Professional Documents

Culture Documents

C402 Rev A - ASTM A182 F304: All Mechanical Tests To Be Carried Out To ASTM A370 After Final Heat Treatment

C402 Rev A - ASTM A182 F304: All Mechanical Tests To Be Carried Out To ASTM A370 After Final Heat Treatment

Uploaded by

RajkumarCopyright:

Available Formats

You might also like

- Ams4945h 2020Document10 pagesAms4945h 2020BauyrzhanNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- NASA Process Specification For The Heat Treatment of Steel AlloysDocument9 pagesNASA Process Specification For The Heat Treatment of Steel AlloysisraelkkNo ratings yet

- Astm A958Document4 pagesAstm A958Gilmarasan100% (1)

- Table A-20Document1 pageTable A-20D7ooM_612No ratings yet

- EN6114Document17 pagesEN6114Andrei Cozma67% (3)

- Astm A 312Document2 pagesAstm A 312Raj KumarNo ratings yet

- WN SA-105 B16 5 TT Rev0Document2 pagesWN SA-105 B16 5 TT Rev0Aço SalgueiroNo ratings yet

- C216 Rev F - AISI4140Document2 pagesC216 Rev F - AISI4140Rama KrishnaNo ratings yet

- Astm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsDocument3 pagesAstm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed Steelsssip officeNo ratings yet

- Astm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsDocument3 pagesAstm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsSuresh NairNo ratings yet

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoNo ratings yet

- H151Document2 pagesH151KalpanaBansalNo ratings yet

- ASTM A249/A249M-04a and UI: Not For Production Use (For Reference Only)Document1 pageASTM A249/A249M-04a and UI: Not For Production Use (For Reference Only)nieav280No ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- Aluminium 2014 t6 2014 t651Document3 pagesAluminium 2014 t6 2014 t651Agung Sapto AjiNo ratings yet

- Uns S31803Document2 pagesUns S31803Amjath PallasNo ratings yet

- Astm A 829 - GRADE 4140 / GRADE 4142: CR Mo-Alloyed Vacuum Degassed SteelsDocument3 pagesAstm A 829 - GRADE 4140 / GRADE 4142: CR Mo-Alloyed Vacuum Degassed SteelssaltbathNo ratings yet

- 1.4125 440c PDFDocument2 pages1.4125 440c PDFsuntansueNo ratings yet

- Material Specification Sheet Saarstahl - P295GH (17Mn4)Document1 pageMaterial Specification Sheet Saarstahl - P295GH (17Mn4)raduonoNo ratings yet

- EN8 SteelDocument1 pageEN8 SteelDeep Narayan JaiswalNo ratings yet

- A RM 105 19 18 096 SourDocument5 pagesA RM 105 19 18 096 SourGuilherme RochaNo ratings yet

- SMS015R0Document1 pageSMS015R0PRASANTH PRASANTHNo ratings yet

- SMS002R0Document1 pageSMS002R0PRASANTH PRASANTHNo ratings yet

- Pressure Control BrochureDocument12 pagesPressure Control Brochurebkpaul3107No ratings yet

- Sae 4140Document3 pagesSae 4140Anurag JainNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- 17Mn4 P295GHDocument1 page17Mn4 P295GHKarthikeyan ShanmugavelNo ratings yet

- Design Computations: Exhaust Tailpipe Extension Material Selection and Material Endurance StrengthDocument9 pagesDesign Computations: Exhaust Tailpipe Extension Material Selection and Material Endurance StrengthMarc Joshua MACATANGAYNo ratings yet

- Mcut-3082 Epp-202 Fact Sheet 02Document2 pagesMcut-3082 Epp-202 Fact Sheet 02rabacet2923No ratings yet

- Welding Recommendation TS890Document2 pagesWelding Recommendation TS890max_powerNo ratings yet

- A 0131 01 Acero Estructural BarcosDocument6 pagesA 0131 01 Acero Estructural BarcosRosy GaraNo ratings yet

- Pressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceDocument3 pagesPressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceStanley HallNo ratings yet

- TDC PP742 F2Document3 pagesTDC PP742 F2Arjun PrajapatiNo ratings yet

- ME 205 - 432 - Assignment 1Document9 pagesME 205 - 432 - Assignment 1جعفر السلطانNo ratings yet

- Ductile Iron Casting Specfications and Details All Standards PDFDocument15 pagesDuctile Iron Casting Specfications and Details All Standards PDFSiriusNo ratings yet

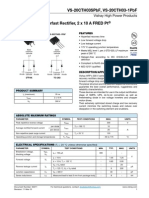

- Vs-20Cth03Spbf, Vs-20Cth03-1Pbf: Vishay High Power ProductsDocument9 pagesVs-20Cth03Spbf, Vs-20Cth03-1Pbf: Vishay High Power ProductsrrebollarNo ratings yet

- A1014Document3 pagesA1014malika_00No ratings yet

- IG 74 MESC 14d - 2021Document3 pagesIG 74 MESC 14d - 2021bmanojkumar16No ratings yet

- A 268 - A 268M - 01 Qti2oc0wmq - PDFDocument6 pagesA 268 - A 268M - 01 Qti2oc0wmq - PDFMan98No ratings yet

- A582 - A582m - 2005 PDFDocument4 pagesA582 - A582m - 2005 PDFPatricio Altavilla100% (2)

- 42CrMo4 10083Document5 pages42CrMo4 10083DavindRa SoniNo ratings yet

- CLU038-1210C4: Citiled Cob Series Standard Type Ra70 Min., Ra80 Min. ModelDocument15 pagesCLU038-1210C4: Citiled Cob Series Standard Type Ra70 Min., Ra80 Min. ModelJuan TricariqueNo ratings yet

- ASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe For High - Temperature ServiceDocument4 pagesASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe For High - Temperature ServiceSumedh ParadkarNo ratings yet

- Thyssenkrupp Materials International: Material Data SheetDocument4 pagesThyssenkrupp Materials International: Material Data SheetjaseerkannothNo ratings yet

- Process Specification For Pickling, Etching, and Descaling of MetalsDocument10 pagesProcess Specification For Pickling, Etching, and Descaling of MetalsGys100% (1)

- A 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFDocument4 pagesA 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFMan98No ratings yet

- Astm A321Document2 pagesAstm A321clevercog0% (1)

- A 789 - A 789M - 02 Qtc4os0wmkeDocument4 pagesA 789 - A 789M - 02 Qtc4os0wmkeAhmad HajeerNo ratings yet

- ST 12 - Echivalenta DC01Document12 pagesST 12 - Echivalenta DC01mariussinhoNo ratings yet

- Carbon Steel and Alloy Steel FastenersDocument2 pagesCarbon Steel and Alloy Steel FastenersagnisivadasanNo ratings yet

- Bolts, NutsDocument20 pagesBolts, Nutshlsimon100% (2)

- Metal Specifications PDFDocument4 pagesMetal Specifications PDFJaeup YouNo ratings yet

- ASTM A283 A283M 18 - PreDocument2 pagesASTM A283 A283M 18 - Prebruno.abuafNo ratings yet

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- Small&medium ICE Motors PDFDocument3 pagesSmall&medium ICE Motors PDFeng_mhassan1No ratings yet

- Required Thicknesses of Pipe or Tube Per Asme B31.3-2010 Process Piping CodeDocument1 pageRequired Thicknesses of Pipe or Tube Per Asme B31.3-2010 Process Piping CodeZoebairNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

C402 Rev A - ASTM A182 F304: All Mechanical Tests To Be Carried Out To ASTM A370 After Final Heat Treatment

C402 Rev A - ASTM A182 F304: All Mechanical Tests To Be Carried Out To ASTM A370 After Final Heat Treatment

Uploaded by

RajkumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C402 Rev A - ASTM A182 F304: All Mechanical Tests To Be Carried Out To ASTM A370 After Final Heat Treatment

C402 Rev A - ASTM A182 F304: All Mechanical Tests To Be Carried Out To ASTM A370 After Final Heat Treatment

Uploaded by

RajkumarCopyright:

Available Formats

MATERIALSPECIFICATION

C402RevAASTMA182F304

Rev

A

O

Date

29.05.90

ECN

Issue

Revised/Reissued

OriginalIssue

Preparedby

Check/Approved

ProductForm

Standard

Grade

AcceptableClass

DieForgedClamp

ASTMA182

F304

RingForgings

Scope

Thisspecificationoutlinesthemodificationsandadditionalrequirementstothe

relevantASTMSpecificationsforthesupplyofrawmaterialtomanufactureVector

Internationalclampcomponents.

Other

ASTMA370(LatestIssue)

Applicable

ASTMA388(LatestIssue)

Specifications

HeatTreatment SolutionTreat(1040Cmin)andQuench

Chemical

Min

Max

Min

Max

Min

Max

Analysis%

C

Cr

18.00

20.00

0.08 P

0.04

(Heat)

Si

1.00 S

0.03

Mn

2.00 Ni

8.00

11.00

Mechanical

Min

Max

Properties

Tensile(Rm):

75000psi(517MPa)

Yield(Rp0.2):

30000psi(207MPa)

Elongation(A%):

30

R.ofA(Z%):

50

Hardness:

Note:AllmechanicalteststobecarriedouttoASTMA370afterfinalheattreatment.

TestSampling Testcouponsmustrepresentproductionforgings(ringandopendie)andshould

beheattreatedwiththeforgings.Testcouponandforgingstobestackedinthe

furnaceinaccordancewithgoodpracticetoensureevenheattreatment.Thetest

couponsreceiveessentiallythesameforgingreductionratioastheproduction

forgings.

Testcouponsmustbetakenfromtheproductionforgingwhencloseddieforgings

areused.

N.D.E.

100%VisualinspectionondieforgingstoASTMA350(LatestIssue).

100%UTonforgingbilletinaccordancewithASTMA388(LatestIssue).

100%LPIonfinisheddieforgingsinaccordancewithASMEV.AcceptancetoASME

VIII.

MATERIALSPECIFICATION

C402RevAASTMA182F304

SurfaceFinish

andQuality

Repairof

Defects

Marking

Certification

Notes

100%UTonringforgingsinaccordancewithASTMA388(LatestIssue).

RingforgingstobeofsufficientqualityforLPIcheck.LPIonfinishedmachined

partstobeundertakenbyVectorInternationalLtd.

Forgingsshallbesuppliedfreeofdefects(Slaginclusions,scale,laps,cracks).

Weldrepairisnotacceptable.

ForgingstobemarkedwithHeatNumber,MaterialGrade,andVector

Specification.

CertificationinaccordancewithEN102043.1:ChemicalAnalysis,Mechanical

Analysis,HeatTreatmentReport/Graphs,MillCertificate(WetStamped).

Certificationmustbetraceabletoeachheattreatlot.

1. RefertoPOforsupplementaldetails.

2. Anydeviationfromthisspecificationmustberaisedformallyasaconcession

requestpriortodelivery.Certificationmustincludeconcessiondocumentation.

You might also like

- Ams4945h 2020Document10 pagesAms4945h 2020BauyrzhanNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- NASA Process Specification For The Heat Treatment of Steel AlloysDocument9 pagesNASA Process Specification For The Heat Treatment of Steel AlloysisraelkkNo ratings yet

- Astm A958Document4 pagesAstm A958Gilmarasan100% (1)

- Table A-20Document1 pageTable A-20D7ooM_612No ratings yet

- EN6114Document17 pagesEN6114Andrei Cozma67% (3)

- Astm A 312Document2 pagesAstm A 312Raj KumarNo ratings yet

- WN SA-105 B16 5 TT Rev0Document2 pagesWN SA-105 B16 5 TT Rev0Aço SalgueiroNo ratings yet

- C216 Rev F - AISI4140Document2 pagesC216 Rev F - AISI4140Rama KrishnaNo ratings yet

- Astm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsDocument3 pagesAstm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed Steelsssip officeNo ratings yet

- Astm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsDocument3 pagesAstm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsSuresh NairNo ratings yet

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoNo ratings yet

- H151Document2 pagesH151KalpanaBansalNo ratings yet

- ASTM A249/A249M-04a and UI: Not For Production Use (For Reference Only)Document1 pageASTM A249/A249M-04a and UI: Not For Production Use (For Reference Only)nieav280No ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- Aluminium 2014 t6 2014 t651Document3 pagesAluminium 2014 t6 2014 t651Agung Sapto AjiNo ratings yet

- Uns S31803Document2 pagesUns S31803Amjath PallasNo ratings yet

- Astm A 829 - GRADE 4140 / GRADE 4142: CR Mo-Alloyed Vacuum Degassed SteelsDocument3 pagesAstm A 829 - GRADE 4140 / GRADE 4142: CR Mo-Alloyed Vacuum Degassed SteelssaltbathNo ratings yet

- 1.4125 440c PDFDocument2 pages1.4125 440c PDFsuntansueNo ratings yet

- Material Specification Sheet Saarstahl - P295GH (17Mn4)Document1 pageMaterial Specification Sheet Saarstahl - P295GH (17Mn4)raduonoNo ratings yet

- EN8 SteelDocument1 pageEN8 SteelDeep Narayan JaiswalNo ratings yet

- A RM 105 19 18 096 SourDocument5 pagesA RM 105 19 18 096 SourGuilherme RochaNo ratings yet

- SMS015R0Document1 pageSMS015R0PRASANTH PRASANTHNo ratings yet

- SMS002R0Document1 pageSMS002R0PRASANTH PRASANTHNo ratings yet

- Pressure Control BrochureDocument12 pagesPressure Control Brochurebkpaul3107No ratings yet

- Sae 4140Document3 pagesSae 4140Anurag JainNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- 17Mn4 P295GHDocument1 page17Mn4 P295GHKarthikeyan ShanmugavelNo ratings yet

- Design Computations: Exhaust Tailpipe Extension Material Selection and Material Endurance StrengthDocument9 pagesDesign Computations: Exhaust Tailpipe Extension Material Selection and Material Endurance StrengthMarc Joshua MACATANGAYNo ratings yet

- Mcut-3082 Epp-202 Fact Sheet 02Document2 pagesMcut-3082 Epp-202 Fact Sheet 02rabacet2923No ratings yet

- Welding Recommendation TS890Document2 pagesWelding Recommendation TS890max_powerNo ratings yet

- A 0131 01 Acero Estructural BarcosDocument6 pagesA 0131 01 Acero Estructural BarcosRosy GaraNo ratings yet

- Pressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceDocument3 pagesPressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceStanley HallNo ratings yet

- TDC PP742 F2Document3 pagesTDC PP742 F2Arjun PrajapatiNo ratings yet

- ME 205 - 432 - Assignment 1Document9 pagesME 205 - 432 - Assignment 1جعفر السلطانNo ratings yet

- Ductile Iron Casting Specfications and Details All Standards PDFDocument15 pagesDuctile Iron Casting Specfications and Details All Standards PDFSiriusNo ratings yet

- Vs-20Cth03Spbf, Vs-20Cth03-1Pbf: Vishay High Power ProductsDocument9 pagesVs-20Cth03Spbf, Vs-20Cth03-1Pbf: Vishay High Power ProductsrrebollarNo ratings yet

- A1014Document3 pagesA1014malika_00No ratings yet

- IG 74 MESC 14d - 2021Document3 pagesIG 74 MESC 14d - 2021bmanojkumar16No ratings yet

- A 268 - A 268M - 01 Qti2oc0wmq - PDFDocument6 pagesA 268 - A 268M - 01 Qti2oc0wmq - PDFMan98No ratings yet

- A582 - A582m - 2005 PDFDocument4 pagesA582 - A582m - 2005 PDFPatricio Altavilla100% (2)

- 42CrMo4 10083Document5 pages42CrMo4 10083DavindRa SoniNo ratings yet

- CLU038-1210C4: Citiled Cob Series Standard Type Ra70 Min., Ra80 Min. ModelDocument15 pagesCLU038-1210C4: Citiled Cob Series Standard Type Ra70 Min., Ra80 Min. ModelJuan TricariqueNo ratings yet

- ASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe For High - Temperature ServiceDocument4 pagesASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe For High - Temperature ServiceSumedh ParadkarNo ratings yet

- Thyssenkrupp Materials International: Material Data SheetDocument4 pagesThyssenkrupp Materials International: Material Data SheetjaseerkannothNo ratings yet

- Process Specification For Pickling, Etching, and Descaling of MetalsDocument10 pagesProcess Specification For Pickling, Etching, and Descaling of MetalsGys100% (1)

- A 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFDocument4 pagesA 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFMan98No ratings yet

- Astm A321Document2 pagesAstm A321clevercog0% (1)

- A 789 - A 789M - 02 Qtc4os0wmkeDocument4 pagesA 789 - A 789M - 02 Qtc4os0wmkeAhmad HajeerNo ratings yet

- ST 12 - Echivalenta DC01Document12 pagesST 12 - Echivalenta DC01mariussinhoNo ratings yet

- Carbon Steel and Alloy Steel FastenersDocument2 pagesCarbon Steel and Alloy Steel FastenersagnisivadasanNo ratings yet

- Bolts, NutsDocument20 pagesBolts, Nutshlsimon100% (2)

- Metal Specifications PDFDocument4 pagesMetal Specifications PDFJaeup YouNo ratings yet

- ASTM A283 A283M 18 - PreDocument2 pagesASTM A283 A283M 18 - Prebruno.abuafNo ratings yet

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- Small&medium ICE Motors PDFDocument3 pagesSmall&medium ICE Motors PDFeng_mhassan1No ratings yet

- Required Thicknesses of Pipe or Tube Per Asme B31.3-2010 Process Piping CodeDocument1 pageRequired Thicknesses of Pipe or Tube Per Asme B31.3-2010 Process Piping CodeZoebairNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)