Professional Documents

Culture Documents

Farasan

Farasan

Uploaded by

mOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Farasan

Farasan

Uploaded by

mCopyright:

Available Formats

IPMI

MSA

Epoxy Glue Coupling

ISOICO

NIOC

Pars Oil & Gas Company

Payandan Co.

NIDC

Contract No.: POGC 653-89-35

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

NATIONAL IRANIAN OIL COMPANY

SOUTH

PARS GAS

FIELD DEVELOPMENT

(

AP

)

Issue Purpose:

Result Code: AP, AC, CO, RE, NC

Next Status: IFA, IFI, IFR, AFC, As Built (

Resubmission Date: (

PHASE 14

Approval or review hereunder shall not be construed to

TOMBAK-ONHSORE

relieve Vendor / Subcontractor of his responsibilities

and

FACILITIES

liability under the contract

CP Department:

Responsible Department:

Issue Purpose

Result Code : AP, AC, CO, RE

Next Status: FA, FI, FR, AFC, AB

Approval or review hereunder shall not be construed to

relieve Vendor / Subcontractor of his responsibilities and

liability under the contract.

Responsible Department

Document No.:

VP-14-999-1360-500-G011

Commented Date:

DOCUMENT TYPE

: Transmittal

DOCUMENT TITLE

DOCUMENT NUMBER

: Epoxy Glue Coupling

: VP-14-999-1360-500 -G011

SITE

: TOMBAK/ SOUTH PARS GAS FIELD DEVELOPMENT, PERSIAN GULF, IRAN

22-May-2012

Issued for Information

IPMI

N.M

M.S

H.ZH

P.T.B

REV

Date

DESCRIPTION

ORIG.

PRPD

CHKD

APPD

CONTRACTOR

APPD

IPM

NID

Payandan Co.

Page 1 of 17

IPMI

MSA

Epoxy Glue Coupling

ISOICO

NIOC

Pars Oil & Gas Company

Payandan Co.

NIDC

Contract No.: POGC 653-89-35

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

REVISION RECORD SHEET

Revision

Sheet

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Revision

5

Remark

Sheet

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

IPM

NID

Payandan Co.

Page 2 of 17

Remark

IPMI

MSA

NIDC

ISOICO

Epoxy Glue Coupling

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

NIOC

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

Table of Contents

Page

1.0 Scope

2.0 Definition

3.0 Reference

4.0 Introduction

4.1 Tools and Equipment

5.0 Installation Procedure

6.0 Curing

14

Attachment 1

16

IPM

NID

Payandan Co.

Page 3 of 17

IPMI

MSA

NIDC

Epoxy Glue Coupling

ISOICO

NIOC

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

1.0 SCOPE

This Documents Covers Adhesive Bonded Taper / taper Joint and FARASSAN Adhesive Kit

Instruction (Epoxy Glue Coupling Procedure).

2.0 DEFINITION:

For the purpose of this Requisition, the definitions shall apply:

PROJECT: South Pars Gas Field Development, Phase 14 onshore facilities

COMPANY (OWNER): Pars Oil and Gas Company (POGC)

CONTRACTOR / PURCHASER: IPMI Company

VENDOR: Farassan Man. & Ind. Company

3.0 REFERENCE

LIST OF STANDARDS AND CODES

The design, construction and inspection of Fiberglass Reinforced Plastic (FRP) pipes and

fittings produced by FARASSAN company are made under the latest revision of following

codes and standards:

ASTM (American Society for Testing and Materials)

ASTM D3517

Fiberglass Pressure Pipe

ASTM D3262

Standard Specification for Fiberglass Pipe and Fittings

ASTM D4161

Standard Specification for Fiberglass Pipe Joints Using Flexible

Electrometric Seals

ASTM D2996

Specification for filament wound reinforced thermosetting resin pipe

ASTM D2412

Test for external loading properties of plastic pipe by parallel - Plate

loading

ASTM D2471

Test for gel time and peak exothermic temperature of reacting

thermosetting resins

ASTM D2105

Test for longitudinal tensile properties of reinforced thermosetting plastic

pipe and tube

ASTM D2122

Determining dimensions of thermoplastic pipe and fittings

IPM

NID

Payandan Co.

Page 4 of 17

IPMI

MSA

NIDC

NIOC

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

ASTM D2992

Epoxy Glue Coupling

ISOICO

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

Obtaining hydrostatic design basis for reinforced thermosetting resin pipe

and fittings

ASTM D3567

Standard Practice for Determining Dimensions of Fiber Glass (GlassFiber-Reinforced Thermosetting-Resin) Pipe and Fittings

ASTM D570

Test for water absorption of plastics

ASTM D648

Standard Test Method for Deflection Temperature of Plastics Under

Flexural Load in the Edgewise position

ASTM D2310

Standard Classification for Machine-Made "Fibreglass" (Glass-FiberReinforced Thermosetting-Resin) Pipe

ASTM D2563

Standard Practice for Classifying Visual Defects in Glass-Reinforced

Plastic Laminate Parts

ASTM D2583

Test for indentation hardness of rigid plastics by means of a Barcol

impressor.

ASTM D2143

Standard test Method for Cyclic Pressure Strength of Reinforced,

thermosetting Plastic Pipe

ASTM D2343

Test for tensile properties of glass fibre strands, yarns and rovings used

in reinforced plastics

ASTM D2584

Test for ignition loss of cured reinforced resins.

ASME (American Society of Mechanical Engineers)

ASME B31.3

Chemical plant and petroleum refinery piping

ASME B16.5

Steel pipe flanges and flanged fittings

ISO (International Organization for Standardization)

ISO 10639

Plastic piping system for pressure and non pressure water supply

ISO 7005-1

Metallic flanges

ISO 14692-1

Petroleum and Natural Gas Industries Glass Reinforced Plastic Piping

Part 1: Vocabulary, Symbols, Applications and Materials

ISO 14692-2

Petroleum and Natural Gas Industries Glass Reinforced Plastic Piping

Part 2: Qualification and Manufacture

IPM

NID

Payandan Co.

Page 5 of 17

IPMI

MSA

NIDC

NIOC

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

ISO 14692-3

Epoxy Glue Coupling

ISOICO

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

Petroleum and Natural Gas Industries Glass Reinforced Plastic Piping

Part 3: System Design

ISO 14692-4

Petroleum and Natural Gas Industries Glass Reinforced Plastic Piping

Part 4: Fabrication, Installation and Operation

AWWA (American Water Works Association)

AWWA C950

Fiberglass Pressure Pipe

AWWA M-45

Fiberglass Pipe Design Manual

API (American Petroleum Institute)

API 15 LR

Specification for Low Pressure fiberglass Line Pipe

ISIRI (Institute of Standards and Industrial Research of Iran)

ISIRI 10729

Plastics- "Fiberglass" (glass reinforced thermosetting resin "GRP")

pressure pipes applicable in water supply systems-Specifications and test

methods

ISIRI 10730

Plastics- "Fiberglass" (glass reinforced thermosetting resin "GRP") nonpressure pipes applicable in gravity sewerage systems-Specifications and

test methods

Others

IPS-E-TP-740

Engineering Standard for Piping Materials Selection Requirements for

Glass Fiber Reinforced Epoxy Pipe and Fitting

Project Specification

RP-14-999-1300-027

Glass Reinforced Plastic Piping Materials(Tubes and Accessories)

Job Specification

DI-14-999-1360-500-P

Material Requisition for GRP Pipes

DI-14-999-1360-505-P

Material Requisition for GRP Fittings

DI-14-999-1360-510-P

Material Requisition for GRP Flanges

IPM

NID

Payandan Co.

Page 6 of 17

IPMI

MSA

NIDC

Epoxy Glue Coupling

ISOICO

NIOC

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

4. Introduction

FARATEC Bell & Spigot adhesive bonded pipe is designed for diameter25-800 mm. The pipes

are designed for biaxial system and covers pressure from 1-32 bar. These kinds of pipes are

suitable for aboveground and also underground system without trust blocks.

All Pipes will be produced with one female side (bell) and one male side (spigot) with factory

spigot calibration

All Fittings will be with only female side (bell)

Adaptors will be with both sides as female (bell)

4.1.Tools and equipment

Epoxy glue, FARATEC approved type

Balance weight (5Kg) / Volumetric flask (beaker)

Grinding drum diameter 25 to 50

Rolled grinding paper, grit 40 to 80

High speed die grinder

Angle cutter

Saw blade for GRP

Grinding disk grit 40 to 80

Putty knife

IPM

NID

Payandan Co.

Page 7 of 17

IPMI

MSA

NIDC

ISOICO

Epoxy Glue Coupling

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

Doc. No.: VP-14-999-1360-500- G011

Safety equipment (Glass, dust mask, Gloves )

Acetone

Cloths

Come along jack

Pot 1 to 2 Litter

Hammer

Flexible belt strap

Epoxy Glue

Grinding Tools

Accessories

IPM

NID

NIOC

Payandan Co.

Page 8 of 17

Rev.: 0

Class: 3

IPMI

MSA

NIDC

ISOICO

NIOC

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

Epoxy Glue Coupling

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

Accessories

5. Installation procedure

x

The Bell & Spigot pipes has standard wooden package from factory for pipe sizes below 600

mm. It is recommended to use this wooden package for loading, unloading or transportation

and also keep pipes in package while storing.

For pipe sizes above 600mm handling should be done according to Farassans handling &

installation instruction.

IPM

NID

Payandan Co.

Page 9 of 17

IPMI

MSA

NIDC

NIOC

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

Epoxy Glue Coupling

ISOICO

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

Before installation take out pipe one by one and place them along the trench or pipe rack side.

It should be considered to keep these pipes in clean and dry area to avoid extra cleaning and

drying at the bell or spigot side.

Note: safety shall be always considered, so wearing safety glasses, gloves and dust mask is

required.

Bell and spigot area which will have contact with glue shall be grinded properly.

Die Grinder with long neck is recommended for grinding inside of bell.

The spigot is grinded from factory so only refreshing surface by grinding paper is required .

IPM

NID

Payandan Co.

Page 10 of 17

IPMI

MSA

NIDC

ISOICO

Epoxy Glue Coupling

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

NIOC

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

Normal disc grinder is recommended for onsite calibration. For Grinding of spigot, the spigot

edge should have the same shape as bell.

Note: Before mixing adhesive bond components, make sure that bell and spigot areas are

clean; else clean those areas with Acetone and some cloths

x

Bonding paste and hardener should be mixed in a ratio specified by glue procedure.

The ratio is given as instructions on the package or technical datasheets. To obtain proper

homogen mixture use plastic/wood/steel stirrer.

Alternatives for mixing bonding paste and hardener:

Balance weight

Use balance weight and add correct amount of bonding paste and hardeners.

IPM

NID

Payandan Co.

Page 11 of 17

IPMI

MSA

NIDC

ISOICO

Epoxy Glue Coupling

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

NIOC

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

Scale (volume)

Use volumetric flask (beaker) and add each component to reach correct volume of each

component.

Volume

Mark two different pot according to the required volume then fill each component in each pot

up to the marked line then pour them in different (third) pot and mix them together.

Use wooden sticks or putty knife and apply glue in an even thickness of 2-3 mm to the surface

of spigot and 1-2mm inside of bell and make sure that all the area is covered with glue.

Chamfered area is the most important to get proper glue distribution.

IPM

NID

Payandan Co.

Page 12 of 17

IPMI

MSA

NIDC

NIOC

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

Epoxy Glue Coupling

ISOICO

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

Insert spigot pipe into the bell by only pushing and no twisting of pipe under

installation; make sure that spigot is in place, recommended to force the pipes together

by controlled use of hammer and piece of wood to protect the pipe .avoid applying

higher force than needed, high energy from hammering can damage pipe.

For larger diameter it can use come along jack and belt around pipe to pull pipe

together. By this method the force from jacks keeps the bell spigot in correct position

and there will be no need for hammering.

After joining pipes, while curing of glue, the pipes should have no movement to avoid

cracks and voids in the glued area.

IPM

NID

Payandan Co.

Page 13 of 17

IPMI

MSA

NIDC

Epoxy Glue Coupling

ISOICO

NIOC

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Class: 3

6. Curing

Bonding paste has an exothermic reaction and by its releasing heat will be cured. Curing time

also depends on applied temperature to the adhesive bond.

The curing time at room temperature (25 C) is at least 24 hour. By applying heat to the joint

the curing time will be reduced. At a curing temperature of 80 C the curing time will be

approximately 6-8 hour.

Required Glue for Bell & Spigot Pipes

No.

DN(mm)

PN(bar)

1

2

3

4

5

6

7

8

9

10

11

12

100

150

200

250

300

350

400

450

500

550

600

650

10

10

10

10

10

10

10

10

10

10

10

10

IPM

NID

Payandan Co.

Page 14 of 17

Required

Glue(gr)

116

173

320

404

583

1082

1234

1465

1769

2037

2410

2840

IPMI

MSA

NIDC

Epoxy Glue Coupling

ISOICO

NIOC

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

Doc. No.: VP-14-999-1360-500- G011

13

14

15

700

750

800

10

10

10

Rev.: 0

Class: 3

3255

3696

4169

Curing System

Gel Time(min)

50-60

Cobalt 10%

0.5 phr

DMA 100%

0.5 phr

Catalyst(LPT)

10 phr

phr: Per Hundred Gram Glue

Note : These values are determined in 25C and humidity 50%. Daily checking is essential. The

values will change over time and ambient temperature and humidity.

IPM

NID

Payandan Co.

Page 15 of 17

IPMI

MSA

NIDC

ISOICO

Epoxy Glue Coupling

NIOC

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

Doc. No.: VP-14-999-1360-500- G011

Rev.: 0

Attachment 1

Data sheet for Adhesive bonded Bell 7 Spigot Joint System

IPM

NID

Payandan Co.

Page 16 of 17

Class: 3

IPMI

MSA

NIDC

ISOICO

Epoxy Glue Coupling

Pars Oil & Gas Company

Payandan Co.

Contract No.: POGC 653-89-35

Doc. No.: VP-14-999-1360-500- G011

IPM

NID

NIOC

Payandan Co.

Page 17 of 17

Rev.: 0

Class: 3

You might also like

- SAEP-387 Design of Thermoplastic Tight Fit GroovedDocument23 pagesSAEP-387 Design of Thermoplastic Tight Fit GroovedFlorante Nobleza100% (4)

- Quality Procedure For Dual FBE Coating Rev.01Document39 pagesQuality Procedure For Dual FBE Coating Rev.01Nebu Mathew100% (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- 05-Division 2-Section 02200 GRP Pipelines Materials-Ver 2.0Document30 pages05-Division 2-Section 02200 GRP Pipelines Materials-Ver 2.0Avaan IvaanNo ratings yet

- GRP Pipe For SeawaterDocument22 pagesGRP Pipe For Seawatersethu1091100% (2)

- CW4Document19 pagesCW4Steve Cowan100% (1)

- Hatflex ChinaDocument31 pagesHatflex ChinaedgarmerchanNo ratings yet

- Technical Specification GRP PipesDocument218 pagesTechnical Specification GRP PipesNabendu Lodh100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- JLPT n5 Study Material - Nihongo IchibanDocument13 pagesJLPT n5 Study Material - Nihongo IchibankirankumarmrNo ratings yet

- DragonFace EnglishDocument26 pagesDragonFace EnglishAngel Diaz0% (1)

- Specification For 3LPE CoatingDocument32 pagesSpecification For 3LPE Coatinggauravagrawal2010No ratings yet

- FRP GRP GRE StandardsDocument4 pagesFRP GRP GRE StandardsT. LimNo ratings yet

- RTR Question and Answer For OWS and Utility LinesDocument18 pagesRTR Question and Answer For OWS and Utility Linesjana.alqimmaNo ratings yet

- 01-SAMSS-042 - Dec. 30, 2013Document37 pages01-SAMSS-042 - Dec. 30, 2013LainhatanhNo ratings yet

- 2014 12 05 - Wi PFX GRP 0001Document22 pages2014 12 05 - Wi PFX GRP 0001hariharanoilgasNo ratings yet

- Saudi PipesDocument47 pagesSaudi Pipesneels06274No ratings yet

- W P Ss 004Document12 pagesW P Ss 004BETLAHORENo ratings yet

- Astm D2239-12-Tubo Plástico Pe (Sidr-Pr)Document7 pagesAstm D2239-12-Tubo Plástico Pe (Sidr-Pr)Marlon TurnerNo ratings yet

- Inspection Check List 3Document22 pagesInspection Check List 3r.devendranNo ratings yet

- General 1.1. Scope: WWW - Uponor.caDocument6 pagesGeneral 1.1. Scope: WWW - Uponor.caalfredo_mqiNo ratings yet

- Ml-09 Work Procedure For Field Joint Coating & RepairDocument11 pagesMl-09 Work Procedure For Field Joint Coating & RepairBrijesh Katariya VCSNo ratings yet

- Glass Reinforced PlasticDocument6 pagesGlass Reinforced PlastickarunaNo ratings yet

- Bondstrand Bonder TrainingDocument60 pagesBondstrand Bonder Trainingminhthanhmos100% (1)

- 18-Division 2-Section 02900 PP Pipelines, Materials, Installation & TestingDocument19 pages18-Division 2-Section 02900 PP Pipelines, Materials, Installation & TestingAvaan IvaanNo ratings yet

- S-022-1520-0002PM HDPE Control Procedure RevADocument10 pagesS-022-1520-0002PM HDPE Control Procedure RevAHoang Phuong NguyenNo ratings yet

- Coating Standards Specifically AvailableDocument14 pagesCoating Standards Specifically Availableahmed sobhyNo ratings yet

- 01 Samss 045 PDFDocument22 pages01 Samss 045 PDFCarlos MondragomNo ratings yet

- Dynaflow - GRE Piping - March 26 2009Document60 pagesDynaflow - GRE Piping - March 26 2009sammar_10100% (3)

- 1.4.2 Resource Center Sample Spec Csi Section 15300 Fire Protection Spec RevDocument3 pages1.4.2 Resource Center Sample Spec Csi Section 15300 Fire Protection Spec RevJulio RodriguezNo ratings yet

- ASTM StandardsDocument4 pagesASTM StandardsFernando Alfredo Sepúlveda Jiménez0% (1)

- 13230Document19 pages13230sidnowsheraNo ratings yet

- VV216A-109-A-801 - 1 Installation & Oper Main. Procedure PDFDocument253 pagesVV216A-109-A-801 - 1 Installation & Oper Main. Procedure PDFLê Phước PhúNo ratings yet

- D 2239 - 03 RdiymzkDocument7 pagesD 2239 - 03 RdiymzkToapanta FredyNo ratings yet

- Maart 2009Document60 pagesMaart 2009Ricardo MendesNo ratings yet

- WP PEX - Thermopex SubmittalDocument26 pagesWP PEX - Thermopex SubmittalMohammad Rashad BarakatNo ratings yet

- IPS-G-TP-335-Material and Construction Standard For Three Layer Polyethylene Coating System Original EditionDocument25 pagesIPS-G-TP-335-Material and Construction Standard For Three Layer Polyethylene Coating System Original Editionseguridadyambiente641No ratings yet

- BlazeMaster Sample Specification - CanadaDocument4 pagesBlazeMaster Sample Specification - CanadaHugo Mario Ariza PalacioNo ratings yet

- Astm D3517 PDFDocument12 pagesAstm D3517 PDFsomphong.bkk5576No ratings yet

- Q/SQR: Enterprise Standard of Chery Automobile Co., LTDDocument22 pagesQ/SQR: Enterprise Standard of Chery Automobile Co., LTDDiego CamargoNo ratings yet

- Drainage Handbook SpecificationsDocument57 pagesDrainage Handbook Specificationshussainelarabi100% (1)

- Materials System SpecificationDocument18 pagesMaterials System SpecificationAli AldubaikhiNo ratings yet

- MS 322 HDPE SDR 11 Nascon Bel Air ClusterDocument87 pagesMS 322 HDPE SDR 11 Nascon Bel Air Clustersasi kNo ratings yet

- Future Pipe InfoDocument29 pagesFuture Pipe Infomekag94No ratings yet

- Product Submittal-PRC MT PipesDocument390 pagesProduct Submittal-PRC MT PipesTayseer Al AbedNo ratings yet

- FRP PipesDocument20 pagesFRP PipesThomasFrenchNo ratings yet

- HDPE Pipe and Fitting Materials Fusion Joining and Installation 1Document8 pagesHDPE Pipe and Fitting Materials Fusion Joining and Installation 1Mohamed ElsayedNo ratings yet

- Gas Industry Standard: GIS/PL2-2:2008Document83 pagesGas Industry Standard: GIS/PL2-2:2008nedalinaNo ratings yet

- 01 Samss 029Document15 pages01 Samss 029inatt101No ratings yet

- VNM-IPGN-PPL-SPC-EDG-0000-00019-00-G03 FBE SpecDocument29 pagesVNM-IPGN-PPL-SPC-EDG-0000-00019-00-G03 FBE SpecĐiệnBiênNhâm100% (1)

- 01-SAMSS-034 RTR (Fiberglass) Pressure Pipe and Fittings 19-MAR-2013Document19 pages01-SAMSS-034 RTR (Fiberglass) Pressure Pipe and Fittings 19-MAR-2013asiqnaNo ratings yet

- Jis PDFDocument145 pagesJis PDFtoepal67% (6)

- FM 1613 2017 Sample Specification HDPE Pipe Fittings Fusion For Firewater ServiceDocument6 pagesFM 1613 2017 Sample Specification HDPE Pipe Fittings Fusion For Firewater Servicemohamed fathiNo ratings yet

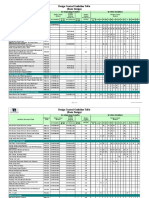

- Piping Design CriteriaDocument20 pagesPiping Design Criteriasuman_ghosh6798No ratings yet

- 08-Section 2-Section 02210 HDPE Pipeline-Version 2.0Document20 pages08-Section 2-Section 02210 HDPE Pipeline-Version 2.0Avaan IvaanNo ratings yet

- GCMT-13-CIV-SPC-005 Civil Specification Fencing and Gates Materials (IFA - RevC)Document19 pagesGCMT-13-CIV-SPC-005 Civil Specification Fencing and Gates Materials (IFA - RevC)Dwiadi Cahyabudi100% (1)

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Ceramic Materials for Energy Applications VIFrom EverandCeramic Materials for Energy Applications VIHua-Tay LinNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Data Sheet For Dry Chemical Portable Pportable Extinguisher: ProjectDocument3 pagesData Sheet For Dry Chemical Portable Pportable Extinguisher: ProjectmNo ratings yet

- Procedure For Preparation of Dry Chemical Wheeled Extinguishers Data SheetDocument5 pagesProcedure For Preparation of Dry Chemical Wheeled Extinguishers Data SheetmNo ratings yet

- Procedure For Fire Water Max. Demand Calculation: Quality Management System DocumentDocument4 pagesProcedure For Fire Water Max. Demand Calculation: Quality Management System DocumentmNo ratings yet

- PCD SF 191Document7 pagesPCD SF 191mNo ratings yet

- Procedure For Preparation of Water/Foam Monitor Data Sheet: Quality Management System DocumentDocument7 pagesProcedure For Preparation of Water/Foam Monitor Data Sheet: Quality Management System DocumentmNo ratings yet

- Procedure For Preparation of Water Hose Reel Data Sheet: Quality Management System DocumentDocument6 pagesProcedure For Preparation of Water Hose Reel Data Sheet: Quality Management System DocumentmNo ratings yet

- PCD-SF-187-Attachment#1 Water Hose Reel Data SheetDocument4 pagesPCD-SF-187-Attachment#1 Water Hose Reel Data SheetmNo ratings yet

- Procedure For Fire Water Max. Demand Calculation: Quality Management System DocumentDocument4 pagesProcedure For Fire Water Max. Demand Calculation: Quality Management System DocumentmNo ratings yet

- Procedure For Application of Foam Protection System: Quality Management System DocumentDocument9 pagesProcedure For Application of Foam Protection System: Quality Management System DocumentmNo ratings yet

- Syme Mebasc Enme Speq 0210 b03 PDFDocument12 pagesSyme Mebasc Enme Speq 0210 b03 PDFmNo ratings yet

- Syme Hvbasc Enhv Bsde 0001 B02Document16 pagesSyme Hvbasc Enhv Bsde 0001 B02mNo ratings yet

- Electrical Load List: Project: South Yaran Oil Field Development ProjectDocument8 pagesElectrical Load List: Project: South Yaran Oil Field Development ProjectmNo ratings yet

- Syme Elbasc Enel Rqma 0001 b02Document16 pagesSyme Elbasc Enel Rqma 0001 b02m100% (1)

- Refrence DWG.: Yaran Oil Field Development ProjectDocument4 pagesRefrence DWG.: Yaran Oil Field Development Projectm100% (1)

- Syme Elbasc Enel Lilc 0002 b02Document6 pagesSyme Elbasc Enel Lilc 0002 b02m100% (1)

- Design Input Control Checklist: 1) Complete 2) Incomplete But Sufficient To Start 3) InsufficientDocument3 pagesDesign Input Control Checklist: 1) Complete 2) Incomplete But Sufficient To Start 3) InsufficientmNo ratings yet

- PCD ED 451 Attachment 02Document13 pagesPCD ED 451 Attachment 02mNo ratings yet

- PCD ED 451 Attachment 11Document2 pagesPCD ED 451 Attachment 11mNo ratings yet

- North Yaran Oil Field Development ClusterDocument4 pagesNorth Yaran Oil Field Development ClustermNo ratings yet

- .:f:.t:::l:. L::. (I.::,.i. .Document12 pages.:f:.t:::l:. L::. (I.::,.i. .mNo ratings yet

- Vendor Progress Report-01Document2 pagesVendor Progress Report-01mNo ratings yet

- C006a JDocument44 pagesC006a JVignesh WaranNo ratings yet

- The PowerPoint 2013handoutsDocument10 pagesThe PowerPoint 2013handoutsDef GopNo ratings yet

- Model Delone and Mclean Dalam Aplikasi Absensi Super Hana Di PT Telkom PalembangDocument6 pagesModel Delone and Mclean Dalam Aplikasi Absensi Super Hana Di PT Telkom PalembangZahwa PutriNo ratings yet

- Guaphan DM Syrup Patient Information LeafletDocument1 pageGuaphan DM Syrup Patient Information Leafletpharmacia1.comNo ratings yet

- Quality MGT Practices and Impact On PerformanceDocument28 pagesQuality MGT Practices and Impact On PerformanceMizaa Jamali0% (1)

- GeolineDocument15 pagesGeolineRepresentaciones y Distribuciones FALNo ratings yet

- Waked Money Laundering Organization: Panama-Based WAKED MLO AssociatesDocument2 pagesWaked Money Laundering Organization: Panama-Based WAKED MLO AssociatesErika Anruth Martinez LopezNo ratings yet

- 0 - 10 3 0 DBGFC 6 37 - I::.Batalog Pa&E Nqi 5 0 - Customer Part No. 11339772Document2 pages0 - 10 3 0 DBGFC 6 37 - I::.Batalog Pa&E Nqi 5 0 - Customer Part No. 11339772Miguel RojasNo ratings yet

- Product Description of A Harrier Jump JetDocument6 pagesProduct Description of A Harrier Jump Jetapi-584335700No ratings yet

- Dawn Editorials 07june 2021Document6 pagesDawn Editorials 07june 2021Salman MemonNo ratings yet

- Causation and WearTear Exclusions in Property ClaimsDocument17 pagesCausation and WearTear Exclusions in Property Claimszoltan zavoczkyNo ratings yet

- Appendix D-2 ASTM D5084 Hydraulic ConductivityDocument3 pagesAppendix D-2 ASTM D5084 Hydraulic ConductivityomerNo ratings yet

- Hay Pitch Deck - Https://howareyou - WorkDocument18 pagesHay Pitch Deck - Https://howareyou - WorkMarius StankiewiczNo ratings yet

- IRS Module5-IDocument15 pagesIRS Module5-IPravin ShindeNo ratings yet

- Master Thesis in Chaotic CryptographyDocument5 pagesMaster Thesis in Chaotic Cryptographyafktdftdvqtiom100% (2)

- Iso TTR 18931 2001 (E)Document14 pagesIso TTR 18931 2001 (E)marco9991No ratings yet

- Gate Ques DbmsDocument10 pagesGate Ques DbmsBrinda BMNo ratings yet

- Roland Berger The Second National Tourism Development Plan 2017 2021Document112 pagesRoland Berger The Second National Tourism Development Plan 2017 2021suzNo ratings yet

- Air Conditioning System Presentation: A318/A319/A320/A321 General Familiarization Course Air ConditioningDocument134 pagesAir Conditioning System Presentation: A318/A319/A320/A321 General Familiarization Course Air ConditioningvvNo ratings yet

- Slurry Pumps Ar1 PDFDocument40 pagesSlurry Pumps Ar1 PDFsanjayagrawal70-1No ratings yet

- Nigerian Electricity Regulatory Commission: Eligible Customer Regulations 2017 Regulation No. Nerc-R-111Document30 pagesNigerian Electricity Regulatory Commission: Eligible Customer Regulations 2017 Regulation No. Nerc-R-111olisamc_628730283No ratings yet

- Metrel 3200Document2 pagesMetrel 3200Ing Kemberly OrdosgoittyNo ratings yet

- Index of OP Project HIRA Activities ID No. Activities Remarks Format NoDocument7 pagesIndex of OP Project HIRA Activities ID No. Activities Remarks Format NoSameer JogasNo ratings yet

- 1.8L - Engine - Motronic Multiport Fuel Injection (MFI) 132 KDocument18 pages1.8L - Engine - Motronic Multiport Fuel Injection (MFI) 132 KSteeven RodriguezNo ratings yet

- Book 1Document219 pagesBook 1Ardi AnsyahNo ratings yet

- PTC Creo Schematics DatasheetDocument5 pagesPTC Creo Schematics DatasheetJose Angel RodriguezNo ratings yet

- Arsi University ICT Directorate ICT Club Formation ProposalDocument8 pagesArsi University ICT Directorate ICT Club Formation ProposalMilion NugusieNo ratings yet

- Pictographs: Bowler Overs Runs Given Wickets TakenDocument4 pagesPictographs: Bowler Overs Runs Given Wickets TakenJINESH KOTHARINo ratings yet