Professional Documents

Culture Documents

Dms2015 Crolla Smarternodes

Dms2015 Crolla Smarternodes

Uploaded by

Rohit GadekarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dms2015 Crolla Smarternodes

Dms2015 Crolla Smarternodes

Uploaded by

Rohit GadekarCopyright:

Available Formats

Design Modelling Symposium Copenhagen 2015 Author Guidelines

Challenges of Scale in Modelling Material

Behaviour of Additive-Manufactured Nodes

Nicholas Williams, Daniel Prohasky, Jane Burry, Spatial Information Architecture Laboratory (SIAL), School of Architecture and

Design, RMIT University, Melbourne, Australia.

Kristof Crolla, Chinese University of Hong Kong, Hong Kong.

Martin Leary, Milan Brandt, Advanced Manufacturing Precinct (AMP), RMIT University, Melbourne, Australia.

Yi Min Xie, Hamed Seifi, Centre for Innovative Structures and Materials, RMIT University, Melbourne, Australia.

ABSTRACT

The application of Additive Manufacturing (AM) technologies promises much innovation across the manufacturing sector, and has

generated great interest in the Architecture, Engineering and Construction (AEC) industry. This paper presents and reflects upon

early prototypes for integrating AM in a construction application, through the design of a prototype frame structure with linear

members connected by nodes of unique shapes. As an enabler for design, a system is developed and implemented to integrate

expertise across architecture, structural engineering and advanced manufacturing in order to design and detail components for single

layer canopies. This includes the topology optimisation and additive manufacture of nodes, both of which require the control of

material behaviour at small scales. A scaled pavilion structure and full-scale node prototypes were successfully realised. However,

this first stage of research presented a number of challenges to modelling material behaviour across scales both the physical size

and production volumes.

INTRODUCTION

Figure 1. Stainless steel prototypes of proposed construction nodes.

Amidst much excitement about the potentials of additive manufacturing to change manufacturing, the construction industry presents

significant challenges of scale. These are both physical related to the size of buildings - and also in terms systems design, related to

1

Design Modelling Symposium Copenhagen 2015 Author Guidelines

production volumes suitable to the project by project context of the AEC industry. The research presented here takes a clear position

on each aspect of scale to explore a potential application for additive manufacturing in construction. To bypass limitations of

physical size, additive manufacturing is targeted at the relatively small, connection components, so-called nodes as part of larger

assembly. Embracing a manufacturing context of mass-customisation, each node is considered as a unique iteration derived from a

common design system.

A team of experts from across architectural design, structural design, topology optimisation and AM was assembled to address the

challenge of prototyping a design system and exemplar structure. The project aimed to integrate knowledge through connecting a

series of existing technologies and techniques, namely Selective Laser Melting (SLM) for additive manufacture, Bi-directional

Evolutionary Structural Optimisation (BESO) (Huang and Xie, 2010) for topology optimisation of node design, and parametric

models with lightweight analysis tools for architectural and structural design of building form and detailing.

A digital workflow was implemented, linking modules across a design and production process. With these tools, both full-scale

exemplar nodes printed in stainless steel (Fig. 1), and a pavilion structure at scale 1:5, constructed with timber beams linked by ABS

printed plastic nodes (Fig. 4), were realised. These early prototypes offer promise that such a system might be feasible in the

construction industry as technologies, in particular SLM additive manufacture, improve in terms of speed and cost.

Despite this promise, however, this early research raises significant further design questions. The project demands that node design

incorporates the modelling of material behaviour in multiple contexts. Firstly, current techniques abstract material behaviour in order

to optimise topologies in response to given load cases. While this reduces weight and material volume, manufacturing parameters are

not considered. Secondly, AM requires that material behaviour is controlled to ensure successful results. For further development,

the system needs to respond to manufacturing parameters to improve the design of nodes.

BACKGROUND

Additive Manufacturing in Metals

ASTM: F2792 - 12a (2012) defines AM as the "process of joining materials to make objects from 3D model data, usually layer upon

layer, as opposed to subtractive manufacturing methodologies, such as traditional machining. AM requires a Computer Aided

Design (CAD) representation of the intended geometry. This CAD data has traditionally been represented in Stereolithography (STL)

format (Gibson et al., 2010). However, enhanced data representations are under development, such as the Additive Manufacturing

Format (AMF) (ISO/ASTM, 2014). This AM data is then converted to a sequence of two-dimensional scan paths (Zhai, 2014) that

are sequentially processed by the AM process.

AM is an enabling technology with economic and technical attributes that allow design innovation including: reduced cycle times

and unit cost (Ruffo et al., 2006), repair of high-value components (Shepeleva et al., 2000), and manufacture of high efficiency

structures not compatible with traditional methods (Brandt et al., 2013). Plastic parts manufactured through Fused Deposition

Modelling (FDM) are nowadays common and accessible to non-expert users. Metal-based AM systems are less common but provide

opportunity for commercial benefit (Atzeni and Salmi, 2012; Atzeni et al., 2010).

Selective Laser Melting (SLM) applies a laser power source to selectively solidify powder in a powder-bed. SLM can process a range

of useful engineering materials including: high-strength and alloy steels; light alloys, including aluminium, titanium and magnesium;

and precious metals. Despite the associated design opportunities, SLM is subject to complex, dynamic manufacturing constraints. For

example, SLM melt pool dynamics and is governed by over 130 parameters (Rehme and Emmelmann, 2006). Furthermore, the

associated heat transfer is both spatially and temporally transient, resulting in significant challenges to the manufacture of

commercially robust components (Gu et al., 2012); especially associated with optimisation of orientation and distribution of support

materials (Brandt, et al., 2013; Leary, et al., 2014).

2

Design Modelling Symposium Copenhagen 2015 Author Guidelines

Node Precedents

Many in the AEC industry have identified that relatively small connection elements are key to the design of larger assemblies of

parts. This includes key examples of pre-fabricated , modular housing systems (Wachsmann, 1946); space frames (Bardell et.al.,

1996); and gridshell frames (Carlow and Crolla, 2013). This latter case presents particular challenges as nodes are highly varied to

meet angles of adjacent members.

The design of connection parts has also received attention in high-value automotive and aerospace design. As SLM technologies

have matured, designs have been proposed for key structural components in jet engine (Halchak et al., 2012), aerospace (Brandt et

al., 2013), and automotive (Cooper et al., 2012) that are incompatible with traditional manufacturing methods. These are designed to

replace existing components and exploit weight savings which can be achieved with optimised, additive manufactured parts. As

though parts are produced for runs of vehicles, multiple versions and design prototypes can be produced and tested.

A first proposal for such an application of AM in construction has been proposed for application to a node in a tensegrity structure

(Galjaard et al., 2015). This focusses on a case of a joint connecting a series of tension cables to a rigid member in compression. The

design of the part employed optimisation techniques to reduce weight and a first prototype has been manufactured using SLM

technology.

Design and Optimisation for Additive Manufacture

A number of preliminary studies have highlighted benefits of topology optimisation for additive manufacturing. Two techniques

have received particular attention BESO and SIMP (Aremu et al. 2010; Brackett et.al. 2011).

BESO routines, used here, develop optimal results through the iterative removal of inefficient material. A given design space is

divided into spatial volumes, typically a grid of voxels, and results can be determined for stress, stiffness and other factors (Yang et.

al., 2005, 957). This results in a minimisation of material volumes through specific and commonly freeform geometries. While these

shapes present challenges to manufacture using conventional technologies, AM bypasses many common limitations.

Design Modelling Symposium Copenhagen 2015 Author Guidelines

THE SMARTNODES DESIGN SYSTEM AND PROTOTYPES

Figure 2. Proposed design of a single layer canopy with standard beams connected to customised nodes.

A design system was conceived to link modules across architectural design, structural analysis and design, topology optimisation of

nodes and the generation of data for fabrication. Such a close linking a series of modules enables information to quickly flow both

downstream and upstream, offering improved designs through iterative input across many project details. Key to these systems is

consistent interfaces between modules, concisely defining data but with sufficient redundancy to enable flexibility (Marble, 2012,

130).

The design system was implemented, firstly, around a series of parametric models in McNeel Rhinoceros. In parallel to this, modules

were developed to undertake more detailed structural analysis and topology optimisation of nodes (Figure. 2). Agreed interfaces in a

neutral csv format describe firstly, the setout of axes across the form allowing them to be imported into GSA for structural analysis,

and later, results from this analysis of the model which were interpreted into Abaqus tools for BESO algorithms.

Design Modelling Symposium Copenhagen 2015 Author Guidelines

Figure 3. Key workflow structure showing modules and interface formats.

Through a custom interface created for Rhinoceros, a pavilion form was designed with linear members meeting at nodes. In order to

accommodate a freeform shape, each node was assumed to have a unique geometric set-out, connecting between three and five

beams in directions unconstrained by local conditions. The geometric setout was then exported in a neutral format for use in each

branch of the workflow.

Structural analysis in response to gravity loads was generated. The results produced by Karamba, a plugin for Grasshopper, were

compared to the results generated in the commercial structural design software Oasys GSA. The results correlated closely, with the

latter providing verification for results from the lightweight tools.

Using the lightweight tools, the 144 nodes of the structure were topology optimised using millipede, a plugin for Grasshopper. In

parallel, example nodes were identified and optimised in more detail for full-scale production. These parallel processes involved

significant differences in resolution. For lightweight analysis, starting forms were modelled as spheres of 35,000 voxels. BESO

algorithms were then run for six iterations, providing relatively simple topologies with crude levels of detail. This could be processed

in only a few minutes on a desktop computer. The resulting forms were suitable for additive manufacture as demonstrator

components at scale 1:5, providing minimum material thicknesses of 0.5mm. In some contrast to this, the BESO algorithms applied

to the full scale prototypes used a starting mesh with greater than 500,000 voxels. The three node cases, one connecting each of 3, 4

and 5 members, each required over 48 hours to process 100 iterations. Results were of a much finer grain and offer significantly

better outcomes, in terms of volume and weight, than the scaled versions.

The manufacturing of nodes through each of the parallel processes was undertaken. The scaled demonstrator nodes at 1:5 were

printed using a Stratasys Fortus printer. Support material was generated using proprietary Stratasys software and manufacture

required between 2 and 2.5 hours per part. At full scale, two of the three nodes were manufactured in stainless steel using an SLM

printer. Print times of greater than 40hrs were required for these. As well, further skilled labour was required to orient the part, design

support material and subsequently to remove this material after manufacture. Parts were successfully manufactured (Fig.1) however

some minor problems were encountered.

DISCUSSION

Flexibility for Customisation in Construction

Figure 4. The fabricated pavilion prototype at scale 1:5 showing (left) a network of beams and (right) a typical node manufactured by an FDM

machine.

The bifurcation of the project workflow into parallel streams was driven by pragmatic issues around managing levels of detail. As the

project developed, large model sizes and lengthy processing times were identified as threats to both feasibility and flexibility for

design. For example, taking the required BESO optimisation time of a full-scale node and applying it to the 144 node scenarios

5

Design Modelling Symposium Copenhagen 2015 Author Guidelines

across the pavilion would require many days using current computers. Even assuming improvements in computer processing, a

relatively lightweight process is required to be feasible for a volume of parts such as this.

The manufacture of 144 nodes with FDM machines was straightforward, with all jobs successfully completed and parts within

tolerance (Figure 4.). This demonstrates file to factory principles which promise customised manufacture and flexibility in design.

In comparison to this, the SLM technology applied to the full scale parts is relatively new and caution has been advised in drawing

simple comparisons between the two (Brewster, 2014). Given this context, it was unsurprising that some problems were experienced.

Firstly, incorrect humidity levels caused failure through material slumping in one job. The second problem centres on difficulties in

orienting the complex forms for printing. The design of an adequate support structure to ensure successful manufacture proved very

challenging, and the proposals contained excessive amounts of material. As a result a prototype of a 5-sided node was not attempted.

These technical challenges to SLM demand further development of the technology for consideration in commercial construction.

Much research is being pursued in this area and it is foreseeable that these issues will be largely overcome. Beyond this, however,

human labour required for designing and removing support material is a significant impost to SLM manufacture. To enable

flexibility for customised manufacture, this labour must be significantly reduced through algorithms using rules of thumb to

automate orientation and design of efficient support structures.

Optimisation for Broader Criteria

BESO optimisation techniques are conceived to address a given set of load cases. Simulations typically use stopping conditions

related to material stress or volume. While such optimisation techniques are highly sophisticated, the optimisation criteria addressed

here reflect only a fraction of broader design issues being addressed. Simply, weight and volume are not directly proportional to

economic issues underlying manufacture.

The challenges in SLM manufacture encountered in this research suggest that the inclusion of manufacturing parameters in

optimisation processes would be of benefit. It is conceivable that suitable orientation of parts could be automated in response to

geometric analysis. Once a suitable orientation is identified, support material could be generated for required areas using rules of

thumb. Algorithms for generating efficient support structures for FDM printing are available through softwares such as Autodesk

Meshmixer. Future research will explore whether similar ideas can be applied to SLM.

In opposition to this, however, this research also highlights significant computation time. As a result, the simple addition of further

optimisation criteria and routines is not straightforward. Trade-offs between computation time for optimisation routines, and the

material, labour and time for manufacturing must be negotiated. The consideration of broader criteria might alternatively lead to

exploration of other optimisation strategies.

CONCLUSION

Through the study of parallel workflows applying both BESO and AM to the design of components at different scales, this paper

highlights challenges in modelling material behaviour at an architectural scale. Scale parts using relatively simple optimisation

routines and mature FDM technology were rapidly realised. This offers significant customisation and flexibility in the design of built

form. However, for full-scale components using relatively complex BESO optimisation and SLM manufacture, technical challenges

were encountered and design and production times were excessive.

This suggests that recent claims that AM allows architects to design at the scale of matter are overly simplistic. While it is possible to

design highly detailed parts, the sheer size of a building requires that designers are strategic in identifying key components for such a

level of attention. Further to this, the short production volumes and high degrees of customisation typical to construction demand

flexibility in manufacturing. This requires robust processes (Piller, 2013) with many challenges still ahead for AM in metals to meet

such a context.

Design Modelling Symposium Copenhagen 2015 Author Guidelines

REFERENCES

ASTM F2792 - 12a, Standard Terminology for Additive Manufacturing Technologies, West Conshohocken, 2012.

ISO/ASTM 52915:2013 Standard specification for additive manufacturing file format (AMF) Version 1.1, 2014.

Aremu, A. et al. (2010): Suitability of SIMP and BESO Topology Optimization Algorithms for Additive Manufacture, 21st Annual

International Solid Freeform Fabrication Symposium (SFF) An Additive Manufacturing Conference, Austin, Texas, 679-692.

Atzeni. E. and Salmi, A. (2012): Economics of additive manufacturing for end-usable metal parts, Int. J. Adv. Manuf. Technol., vol.

62, no. 912, pp. 11471155.

Atzeni, E., Iuliano, L., Minetola, P., and Salmi, A. (2010): Redesign and cost estimation of rapid manufactured plastic parts, Rapid

Prototyp. J., vol. 16, no. 5, pp. 308317.

Bardell, N. et. al, (1996): The Development of MURJ-3D: A Modular, Universal, Reconfigurable Joint for in 3D Space Frame

Applications, International Journal of Space Structures, 2(12), pp.89-107.

Brewster, S.(2014): Why you wont see a laser sintering printer on your desk any time soon, https://gigaom.com/2014/04/25/whyyou-wont-see-a-laser-sintering-3d-printer-on-your-desk-anytime-soon, accessed 29/04/14.

Carlow, J. and Crolla, K. (2013): Shipping Complexity: Parametric Design for Remote Communities, in Zhang et.al. [eds.], Global

Design and Local Materialization, 15th International Conference, CAAD Futures 2103, Shanghai, China, July 3-5, 2013,

Proceedings, Springer, New York

Galjaard, S., Hoffman, S. Ren, S. (2015): New Opportunities to Optimize Structural Designs in Metal by Using Additive

Manufacturing, in P. Block et al. (eds.), Advances in Architectural Geometry 2014, SpringerSwitzerland, pp. 79-92

Gibson, I., Rosen, D., and Stucker, B. (2010): Chapter 11 - Additive Manufacturing Technologies in Additive Manufacturing

Technologies Rapid Prototyping to Direct Digital Manufacturing, Boston, MA: Springer US.

Gu, D., Meiners, W., Wissenbach, K. and Poprawe, R. (2012): Laser additive manufacturing of metallic components: materials,

processes and mechanisms, Int. Mater. Rev., vol. 57, no. 3, 133164.

Halchak, J, Wooten, J, McEnerney, B, (2012): Layer build of titanium alloy complex-geometry components for rocket engines, Ti

2011 - Proceedings of the 12th World Conference on Titanium, Vol. 3, Beijing; China, 1715-1718,.

Huang, X. and Y.M. Xie (2010), Evolutionary Topology Optimization of Continuum Structures: Methods and Applications. John

Wiley & Sons, Chichester, England.

Leary, M., Merli, L., Torti, F., Mazur, M., Brandt, M. (2014): Optimal topology for additive manufacture: A method for enabling

additive manufacture of support-free optimal structures, Materials & Design 63, 678-690

Marble, S., Ed. (2012). Digital worklows in architecture : designing design - designing assembly - designing industry. Basel, Basel :

Birkhuser.

Piller, F. (2013): Three capabilities that make mass-customisation work in Piroozfar, P.; Piller, F. T. [eds.], Mass Customisation and

Personalisation in Architecture and Construction, Routledge, New York, pp. 17-30.

Rehme, O. and Emmelman, C. (2006): Rapid manufacturing of lattice structures with Selective Laser Melting, in Solid Freeform

Fabrication, vol. 6107, p. 61070K61070K12.

Ruffo, M., Tuck, C. and Hague, R. (2006): Cost estimation for rapid manufacturing-laser sintering production for low to medium

volumes, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., vol. 220, no. 9, pp. 14171427.

Yang, X., Xie, Y.M., Steven, G. (2005): Evolutionary Methods for topology optimisation of continuous structures with design

dependent loads, Computers and Structures, 83, Elsevier, 956-963.

Zhai, Y., Lados, D., and LaGoy, J. (2014): Additive Manufacturing: Making Imagination the Major Limitation, JOM, vol. 66, no. 5,

pp. 808816.

You might also like

- Estimation Cost For DMLSDocument13 pagesEstimation Cost For DMLSfasihahNo ratings yet

- Logistics Quality ManualDocument25 pagesLogistics Quality ManualbmkallarackalNo ratings yet

- Additivemanufacturing 2023-24: Department of Mechanical Engineering 1Document15 pagesAdditivemanufacturing 2023-24: Department of Mechanical Engineering 1raveshrathod061No ratings yet

- Support Structure Constrained Topology Optimization For Additive ManufacturingDocument38 pagesSupport Structure Constrained Topology Optimization For Additive ManufacturingJon SnowNo ratings yet

- Rohini 15111698981Document12 pagesRohini 15111698981Kishore ImmanvelNo ratings yet

- Additive Manufacturing A Framework For ImplementationDocument8 pagesAdditive Manufacturing A Framework For Implementationnicero555No ratings yet

- 2017 Lattice Structure DesignDocument15 pages2017 Lattice Structure DesignYusuf YamanerNo ratings yet

- Neural NetworkDocument14 pagesNeural NetworkSimachew addisuNo ratings yet

- 1 s2.0 S0079642521001420 MainDocument43 pages1 s2.0 S0079642521001420 MainOğuzhan DündarNo ratings yet

- Numero 59 Art 13Document16 pagesNumero 59 Art 13mulualemNo ratings yet

- Robotics and Computer Integrated ManufacturingDocument11 pagesRobotics and Computer Integrated ManufacturingIrfan IsdhiantoNo ratings yet

- Literature Review On Additive ManufacturingDocument5 pagesLiterature Review On Additive Manufacturingc5m8rk4d100% (1)

- Redesign and Topology Optimization of An Industrial Robot Link For Additive ManufacturingDocument10 pagesRedesign and Topology Optimization of An Industrial Robot Link For Additive ManufacturingGogyNo ratings yet

- Additive Manufacturing: Ajit Panesar, Meisam Abdi, Duncan Hickman, Ian AshcroftDocument14 pagesAdditive Manufacturing: Ajit Panesar, Meisam Abdi, Duncan Hickman, Ian AshcroftrahulNo ratings yet

- XXXXXXXXXXXX Proof XXXXXXXXXXXXXXXDocument16 pagesXXXXXXXXXXXX Proof XXXXXXXXXXXXXXXficuniNo ratings yet

- Engineering: Research Additive Manufacturing-ReviewDocument9 pagesEngineering: Research Additive Manufacturing-Reviewuday vermaNo ratings yet

- Modelling and Characterization of A Porosity Graded Lattice Structure For Additively Manufactured BiomaterialsDocument20 pagesModelling and Characterization of A Porosity Graded Lattice Structure For Additively Manufactured BiomaterialsRob GNNo ratings yet

- Computer Aided Design For Additive Manufacturing of Cellular StructuresDocument11 pagesComputer Aided Design For Additive Manufacturing of Cellular StructuresthlpapNo ratings yet

- (2015) 1combining Additive Manufacturing With CFRPDocument13 pages(2015) 1combining Additive Manufacturing With CFRPvinay kumarNo ratings yet

- Materials 16 05422Document17 pagesMaterials 16 05422Amit RohilaNo ratings yet

- Design and Development of Cellular Structures For Additive ManufacturingDocument10 pagesDesign and Development of Cellular Structures For Additive ManufacturingSeçkin KoçNo ratings yet

- Hippopotamus Optimization Algorithm: A Novel Nature Inspired Optimization AlgorithmDocument18 pagesHippopotamus Optimization Algorithm: A Novel Nature Inspired Optimization Algorithmkamel BousninaNo ratings yet

- Cost Optimisation of The Design of ReinfDocument15 pagesCost Optimisation of The Design of ReinfALINo ratings yet

- 3d Printing of Column Structures For Architectural ApplicationsDocument10 pages3d Printing of Column Structures For Architectural Applicationslethao2011No ratings yet

- Practical Design Optimization of Truss Structures Using The Genetic AlgorithmsDocument12 pagesPractical Design Optimization of Truss Structures Using The Genetic AlgorithmsYoyok SetyoNo ratings yet

- Digital Twin-Enabled Collaborative Data Management For Metal AdditiveDocument18 pagesDigital Twin-Enabled Collaborative Data Management For Metal Additivedecardo.ivander.simarmataNo ratings yet

- A CAD Toolbox For Composite Materials Modelling and DrawingDocument9 pagesA CAD Toolbox For Composite Materials Modelling and DrawingAdrian BerghorstNo ratings yet

- 3D Printing of Aluminium Alloys Additive Manufacturing of Aluminium Alloys Using Selective Laser MeltingDocument45 pages3D Printing of Aluminium Alloys Additive Manufacturing of Aluminium Alloys Using Selective Laser MeltingGonçalo MonteiroNo ratings yet

- Applsci 13 13218Document17 pagesApplsci 13 13218bareya.eztuNo ratings yet

- Materials Science & Engineering ADocument14 pagesMaterials Science & Engineering AAnonymous 5AmJ13mLkNo ratings yet

- latticestructuredesignforAM Researchgate PDFDocument9 pageslatticestructuredesignforAM Researchgate PDFGunaseelanMurugesanNo ratings yet

- AcceptedManuscript LCA WAAM BekkerVerlindenDocument19 pagesAcceptedManuscript LCA WAAM BekkerVerlindenvenkatsrNo ratings yet

- Computational Modelling of Process Structure Property Performance Relationships in Metal Additive Manufacturing A ReviewDocument47 pagesComputational Modelling of Process Structure Property Performance Relationships in Metal Additive Manufacturing A ReviewVenkatesh PandianNo ratings yet

- Design and Development of An Additive Manufactured Component by Topology OptimisationDocument6 pagesDesign and Development of An Additive Manufactured Component by Topology OptimisationJon SnowNo ratings yet

- A Knowledge-Based Master Modeling Approach To System Analysis and DesignDocument10 pagesA Knowledge-Based Master Modeling Approach To System Analysis and DesignHeribertoNo ratings yet

- Developments in Large Scale Additive Manufacture - The Potential and Limitations of Wire Arc Additive Manufacture and Associated TechnologiesDocument5 pagesDevelopments in Large Scale Additive Manufacture - The Potential and Limitations of Wire Arc Additive Manufacture and Associated TechnologiesBita MohajerniaNo ratings yet

- Shaft-Hub Couplings With Polygonal Profiles - Citarella-Gerbino2001Document8 pagesShaft-Hub Couplings With Polygonal Profiles - Citarella-Gerbino2001sosu_sorin3904No ratings yet

- Lattice Structure Design For AmDocument9 pagesLattice Structure Design For AmNishar Alam Khan 19MCD0042No ratings yet

- Metals 13 01138Document23 pagesMetals 13 01138ชลธิชา โยชาลีNo ratings yet

- Additive Manufacturing - Technology Applications and Research NeedsDocument29 pagesAdditive Manufacturing - Technology Applications and Research NeedsCRISA3000000No ratings yet

- AM Using RobotsDocument13 pagesAM Using RobotsNhung Nguyễn HồngNo ratings yet

- A Review On Additive ManufacturingDocument10 pagesA Review On Additive ManufacturingKamlesh RanaNo ratings yet

- Artigo 9Document15 pagesArtigo 9Edmilson LimaNo ratings yet

- Integrated Process Simulation and Die-Design in Sheet Metal FormingDocument10 pagesIntegrated Process Simulation and Die-Design in Sheet Metal FormingsilvermeccatiaNo ratings yet

- Advanced Composite Engineering Using MSC - Patran and FibersimDocument15 pagesAdvanced Composite Engineering Using MSC - Patran and FibersimSandeep BandyopadhyayNo ratings yet

- Dilberoglu 2021Document26 pagesDilberoglu 2021Ivan La Fe PerdomoNo ratings yet

- 1 s2.0 S1000936120304520 MainDocument20 pages1 s2.0 S1000936120304520 MainFlávia de Souza BastosNo ratings yet

- Materials 15 01838 v2Document11 pagesMaterials 15 01838 v2Seçkin KoçNo ratings yet

- Additive Manufacturing of Materials Opportunities and Challenges (2015)Document8 pagesAdditive Manufacturing of Materials Opportunities and Challenges (2015)Tiago Camargo AlvesNo ratings yet

- 7-2018-Experimental Testing and Numerical Analysis of FDM Multi-Cell Inserts Andhybrid StructureDocument16 pages7-2018-Experimental Testing and Numerical Analysis of FDM Multi-Cell Inserts Andhybrid StructureLeyton DanyNo ratings yet

- 3D STM OptimizeDocument18 pages3D STM OptimizeTùng HìNo ratings yet

- Computer-Aided Design: Dawei Li, Wenhe Liao, Ning Dai, Guoying Dong, Yunlong Tang, Yi Min XieDocument13 pagesComputer-Aided Design: Dawei Li, Wenhe Liao, Ning Dai, Guoying Dong, Yunlong Tang, Yi Min XieMoad BouzidaNo ratings yet

- Knowledge-Based System On Optimum Design of Liquid Retaining Structures With GeneticDocument23 pagesKnowledge-Based System On Optimum Design of Liquid Retaining Structures With GeneticPiyush GaikwadNo ratings yet

- Topology Optimization Using Additive Manufacturing ConstraintsDocument22 pagesTopology Optimization Using Additive Manufacturing ConstraintsManoj NehraNo ratings yet

- MT 210081Document12 pagesMT 210081s.rebecchiNo ratings yet

- Multi-Objective Optimization of Reinforced Concrete Frames Using Nsga-Ii AlgorithmDocument8 pagesMulti-Objective Optimization of Reinforced Concrete Frames Using Nsga-Ii AlgorithmAusbel Joab Cuyo TtitoNo ratings yet

- Paper 18Document44 pagesPaper 18FelipeArroyo21No ratings yet

- SMiRT 25 Special Session Kobe Cerisano KovacevicDocument10 pagesSMiRT 25 Special Session Kobe Cerisano KovacevicbaizidffffNo ratings yet

- Buildings: Optimum Design of RC Footings With Genetic Algorithms According To ACI 318-19Document17 pagesBuildings: Optimum Design of RC Footings With Genetic Algorithms According To ACI 318-19Muhammed M.HNo ratings yet

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresFrom EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNo ratings yet

- NutDocument12 pagesNutRohit GadekarNo ratings yet

- 02 Bolt TighteningDocument2 pages02 Bolt TighteningRohit GadekarNo ratings yet

- Material-Datasheet Saarstahl - C15Document1 pageMaterial-Datasheet Saarstahl - C15Rohit GadekarNo ratings yet

- Gear Crack Propagation Investigations: Iqgo LaloDocument16 pagesGear Crack Propagation Investigations: Iqgo LaloRohit GadekarNo ratings yet

- Detecting Gear Tooth Fatigue Cracks in Advance of Complete FractureDocument18 pagesDetecting Gear Tooth Fatigue Cracks in Advance of Complete FractureRohit GadekarNo ratings yet

- A Unified Curvature Theory in Kinematic Mechanism PDFDocument7 pagesA Unified Curvature Theory in Kinematic Mechanism PDFRohit GadekarNo ratings yet

- For Isotropic PlatesDocument5 pagesFor Isotropic PlatesRohit GadekarNo ratings yet

- 152 1199 2 PB PDFDocument16 pages152 1199 2 PB PDFRohit GadekarNo ratings yet

- Flexpip4 PDFDocument16 pagesFlexpip4 PDFdevpal78No ratings yet

- Gujarat Maharashtra List Non ITDocument205 pagesGujarat Maharashtra List Non ITContact PG100% (1)

- Pipe SupportsDocument87 pagesPipe SupportsVeeramanikandanNo ratings yet

- Essae Taeroka DS451Document4 pagesEssae Taeroka DS451Ganesh BabuNo ratings yet

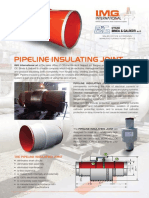

- IMG Scheda ISOLATION-JOINTS Web PDFDocument2 pagesIMG Scheda ISOLATION-JOINTS Web PDFdevpal78No ratings yet

- Preventing Air Bubbles in Epoxy ResinDocument4 pagesPreventing Air Bubbles in Epoxy ResinApitNo ratings yet

- Iso 20crmo4Document2 pagesIso 20crmo4Kumar SanthanamNo ratings yet

- Types of Steel BarsDocument6 pagesTypes of Steel BarsvitamkupaNo ratings yet

- Process Flow of Cutting and Cutting EquipmentDocument8 pagesProcess Flow of Cutting and Cutting EquipmentarunkadveNo ratings yet

- Water Proofing - W02 - Work Method StatementDocument3 pagesWater Proofing - W02 - Work Method StatementJohn Rhey Lofranco TagalogNo ratings yet

- Steel Section SizesDocument96 pagesSteel Section Sizesabbasshaikh21682No ratings yet

- OptDocument1 pageOptDarkedgeNo ratings yet

- Machine Design Chap1 2012Document16 pagesMachine Design Chap1 2012Anirban SardarNo ratings yet

- Production ProcessDocument4 pagesProduction ProcessLeo MilosevNo ratings yet

- MECH 6541 - Quiz 2 2017Document15 pagesMECH 6541 - Quiz 2 2017Abhay Shankar MishraNo ratings yet

- ASCOM HiPer Sand Removal CycloneDocument1 pageASCOM HiPer Sand Removal CycloneShawn AngNo ratings yet

- Structural Properties.Document15 pagesStructural Properties.Doroty CastroNo ratings yet

- 2014 LTA CatalogDocument12 pages2014 LTA Catalogjerimiah_manzonNo ratings yet

- Gas Assisted Injection MoldingDocument10 pagesGas Assisted Injection MoldingMarioNo ratings yet

- ARIFLEXDocument8 pagesARIFLEXRiyas Udheen50% (2)

- Plastic Link March 2016Document4 pagesPlastic Link March 2016WalidNo ratings yet

- Evolution of Quality Control PDFDocument2 pagesEvolution of Quality Control PDFMatt0% (1)

- ShoringDocument4 pagesShoringPraveenkumar ShanmugamNo ratings yet

- Steel Making - Open-Hearth TehniqueDocument5 pagesSteel Making - Open-Hearth TehniqueMarcelo Rodriguez FujimotoNo ratings yet

- Production Conventional Question and AnswerDocument10 pagesProduction Conventional Question and AnswerRamesh ChandraNo ratings yet

- Appendix B3-05 Welding Procedure Specification ENB-MA-WPS-5 Rev. 0 - A4A2E4Document14 pagesAppendix B3-05 Welding Procedure Specification ENB-MA-WPS-5 Rev. 0 - A4A2E4Fadil WimalaNo ratings yet

- Enhancing White and Colored Concrete With MetaMaxDocument3 pagesEnhancing White and Colored Concrete With MetaMaxm.shahbaghiNo ratings yet

- Viw Lesson PlanDocument5 pagesViw Lesson PlanMohamed AlkhawagaNo ratings yet

- SHPbrochure (Rev-01,2014 2 16)Document8 pagesSHPbrochure (Rev-01,2014 2 16)Epure GabrielNo ratings yet