Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

46 viewsApêndice EE

Apêndice EE

Uploaded by

saulookASME VIII - Jacket

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- A New China: An Intermediate Reader of Modern Chinese - Revised EditionFrom EverandA New China: An Intermediate Reader of Modern Chinese - Revised EditionRating: 4 out of 5 stars4/5 (2)

- Oh, China!: An Elementary Reader of Modern Chinese for Advanced Beginners - Revised EditionFrom EverandOh, China!: An Elementary Reader of Modern Chinese for Advanced Beginners - Revised EditionRating: 5 out of 5 stars5/5 (4)

- Nino Rota DuettiDocument6 pagesNino Rota DuettiAndrea_oboe100% (4)

- A Trip to China: An Intermediate Reader of Modern Chinese - Revised EditionFrom EverandA Trip to China: An Intermediate Reader of Modern Chinese - Revised EditionRating: 3.5 out of 5 stars3.5/5 (8)

- IMSLP30974-PMLP70670-Saint-Sa Ns - Romance Op. 37 Flute and PianoDocument11 pagesIMSLP30974-PMLP70670-Saint-Sa Ns - Romance Op. 37 Flute and PianoLux Nieve100% (1)

- Raymonda Act3Document52 pagesRaymonda Act3Mikae Genis Natsuyama0% (1)

- Msc. Clinical PsychologyDocument2 pagesMsc. Clinical PsychologyAnanya AgarwalNo ratings yet

- (Fry - (P.,ZP: - : 2,//J ', (O) LFDocument4 pages(Fry - (P.,ZP: - : 2,//J ', (O) LFRowen PratherNo ratings yet

- Ent 1Document25 pagesEnt 1try.gkbNo ratings yet

- Adhoc Unit 1,2 IncompleteDocument18 pagesAdhoc Unit 1,2 IncompleteMayank SharmaNo ratings yet

- StrategyDocument10 pagesStrategyyyyouyang99No ratings yet

- ChemsitryDocument17 pagesChemsitryVaibhavNo ratings yet

- bs notes 2Document12 pagesbs notes 2Simranjot KaurNo ratings yet

- Adobe Scan Apr 13, 2024Document6 pagesAdobe Scan Apr 13, 2024pasivanandham77No ratings yet

- Cs Assignment 3Document13 pagesCs Assignment 3vivekvicky1267No ratings yet

- Scan 30-Nov-2023Document14 pagesScan 30-Nov-2023ashishdt68No ratings yet

- Wave OpticsDocument11 pagesWave Opticsmamtakalra3632No ratings yet

- Work and EnergyDocument18 pagesWork and EnergyAerotech ProductionNo ratings yet

- Bach - BWV 1060 Concerto For Oboe, Violin and Orchestra, - Orchestral Score and SolosDocument37 pagesBach - BWV 1060 Concerto For Oboe, Violin and Orchestra, - Orchestral Score and SolosAndreea Alexandra100% (1)

- Scuttle Buttin'Document6 pagesScuttle Buttin'Dunemate13100% (1)

- Karl Goldmark Violin ConcertoDocument92 pagesKarl Goldmark Violin ConcertohvulicNo ratings yet

- Humouresque Pietro YonDocument14 pagesHumouresque Pietro YonivormuseNo ratings yet

- Differential Equations NotesDocument13 pagesDifferential Equations NotesEthanNo ratings yet

- 56 Hora StaccatoDocument5 pages56 Hora StaccatoAndrei DrutaNo ratings yet

- Adobe Scan 25 Nov 2021Document6 pagesAdobe Scan 25 Nov 2021Aparna KumariNo ratings yet

- Phy Ch3 FormulaDocument21 pagesPhy Ch3 FormulaBISHAL KUMAR MAITYNo ratings yet

- Aires ChoquerosDocument9 pagesAires ChoquerosFausto Leali100% (2)

- Faure Violin Sonata 1 ScoreDocument43 pagesFaure Violin Sonata 1 ScoreWild RagionierNo ratings yet

- build. science notesDocument25 pagesbuild. science notesSimranjot KaurNo ratings yet

- aids assign 1Document8 pagesaids assign 1xeleh36264No ratings yet

- Physics Note 4-9-2023Document1 pagePhysics Note 4-9-2023ashwinrajkr30No ratings yet

- Adobe Scan 05-AugDocument4 pagesAdobe Scan 05-AugMaitri PanchalNo ratings yet

- Biology NotesDocument8 pagesBiology NotesMinal FatimaNo ratings yet

- Eco 3Document4 pagesEco 3Yashveer YadavNo ratings yet

- PhaeophytaDocument7 pagesPhaeophytasashna422No ratings yet

- Control EngDocument15 pagesControl EngIsiaka Azeez AkanniNo ratings yet

- Covid 19Document2 pagesCovid 19ArhamNo ratings yet

- Chemistry ThermodynamicsDocument25 pagesChemistry ThermodynamicsKhushi RathiNo ratings yet

- Operations On Functions Unit AssignmentDocument4 pagesOperations On Functions Unit AssignmentEshum MateenNo ratings yet

- OB Unit 1Document6 pagesOB Unit 1nidhijha18000No ratings yet

- Scansione 9 Apr 2020 PDFDocument10 pagesScansione 9 Apr 2020 PDFElena CavaniNo ratings yet

- COA 2 NotesDocument18 pagesCOA 2 NotesakashNo ratings yet

- CH 2 NotesDocument7 pagesCH 2 NotesrohillaNo ratings yet

- EE 441 - Assignment - BetaDocument15 pagesEE 441 - Assignment - BetakkdbiggyNo ratings yet

- Network Analysis and SynthesisDocument14 pagesNetwork Analysis and SynthesisakhilbhartilucknowNo ratings yet

- Market EquilibriumDocument25 pagesMarket EquilibriumSiddhi GuptaNo ratings yet

- 1st Phase of National Mvt... Early NationalistDocument6 pages1st Phase of National Mvt... Early NationalistSuryansh singh 43No ratings yet

- Piano Sonata in A Major, D. 664 SchubertDocument12 pagesPiano Sonata in A Major, D. 664 SchubertconostarNo ratings yet

- Adobe Scan 12 Jul 2021Document13 pagesAdobe Scan 12 Jul 2021Indu DeviNo ratings yet

- FMHM Notes - AKDocument20 pagesFMHM Notes - AKYusuf GoriawalaNo ratings yet

- RR - ( :o/) :::... L L ... R... E:. !: .Document18 pagesRR - ( :o/) :::... L L ... R... E:. !: .Sathya BNo ratings yet

- Adobe Scan Sep 23, 2022Document18 pagesAdobe Scan Sep 23, 2022HOt sHoTs leGEndNo ratings yet

- PoojaDocument6 pagesPoojaPooja ShuklaNo ratings yet

- Nutcracker Transcription EsipoffDocument36 pagesNutcracker Transcription EsipoffSabra W.100% (1)

- In TrousersDocument257 pagesIn Trousersst02No ratings yet

- Chemistry PracticalDocument3 pagesChemistry Practicalphil JONo ratings yet

- The Maddest Idea: An Isaac Biddlecomb NovelFrom EverandThe Maddest Idea: An Isaac Biddlecomb NovelRating: 3.5 out of 5 stars3.5/5 (9)

- FiltrosDocument8 pagesFiltrossaulookNo ratings yet

- Fasano J.B., Bakker A., Penney W.R. (1994) Advanced Impeller Geometry Boosts Liquid Agitation. Chemical Engineering, August 1994, 7 PagesDocument7 pagesFasano J.B., Bakker A., Penney W.R. (1994) Advanced Impeller Geometry Boosts Liquid Agitation. Chemical Engineering, August 1994, 7 PagessaulookNo ratings yet

- Filtro Unicell Serie CDocument20 pagesFiltro Unicell Serie CsaulookNo ratings yet

- AB Emflon PFRDocument2 pagesAB Emflon PFRsaulookNo ratings yet

Apêndice EE

Apêndice EE

Uploaded by

saulook0 ratings0% found this document useful (0 votes)

46 views5 pagesASME VIII - Jacket

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentASME VIII - Jacket

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

46 views5 pagesApêndice EE

Apêndice EE

Uploaded by

saulookASME VIII - Jacket

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

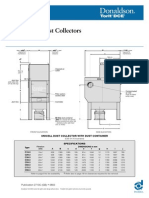

22007 SECTION VIII — DIVISION 1

IONMANDATORY APPENDIX EE

HALF-PIPE JACKETS

EEA GENERAL.

‘The calculation procedure in this Appendix shall be used.

only if both of the following conditions apply:

(a) There is positive pressure inside the shell or head

(b) Theres positive pressure inside the half-pipe jacket

EE-2 HALR-PIPE JACKETS

‘The maximum permissible pressure P” in half-pipe jack-

ets shall be determined from the following formula:

PPK @

where

P’ = permissible jacket pressure, psi

F=158-S)

(F shall not exceed 1.5 8)

‘maximum allowable tensile stress at design tem-

perature of shell or head material, psi

actual longitudinal tensile stress in shell or bead

due to internal pressure and other axial forces,

psi. When axial forces are negligible, 5” shall be

taken as PR/2r. When the combination of axial

forces and pressure stress (PR/21) is such that S”

‘would be anegative number, then "shal be taken

a 2er0.

factor obtained from Fig. EE-1, BF-2, or FF-3

ternal design pressure (see UG-21) in vessel, psi

2R = inside shell or head radius, in

D=R

The minimum thickness ofa half-pipe jacket, when the

thickness does not exceed one-half ofthe inside pipe radius

or P does not exceed 0.3855, is given by

ae

Pr

®

‘minimum thickness of half-pipe jacket, in.

inside radius of jacket defined in Fig. EE-4, in

allowable tensile stress of jacket material at design

temperature, psi

jesign pressure in jacket, psi. (P, shall not

exceed P’)

‘The fillet weld attaching the half-pipe jacket tothe vesse!

shall have a throat thickness not less than the smaller of

the jacket or shell thickness. Through thickness jacket

‘welds with a fillet shall be considered when the jacket is

in eyolic service,

FE3 JACKETS WITH OTHER

GEOMETRIES

For other jacket geometries such as shown in Fig, EE-5,

the permissible pressure P” may be obtained from the rules

of UG-47 for stayed construction or 9-5 for jacketed

vessels.

Example

‘What is the required thickness of a cylindrical shell

subjected to an inside pressure of 190 psi and a half-pipe

Jacket pressure of 300 psi? The jacket is in noneyclic

service. Let

LD. of shell = 40 in,

allowable stress of shell

joint efficiency of shell

hhalf-pipe jacket is NPS 3

allowable stress of jacket material = 12,000 psi

Jjacket girth welds are not radiographed

corrosion allowance = 0

SoLUTION: The required thickness of the shell due 10

internal pressute is calculated from eq. (1) of UG-27 as,

16,000 psi

10

= 024 in.

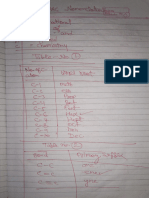

(a) Try ¢ = in: From Fig. BE-2, with D = 40 in,

and ¢ = 4 in. K =60:

8° = PRI2 = (190 x 20)/2 * 025)

= 7,60 psi

P= F/K = (15 * 16,900 ~ 7.60060

= 273 pai < 300 psi nt adequate

636

+ ooraed

“0

5060

2007 SECTION Vint — DIVISION 1

FIG. EE-1 NPS 2 PIPE JACKET

‘Shell thickness

asin.

ain,

2in.

7 6 90 100 110 120

D

on

130

a0

150

160

70

2007 SECTION VIII — DIVISION 1

FIG. EE-2 NPS 3 PIPE JACKET

1000

Shell thickness

ao avaod

1 -

9 4 50 60 70 8 90 100 110 120 130 140 150 160 170

638

+ 2 or008

2007 SECTION Vill — DIVISION 1

FIG. EE-3 NPS 4 PIPE JACKET

70

‘Shell thickness

2 90

109)

>

639

110

120)

720

40

150

160

170

FIG, EE

(b) Try t = Yio in.: From Fig. EE-2, with D

9:

and t = %g in, K =

SY = PRI2t = (190 x 20)1(2 * 03125)

6,080 psi

P= FIK = (15 x 16,000 ~ 6080)/49

= 366 psi > 300 psi adequate

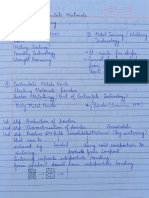

(e) Try Sch. 58 Pipe:

1083 x 0.875,

3592-0073

0.073 in

L677,

2007 SECTION VIII — DIVISION 1

FIG. EES

40 in.

‘The required half-pipe jacket thickness is

Tr

_ 300 x 1.677

* DBS % 12,000 - 06 ¥ 305

0.050 in, OK

‘The minimum fillet weld size is equal to 0.083 x

AL = 0.12 in, Use shell thickness of % in. half pipe

jacket of NPS 3 Sch, 5S, and fillet weld sizeof % in

640

You might also like

- A New China: An Intermediate Reader of Modern Chinese - Revised EditionFrom EverandA New China: An Intermediate Reader of Modern Chinese - Revised EditionRating: 4 out of 5 stars4/5 (2)

- Oh, China!: An Elementary Reader of Modern Chinese for Advanced Beginners - Revised EditionFrom EverandOh, China!: An Elementary Reader of Modern Chinese for Advanced Beginners - Revised EditionRating: 5 out of 5 stars5/5 (4)

- Nino Rota DuettiDocument6 pagesNino Rota DuettiAndrea_oboe100% (4)

- A Trip to China: An Intermediate Reader of Modern Chinese - Revised EditionFrom EverandA Trip to China: An Intermediate Reader of Modern Chinese - Revised EditionRating: 3.5 out of 5 stars3.5/5 (8)

- IMSLP30974-PMLP70670-Saint-Sa Ns - Romance Op. 37 Flute and PianoDocument11 pagesIMSLP30974-PMLP70670-Saint-Sa Ns - Romance Op. 37 Flute and PianoLux Nieve100% (1)

- Raymonda Act3Document52 pagesRaymonda Act3Mikae Genis Natsuyama0% (1)

- Msc. Clinical PsychologyDocument2 pagesMsc. Clinical PsychologyAnanya AgarwalNo ratings yet

- (Fry - (P.,ZP: - : 2,//J ', (O) LFDocument4 pages(Fry - (P.,ZP: - : 2,//J ', (O) LFRowen PratherNo ratings yet

- Ent 1Document25 pagesEnt 1try.gkbNo ratings yet

- Adhoc Unit 1,2 IncompleteDocument18 pagesAdhoc Unit 1,2 IncompleteMayank SharmaNo ratings yet

- StrategyDocument10 pagesStrategyyyyouyang99No ratings yet

- ChemsitryDocument17 pagesChemsitryVaibhavNo ratings yet

- bs notes 2Document12 pagesbs notes 2Simranjot KaurNo ratings yet

- Adobe Scan Apr 13, 2024Document6 pagesAdobe Scan Apr 13, 2024pasivanandham77No ratings yet

- Cs Assignment 3Document13 pagesCs Assignment 3vivekvicky1267No ratings yet

- Scan 30-Nov-2023Document14 pagesScan 30-Nov-2023ashishdt68No ratings yet

- Wave OpticsDocument11 pagesWave Opticsmamtakalra3632No ratings yet

- Work and EnergyDocument18 pagesWork and EnergyAerotech ProductionNo ratings yet

- Bach - BWV 1060 Concerto For Oboe, Violin and Orchestra, - Orchestral Score and SolosDocument37 pagesBach - BWV 1060 Concerto For Oboe, Violin and Orchestra, - Orchestral Score and SolosAndreea Alexandra100% (1)

- Scuttle Buttin'Document6 pagesScuttle Buttin'Dunemate13100% (1)

- Karl Goldmark Violin ConcertoDocument92 pagesKarl Goldmark Violin ConcertohvulicNo ratings yet

- Humouresque Pietro YonDocument14 pagesHumouresque Pietro YonivormuseNo ratings yet

- Differential Equations NotesDocument13 pagesDifferential Equations NotesEthanNo ratings yet

- 56 Hora StaccatoDocument5 pages56 Hora StaccatoAndrei DrutaNo ratings yet

- Adobe Scan 25 Nov 2021Document6 pagesAdobe Scan 25 Nov 2021Aparna KumariNo ratings yet

- Phy Ch3 FormulaDocument21 pagesPhy Ch3 FormulaBISHAL KUMAR MAITYNo ratings yet

- Aires ChoquerosDocument9 pagesAires ChoquerosFausto Leali100% (2)

- Faure Violin Sonata 1 ScoreDocument43 pagesFaure Violin Sonata 1 ScoreWild RagionierNo ratings yet

- build. science notesDocument25 pagesbuild. science notesSimranjot KaurNo ratings yet

- aids assign 1Document8 pagesaids assign 1xeleh36264No ratings yet

- Physics Note 4-9-2023Document1 pagePhysics Note 4-9-2023ashwinrajkr30No ratings yet

- Adobe Scan 05-AugDocument4 pagesAdobe Scan 05-AugMaitri PanchalNo ratings yet

- Biology NotesDocument8 pagesBiology NotesMinal FatimaNo ratings yet

- Eco 3Document4 pagesEco 3Yashveer YadavNo ratings yet

- PhaeophytaDocument7 pagesPhaeophytasashna422No ratings yet

- Control EngDocument15 pagesControl EngIsiaka Azeez AkanniNo ratings yet

- Covid 19Document2 pagesCovid 19ArhamNo ratings yet

- Chemistry ThermodynamicsDocument25 pagesChemistry ThermodynamicsKhushi RathiNo ratings yet

- Operations On Functions Unit AssignmentDocument4 pagesOperations On Functions Unit AssignmentEshum MateenNo ratings yet

- OB Unit 1Document6 pagesOB Unit 1nidhijha18000No ratings yet

- Scansione 9 Apr 2020 PDFDocument10 pagesScansione 9 Apr 2020 PDFElena CavaniNo ratings yet

- COA 2 NotesDocument18 pagesCOA 2 NotesakashNo ratings yet

- CH 2 NotesDocument7 pagesCH 2 NotesrohillaNo ratings yet

- EE 441 - Assignment - BetaDocument15 pagesEE 441 - Assignment - BetakkdbiggyNo ratings yet

- Network Analysis and SynthesisDocument14 pagesNetwork Analysis and SynthesisakhilbhartilucknowNo ratings yet

- Market EquilibriumDocument25 pagesMarket EquilibriumSiddhi GuptaNo ratings yet

- 1st Phase of National Mvt... Early NationalistDocument6 pages1st Phase of National Mvt... Early NationalistSuryansh singh 43No ratings yet

- Piano Sonata in A Major, D. 664 SchubertDocument12 pagesPiano Sonata in A Major, D. 664 SchubertconostarNo ratings yet

- Adobe Scan 12 Jul 2021Document13 pagesAdobe Scan 12 Jul 2021Indu DeviNo ratings yet

- FMHM Notes - AKDocument20 pagesFMHM Notes - AKYusuf GoriawalaNo ratings yet

- RR - ( :o/) :::... L L ... R... E:. !: .Document18 pagesRR - ( :o/) :::... L L ... R... E:. !: .Sathya BNo ratings yet

- Adobe Scan Sep 23, 2022Document18 pagesAdobe Scan Sep 23, 2022HOt sHoTs leGEndNo ratings yet

- PoojaDocument6 pagesPoojaPooja ShuklaNo ratings yet

- Nutcracker Transcription EsipoffDocument36 pagesNutcracker Transcription EsipoffSabra W.100% (1)

- In TrousersDocument257 pagesIn Trousersst02No ratings yet

- Chemistry PracticalDocument3 pagesChemistry Practicalphil JONo ratings yet

- The Maddest Idea: An Isaac Biddlecomb NovelFrom EverandThe Maddest Idea: An Isaac Biddlecomb NovelRating: 3.5 out of 5 stars3.5/5 (9)

- FiltrosDocument8 pagesFiltrossaulookNo ratings yet

- Fasano J.B., Bakker A., Penney W.R. (1994) Advanced Impeller Geometry Boosts Liquid Agitation. Chemical Engineering, August 1994, 7 PagesDocument7 pagesFasano J.B., Bakker A., Penney W.R. (1994) Advanced Impeller Geometry Boosts Liquid Agitation. Chemical Engineering, August 1994, 7 PagessaulookNo ratings yet

- Filtro Unicell Serie CDocument20 pagesFiltro Unicell Serie CsaulookNo ratings yet

- AB Emflon PFRDocument2 pagesAB Emflon PFRsaulookNo ratings yet