Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

140 viewsBasic Explanation & Schematic View - Injection Moulding Process

Basic Explanation & Schematic View - Injection Moulding Process

Uploaded by

NazriThe injection moulding process involves 4 main stages: (1) plastic material is melted and injected into a closed metal mould tool under pressure, (2) the molten plastic cools and hardens inside the mould, (3) the tool is held closed under pressure until the plastic fully sets, (4) the tool then opens and the finished part is ejected to begin the next cycle. The process continuously melts, injects, cools and ejects plastic to form parts.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You might also like

- Final Report-Plastic Injection MoldingDocument40 pagesFinal Report-Plastic Injection MoldingAnant Sharma86% (42)

- Monobloc ChairDocument2 pagesMonobloc ChairJen gemudianoNo ratings yet

- Final Report Plastic Injection MoldingDocument48 pagesFinal Report Plastic Injection MoldingGunjan Trivedi0% (1)

- WC-475 - Weld Joints, Sections, Symbols PDFDocument1 pageWC-475 - Weld Joints, Sections, Symbols PDFNathanLaertePiaiNo ratings yet

- Plastic Injection MoldingDocument24 pagesPlastic Injection MoldingelectroternalNo ratings yet

- Injection MouldingDocument4 pagesInjection MouldinganipcatalyzerNo ratings yet

- Ae 301 Injection Moulding ProcessDocument15 pagesAe 301 Injection Moulding ProcessschaNo ratings yet

- Plastic Injection MoldingDocument24 pagesPlastic Injection Moldingmechhandbook100% (1)

- Clamping: Clamping Forces Dry Cycle TimeDocument1 pageClamping: Clamping Forces Dry Cycle TimeschaNo ratings yet

- Clamping: Clamping Forces Dry Cycle TimeDocument1 pageClamping: Clamping Forces Dry Cycle TimeschaNo ratings yet

- Section-A Plastic Shaping Processes Experiment No. 1: Name: Grade EarnedDocument6 pagesSection-A Plastic Shaping Processes Experiment No. 1: Name: Grade EarnedRaza KhanNo ratings yet

- Manual Injection MoldingDocument5 pagesManual Injection MoldingM. AhmadNo ratings yet

- Design of Singe Impression Injection Mould For Lower Bearing Cover IJERTV4IS050974Document5 pagesDesign of Singe Impression Injection Mould For Lower Bearing Cover IJERTV4IS050974Harshvardhan KharatNo ratings yet

- Injection MoldingDocument2 pagesInjection MoldingShafiq ShfqqNo ratings yet

- ASWIN MANOJ PresentationDocument13 pagesASWIN MANOJ PresentationAswin MNo ratings yet

- Vero Plastic Moulds برزينتيشن PDFDocument50 pagesVero Plastic Moulds برزينتيشن PDFMohammed Hassan RashadNo ratings yet

- Injection Molding FinalDocument49 pagesInjection Molding FinalShoaib RathoreNo ratings yet

- Injection MouldingDocument23 pagesInjection MouldingPrathmeshBhokari100% (1)

- INDUSTRIAL TRANING SEMINAR - PPTX AnshuDocument31 pagesINDUSTRIAL TRANING SEMINAR - PPTX Anshuanshu rajNo ratings yet

- Plastic Injection MouldingDocument28 pagesPlastic Injection MouldingDavid StefanNo ratings yet

- Part 4 - 2 - Polymers Processing TechsDocument42 pagesPart 4 - 2 - Polymers Processing TechsAlemu MergaNo ratings yet

- Summer Training Project ReportDocument28 pagesSummer Training Project ReportSaurav GabaNo ratings yet

- Components of An Injection Molding Machine R1Document11 pagesComponents of An Injection Molding Machine R1Cesar GarciaNo ratings yet

- Injection MoldingDocument46 pagesInjection MoldingBeer with FriendsNo ratings yet

- Injection Blow MoldingDocument3 pagesInjection Blow MoldingMaximiliano RiccaNo ratings yet

- IMM - Write UpDocument5 pagesIMM - Write UpvanmanNo ratings yet

- Lecture 09 Injection Molding-IDocument19 pagesLecture 09 Injection Molding-IVishwajit GaunsNo ratings yet

- Plasting ProcessingDocument19 pagesPlasting Processingnethumini GunawardanaNo ratings yet

- The Plastic Manufacturing ProcessDocument2 pagesThe Plastic Manufacturing Processskiran_56No ratings yet

- Polymer Processing: Structure and Properties of Engineering PolymersDocument42 pagesPolymer Processing: Structure and Properties of Engineering Polymersمحمد ناصف الجداوىNo ratings yet

- Injection MouldingDocument2 pagesInjection MouldingVinayakNo ratings yet

- Injection Molding: Manufacturing Plastic Material Pressure Mould Mouldmaker Steel Aluminium CarsDocument37 pagesInjection Molding: Manufacturing Plastic Material Pressure Mould Mouldmaker Steel Aluminium CarslakhancipetNo ratings yet

- Injection Moulding MachineDocument4 pagesInjection Moulding MachinescbrajaNo ratings yet

- .Fabrication of Manual Plastic Injection Moulding MachineDocument3 pages.Fabrication of Manual Plastic Injection Moulding MachineRing MasterNo ratings yet

- Injection Moulding: Points CoveredDocument14 pagesInjection Moulding: Points Coveredanilkolekar0% (1)

- Mould Theory PDFDocument35 pagesMould Theory PDFArunava Bala75% (4)

- Gear Type Injection Moulding MachineDocument4 pagesGear Type Injection Moulding MachineJeya KumarNo ratings yet

- Lab Report Injection MoldingDocument4 pagesLab Report Injection MoldingMuzamil RazaNo ratings yet

- Plastic Industry Me 233 GroupDocument29 pagesPlastic Industry Me 233 GroupIram MustaviNo ratings yet

- Injection mouldingCH2Document8 pagesInjection mouldingCH2prasanna_326avanthiNo ratings yet

- Polymer Processing (Molding) : D. Jim Livingston Faculty of Chemistry, St. John's CollegeDocument26 pagesPolymer Processing (Molding) : D. Jim Livingston Faculty of Chemistry, St. John's CollegeJim LivingstonNo ratings yet

- Injection MoldingDocument14 pagesInjection MoldingmmanharNo ratings yet

- Injection Molding DOEDocument8 pagesInjection Molding DOEMatt McLouthNo ratings yet

- Design and Manufacturing of Plastic Injection MouldDocument31 pagesDesign and Manufacturing of Plastic Injection MouldSuneth TharakaNo ratings yet

- Design and Manufacture of C-Clamp by Injection Molding ProcessDocument6 pagesDesign and Manufacture of C-Clamp by Injection Molding ProcessEng Stephen ArendeNo ratings yet

- I/ Reading 1 1. What Is Plastic Injection Molding?Document5 pagesI/ Reading 1 1. What Is Plastic Injection Molding?Hieu Nguyen TrungNo ratings yet

- 1.polymer ProcessingDocument23 pages1.polymer Processingafia rahmanNo ratings yet

- Esmm 5 F 713Document21 pagesEsmm 5 F 713overlord5555No ratings yet

- Injection MouldingDocument33 pagesInjection MouldingArpit S SavarkarNo ratings yet

- Final Report Plastic Injection MoldingDocument38 pagesFinal Report Plastic Injection MoldingshriNo ratings yet

- Lecture 6-Other IM ProcessesDocument23 pagesLecture 6-Other IM ProcessesAhmed WaelNo ratings yet

- In Jection MouldingDocument21 pagesIn Jection MouldingAbhinandan PatilNo ratings yet

- Injection MoldingDocument32 pagesInjection Moldingamdan srlNo ratings yet

- Notes - Injection MoldingDocument10 pagesNotes - Injection MoldingNaveen VasanthNo ratings yet

- A Brief Study On Plastic Injection Molding ProcessDocument42 pagesA Brief Study On Plastic Injection Molding ProcessDinesh arNo ratings yet

- Design and Fabrication of Injection Moulding Machine-Mechanical ProjectDocument4 pagesDesign and Fabrication of Injection Moulding Machine-Mechanical ProjectUr FriendNo ratings yet

- Se - Experiment 6Document12 pagesSe - Experiment 6Manoj DohaleNo ratings yet

- MODULE I Injection Molding ProcessDocument40 pagesMODULE I Injection Molding ProcessAntonius PrakosaNo ratings yet

- Removable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingDocument14 pagesRemovable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingNazriNo ratings yet

- Pengenalan Asas Solidworks® 2018: By: Nazri Bin MD Ali Institut Latihan Perindustrian Bukit Katil MelakaDocument18 pagesPengenalan Asas Solidworks® 2018: By: Nazri Bin MD Ali Institut Latihan Perindustrian Bukit Katil MelakaNazriNo ratings yet

- Real 3 Corrision PipeDocument8 pagesReal 3 Corrision PipeNazriNo ratings yet

- How To Use Hole WizardDocument4 pagesHow To Use Hole WizardNazriNo ratings yet

- How Solidworks WorksDocument7 pagesHow Solidworks WorksNazriNo ratings yet

- Correction Coment PRSDocument20 pagesCorrection Coment PRSNazriNo ratings yet

- Technical Specifications For Aerial BunchedDocument5 pagesTechnical Specifications For Aerial BunchedNazriNo ratings yet

- Discuss Basic Injection Moulding Machine SafetyDocument3 pagesDiscuss Basic Injection Moulding Machine SafetyNazriNo ratings yet

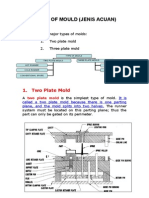

- Carry Out Two Plate Mould Drawing InterpretDocument4 pagesCarry Out Two Plate Mould Drawing InterpretNazri100% (1)

- Long-Range Guided-Wave Ultrasonics A New Age in Pipeline Inspection - 2007 - Birch, Baker - Un PDFDocument5 pagesLong-Range Guided-Wave Ultrasonics A New Age in Pipeline Inspection - 2007 - Birch, Baker - Un PDFNazriNo ratings yet

- Micron Scorpion Z4120C, Z6020C and Z8020C User ManualDocument18 pagesMicron Scorpion Z4120C, Z6020C and Z8020C User ManualNazri0% (1)

- Nota Sem 3 Blue Print ReadDocument149 pagesNota Sem 3 Blue Print ReadNazri0% (1)

- Scorpion Z4120C Z6020C Z8020C Installer ManualDocument23 pagesScorpion Z4120C Z6020C Z8020C Installer ManualNazriNo ratings yet

- Explain Basic Injection Molding Machine ProcessDocument9 pagesExplain Basic Injection Molding Machine ProcessNazriNo ratings yet

- LKM Standard Mould BaseDocument86 pagesLKM Standard Mould BaseNazriNo ratings yet

- Pme Mould & Die Standard Components PDFDocument84 pagesPme Mould & Die Standard Components PDFNazriNo ratings yet

- Produk 2/2013: A Detail A Scale 4: 1 Unit: MMDocument1 pageProduk 2/2013: A Detail A Scale 4: 1 Unit: MMNazriNo ratings yet

- 2.describe Mould Parts and ConstructionDocument49 pages2.describe Mould Parts and ConstructionNazri100% (4)

- Bolts Design Strength Tables EN 1993-1-8Document2 pagesBolts Design Strength Tables EN 1993-1-8ValentinNo ratings yet

- Effects On Etching Rates of Copper in Ferric Chloride SolutionsDocument5 pagesEffects On Etching Rates of Copper in Ferric Chloride SolutionsMein samayNo ratings yet

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDocument1 pageBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNo ratings yet

- Aramco Interview Questions-4Document21 pagesAramco Interview Questions-4chandu666creator100% (4)

- Assignment Engineering MaterialsDocument8 pagesAssignment Engineering MaterialsMirza HumzaNo ratings yet

- SGS 6 Basic Iron Sulphate in POX Processing of Refractory GoldDocument10 pagesSGS 6 Basic Iron Sulphate in POX Processing of Refractory Goldboanerges wino pattyNo ratings yet

- Kemet Metallographic BrochureDocument24 pagesKemet Metallographic Brochurevantuan17792No ratings yet

- Dgca Module 12 Part 02Document20 pagesDgca Module 12 Part 02Sonam Lodhi100% (1)

- Thermistor Resistance TableDocument1 pageThermistor Resistance TablePin KisNo ratings yet

- Damage MechanismDocument10 pagesDamage MechanismAndiappan PillaiNo ratings yet

- CatalogueDocument2 pagesCataloguePratik TapadiaNo ratings yet

- Worldwide Steel GradeDocument2 pagesWorldwide Steel Grademyusuf123No ratings yet

- Technical Presentation On Engine ValvesDocument32 pagesTechnical Presentation On Engine ValvesRockey RahulNo ratings yet

- 8.2 Fundamentals of Manufacturing For EngineersDocument13 pages8.2 Fundamentals of Manufacturing For EngineersKhánh ĐàoNo ratings yet

- The New 200-Series: An Alternative Answer To Ni. Surcharge ? Dream or Nightmare?Document9 pagesThe New 200-Series: An Alternative Answer To Ni. Surcharge ? Dream or Nightmare?alban500100% (1)

- A Furnace Is An Equipment Used To Melt Metals For Casting or To Heat Materials To Change Their ShapeDocument2 pagesA Furnace Is An Equipment Used To Melt Metals For Casting or To Heat Materials To Change Their Shapegosaye desalegn100% (1)

- Ferrum MetDocument75 pagesFerrum Metअनुरूपम स्वामीNo ratings yet

- NC 559 Asm TF PDFDocument2 pagesNC 559 Asm TF PDFroto44No ratings yet

- Hollow Structural Sections Column Load TablesDocument128 pagesHollow Structural Sections Column Load TablesPedro PereiraNo ratings yet

- Single Cylinder Oscillating Steam Engine Named "Lucy" General Arrangement and Components A3Document3 pagesSingle Cylinder Oscillating Steam Engine Named "Lucy" General Arrangement and Components A3Jhon Fredy MartinNo ratings yet

- Anti-Ram Bollards: Sales Office: 0870 600 2425Document4 pagesAnti-Ram Bollards: Sales Office: 0870 600 2425rajivr_ranjan_vermaNo ratings yet

- Mbdaily 20150506Document37 pagesMbdaily 20150506ClaudiaKlausyNo ratings yet

- 4.4 Process Parameters On Tool Life - Class NotesDocument35 pages4.4 Process Parameters On Tool Life - Class NotesTAMILARASAN MNo ratings yet

- History of TitaniumDocument12 pagesHistory of TitaniumjagadeesanbNo ratings yet

- Automotive SteelsDocument12 pagesAutomotive SteelspratyaygeminiNo ratings yet

- Grade 8 Chemistry NoteDocument4 pagesGrade 8 Chemistry NotebelleNo ratings yet

- Metal GuideDocument16 pagesMetal Guidesmrithi MohanNo ratings yet

- Technical Data - PDDocument49 pagesTechnical Data - PDThiruThirunavukkarasuNo ratings yet

- PSSLDocument8 pagesPSSLlokelooksNo ratings yet

Basic Explanation & Schematic View - Injection Moulding Process

Basic Explanation & Schematic View - Injection Moulding Process

Uploaded by

Nazri0 ratings0% found this document useful (0 votes)

140 views1 pageThe injection moulding process involves 4 main stages: (1) plastic material is melted and injected into a closed metal mould tool under pressure, (2) the molten plastic cools and hardens inside the mould, (3) the tool is held closed under pressure until the plastic fully sets, (4) the tool then opens and the finished part is ejected to begin the next cycle. The process continuously melts, injects, cools and ejects plastic to form parts.

Original Description:

Original Title

Process

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe injection moulding process involves 4 main stages: (1) plastic material is melted and injected into a closed metal mould tool under pressure, (2) the molten plastic cools and hardens inside the mould, (3) the tool is held closed under pressure until the plastic fully sets, (4) the tool then opens and the finished part is ejected to begin the next cycle. The process continuously melts, injects, cools and ejects plastic to form parts.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

140 views1 pageBasic Explanation & Schematic View - Injection Moulding Process

Basic Explanation & Schematic View - Injection Moulding Process

Uploaded by

NazriThe injection moulding process involves 4 main stages: (1) plastic material is melted and injected into a closed metal mould tool under pressure, (2) the molten plastic cools and hardens inside the mould, (3) the tool is held closed under pressure until the plastic fully sets, (4) the tool then opens and the finished part is ejected to begin the next cycle. The process continuously melts, injects, cools and ejects plastic to form parts.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 1

Home Injection Mould Tools Injection Moulding Vacuum Forming Company Profile News Contact Us Help

Basic explanation & schematic view - injection moulding process

The injection moulding process involves heating & injecting plastic material under pressure into a closed metal mould tool.

The molten plastic cools & hardens into the shape inside the mould tool, which then opens to allow the mouldings to be

ejected or removed for inspection, delivery or secondary operations.

injection moulding process - stage 1

Material granules from the hopper feed into

the heated barrel & rotating screw.

Material melted by heat, friction & shear

force is forced through a check valve to the

front by the rotating screw.

injection moulding process - stage 2

Having been moved backwards by the shot

of material at the front , the screw is forced

forward by a hydraulic ram.

This action injects material into the mould

cavity in the closed mould tool.

injection moulding process - stage 3

The tool is held closed under pressure until

the plastic material cools & sets hard in the

mould tool cavity.

This is often the longest part of the injection

moulding process

injection moulding process - stage 4

The screw starts to move back for the next

moulding. The tool then opens & the finished

plastic part is ejected.

The tool is closed and the injection moulding

process starts again at 1.

Further help with injection moulding process and other help & advice is available from our help page.

You might also like

- Final Report-Plastic Injection MoldingDocument40 pagesFinal Report-Plastic Injection MoldingAnant Sharma86% (42)

- Monobloc ChairDocument2 pagesMonobloc ChairJen gemudianoNo ratings yet

- Final Report Plastic Injection MoldingDocument48 pagesFinal Report Plastic Injection MoldingGunjan Trivedi0% (1)

- WC-475 - Weld Joints, Sections, Symbols PDFDocument1 pageWC-475 - Weld Joints, Sections, Symbols PDFNathanLaertePiaiNo ratings yet

- Plastic Injection MoldingDocument24 pagesPlastic Injection MoldingelectroternalNo ratings yet

- Injection MouldingDocument4 pagesInjection MouldinganipcatalyzerNo ratings yet

- Ae 301 Injection Moulding ProcessDocument15 pagesAe 301 Injection Moulding ProcessschaNo ratings yet

- Plastic Injection MoldingDocument24 pagesPlastic Injection Moldingmechhandbook100% (1)

- Clamping: Clamping Forces Dry Cycle TimeDocument1 pageClamping: Clamping Forces Dry Cycle TimeschaNo ratings yet

- Clamping: Clamping Forces Dry Cycle TimeDocument1 pageClamping: Clamping Forces Dry Cycle TimeschaNo ratings yet

- Section-A Plastic Shaping Processes Experiment No. 1: Name: Grade EarnedDocument6 pagesSection-A Plastic Shaping Processes Experiment No. 1: Name: Grade EarnedRaza KhanNo ratings yet

- Manual Injection MoldingDocument5 pagesManual Injection MoldingM. AhmadNo ratings yet

- Design of Singe Impression Injection Mould For Lower Bearing Cover IJERTV4IS050974Document5 pagesDesign of Singe Impression Injection Mould For Lower Bearing Cover IJERTV4IS050974Harshvardhan KharatNo ratings yet

- Injection MoldingDocument2 pagesInjection MoldingShafiq ShfqqNo ratings yet

- ASWIN MANOJ PresentationDocument13 pagesASWIN MANOJ PresentationAswin MNo ratings yet

- Vero Plastic Moulds برزينتيشن PDFDocument50 pagesVero Plastic Moulds برزينتيشن PDFMohammed Hassan RashadNo ratings yet

- Injection Molding FinalDocument49 pagesInjection Molding FinalShoaib RathoreNo ratings yet

- Injection MouldingDocument23 pagesInjection MouldingPrathmeshBhokari100% (1)

- INDUSTRIAL TRANING SEMINAR - PPTX AnshuDocument31 pagesINDUSTRIAL TRANING SEMINAR - PPTX Anshuanshu rajNo ratings yet

- Plastic Injection MouldingDocument28 pagesPlastic Injection MouldingDavid StefanNo ratings yet

- Part 4 - 2 - Polymers Processing TechsDocument42 pagesPart 4 - 2 - Polymers Processing TechsAlemu MergaNo ratings yet

- Summer Training Project ReportDocument28 pagesSummer Training Project ReportSaurav GabaNo ratings yet

- Components of An Injection Molding Machine R1Document11 pagesComponents of An Injection Molding Machine R1Cesar GarciaNo ratings yet

- Injection MoldingDocument46 pagesInjection MoldingBeer with FriendsNo ratings yet

- Injection Blow MoldingDocument3 pagesInjection Blow MoldingMaximiliano RiccaNo ratings yet

- IMM - Write UpDocument5 pagesIMM - Write UpvanmanNo ratings yet

- Lecture 09 Injection Molding-IDocument19 pagesLecture 09 Injection Molding-IVishwajit GaunsNo ratings yet

- Plasting ProcessingDocument19 pagesPlasting Processingnethumini GunawardanaNo ratings yet

- The Plastic Manufacturing ProcessDocument2 pagesThe Plastic Manufacturing Processskiran_56No ratings yet

- Polymer Processing: Structure and Properties of Engineering PolymersDocument42 pagesPolymer Processing: Structure and Properties of Engineering Polymersمحمد ناصف الجداوىNo ratings yet

- Injection MouldingDocument2 pagesInjection MouldingVinayakNo ratings yet

- Injection Molding: Manufacturing Plastic Material Pressure Mould Mouldmaker Steel Aluminium CarsDocument37 pagesInjection Molding: Manufacturing Plastic Material Pressure Mould Mouldmaker Steel Aluminium CarslakhancipetNo ratings yet

- Injection Moulding MachineDocument4 pagesInjection Moulding MachinescbrajaNo ratings yet

- .Fabrication of Manual Plastic Injection Moulding MachineDocument3 pages.Fabrication of Manual Plastic Injection Moulding MachineRing MasterNo ratings yet

- Injection Moulding: Points CoveredDocument14 pagesInjection Moulding: Points Coveredanilkolekar0% (1)

- Mould Theory PDFDocument35 pagesMould Theory PDFArunava Bala75% (4)

- Gear Type Injection Moulding MachineDocument4 pagesGear Type Injection Moulding MachineJeya KumarNo ratings yet

- Lab Report Injection MoldingDocument4 pagesLab Report Injection MoldingMuzamil RazaNo ratings yet

- Plastic Industry Me 233 GroupDocument29 pagesPlastic Industry Me 233 GroupIram MustaviNo ratings yet

- Injection mouldingCH2Document8 pagesInjection mouldingCH2prasanna_326avanthiNo ratings yet

- Polymer Processing (Molding) : D. Jim Livingston Faculty of Chemistry, St. John's CollegeDocument26 pagesPolymer Processing (Molding) : D. Jim Livingston Faculty of Chemistry, St. John's CollegeJim LivingstonNo ratings yet

- Injection MoldingDocument14 pagesInjection MoldingmmanharNo ratings yet

- Injection Molding DOEDocument8 pagesInjection Molding DOEMatt McLouthNo ratings yet

- Design and Manufacturing of Plastic Injection MouldDocument31 pagesDesign and Manufacturing of Plastic Injection MouldSuneth TharakaNo ratings yet

- Design and Manufacture of C-Clamp by Injection Molding ProcessDocument6 pagesDesign and Manufacture of C-Clamp by Injection Molding ProcessEng Stephen ArendeNo ratings yet

- I/ Reading 1 1. What Is Plastic Injection Molding?Document5 pagesI/ Reading 1 1. What Is Plastic Injection Molding?Hieu Nguyen TrungNo ratings yet

- 1.polymer ProcessingDocument23 pages1.polymer Processingafia rahmanNo ratings yet

- Esmm 5 F 713Document21 pagesEsmm 5 F 713overlord5555No ratings yet

- Injection MouldingDocument33 pagesInjection MouldingArpit S SavarkarNo ratings yet

- Final Report Plastic Injection MoldingDocument38 pagesFinal Report Plastic Injection MoldingshriNo ratings yet

- Lecture 6-Other IM ProcessesDocument23 pagesLecture 6-Other IM ProcessesAhmed WaelNo ratings yet

- In Jection MouldingDocument21 pagesIn Jection MouldingAbhinandan PatilNo ratings yet

- Injection MoldingDocument32 pagesInjection Moldingamdan srlNo ratings yet

- Notes - Injection MoldingDocument10 pagesNotes - Injection MoldingNaveen VasanthNo ratings yet

- A Brief Study On Plastic Injection Molding ProcessDocument42 pagesA Brief Study On Plastic Injection Molding ProcessDinesh arNo ratings yet

- Design and Fabrication of Injection Moulding Machine-Mechanical ProjectDocument4 pagesDesign and Fabrication of Injection Moulding Machine-Mechanical ProjectUr FriendNo ratings yet

- Se - Experiment 6Document12 pagesSe - Experiment 6Manoj DohaleNo ratings yet

- MODULE I Injection Molding ProcessDocument40 pagesMODULE I Injection Molding ProcessAntonius PrakosaNo ratings yet

- Removable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingDocument14 pagesRemovable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingNazriNo ratings yet

- Pengenalan Asas Solidworks® 2018: By: Nazri Bin MD Ali Institut Latihan Perindustrian Bukit Katil MelakaDocument18 pagesPengenalan Asas Solidworks® 2018: By: Nazri Bin MD Ali Institut Latihan Perindustrian Bukit Katil MelakaNazriNo ratings yet

- Real 3 Corrision PipeDocument8 pagesReal 3 Corrision PipeNazriNo ratings yet

- How To Use Hole WizardDocument4 pagesHow To Use Hole WizardNazriNo ratings yet

- How Solidworks WorksDocument7 pagesHow Solidworks WorksNazriNo ratings yet

- Correction Coment PRSDocument20 pagesCorrection Coment PRSNazriNo ratings yet

- Technical Specifications For Aerial BunchedDocument5 pagesTechnical Specifications For Aerial BunchedNazriNo ratings yet

- Discuss Basic Injection Moulding Machine SafetyDocument3 pagesDiscuss Basic Injection Moulding Machine SafetyNazriNo ratings yet

- Carry Out Two Plate Mould Drawing InterpretDocument4 pagesCarry Out Two Plate Mould Drawing InterpretNazri100% (1)

- Long-Range Guided-Wave Ultrasonics A New Age in Pipeline Inspection - 2007 - Birch, Baker - Un PDFDocument5 pagesLong-Range Guided-Wave Ultrasonics A New Age in Pipeline Inspection - 2007 - Birch, Baker - Un PDFNazriNo ratings yet

- Micron Scorpion Z4120C, Z6020C and Z8020C User ManualDocument18 pagesMicron Scorpion Z4120C, Z6020C and Z8020C User ManualNazri0% (1)

- Nota Sem 3 Blue Print ReadDocument149 pagesNota Sem 3 Blue Print ReadNazri0% (1)

- Scorpion Z4120C Z6020C Z8020C Installer ManualDocument23 pagesScorpion Z4120C Z6020C Z8020C Installer ManualNazriNo ratings yet

- Explain Basic Injection Molding Machine ProcessDocument9 pagesExplain Basic Injection Molding Machine ProcessNazriNo ratings yet

- LKM Standard Mould BaseDocument86 pagesLKM Standard Mould BaseNazriNo ratings yet

- Pme Mould & Die Standard Components PDFDocument84 pagesPme Mould & Die Standard Components PDFNazriNo ratings yet

- Produk 2/2013: A Detail A Scale 4: 1 Unit: MMDocument1 pageProduk 2/2013: A Detail A Scale 4: 1 Unit: MMNazriNo ratings yet

- 2.describe Mould Parts and ConstructionDocument49 pages2.describe Mould Parts and ConstructionNazri100% (4)

- Bolts Design Strength Tables EN 1993-1-8Document2 pagesBolts Design Strength Tables EN 1993-1-8ValentinNo ratings yet

- Effects On Etching Rates of Copper in Ferric Chloride SolutionsDocument5 pagesEffects On Etching Rates of Copper in Ferric Chloride SolutionsMein samayNo ratings yet

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDocument1 pageBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNo ratings yet

- Aramco Interview Questions-4Document21 pagesAramco Interview Questions-4chandu666creator100% (4)

- Assignment Engineering MaterialsDocument8 pagesAssignment Engineering MaterialsMirza HumzaNo ratings yet

- SGS 6 Basic Iron Sulphate in POX Processing of Refractory GoldDocument10 pagesSGS 6 Basic Iron Sulphate in POX Processing of Refractory Goldboanerges wino pattyNo ratings yet

- Kemet Metallographic BrochureDocument24 pagesKemet Metallographic Brochurevantuan17792No ratings yet

- Dgca Module 12 Part 02Document20 pagesDgca Module 12 Part 02Sonam Lodhi100% (1)

- Thermistor Resistance TableDocument1 pageThermistor Resistance TablePin KisNo ratings yet

- Damage MechanismDocument10 pagesDamage MechanismAndiappan PillaiNo ratings yet

- CatalogueDocument2 pagesCataloguePratik TapadiaNo ratings yet

- Worldwide Steel GradeDocument2 pagesWorldwide Steel Grademyusuf123No ratings yet

- Technical Presentation On Engine ValvesDocument32 pagesTechnical Presentation On Engine ValvesRockey RahulNo ratings yet

- 8.2 Fundamentals of Manufacturing For EngineersDocument13 pages8.2 Fundamentals of Manufacturing For EngineersKhánh ĐàoNo ratings yet

- The New 200-Series: An Alternative Answer To Ni. Surcharge ? Dream or Nightmare?Document9 pagesThe New 200-Series: An Alternative Answer To Ni. Surcharge ? Dream or Nightmare?alban500100% (1)

- A Furnace Is An Equipment Used To Melt Metals For Casting or To Heat Materials To Change Their ShapeDocument2 pagesA Furnace Is An Equipment Used To Melt Metals For Casting or To Heat Materials To Change Their Shapegosaye desalegn100% (1)

- Ferrum MetDocument75 pagesFerrum Metअनुरूपम स्वामीNo ratings yet

- NC 559 Asm TF PDFDocument2 pagesNC 559 Asm TF PDFroto44No ratings yet

- Hollow Structural Sections Column Load TablesDocument128 pagesHollow Structural Sections Column Load TablesPedro PereiraNo ratings yet

- Single Cylinder Oscillating Steam Engine Named "Lucy" General Arrangement and Components A3Document3 pagesSingle Cylinder Oscillating Steam Engine Named "Lucy" General Arrangement and Components A3Jhon Fredy MartinNo ratings yet

- Anti-Ram Bollards: Sales Office: 0870 600 2425Document4 pagesAnti-Ram Bollards: Sales Office: 0870 600 2425rajivr_ranjan_vermaNo ratings yet

- Mbdaily 20150506Document37 pagesMbdaily 20150506ClaudiaKlausyNo ratings yet

- 4.4 Process Parameters On Tool Life - Class NotesDocument35 pages4.4 Process Parameters On Tool Life - Class NotesTAMILARASAN MNo ratings yet

- History of TitaniumDocument12 pagesHistory of TitaniumjagadeesanbNo ratings yet

- Automotive SteelsDocument12 pagesAutomotive SteelspratyaygeminiNo ratings yet

- Grade 8 Chemistry NoteDocument4 pagesGrade 8 Chemistry NotebelleNo ratings yet

- Metal GuideDocument16 pagesMetal Guidesmrithi MohanNo ratings yet

- Technical Data - PDDocument49 pagesTechnical Data - PDThiruThirunavukkarasuNo ratings yet

- PSSLDocument8 pagesPSSLlokelooksNo ratings yet