Section 6, REVISION SUMMARY.

2. DESCRIPTION

(See Figure 1)

Each connector kit consists of a connector housing,

connector assembly, strain relief, inner eyelet, crimp

eyelet, and clear tubing. Each kit is also supplied with

a bare buffer boot and small tubing to compensate for

small diameter cable. Also included, assembled onto

the connector, are dust caps for the ferrule (front of

connector) and plunger (rear of connector).

3. SAFETY PRECAUTIONS

DANGER

NEVER look into the end of terminated or

unterminated fibers. Laser radiation is invisible

but can damage eye tissue. NEVER eat, drink, or

smoke when working with fibers. This could lead

to ingestion of glass particles.

DANGER

To avoid personal injury, ALWAYS wear eye

protection when working with optical fibers.

900- m Buffered Break-Out Fiber

Be very careful to dispose of fiber ends properly.

The fibers create slivers that can easily puncture

900- m Easy Strip or Semi-Tight Buffered Fiber

the skin and cause irritation.

Refer to the referenced paragraphs for assembly

procedures. Read these instructions thoroughly

before assembling the connector kits.

2005 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

AMP and Tyco are trademarks.

Dimensions on this document are in metric units.

CAUTION

DO NOT use damaged components. Replace

them with new components.

This controlled document is subject to change.

TOOLING ASSISTANCE CENTER 1-800-722-1111

For latest revision, call the FAX/PRODUCT INFO number.

FAX/PRODUCT INFO 1-800-522-6752

*Trademark

Other products, logos, and company names used are the property of their respective owners.

For Regional Customer Service, visit our website at

www.tycoelectronics.com

1 of 19

LOC B

408-4471

LightCrimp Plus SC Simplex Connector Kits

4. REQUIRED TOOLS AND MATERIALS

FOR ASSEMBLY

Fiber Optic Combination Strip Tool 12789471

Scissors 5010141

Cable Holder Assembly 12780231

Cleave Tool 4926741

PROCRIMPER* Hand Tool Assembly

4927821

Alcohol Fiber Wipe Packet 5018572

NOTE

The above items are included in LightCrimp Plus

4. Mark the buffer at each crossslot on the

channel. See Figure 2, Detail B. Remove the buffer

from the cable holder assembly.

5. Using the strip tool, strip the fiber to the first

mark. It is recommended holding the strip tool at

an angle to the fiber and stripping the fiber in three

sections. See Figure 2, Detail C. Clean the fiber

with an alcohol fiber wipe to remove the fiber

coating residue.

CAUTION

Termination Kits 1278022-1 and 1278118-1.

Before using the strip tool, make sure that the V"

opening is clean; otherwise the fiber could break.

Only use isopropyl alcohol on the tool.

isopropyl alcohol

B. Cleaving

5. ASSEMBLY PROCEDURE

5.1.

NOTE

(Figure 3)

To avoid damage to the fiber, make sure that the

cleave tool blade and the area around the blade

are clean; only use isopropyl alcohol on the tool.

900-mm Bare Buffered Fiber

Make sure that the cleave blade floats up and

down in its housing with very light force.

Kit Components Required

Lubricate with isopropyl alcohol as required.

(Discard Other Components)

1. Push the lever of the cleave tool to open the

clamp, and lay the fiber in the groove of the tongue

with the buffer started at the 8mm

scale marking (+0.5 mm). See Figure 3, Detail A.

Plunger

Dust Cap

Connector

Assembly

Bare Buffer

Ferrule

Boot

Dust Cap

2. Holding the fiber in place, release the lever so

that the fiber is secure. For best results, it is

extremely important that the cleave tool be held as

shown in Figure 3, Detail B. Making sure that the

tool tongue stays flat, gently depress the tool arm

to scribe the fiber. The edge of the blade should

only touch the fiber. Release the arm.

Connector

Housing

G Connectors are shipped with dust caps installed onto the

connector. Keep dust caps in place until ready for assembly.

A. Preparing 900-mm Bare Buffered Fiber

(Figure 2)

CAUTION

CAUTION

2. Remove both dust caps from the connector

assembly. Keep the ferrule dust cap; discard the

plunger dust cap.

NOTE

2 of 19

excessive pressure when depressing the arm.

3. Keeping the fiber in position, slowly bend, but

do not twist, the tongue to cleave the fiber. See

Figure 3, Detail C. Do not touch, or otherwise

contaminate, the cleaved fiber end. Do not clean

the cleaved fiber end.

1. Slide the bare buffer boot (small diameter end

first) over the buffer. See Figure 2, Detail A.

3. Push the connector assembly into the holder of

the cable holder assembly with the ferrule facing

outward. Make sure that the connector butts

against the lip on the arm of the cable holder

assembly. Slide the fiber into the channel marked

BUFFER. Make sure that the tip of the buffer

butts against the end of the channel. See Figure 2,

Detail B.

To avoid damage to the fiber, DO NOT use

C. Crimping

To avoid damage to the tool tongue, DO NOT

bend the tongue beyond a 45 angle.

Cleave blade life is 1,000 cleaves.

Use Replacement Blade 1278219-1.

(Figures 4 and 5)

1. Open the cable clamp of the cable holder

assembly, and position the buffer (with the cleaved

end facing the connector) inside the clamp. Move

the buffer so that the end of the fiber is even with

the front of the arm of the cable holder assembly,

and holding the buffer in place, close the clamp.

See Figure 4, Detail A.

Rev

LightCrimp Plus SC Simplex Connector Kits

2. Carefully insert the fiber into the plunger of the

connector assembly until the fiber bottoms against

the internal fiber. Make sure that the remaining

mark on the buffer enters the plunger (if mark does

not enter the plunger, the fiber must be

restripped). The resultant bend in the buffer

should hold the fiber against the internal fiber. See

Figure 4, Detail B.

NOTE

It is important that the fiber bottoms against, and

408-4471

6. Position the plunger of the connector assembly

in the first (smallest) cavity of the front die with the

knurl against the edge of the groove in the die and

the ferrule pointed in the direction of the arrow. See

Figure 5, Detail A.

7. Slowly squeeze the tool handles together until

the ratchet releases. Allow the handles to open

fully, and remove the connector assembly from the

die.

remains against, the internal fiber. If the mark

does not enter the plunger or if the fiber does not

seem to bottom against the internal fiber, the

fiber may be caught on internal guides. Rotating

the connector and backing the fiber out a small

amount and re-entering may help.

Make sure that the fiber does not pull rearward

8. Install the dust cap onto the ferrule, and slide

the bare buffer boot over the plunger until the boot

butts against the connector assembly. See Figure

5, Detail B.

9. Remove the connector assembly from the cable

holder assembly.

from the contact with the internal fiber during the

crimping operation.

3. Squeeze the handles of the hand tool until the

ratchet releases. Allow handles to open fully.

Slowly close the tool handles until you hear two

clicks from the ratchet.

4. With the connector assembly in the cable holder

assembly, position the ferrule in the upper cavity of

the front die and the plunger in the upper cavity of

the rear die. See Figure 4, Detail C.

CAUTION

10. Align the key of the connector housing with the

chamfered edges of the connector assembly. Slide

the housing over the assembly until it snaps in

place. See Figure 5, Detail C.

NOTE

DO NOT force the components together. They

are designed to fit only one way.

The assembly procedure for 900mm bare buffered

fiber is now complete.

The arrows marked on the front die indicate the

direction that the ferrule must be pointing when

the connector is positioned in that cavity.

For proper placement, and to avoid damage to

the fiber, the direction of the arrows must be

observed. Refer to Figure 4, Detail C and

Figure 5, Detail A.

5. Gently push the buffer toward the connector

assembly to make sure that the fiber is still

bottomed, then slowly squeeze the tool handles

together until the ratchet releases. Allow the

handles to open fully, and remove connector from

the dies.

Rev F

3 of 19

408-4471

LightCrimp Plus SC Simplex Connector Kits

B. Cleaving

250-mm Coated Fiber

5.2.

NOTE

Kit Components Required

(Figure 3)

To avoid damage to the fiber, make sure that the

cleave tool blade, and the area around the blade,

are clean; only use isopropyl alcohol on the tool.

(Discard Other Components)

Make sure that the cleave blade floats up and

Plunger

down in its housing with very light force.

Dust Cap

Lubricate with isopropyl alcohol as required.

Connector

Assembly

Bare Buffer

Ferrule

Boot

Dust Cap

Small

Tubing

Connector

Housing

G Connectors are shipped with dust caps installed onto the

1. Push the lever of the cleave tool to open the

clamp, and lay the fiber in the groove on the

tongue with the fiber coating started at the 8mm

scale marking (+0.5 mm). See Figure 3, Detail A.

2. Holding the fiber in place, release the lever so

that the fiber is secure. For best results, it is

extremely important that the cleave tool be held as

shown in Figure 3, Detail B. Making sure that the

tool tongue stays flat, gently depress the tool arm

to scribe the fiber. The edge of the blade should

only touch the fiber. Release the arm.

CAUTION

connector. Keep dust caps in place until ready for assembly.

A. Preparing 250-mm Coated Fiber

(Figure 2)

1. Slide the bare buffer boot (small diameter end

first) over the fiber. See Figure 2, Detail A.

2. Remove both dust caps from the connector

assembly. Keep the ferrule dust cap; discard the

plunger dust cap.

3. Insert the small (white) tubing into the plunger of

the connector assembly until the tubing bottoms.

See Figure 2, Detail A.

To avoid damage to the fiber, DO NOT use

excessive pressure when depressing the arm.

3. Keeping the fiber in position, slowly bend, but

do not twist, the tongue to cleave the fiber. See

Figure 3, Detail C. Do not touch, or otherwise

contaminate, the cleaved fiber end. Do not clean

the cleaved fiber end.

CAUTION

NOTE

C. Crimping

To avoid damage to the tool tongue, DO NOT

bend the tongue beyond a 45 angle.

Cleave blade life is 1,000 cleaves.

Use Replacement Blade 1278219-1.

(Figures 4 and 5)

4. Push the connector assembly into the holder of

the cable holder assembly with the ferrule facing

outward. Make sure that the connector butts

against the lip on the arm of the cable holder

assembly. Slide the fiber into the channel marked

BUFFER. Make sure that the tip of the fiber butts

against the end of the channel. See Figure 2,

Detail B.

1. Open the cable clamp of the cable holder

assembly, and position the fiber (with the cleaved

end facing the connector) inside the clamp. Move

the fiber so that the end of the fiber is even with

the front of the arm of the cable holder assembly,

and holding the fiber in place, close the clamp. See

Figure 4, Detail A.

5. Mark the fiber at each crossslot on the

channel. See Figure 2, Detail B. Remove the fiber

from the cable holder assembly.

2. Carefully insert the fiber into the plunger of the

connector assembly until the fiber bottoms against

the internal fiber. Make sure that the remaining

mark on the fiber enters the plunger (if the mark

does not enter the plunger, the fiber must be

restripped). The resultant bend in the fiber should

hold the fiber against the internal fiber. See Figure

4, Detail B.

6. Using the strip tool, strip the fiber to the first

mark. It is recommended holding the strip tool at

an angle to the fiber and stripping the fiber in three

sections. See Figure 2, Detail C. Clean the fiber

with an alcohol fiber wipe to remove the fiber buffer

residue.

CAUTION

Before using the strip tool, make sure that the V"

opening is clean; otherwise the fiber could break.

Only use isopropyl alcohol on the tool.

4 of 19

Also, the fiber coating must enter the small tubing

installed in the back (plunger) of the connector

assembly in Step 3 of Paragraph 5.2.A. Make sure

that the start of the fiber coating is not caught on

the entry to the small tubing.

Rev

LightCrimp Plus SC Simplex Connector Kits

NOTE

It is important that the fiber bottoms against, and

remains against, the internal fiber. If the mark

does not enter the plunger or if the fiber does not

seem to bottom against the internal fiber, the

fiber may be caught on internal guides. Rotating

the connector and backing the fiber out a small

amount and re-entering may help.

Make sure that the fiber does not pull rearward

from the contact with the internal fiber during the

408-4471

6. Position the plunger of the connector assembly

in the first (smallest) cavity of the front die with the

knurl against the edge of the groove in the die and

the ferrule pointed in the direction of the arrow. See

Figure 5, Detail A.

7. Slowly squeeze the tool handles together until

the ratchet releases. Allow the handles to open

fully, and remove the connector assembly from the

die.

crimping operation.

3. Squeeze the handles of the hand tool until the

ratchet releases. Allow the handles to open fully.

Slowly close the tool handles until you hear two

clicks from the ratchet.

4. With the connector assembly in the cable holder

assembly, position the ferrule in the upper cavity of

the front die and the plunger in the upper cavity of

the rear die. See Figure 4, Detail C.

CAUTION

The arrows marked on the front die indicate the

direction that the ferrule must be pointing when

the connector is positioned in that cavity.

8. Install the dust cap onto the ferrule, and slide

the bare buffer boot over the plunger until the boot

butts against the connector assembly. See Figure

5, Detail B.

9. Remove the connector assembly from the cable

holder assembly.

10. Align the key of the connector housing with the

chamfered edges of the connector assembly. Slide

the housing over the assembly until it snaps in

place. See Figure 5, Detail C.

NOTE

DO NOT force the components together. They

are designed to fit only one way.

For proper placement, and to avoid damage to

the fiber, the direction of the arrows must be

observed. Refer to Figure 4, Detail C and

The assembly procedure for 250mm coated fiber is

now complete.

Figure 5, Detail A.

5. Gently push the fiber toward the connector

assembly to make sure that the fiber is still

bottomed, then slowly squeeze the tool handles

together until the ratchet releases. Allow the

handles to open fully, and remove the connector

from the dies.

Rev F

5 of 19

408-4471

LightCrimp Plus SC Simplex Connector Kits

Figure 2:

Figure 3:

Preparing the Fiber

Detail A

Cleaving

Detail A

mm Bare

Fiber) or Fiber (250-mm

Push Lever to

Secure Fiber

Buffer (900-

Small Diameter End

Coated Fiber)

Blade

of Bare Buffer Boot

Tongue

Plunger of Connector

Buffer or Fiber Coating Started

Assembly

at 8-mm Scale Mark (+0.5 mm)

(For 250- m

Small Tubing

Coated Fiber)

Detail B

Detail B

Mark Buffer or Fiber

mm

Tip of Buffer (900-

Hold Cleave Tool As Shown

at Cross-Slots

Gently Depress Arm to Scribe Fiber

Bare Fiber) or Fiber

mm Coated Fiber)

(250-

Left Index Finger

Right Index Finger

Against End of Channel

Connector Assembly

in Holder with Ferrule

Facing Outward

Cable Holder

Left Thumb

Right Thumb

Assembly

12.7 mm (Approx)

Detail C

Strip Fiber in

Strip Tool

Correct Edge of Blade

Incorrect Excessive

Only Touching Fiber

Pressure Applied to Arm

Sections to First Mark

Hold Strip Tool at

_ Angle (Approx)

45

Detail C

to Fiber

Direction

of Strip

6 of 19

Slowly Bend Tongue

to Cleave Fiber

Rev

408-4471

LightCrimp Plus SC Simplex Connector Kits

Figure 4:

Detail A

Figure 5:

Crimping

Crimping

Detail A

Buffer (900-mm Bare Fiber) or

Fiber (250-mm Coated Fiber)

Held in Cable Clamp

Plunger in First Cavity

of Front Die with

Ferrule Pointed in

Direction of Arrow

Cleaved End of Fiber

Even with Front of Arm of

Cable Holder Assembly

Knurl Against Edge

of Groove in Die

Detail B

Ferrule Facing

Outward

Fiber Bottomed

in Plunger

Bend Formed to

Hold End of Fiber

in Place

Detail B

Bare Buffer Boot Over

Plunger and Against

Connector Assembly

Dust Cap

Over Ferrule

Detail C

Ferrule in Upper Cavity

of Front Die and Pointed

in Direction of Arrow

Detail C

Key of Connector Housing

Aligned with Chamfered Edges

of Connector Assembly

Slide Housing

Plunger in Upper

Cavity of Rear Die

Rev F

Over Assembly

7 of 19

408-4471

LightCrimp Plus SC Simplex Connector Kits

7. Slide the crimp eyelet onto the buffer and using

the eyelet, fold the strength members back over

the jacket. Continue sliding the eyelet over the

jacket until the strength members appear at the

front of the eyelet. See Figure 7, Detail A.

2.5- to 3.0-mm Loose Jacketed Cable

5.3.

DO NOT use with singlemode fiber.

Kit Components Required

8. Slide the inner eyelet, nonflanged end first,

onto the buffer. Push the eyelet under the strength

members until the eyelet is flush with the front of

the crimp eyelet. See Figure 7, Detail B.

(Discard Other Components)

Plunger

Dust Cap

Connector

Assembly

Strain

Relief

Ferrule

Dust Cap

Inner

Eyelet

Crimp

Eyelet

Connector

Housing

G Connectors are shipped with dust caps installed onto the

9. Slide the buffer into the channel marked

BUFFER on the cable holder assembly. Make

sure that the tip of the buffer butts against the end

of the channel. See Figure 7, Detail C.

10. Mark the buffer at each crossslot on the

channel. See Figure 7, Detail C. Remove the buffer

from the cable holder assembly.

11. Using the strip tool, strip the buffer to the first

mark. It is recommended holding the strip tool at

an angle to the buffer and stripping the buffer in

three sections. See Figure 7, Detail D. Clean the

fiber with an alcohol fiber wipe to remove fiber

coating residue.

CAUTION

opening is clean; otherwise the fiber could break.

Only use isopropyl alcohol on the tool.

connector. Keep dust caps in place until ready for assembly.

B. Cleaving

A. Preparing 2.5- to 3.0-mm Loose Jacketed Cable

Before using the strip tool, make sure that the V"

NOTE

(Figures 6 and 7)

(Figure 8)

To avoid damage to the fiber, make sure that the

cleave tool blade, and the area around the blade,

are clean; only use isopropyl alcohol on the tool.

1. Slide the strain relief (small diameter end first)

over the cable. See Figure 6, Detail A.

2. Remove both dust caps from the connector

assembly. Keep the ferrule dust cap; discard the

plunger dust cap.

3. Push the connector assembly into the holder of

the cable holder assembly with the ferrule facing

outward. Make sure that the connector is sitting flat

against the arm of the cable holder assembly. Slide

the cable into the channel marked CABLE. Make

sure that the tip of the jacket butts against the end

of the channel. See Figure 6, Detail B.

4. Mark the cable at each crossslot on the

channel. See Figure 6, Detail B. Remove the cable

from the cable holder assembly.

5. Using the strip tool, cut through the jacket at

each mark in the slot closest to the tool tip. See

Figure 6, Detail C.

6. Remove the first jacket segment, and flare the

strength members away from the buffer. Using the

scissors, cut the strength members even with the

jacket. Then remove the remaining jacket segment.

See Figure 6, Detail D.

8 of 19

Make sure that the cleave blade floats up and

down in its housing with very light force.

Lubricate with isopropyl alcohol as required.

1. Push the lever of the cleave tool to open the

clamp, and lay the fiber in the groove on the

tongue with the buffer started at the 8mm

scale marking (+0.5 mm). See Figure 8, Detail A.

2. Holding the fiber in place, release the lever so

that the fiber is secure. For best results, it is

extremely important that the cleave tool be held as

shown in Figure 8, Detail B. Making sure that the

tool tongue stays flat, gently depress the tool arm

to scribe the fiber. The edge of the blade should

only touch the fiber. Release the arm.

CAUTION

To avoid damage to the fiber, DO NOT use

excessive pressure when depressing the arm.

3. Keeping the fiber in position, slowly bend, but

do not twist, the tongue to cleave the fiber. See

Figure 8, Detail C. Do not touch, or otherwise

contaminate, the cleaved fiber end. Do not clean

the cleaved fiber end.

CAUTION

To avoid damage to the tool tongue, DO NOT

bend the tongue beyond a 45 angle.

Rev

LightCrimp Plus SC Simplex Connector Kits

NOTE

C. Crimping

Cleave blade life is 1,000 cleaves.

Use Replacement Blade 1278219-1.

(Figures 9, 10, and 11)

1. Open the cable clamp of the cable holder

assembly, and position the buffer (with the cleaved

end facing the connector) inside the clamp. Move

the buffer so that the end of the fiber is even with

the front of the arm of the cable holder assembly,

and holding the buffer in place, close the clamp.

See Figure 9, Detail A.

2. Carefully insert the buffer into the plunger of the

connector assembly until the buffer bottoms

against the internal fiber. Make sure that the

remaining mark on the buffer enters the plunger (if

the mark does not enter the plunger, the fiber must

be restripped). The resultant bend in the buffer

should hold the buffer against the internal fiber.

See Figure 9, Detail B.

NOTE

It is important that the fiber bottoms against, and

5. Gently push the buffer toward the connector

assembly to make sure that the fiber is still

bottomed, then slowly squeeze the tool handles

together until the ratchet releases. Allow the

handles to open fully, and remove the connector

from the dies.

6. Position the plunger of the connector assembly

in the first (smallest) cavity of the front die with the

knurl against the edge of the groove in the die and

the ferrule pointed in the direction of the arrow. See

Figure 10, Detail A.

7. Slowly squeeze the tool handles together until

the ratchet releases. Allow the handles to open

fully, and remove the connector assembly from the

die.

8. Slide the crimp eyelet away from the connector

assembly until the strength members are free, then

slide the crimp eyelet toward the connector until

the strength members and crimp eyelet butt

against the connector. See Figure 10, Detail B.

remains against, the internal fiber. If the mark

does not enter the plunger or if the fiber does not

seem to bottom against the internal fiber, the

fiber may be caught on internal guides. Rotating

the connector and backing the buffer out a small

amount and re-entering may help.

Make sure that the fiber does not pull rearward

from the contact with the internal fiber during the

crimping operation.

CAUTION

408-4471

Make sure that a minimum space of

approximately 3.18 mm (nominal 4.76 mm])

exists between the face of the inner eyelet

9. Position the crimp eyelet against the last cavity

of the front die with the ferrule pointed in the

direction of the arrow. Make sure that the

connector assembly is butted against the die. The

crimp eyelet will move into the cavity when the dies

are closed. See Figure 11, Detail A. Slowly

squeeze the tool handles together until the ratchet

releases. Allow the handles to open fully.

10. Install the dust cap onto the ferrule, and slide

the strain relief over the plunger until the strain

relief butts against the connector assembly. See

Figure 11, Detail B.

(shown in Figure 7, Detail B) and the rear most

tip of the connector assembly (plunger). Refer to

Figure 9, Detail B.

Failure to ensure this space exists may result in

improper connector performance when mated to

a connector.

3. Squeeze the handles of the hand tool until the

ratchet releases. Allow the handles to open fully.

Gently close the tool handles until you hear two

clicks from the ratchet.

4. With the connector assembly in the cable holder

assembly, position the ferrule in the upper cavity of

the front die and the plunger in the upper cavity of

the rear die. See Figure 9, Detail C.

CAUTION

11. Remove the connector assembly from the

cable holder assembly.

12. Align the key of the connector housing with the

chamfered edges of the connector assembly, and

slide the housing over the assembly until it snaps

in place. See Figure 11, Detail C.

NOTE

DO NOT force the components together. They

are designed to fit only one way.

The assembly procedure for 2.5 to 3.0mm loose

jacketed cable is now complete.

The arrows marked on the front die indicate the

direction that the ferrule must be pointing when

the connector is positioned in that cavity.

For proper placement, and to avoid damage to

the fiber, the direction of the arrows must be

observed. Refer to Figure 9, Detail C and

Figure 10, Detail A.

Rev

9 of 19

408-4471

LightCrimp Plus SC Simplex Connector Kits

Figure 6:

Preparing the Cable

Figure 7:

Preparing the Cable

Detail A

Detail A

Strength Members

Folded Over Jacket

Small Diameter End

of Strain Relief

Cable

Front of

Crimp Eyelet

Detail B

Detail B

Inner Eyelet Under

Strength Members

Mark Cable at

Cross-Slots

Tip of Jacket Against

End of Channel

Face of

Inner Eyelet

Detail C

Mark Buffer at

Cross-Slots

Cable Holder

Assembly

Detail C

Connector Assembly

in Holder with Ferrule

Facing Outward

Tip of Buffer Against

End of Channel

Strip Tool

Cut Through Jacket

(Using Slot Closest

to the Tool Tip)

Detail D

Strip Tool

Detail D

Strip Buffer in

Sections to First Mark

First Jacket

Segment Removed

Hold Strip Tool at

_ Angle (Approx)

Cut Strength Members

45

Even with Jacket

to Buffer

Direction

of Strip

Remaining Jacket

Segment Removed

10 of 19

Rev F

408-4471

LightCrimp Plus SC Simplex Connector Kits

Figure 8:

Cleaving

Detail A

Figure 9:

Push Lever to

Secure Fiber

Crimping

Detail A

Buffer Held in

Cable Clamp

Cleaved End of Fiber

Blade

Even with Front of Arm of

Cable Holder Assembly

Tongue

Buffer Started at 8-mm

Scale Mark (+0.5 mm)

Detail B

Hold Cleave Tool As Shown

Gently Depress Arm to Scribe Fiber

Left Index Finger

Ferrule Facing

Detail B

Outward

Right Index Finger

Bend Formed to Hold

End of Fiber in Place

3.18 mm (Min

Approx)

Left Thumb

Right Thumb

12.7 mm (Approx)

Correct Edge of Blade

Incorrect Excessive

Only Touching Fiber

Pressure Applied to Arm

Fiber Bottomed in

Plunger of Connector

Assembly

Detail C

Ferrule in Upper Cavity

of Front Die and Pointed

in Direction of Arrow

Detail C

Slowly Bend Tongue

to Cleave Fiber

Plunger in Upper

Cavity of Rear Die

Rev

11 of 19

408-4471

LightCrimp Plus SC Simplex Connector Kits

Figure 10:

Figure 11:

Crimping

Crimping

Detail A

Detail A

Crimp Eyelet Against

Last Cavity of Front Die

with Ferrule Pointed in

Direction of Arrow

Plunger in First Cavity

of Front Die with

Ferrule Pointed in

Direction of Arrow

Connector Assembly

Against Die

Knurl Against Edge

of Groove in Die

Detail B

Detail B

Strain Relief Over Plunger and

Against Connector Assembly

Dust Cap

Over Ferrule

Detail C

Key of Connector Housing

Aligned with Chamfered Edges

of Connector Assembly

Slide Housing

Over Assembly

12 of 19

Rev F

408-4471

LightCrimp Plus SC Simplex Connector Kits

5.4.

Termination to 900-mm Buffered Break-Out Fiber

Kit Components Required

Strain

(Discard Other Components)

Inner

Crimp

Relief

Eyelet

Eyelet

Plunger

Dust Cap

Connector

Small

Assembly

Tubing

Clear

Tubing

Ferrule

Dust Cap

Connector

Housing

G Connectors are shipped with dust caps installed onto the

connector. Keep dust caps in place until ready for assembly.

A. Preparing Fiber and Buffer Tube

(Figure 12)

1. The breakout fiber is assumed to be installed

with one fiber per buffer tube and the fiber and

buffer tubes cut to the same length.

2. Mark a circumferential line (approximately 90_

around) 4 mm from one end of the clear tubing.

See Figure 12, Detail A.

3. Place the inner eyelet, small diameter end first,

inside the clear tubing with the flange of the inner

eyelet against the end of the clear tubing. See

Figure 12, Detail A.

4. Slide the strain relief (small diameter end first),

clear tubing with the inner eyelet inside, and crimp

eyelet onto the fiber. See Figure 12, Detail B.

5. Remove both dust caps from the connector

assembly. Keep the ferrule dust cap. Discard the

plunger dust cap.

9. Slide the 250mm coated fiber into the channel

marked BUFFER on the cable holder assembly.

Make sure that the tip of the fiber butts against the

end of the channel. Mark the fiber at each

crossslot on the channel. See Figure 12, Detail D.

Remove the fiber from the channel.

10. Using the strip tool, strip the 250mm fiber

coating to the first mark. It is recommended

holding the strip tool at an angle to the fiber coating

and stripping the coating in three sections. See

Figure 12, Detail E. Clean the fiber with an alcohol

fiber wipe to remove the fiber coating residue.

CAUTION

8. Mark the buffer tube at the end of the channel

(approximately 43 mm from the fiber tip). See

Figure 12, Detail D. Cut the buffer tube at the

mark, and remove.

NOTE

Rev

The buffer tube is now approximately 43 mm

mm coated fiber.

shorter than the 250-

opening is clean; otherwise the fiber could break.

Only use isopropyl alcohol on the tool.

B. Cleaving

NOTE

(Figure 13)

To avoid damage to the fiber, make sure that the

cleave tool blade, and the area around the blade,

are clean; only use isopropyl alcohol on the tool.

6. Insert the small (white) tubing into the plunger of

the connector assembly until the tubing bottoms.

See Figure 12, Detail C.

7. Push the connector assembly into the holder of

the cable holder assembly with the ferrule facing

outward. Make sure that the connector butts

against the lip on the arm of the cable holder

assembly. Slide the buffer tube into the channel

marked BUFFER. Make sure that the tip of the

buffer tube butts against the end of the channel.

See Figure 12, Detail D.

Before using the strip tool, make sure that the V"

Make sure that the cleave blade floats up and

down in its housing with very light force.

Lubricate with isopropyl alcohol as required.

1. Push the lever of the cleave tool to open the

clamp, and lay the fiber in the groove on the

tongue with the buffer starting at the 8mm scale

marking (+0.5 mm). See Figure 13, Detail A.

2. Holding the fiber in place, release the lever so

that the fiber is secure. For best results, it is

extremely important that the cleave tool be held as

shown in Figure 13, Detail B. Making sure that the

tool tongue stays flat, gently depress the tool arm

to scribe the fiber. The edge of the blade should

only touch the fiber. Release the arm.

CAUTION

To avoid damage to the fiber, DO NOT use

excessive pressure when depressing the arm.

13 of 19

LightCrimp Plus SC Simplex Connector Kits

3. Keeping the fiber in position, slowly bend, but

do not twist, the tongue to cleave the fiber. See

Figure 13, Detail C. Do not touch, or otherwise

contaminate, the cleaved fiber end. Do not clean

the cleaved fiber end.

CAUTION

_angle.

Cleave blade life is 1,000 cleaves.

(Figures 14 and 15)

1. Open the cable clamp of the cable holder

assembly, and position the fiber (with the cleaved

end facing the connector) inside the clamp. Move

the fiber so that the end of the fiber is even with

the front of the arm of the cable holder assembly,

and holding the fiber in place, close the clamp. See

Figure 14, Detail A.

2. Holding the 250mm fiber coating, carefully

insert the fiber into the plunger of the connector

assembly until the fiber bottoms against the

internal fiber. Make sure that the second mark

placed on the coating enters the plunger. The

resultant bend in the fiber should hold the fiber

against the internal fiber. See Figure 14, Detail B.

Also, the fiber coating must enter the small tubing

installed in the back (plunger) of the connector

assembly in Step 6 of Paragraph 5.4.A. Make sure

that the start of the fiber coating is not caught on

the entry to the small tubing.

CAUTION

direction that the ferrule must be pointing when

the connector is positioned in that cavity.

For proper placement, and to avoid damage to

the fiber, the direction of the arrows must be

observed. Refer to Figure 14, Details C and D.

Use Replacement Blade 1278219-1.

C. Crimping

The arrows marked on the front die indicate the

To avoid damage to the tool tongue, do not bend

the tongue beyond a 45

NOTE

CAUTION

408-4471

When inserting the fiber into the connector, make

sure to hold the fiber coating so that the fiber

feeds into the connector. If the fiber is gripped by

the buffer tube, the fiber will slide rearwards into

the buffer tube and will

NOT

contact the internal

5. Gently push the fiber toward the connector

assembly to make sure that the fiber is still

bottomed, then slowly squeeze the tool handles

together until the ratchet releases. Allow the

handles to open fully, and remove the connector

from the dies.

6. Position the plunger of the connector assembly

in the first (smallest) cavity of the front die with the

knurl against the edge of the groove in the die and

the ferrule pointed in the direction of the arrow. See

Figure 14, Detail D.

7. Slowly squeeze the tool handles together until

the ratchet releases. Allow the handles to open

fully, and remove the connector assembly from the

die.

8. Slide the crimp eyelet up to, and until it butts

against, the rear of the connector assembly.

9. Slide the clear tubing with inner eyelet into the

crimp eyelet until the circumferential line is aligned

with the end of the crimp eyelet. See Figure 15,

Detail A.

10. While maintaining the position of the clear

tubing relative to the crimp eyelet, position the

crimp eyelet against the last cavity of the front die

with the ferrule pointed in the direction of the arrow.

Make sure the connector assembly is against the

die and the line on the clear tubing is aligned with

the opposite end of the crimp eyelet. The crimp

eyelet will move into the cavity when the dies are

closed. See Figure 15, Detail B.

fiber.

NOTE

It is important that the fiber bottoms against, and

remains against, the internal fiber. If the mark

does not enter the plunger or if the fiber does not

seem to bottom against the internal fiber, the

fiber may be caught on internal guides. Rotating

the connector and backing the fiber out a small

amount and re-entering may help.

Make sure that the fiber does not pull rearward

from the contact with the internal fiber during the

crimping operation.

3. Squeeze the handles of the hand tool until the

ratchet releases. Allow the handles to open fully.

Slowly close the tool handles until you hear two

clicks from the ratchet.

4. With the connector assembly in the cable holder

assembly, position the ferrule in the upper cavity of

the front die and the plunger in the upper cavity of

the rear die. See Figure 14, Detail C.

14 of 19

11. Slowly squeeze the tool handles together until

the ratchet releases. Allow the handles to open

fully.

12. Install the dust cap onto the ferrule. Open the

cable clamp of the cable holder assembly, and

remove the fiber from the clamp. Slide the strain

relief over the crimp eyelet until it butts against the

connector assembly. See Figure 15, Detail C.

13. Remove the connector assembly from the

cable holder assembly.

14. Align the key of the connector housing with the

chamfered edges of the connector assembly, and

slide the housing over the assembly until it snaps

in place. See Figure 15, Detail D.

NOTE

DO NOT force the components together. They

are designed to fit only one way.

The assembly procedure for 900mm buffered

breakout fiber is now complete.

Rev

408-4471

LightCrimp Plus SC Simplex Connector Kits

5.5.

Termination to 900-mm Easy Strip or Semi-Tight Buffered Fiber

Kit Components Required

(Discard Other Components)

Strain

Inner

Crimp

Relief

Eyelet

Eyelet

Plunger

Dust Cap

Connector

Assembly

Small

Clear

Tubing

Tubing

Ferrule

Dust Cap

Connector

Housing

G Connectors are shipped with dust caps installed onto the

connector. Keep dust caps in place until ready for assembly.

A. Preparing 900-mm Bare Buffered Fiber

(Figure 12)

1. Mark a circumferential line (approximately 90_

around) 4 mm from one end of the clear tubing.

See Figure 12, Detail A.

2. Place the inner eyelet, small diameter end first,

inside the clear tubing with the flange of the inner

eyelet against the end of the clear tubing. See

Figure 12, Detail A.

3. Slide the strain relief (small diameter end first),

clear tubing with the inner eyelet inside, and crimp

eyelet onto the fiber. See Figure 12, Detail B.

4. Remove both dust caps from the connector

assembly. Keep the ferrule dust cap. Discard the

plunger dust cap.

5. Insert the small (white) tubing into the plunger of

the connector assembly until the tubing bottoms.

See Figure 12, Detail C.

fiber with an alcohol fiber wipe to remove the fiber

coating residue.

9. Using the strip tool, apply slightly less pressure

than stripping the 125mm fiber, and strip the buffer

only (leave the 250mm fiber coating in place) to

the second mark. Practice this first.

10. Mark the 250mm fiber coating at the shoulder

of the 900mm buffer. Strip the buffer to the third

mark.

CAUTION

Before using the strip tool, make sure that the V"

opening is clean; otherwise the fiber could break.

Only use isopropyl alcohol on the tool.

B. Cleaving

NOTE

(Figure 13)

To avoid damage to the fiber, make sure that the

cleave tool blade, and the area around the blade,

are clean; only use isopropyl alcohol on the tool.

Make sure that the cleave blade floats up and

6. Push the connector assembly into the holder of

the cable holder assembly with the ferrule facing

outward. Make sure that the connector butts

against the lip on the arm of the cable holder. Slide

the fiber into the channel marked BUFFER. Make

sure that the tip of the fiber butts against the end of

the channel. See Figure 12, Detail D.

7. Mark the fiber at each crossslot on the

channel. See Figure 12, Detail D. Also, mark the

buffer at the end of the channel. Remove the fiber

from the channel.

8. Using the strip tool, strip the 250mm fiber

coating and buffer to the first mark. It is

recommended holding the strip tool at an angle to

the fiber coating and stripping the coating in three

sections. Refer to Figure 12, Detail E. Clean the

Rev

down in its housing with very light force.

Lubricate with isopropyl alcohol as required.

1. Push the lever of the cleave tool to open the

clamp, and lay the fiber in the groove on the

tongue with the buffer starting at the 8mm scale

marking (+0.5 mm). See Figure 13, Detail A.

2. Holding the fiber in place, release the lever so

that the fiber is secure. For best results, it is

extremely important that the cleave tool be held as

shown in Figure 13, Detail B. Making sure that the

tool tongue stays flat, gently depress the tool arm

to scribe the fiber. The edge of the blade should

only touch the fiber. Release the arm.

CAUTION

To avoid damage to the fiber, DO NOT use

excessive pressure when depressing the arm.

15 of 19

LightCrimp Plus SC Simplex Connector Kits

3. Keeping the fiber in position, slowly bend, but

do not twist, the tongue to cleave the fiber. See

Figure 13, Detail C. Do not touch, or otherwise

contaminate, the cleaved fiber end. Do not clean

the cleaved fiber end.

CAUTION

408-4471

The arrows marked on the front die indicate the

direction that the ferrule must be pointing when

the connector is positioned in that cavity.

For proper placement, and to avoid damage to

the fiber, the direction of the arrows must be

observed. Refer to Figure 14, Details C and D.

CAUTION

NOTE

C. Crimping

To avoid damage to the tool tongue, DO NOT

_angle.

bend the tongue beyond a 45

Cleave blade life is 1,000 cleaves.

Use Replacement Blade 1278219-1.

(Figures 14 and 15)

1. Open the cable clamp of the cable holder

assembly, and position the fiber (with the cleaved

end facing the connector) inside the clamp. Move

the fiber so that the end of the fiber is even with

the front of the arm of the cable holder assembly,

and holding the fiber in place, close the clamp. See

Figure 14, Detail A.

2. Holding the 250mm fiber coating, carefully

insert the fiber into the plunger of the connector

assembly until the fiber bottoms against the

internal fiber. Make sure that the second mark

placed on the coating enters the plunger. The

resultant bend in the fiber should hold the fiber

against the internal fiber. See Figure 14, Detail B.

Also, the fiber coating must enter the small tubing

installed in the back (plunger) of the connector

assembly in Step 5 of Paragraph 5.5.A. Make sure

that the start of the fiber coating is not caught on

the entry to the small tubing.

CAUTION

When inserting the fiber into the connector, make

sure to hold the fiber coating so that the fiber

feeds into the connector. If the fiber is gripped by

the buffer tube, the fiber will slide rearwards into

the buffer tube and will

NOT

contact the internal

fiber.

NOTE

It is important that the fiber bottoms against, and

remains against, the internal fiber. If the mark

does not enter the plunger or if the fiber does not

seem to bottom against the internal fiber, the

fiber may be caught on internal guides. Rotating

the connector and backing the fiber out a small

amount and re-entering may help.

Make sure that the fiber does not pull rearward

from the contact with the internal fiber during the

crimping operation.

3. Squeeze the handles of the hand tool until the

ratchet releases. Allow the handles to open fully.

Slowly close the tool handles until you hear two

clicks from the ratchet.

4. With the connector assembly in the cable holder

assembly, position the ferrule in the upper cavity of

the front die and the plunger in the upper cavity of

the rear die. See Figure 14, Detail C.

16 of 19

5. Gently push the fiber toward the connector

assembly to make sure that the fiber is still

bottomed, then slowly squeeze the tool handles

together until the ratchet releases. Allow the

handles to open fully, and remove the connector

from the dies.

6. Position the plunger of the connector assembly

in the first (smallest) cavity of the front die with the

knurl against the edge of the groove in the die and

the ferrule pointed in the direction of the arrow. See

Figure 14, Detail D.

7. Slowly squeeze the tool handles together until

the ratchet releases. Allow the handles to open

fully, and remove the connector assembly from the

die.

8. Slide the crimp eyelet up to, and until it butts

against, the rear of the connector assembly.

9. Slide the clear tubing with inner eyelet into the

crimp eyelet until the circumferential line is aligned

with the end of the crimp eyelet. See Figure 15,

Detail A.

10. While maintaining the position of the clear

tubing relative to the crimp eyelet, position the

crimp eyelet against the last cavity of the front die

with the ferrule pointed in the direction of the arrow.

Make sure the connector assembly is against the

die and the line on the clear tubing is aligned with

the opposite end of the crimp eyelet. The crimp

eyelet will move into the cavity when the dies are

closed. See Figure 15, Detail B.

11. Slowly squeeze the tool handles together until

the ratchet releases. Allow the handles to open

fully.

12. Install the dust cap onto the ferrule. Open the

cable clamp of the cable holder assembly, and

remove the fiber from the clamp. Slide the strain

relief over the crimp eyelet until it butts against the

connector assembly. See Figure 15, Detail C.

13. Remove the connector assembly from the

cable holder assembly.

14. Align the key of the connector housing with the

chamfered edges of the connector assembly, and

slide the housing over the assembly until it snaps

in place. See Figure 15, Detail D.

NOTE

DO NOT force the components together. They

are designed to fit only one way.

The assembly procedure for 900mm easy strip or

semitight buffered fiber is now complete.

Rev

408-4471

LightCrimp Plus SC Simplex Connector Kits

Figure 12:

Preparing the Fiber and Buffer Tube

Detail A

Figure 13:

Cleaving

Detail A

Circumferential

Line

Push Lever to

Secure Fiber

Clear Tubing

4 mm

Blade

Inner Eyelet

Small Diameter End

of Strain Relief

Detail B

Tongue

Buffer Started at 8-mm

Scale Mark (+0.5 mm)

Small

Fiber

Detail C

Tubing

Plunger of Connector

Assembly

Detail D

Tip of Buffer Tube

Detail B

Mark Fiber at

Hold Cleave Tool As Shown

Cross-Slots

Gently Depress Arm to Scribe Fiber

Left Index Finger

(Break-Out Fiber) or Fiber

Right Index Finger

(Easy Strip or Semi-Tight)

Against End of Channel

Mark Buffer Tube

(Break-Out Fiber) or

Buffer (Easy Strip or

Semi-Tight) at End

of Channel

Cable Holder

Assembly

Left Thumb

Connector Assembly

Right Thumb

12.7 mm (Approx)

in Holder with Ferrule

Facing Outward

Correct Edge of Blade

Incorrect Excessive

Only Touching Fiber

Pressure Applied to Arm

Detail E

Strip in Sections

Strip Tool

to First Mark

Hold Strip Tool at

_ Angle (Approx)

Detail C

45

to Fiber

Direction

of Strip

Rev

Slowly Bend Tongue

to Cleave Fiber

17 of 19

408-4471

LightCrimp Plus SC Simplex Connector Kits

Figure 14:

Crimping

Figure 15:

Detail A

Crimping

Detail A

Fiber Held in

Cable Clamp

Cleaved End of Fiber

Even with Front of Arm of

Cable Holder Assembly

Clear Tubing

Circumferential Line

End of

Crimp Eyelet

Detail B

Detail B

Crimp Eyelet Against Last

Cavity of Front Die with Ferrule

Pointed in Direction of Arrow

Ferrule Facing

Outward

Fiber Bottomed

in Plunger

Connector Assembly

Against Die

Bend Formed to Hold

End of Fiber in Place

Detail C

Ferrule in Upper

Cavity of Front Die

and Pointed in

Direction of Arrow

Plunger in Upper

Cavity of Rear Die

Detail D

Detail C

Strain Relief Over Crimp Eyelet

and Against Connector Assembly

Dust Cap

Over Ferrule

Detail D

Plunger in First Cavity of

Front Die with Ferrule Pointed

in Direction of Arrow

Key of Connector Housing

Aligned with Chamfered Edges

of Connector Assembly

Knurl Against Edge

of Groove in Die

Slide Housing

Over Assembly

18 of 19

Rev F

LightCrimp Plus SC Simplex Connector Kits

408-4471

6. REVISION SUMMARY

Revisions to this instruction sheet per EC

0990022505 include:

S Added text to Section 1

S Added loose to jacketed cable

Rev F

19 of 19

You might also like

- Method Statement - Cable Joint LVDocument4 pagesMethod Statement - Cable Joint LVanuraj arackal67% (6)

- AT520JK Users ManualDocument15 pagesAT520JK Users ManualgerezairNo ratings yet

- Bosch Aftertreatment DEF Controller ConnectorDocument4 pagesBosch Aftertreatment DEF Controller ConnectorO mecanicoNo ratings yet

- Service Manual (AT) - J Transmission (AT)Document16 pagesService Manual (AT) - J Transmission (AT)Николай КирилловNo ratings yet

- Boomerang PDFDocument16 pagesBoomerang PDFYusuf SarikayaNo ratings yet

- Conector LC Light Crimp - ManualDocument8 pagesConector LC Light Crimp - ManualTirso W. RodríguezNo ratings yet

- Fi - SCST Multimode Singlemode Connector - II PDFDocument4 pagesFi - SCST Multimode Singlemode Connector - II PDFmirkofedorNo ratings yet

- Fibra Optica - RS DataSheetDocument8 pagesFibra Optica - RS DataSheetAlex MoralesNo ratings yet

- Instruction C02 78.3Document4 pagesInstruction C02 78.3ВиталийКрутиковNo ratings yet

- Assembly Instructions For Cable Gland: 755 32R4: Connection SolutionsDocument4 pagesAssembly Instructions For Cable Gland: 755 32R4: Connection Solutionspvalverdea2014No ratings yet

- Psiipro Coil Connector Assy v3Document3 pagesPsiipro Coil Connector Assy v3reza yousefiNo ratings yet

- DT436 500 Sq. MM PDFDocument3 pagesDT436 500 Sq. MM PDFHamedObaidNo ratings yet

- Troubleshooting Manual, TS2712EN 04Document82 pagesTroubleshooting Manual, TS2712EN 04thibierozNo ratings yet

- Fi Xlr8 Mechanical Splice Fiber Connector IIDocument8 pagesFi Xlr8 Mechanical Splice Fiber Connector IIguideoNo ratings yet

- Cable Termination - Installation Instructions - 755LR - IsDocument5 pagesCable Termination - Installation Instructions - 755LR - Isvladimir_71No ratings yet

- Fibrlok Optical Fiber Splicing System: InstructionsDocument12 pagesFibrlok Optical Fiber Splicing System: InstructionsJohn Amiel LegaspiNo ratings yet

- 2100d Installation GuideDocument20 pages2100d Installation GuideJazz TubaNo ratings yet

- OPGW Splicing GuidelineDocument18 pagesOPGW Splicing Guidelinedc12dc100% (1)

- 2178CL-S Series F/O Splice Case: InstructionDocument13 pages2178CL-S Series F/O Splice Case: InstructionHữu Khánh NguyễnNo ratings yet

- Mid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFDocument12 pagesMid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFMehdi SHNo ratings yet

- 3M Fibrlok II 2539 InstrDocument4 pages3M Fibrlok II 2539 InstrjoseNo ratings yet

- Qt-Iii: Cold Shrink Silicone Rubber TerminationDocument10 pagesQt-Iii: Cold Shrink Silicone Rubber TerminationHJNo ratings yet

- 15kV PM Joints - Straight - KSU - 500-500sq - MMDocument8 pages15kV PM Joints - Straight - KSU - 500-500sq - MMabd elmohsen saedNo ratings yet

- BH138-Instruction Manual L-13 Blanik (Ok07.09.13) Ok - 29Document22 pagesBH138-Instruction Manual L-13 Blanik (Ok07.09.13) Ok - 29Catalin CiocarlanNo ratings yet

- Esd 4873 Au 5 - 09 PDFDocument13 pagesEsd 4873 Au 5 - 09 PDFGeorge IstrateNo ratings yet

- Irvine Tutor 40Document16 pagesIrvine Tutor 40IvanadoNo ratings yet

- Installation Protek Pipe Shoe 04 2018Document1 pageInstallation Protek Pipe Shoe 04 2018Sabuj SaikiaNo ratings yet

- Desktop Printer Service ManualDocument58 pagesDesktop Printer Service ManualMiguel Angel Lasso CastañoNo ratings yet

- Feeder System Installation Procedure - MOPDocument19 pagesFeeder System Installation Procedure - MOPSandeep singh100% (1)

- Matrix Infinity 2Document2 pagesMatrix Infinity 2marianotavaresNo ratings yet

- Fiber Optic Cable TerminationDocument16 pagesFiber Optic Cable TerminationStephenNo ratings yet

- Application Note 058: Connector MaintenanceDocument6 pagesApplication Note 058: Connector Maintenanceosto72No ratings yet

- Fireball Ignition PDFDocument14 pagesFireball Ignition PDFLucian LeonteNo ratings yet

- Technical Service BulletinDocument5 pagesTechnical Service BulletinMiguel AlmoraNo ratings yet

- Twisted Pair Wiring SchemesDocument9 pagesTwisted Pair Wiring SchemesPedroNo ratings yet

- Installation Instructions UTERMKIT Mk3Document4 pagesInstallation Instructions UTERMKIT Mk3aleloc2000No ratings yet

- Eclipse Matrix Blend Installation GuideDocument3 pagesEclipse Matrix Blend Installation GuideMichael KingNo ratings yet

- Connector Modular Plug Amp Tyco XXX 8p8c Rj45 Shielded c6 XXX XXX Emt AssemblyDocument9 pagesConnector Modular Plug Amp Tyco XXX 8p8c Rj45 Shielded c6 XXX XXX Emt AssemblyarifNo ratings yet

- PEAK Sidewall Cutter Data ManualDocument13 pagesPEAK Sidewall Cutter Data ManualRizky WahyuNo ratings yet

- Firecharger Installation ADocument10 pagesFirecharger Installation AAugmotorsNo ratings yet

- Introduction and Installation of FICDocument19 pagesIntroduction and Installation of FICbanigx0xNo ratings yet

- YHT-Installation - Dome Closure CV10-24Document8 pagesYHT-Installation - Dome Closure CV10-24juan joseNo ratings yet

- Fiber Optics Splicing Procedures: Your Source To Fiber Optics, Industrial Datacomm & Fieldbus Products-Solutions-ServicesDocument7 pagesFiber Optics Splicing Procedures: Your Source To Fiber Optics, Industrial Datacomm & Fieldbus Products-Solutions-ServicesHafis Aikal AmranNo ratings yet

- Esd 4872 Au 5 09 PDFDocument10 pagesEsd 4872 Au 5 09 PDFGuler RahimNo ratings yet

- Multiplex Minimag Model RC Airplane Manual M13209Document18 pagesMultiplex Minimag Model RC Airplane Manual M13209Anett ÁrvaiNo ratings yet

- Ig Gabions May 2015Document2 pagesIg Gabions May 2015LynxNo ratings yet

- 15kV Indoor Termination - KSU - 500sq - MMDocument6 pages15kV Indoor Termination - KSU - 500sq - MMabd elmohsen saedNo ratings yet

- Nipple Attachment-OM 151029Document1 pageNipple Attachment-OM 151029W MoralesNo ratings yet

- Splicing/changing Cable: Service InformationDocument8 pagesSplicing/changing Cable: Service InformationSmolovic SrdjanNo ratings yet

- Sealey SMS2008Document3 pagesSealey SMS2008cabuloNo ratings yet

- Connector MaintenanceDocument6 pagesConnector MaintenanceZain MalikNo ratings yet

- Elastimold Compact I JointDocument6 pagesElastimold Compact I Jointwerawatb819No ratings yet

- PNJHY-0001-82-02 (Fast SC - 0.25&0.9) PDFDocument2 pagesPNJHY-0001-82-02 (Fast SC - 0.25&0.9) PDFLêViệtLongNo ratings yet

- Antenna Feeder System InstallationDocument24 pagesAntenna Feeder System InstallationAbdul RahimNo ratings yet

- Activity Performance Worksheet: Computer TechnologyDocument14 pagesActivity Performance Worksheet: Computer TechnologyJefferson CanalejaNo ratings yet

- Pioneer Deh 2100ub 2110ub 2120ubDocument113 pagesPioneer Deh 2100ub 2110ub 2120ubJeki27No ratings yet

- Terminal Con Copa 3M Cold Shrink QT-III 769X-S-4 KitsDocument20 pagesTerminal Con Copa 3M Cold Shrink QT-III 769X-S-4 KitsEnrique G.No ratings yet

- Scotchcast Power Cable Tap Splice Kit 90-B1: InstructionsDocument8 pagesScotchcast Power Cable Tap Splice Kit 90-B1: InstructionsWanessa SuárezNo ratings yet

- Sehs9065 Deutsch CeDocument11 pagesSehs9065 Deutsch CeAlvaro arceNo ratings yet

- Wired Chinese Knot, Wire Jewelry Tutorial: Layer Coiled Crystal Pearls EarringsFrom EverandWired Chinese Knot, Wire Jewelry Tutorial: Layer Coiled Crystal Pearls EarringsRating: 1 out of 5 stars1/5 (1)

- Parachute Cord Craft: Quick & Simple Instructions for 22 Cool ProjectsFrom EverandParachute Cord Craft: Quick & Simple Instructions for 22 Cool ProjectsRating: 4 out of 5 stars4/5 (1)

- Dura. Grout: Non-Shrink Cementitious GroutDocument2 pagesDura. Grout: Non-Shrink Cementitious GroutANILNo ratings yet

- Aqualung - Titan - 1st - Stage - Service - Manual 2Document24 pagesAqualung - Titan - 1st - Stage - Service - Manual 2jmartinezNo ratings yet

- FFDVFDocument1 pageFFDVFshamirNo ratings yet

- Duraplate 8200Document4 pagesDuraplate 8200Carlos VillacrizNo ratings yet

- LMR 400 PDFDocument4 pagesLMR 400 PDFviktor220378No ratings yet

- Propylene Glycol - Market DataDocument3 pagesPropylene Glycol - Market DataSavannah Yonita CNo ratings yet

- ASME Section X InterpretationsDocument6 pagesASME Section X InterpretationsAnonymous UoHUagNo ratings yet

- Is 11218 1984Document5 pagesIs 11218 1984Ahmed HossamNo ratings yet

- Arisa Mandir IDocument20 pagesArisa Mandir IAnanda Tis'aNo ratings yet

- SEN KoreaDocument46 pagesSEN KoreasawwahwahNo ratings yet

- CAP2 - TRiiAGE Tools For Clariion Log Analysis - ENDocument16 pagesCAP2 - TRiiAGE Tools For Clariion Log Analysis - ENakuma27No ratings yet

- Glassheim MostDocument31 pagesGlassheim MostOskari TarkkaNo ratings yet

- Service ManualDocument45 pagesService ManualStoneAge1No ratings yet

- Trinidad Lake Modified Asphalt: Standard Specification ForDocument2 pagesTrinidad Lake Modified Asphalt: Standard Specification ForAhmedNo ratings yet

- Project Report: Traning AND Development Hero Honda CompanyDocument70 pagesProject Report: Traning AND Development Hero Honda CompanySurender Dhuran PrajapatNo ratings yet

- Inspection PT - AekDocument2 pagesInspection PT - AekMemo BongNo ratings yet

- Ser-59 Syspro MangalamDocument2 pagesSer-59 Syspro MangalamMicheal BuckNo ratings yet

- Mechanical and Chemical Weathering PDFDocument47 pagesMechanical and Chemical Weathering PDFYlla JovillanoNo ratings yet

- Pengaruh Laju Erosi Terhadap Umur PipaDocument6 pagesPengaruh Laju Erosi Terhadap Umur PipaDede Si Engghe SurenggheNo ratings yet

- DC Inverter VRF Air Conditioning SystemsDocument35 pagesDC Inverter VRF Air Conditioning SystemsTudor SorbanNo ratings yet

- Praj and Dedini Join Hands in BrazilDocument2 pagesPraj and Dedini Join Hands in BrazilindtnNo ratings yet

- Nayara Carin Report 10-Apr-2024Document3 pagesNayara Carin Report 10-Apr-2024amitk397115No ratings yet

- SPADA Soal Ujian Semester TK 1 EC D3 Sem 1 TA 2020 2021 (11) - Converted - by - AbcdpdfDocument3 pagesSPADA Soal Ujian Semester TK 1 EC D3 Sem 1 TA 2020 2021 (11) - Converted - by - AbcdpdfAlwin Arrahman NasutionNo ratings yet

- Astrophysics XIS 6545Document2 pagesAstrophysics XIS 6545Linchys_880% (1)

- Designing AV Automation For The Mediasite Rich Media RecorderDocument26 pagesDesigning AV Automation For The Mediasite Rich Media RecorderjohnemeryisiNo ratings yet

- Tractor Caterpillar d7r Renr5627 Renr5627 P Esquema HidraulicoDocument32 pagesTractor Caterpillar d7r Renr5627 Renr5627 P Esquema HidraulicoRuberli RJNo ratings yet

- En Safe Load GuidelinesDocument46 pagesEn Safe Load GuidelinesCEIT LogisticaNo ratings yet

- Sika Rokkon RB: Non Explosive Demolition AgentDocument2 pagesSika Rokkon RB: Non Explosive Demolition AgentIsnan Luthfi100% (1)

- K K K Automotive Training Center FacebookDocument1 pageK K K Automotive Training Center Facebookkyaw boNo ratings yet