Professional Documents

Culture Documents

Bob Teal MagnaPulsion US4024421

Bob Teal MagnaPulsion US4024421

Uploaded by

kishbud0 ratings0% found this document useful (0 votes)

316 views6 pagesA MAGNETICALLY OPERABLE ENGINE OR POWER plant embodying a rotary crankshaft having two or more offset cranks which, by means of respective connecting rods pivoted thereto, are actuated to apply torque to the crankshaft for driving purposes. Electrical current is supplied to the magnet windings by fixed distributor switches which are successively operated by one or more cams effectively mounted on the crankshaft. The present invention relates to a magnetically operable engine in that it employs

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA MAGNETICALLY OPERABLE ENGINE OR POWER plant embodying a rotary crankshaft having two or more offset cranks which, by means of respective connecting rods pivoted thereto, are actuated to apply torque to the crankshaft for driving purposes. Electrical current is supplied to the magnet windings by fixed distributor switches which are successively operated by one or more cams effectively mounted on the crankshaft. The present invention relates to a magnetically operable engine in that it employs

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

316 views6 pagesBob Teal MagnaPulsion US4024421

Bob Teal MagnaPulsion US4024421

Uploaded by

kishbudA MAGNETICALLY OPERABLE ENGINE OR POWER plant embodying a rotary crankshaft having two or more offset cranks which, by means of respective connecting rods pivoted thereto, are actuated to apply torque to the crankshaft for driving purposes. Electrical current is supplied to the magnet windings by fixed distributor switches which are successively operated by one or more cams effectively mounted on the crankshaft. The present invention relates to a magnetically operable engine in that it employs

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 6

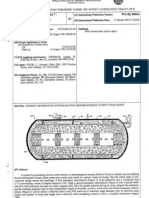

United States Patent 191

Teal

an 4,024,421

45) May 17, 197

[54] MAGNETICALLY OPERABLE ENGINE OR

POWER PLANT

[76] Inventor: Benjiman R. Teal, 611 Marion St.

NW., Madison, Fla. 32340

[22] Filed: Mar. 24, 1976

[21] Appl. No.: 669,900

[52] US. CL... 310/24; 310/34;

310/35

{51} Int CL nnn snnen HORK 7106

[58] Field of Search 310/23, 24, 34, 35,

310/32

(561 References Cited

UNITED STATES PATENTS

568,947 10/1896 Hicks .. 310/24

131,614 3/1915 Radtke 310124

13471002 7/1920 Baule 310/24

1'886,040 11/1932 Moodyman 310124

21056,719 10/1936 Geinaw 310135 x

2,639,544 5/1953 Coffin 310/35 X

3,688,136 8/1972 Salverdo 310/24

3,832,608 9/1974 Mills 310135 x

Primary Examiner—Donovan F. Duggan

Attorney, Agent, or Firm—J. Wesley Everett

(57) ABSTRACT

‘A magnetically operable engine or power plant em-

bodying a rotary crankshaft having two or more offset

cranks which, by means of respective connecting rods

pivoted thereto, and also to the sliding cores or arma-

tures of electromagnets, are actuated to apply torque to

the crankshaft for driving purposes. Electrical current

is supplied to the magnet windings by fixed distributor

switches which are successively operated by one or

‘more cams effectively mounted on the crankshaft, the

switches receiving pulses of current in timed relation-

ship and in such a manner that torque is continuously

to the crankshaft.

2 Claims, 6 Drawing Figures

4,024,421

Sheet 1 of 2

U.S. Patent May 17, 1977

zi

f

{

SETS HTT

Us

U.S. Patent

40.

May 17, 1977 Sheet 2 of 2 4,024,421

FIG. &

28

4 104

1-104 36:

1

MAGNETICALLY OPERABLE ENGINE OR POWER

PLANT

‘The present invention relates to a magnetically oper-

able engine or power plant which, in a general way,

functions in the manner of an internal combustion

engine in that it employs a rotary crankshaft having

offset cranks which derive their motion from power

driven reciprocating members. Unlike a conventional

‘combustion engine, the reciprocating members, instead

‘of being motivated by the explosion of combustible

‘gases in a combustion chamber, are caused to recipro-

‘cate by magnetic attraction, such members being in the

form of cores or armatures which are associated with

electromagnets, there being at least one magnet for

each crank, Motivating current impulses are succes-

sively supplied to the various magnets by distributor

means embodying respective normally open circuit

making and breaking devices which are successively

closed by one or more cams that rotate with the cam-

shaft. The basic principle involved in thus applying

torque to the crankshaft may appropriately be referred

ipulsion” (a coined word) and such term

may be employed where appropriate throughout this,

specification.

‘The present magnetically operable engine or power

plant is capable of being used as a power source in

connection with a wheeled automotive vehicle of either

the passenger-carrying type or as a toy automobile. Its,

also capable of being used as a fixedly mounted power

plant for driving adjacent machinery of various sorts,

but, irrespective of the particular use to which the

invention may be put, the essential features thereof are

at all times preserved,

‘The provision of an engine which is extremely simple

in its construction and which therefore may be manu-

factured at a low cost; one which is comprised of a

minimum number of parts, particularly moving parts,

and which therefore is unlikely to get out of order; one

which is rugged and durable and which therefore will

withstand rough usage; one which is smooth and silent

in its operation; one which is capable of ease of assem-

bly and disassembly for purposes of inspection of parts,

replacement or repair thereof, and one which other-

wise is well adapted to perform the services required of

itare further desirable features which have been borne

in mind in the production and development of the pre-

sent invention.

‘The provision of an engine or power plant such as has

briefly been outlined above, and possessing the stated

advantages, constitutes the principal object of the in-

vention. Numerous other objects and advantages of the

invention, not at this time enumerated, will become

readily apparent as the nature of the invention is better

understood

In the accompanying two sheets of drawings forming

a part of this specification, one illustrative embodiment

‘of the invention has been’ shown.

In these drawings:

FIG. 1 is a perspective view of a magnetically opera-

ble power plant or engine embodying the principles of

the present invention, portions of the framework or

chassis being broken away in the interests of clarity;

FIG. 2 is a sectional view taken substantially on the

vertical plane indicated by the line 2—2 of FIG. 1 and

in the direction of the arrows;

FIG, 3 is an end elevational view taken in the direc-

tion of the arrows associated with the line 3—3 of FIG.

20

2s

30

35

40

45

55

6

6s

4,024,421

2

2; FIG, 4 is an end elevational view taken in the direc-

tion of the arrows associated with the line 4—4 of FIG.

2%

FIG. 5 is an enlarged detail sectional view taken

through one of the electromagnets and its associated

connecting rod and crank which are employed in con-

nection with the invention; and

FIG. 6 is an electric circuit diagram of the power

plant or engine.

Referring now to the drawings in detail, and in partic-

ular to FIGS. 1 and 2, a power plant or engine con-

structed according to the invention is designated in its

entirety by the reference numeral 10 and it embodies in

its general organization a chassis or framework 12

which serves to rotatably support an elongated crank-

shaft 14 on which there is mounted a relatively massive

flywheel 16 in the medial region thereof. A pair of

pulleys 18 on opposite sides of the flywheel 16 have

associated therewith respective drive belts 20 which

may extend to a suitable transmission (not shown) in

the case of a wheeled automative vehicle, or to the

input drive element in the case of a stationary equip-

ment which is to be driven by the power plant.

‘The framework 12 is comprised of an upper rectan-

gular frame having longitudinal frame members 22 and

24 and transverse frame members 26 and 28, and a

lower rectangular frame having longitudinal frame

members 30 and 32 and transverse frame members 34

and 36. The framework 12 further includes a pair of

intermediate posts 40 and front and rear vertical inter-

mediate posts 42 and 44 respectively. A series of longi-

tudinal struts 46 and transverse struts 48 extend vari-

ously between the posts 38, 40, 42, and 44 and estab-

lish an intermediate rectangular frame a slight distance

above the lower rectangular frame 30, 32, 34 and 36.

‘A pair of bearing assemblies $0 are supported upon

transverse support bars 52 and 54 and serve to rotat-

ably support the crankshaft 14, Such crankshaft is pro-

vided with crank arms 56 and $8 on opposite sides of

the flywheel 16 and with offset cranks 60 and 62. The

ccrank 62 is connected by means of connecting rods 64

and 66 to respective electromagnets MI and M2 which

are fixedly mounted on the framework 12, while the

crank arm 60 is similarly connected by connecting rods

{68 and 70 to respective electromagnets M3 and MA, all

in a manner that will be made clear presently.

‘The various electromagnets M1, M2, M3 and Md,

together with their associated connecting rods 64, 66,

68 and 70 are substantially identical and therefore a

description of one of them will suffice for them all

Accordingly, the magnet M1 (see also FIG. 5) embod:

ies a magnet casing or shell 72 within which there i

disposed a magnet winding 74, An armature or core 76

is slidably disposed within the casing 72 and is pivotally

connected as indicated at 78 to the associated connect

ig rod 64. The remaining magnets M2, M3 and Mé are

similarly connected to their associated connecting rods

‘The magnet MI is mounted in a vertical position

upon an upper shelf member 80 while the magnet M2

is mounted in a slightly inclined position upon a lower

shelf member 82. As best shown in FIGS. 1, 2 and 3,

the magnet M2 is seated upon a wedge-shaped base

plate or block 84 which serves to misalign the axis of

the magnet M2 from the axis of the magnet MI by a

small angle for a purpose that will be made clear pres-

ently, The magnet M3 is mounted in a horizontal posi-

tion by means of a support member 86 while the mag-

net Md is similarly mounted in a substantially horizon-

3

tal position by means of a support member 88, the axis

of the magnet Md being slightly misaligned with respect

to the axis of the magnet M3 likewise for a purpose that

will be set forth subsequently.

Referring now to FIGS. 2, 3 and 4, one end of the

flywheel! 16 carries a cam 90 which is designed for

successive engagements with a pair of substantially

diametrically opposed microswitches $1 and $2 which

are carried at the ends of a pair of horizontal support-

ing bars 94 and 96 respectively. Similarly, the other end

of the flywheel 16 carries a cam 92 which is designed

for successive engagement with a pair of substantially

horizontally opposed microswitches $3 and $4 which

are cartied at the ends of a pair of horizontal support-

ing bars 98 and 100 respectively. As will become more

readily apparent when the operation of the herein de

scribed magnetically operable engine or power plant is

set forth in connection with the circuit diagram of FIG.

6, the arrangement of the various cams and micro.

switches is such that upon rotation of the crankshaft 14

and flywheel 16, the contacts associated with the mi-

croswitches S1, $3, S2 and S4 will become individually

closed, successively and in the order named,

Considering mow the operation of the herein de-

scribed magnetically operable engine or power plant

10, and with reference to FIG. 6, it will be assumed that

initially the position of the crankshaft 14 is such that, as

shown in FIG. 3, energization of the magnet M1 will

swing the crank 62 upwardly at such time as the cam 90

engages the microswitch SI. Closure of the C1 contacts

associated with the switch SI will establish a circuit

leading from the negative side of the battery B, through

the master switch MS, through leads 11, 13, magnet

MI, leads 15, 17, contacts C1 of the switch SI, and

leads 19, 21, 23 and 25, back to the positive side of the

battery B. Energization of the magnet MI will draw the

core or armature 76 (FIG. $) into the shell 72 and thus

place the connecting rod 64 under tension so as to pull

the crank 62 upwardly, thereby placing the crankshaft

under torque for motivating purposes.

‘At approximately 90° n the engine cycle, the cam 90

will engage the switch $3 and closure of the contacts

3 thereof will establish a circuit from the master

switch MS through lead 27, magnet M3, leads 29, 31,

C3 contacts of the switch $3, and leads 33, 35 back to

the battery B, thus applying torque to the crankshaft 14

by placing the connecting rod 68 under tension.

‘At approximately 180° in the engine cycle, the cam

90 will engage the switch S2 and closure of the C2

contacts thereof will establish a circuit from the master

switch MS through leads 11, 37, magnet M2, leads 39,

41, contacts C2 of the switch S2, and leads 43, 23, 25

back to the battery B, thus applying torque to the

crankshaft 14 by placing the connecting rod 66 under

tension.

‘At approximately 270° in the engine cycle, the cam

92 will engage the switch $4 and closure of the contacts

C4 thereof will establish a circuit from the master

switch MS, through lead 47, magnet Md, lead 49, C4

contacts of the switch $4, and leads 51, 43, 23, 25 back

to the battery B, thus placing the connecting rod 70

under tension and applying torque to the crankshaft 14.

‘The eycle is repetitious.

‘As shown in FIGS. 1 and 2, a control panel 102 is.

associated with a container or box 104 for the battery

B and such panel may be provided with the aforemen-

tioned master switch MS and an indicator 106 which

may disclose the amperage of current flowing from the

20

25

30

35

45

50

3s

60

65

4,024,421

4

battery B. Four push button switches PBI, PB2, PB3

and PB4 may also be provided on the control panel 102

and, as shown in FIG. 6, such push button switches are

arranged so that they operate upon closure thereof to

establish shunts across the respective microswitches

S1, $2, $3 and S4 so that an initial momentary closure

of a selected push button switch on a trial and error

basis may cause torque to be applied to one or the

other cranks 60 or 62 for initial application of torque to

the crankshaft 14 in the event that neither crank is in a

favorable position for engine starting at the time that

the master switch MS is intially closed

It is to be noted at this point that although the cams

90 and 92 are disclosed in FIG. 2 as being disposed at

approximately 180° from each other on the flywheel

16, such cams appear in FIG. 6 as being 90° apart. It

should be understood however that the disclosure of

FIG. 6 is purely schematic and is intended to illustrate

only the sequence of operation of the four switches $1,

‘82, S3 and S4 under the control of the cams 90 and 92

and that the front and rear end faces 16F and 16R

shown in FIG. 6 rotate in the same direction since they

do not represent front and rear end faces in the sense

that they are illustrated in FIGS. 3 and 4. In other

words, FIG. 6 is predicated solely upon the sequence of

microswitch operation and does not represent a true

positioning of parts such as is disclosed in FIGS. 1 to 4

inclusive. It is also to be noted that by reason of the

slight axial misalignment of the magnets MI and M2,

and of the magnets M3 and M4, continuous crankshaft

movement is effected since at no time will the engine or

power plant 10 attain a position of dead-center where

Closure of the master switch crankshaft 14,

The invention is not to be limited to the exact

rangement of parts shown in the accompanying draw-

ings or described in this specification as various

changes in the details of construction may be resorted

to without departing from the spirit of the invention.

For example, the precise placement of the various cams

90 and 92 and microswitches S1, $2, S3 and S4 on the

flywheel 16 and framework 12 may be varied if desired

as regards their angular relationship with respect to one

another, the only criteria being the attainment of se-

quential operation of the switches in such a manner

that torque is applied to the crankshaft 14 at all times

by at least one of the four connecting rods. Further-

more, if desired a greater or lesser number of electro-

‘magnets suitably mounted on the framework 12, to-

gether with a commensurate modification of the nature

of the crankshaft 14, may be resorted to if deemed

appropriate. Therefore, only insofar as the invention

has particularly been pointed out in the accompanying

claims is the same to be limited.

Tclaim:

1. A magnetically operated power plant comprising a

‘work frame, an axially extended crank shaft rotatably

mounted on said frame, a pair of spaced bearings one

‘on each side of the frame for supporting a crank shaft,

a fly wheel mounted on the crank shaft between the

said spaced bearings, a crank arm fixed to each end of

the crank shaft adjacent the said bearings and substan-

tially 180° apart and on the opposite side of the bear-

ings from the fly wheel, a pair of spaced hollow electro-

magnets positioned substantially diametrically opposite

each other at each side ofthe frame and in substantially

‘the same plane with the crank arm and perpendicular

to the axis of the crank shaft, an armature for each

electro-magnet adapted to, slide within each of the

5

hollow electro-magnets, a connecting rod for each

armature having one end pivotally connected to the

armature and the opposite end connected to one of the

crank arms, an electric current for timely energizing

the electro-magnets when the armature is substantially

adjacent one end of the electro-magnet, a timing means

‘comprising a micro-switch for each’ electro-magnet

fixedly mounted on said frame work, each switch in-

cluding a pair of normally open contacts and disposed

in series relation with said electro-magnet, said switch

‘being disposed in circumferential spaced ‘relationship

about the crank shaft, means carried at each end of the

fly.wheel for closing each of the said switches progres-

20

2s

30

3s

45

so

3s

Cy

65

4,024,421

6

sively on alternate sides of the frame to the respective

electro-magnets in the direction of the operated crank

shaft substantially at the time the solenoid is at one end

of the electro-magnet, the electro-magnets of each pair

having their axes slightly inclined at an angle to each

other whereby the associated crank arms are mini-

mized

2. A magnetically operated power plant as set forth in

claim 1 wherein there is provided a push button switch

for each electro-magnet and is effective upon depres

sion thereof to shunt the contacts of its associated

switch for moving the said crank shaft off center.

You might also like

- Nikola Tesla - The Inventions, Researches and Writings of Nikola TeslaDocument509 pagesNikola Tesla - The Inventions, Researches and Writings of Nikola Teslajrod100% (35)

- Nikola Tesla - The Inventions, Researches and Writings of Nikola TeslaDocument509 pagesNikola Tesla - The Inventions, Researches and Writings of Nikola Teslajrod100% (35)

- Faster Than Light: Warp Drive and Quantum Vacuum PowerFrom EverandFaster Than Light: Warp Drive and Quantum Vacuum PowerRating: 5 out of 5 stars5/5 (2)

- The Newman Motor Plans and Test by JLN 2Document97 pagesThe Newman Motor Plans and Test by JLN 2kishbud86% (28)

- Joseph Newman Energy Machine International PatentDocument1 pageJoseph Newman Energy Machine International Patentkishbud100% (2)

- Joseph Newman Energy Machine International PatentDocument1 pageJoseph Newman Energy Machine International Patentkishbud100% (2)

- Tesla High Frequency Coil by George F. Haller and Elmer Tiling CunninghamDocument130 pagesTesla High Frequency Coil by George F. Haller and Elmer Tiling CunninghamPedroNas30No ratings yet

- Eric Dollard - Collected ArticlesDocument31 pagesEric Dollard - Collected ArticlesNich MossNo ratings yet

- Electric Discharges, Waves and Impulses - Charles Proteus SteinmetzDocument172 pagesElectric Discharges, Waves and Impulses - Charles Proteus SteinmetzNick100% (8)

- John Bedini Schematic For Killing All Viruses Including HIV and Hepatitis CDocument1 pageJohn Bedini Schematic For Killing All Viruses Including HIV and Hepatitis CkishbudNo ratings yet

- Tariel Kapanadze and Tesla CircuitsDocument9 pagesTariel Kapanadze and Tesla Circuitskishbud100% (13)

- Franklin B. Mead Jr. (US Pat. 5590031)Document15 pagesFranklin B. Mead Jr. (US Pat. 5590031)GaleriaTechniki.PLNo ratings yet

- A New System of Alternating Current Motors and Transformers and Other EssaysFrom EverandA New System of Alternating Current Motors and Transformers and Other EssaysRating: 5 out of 5 stars5/5 (1)

- Otto Ronette TPU ECD-V1 0Document55 pagesOtto Ronette TPU ECD-V1 0dimawariNo ratings yet

- Eric DollardDocument30 pagesEric Dollardgeorge100% (1)

- Steinmetz Outline of Theory of Impulse Currents 1916Document31 pagesSteinmetz Outline of Theory of Impulse Currents 1916kishbudNo ratings yet

- Us 5149407Document24 pagesUs 5149407Tomas KriukelisNo ratings yet

- Welcome To Bedini TechnologyDocument26 pagesWelcome To Bedini TechnologyAnonymous CoUBbG1mL100% (2)

- The Thorny Way of Truth Part4 MaririchDocument340 pagesThe Thorny Way of Truth Part4 MaririchEvaldas StankeviciusNo ratings yet

- Impulse Power Secrets-3docDocument8 pagesImpulse Power Secrets-3doc77nicuNo ratings yet

- Cherne TSK IDocument35 pagesCherne TSK Irudy6078100% (1)

- Torsion, Scalar Field and F (R) GravityDocument14 pagesTorsion, Scalar Field and F (R) Gravityp k mahatoNo ratings yet

- Teal NewspaperDocument3 pagesTeal NewspaperkishbudNo ratings yet

- Mueller Experiments Kromrey Brandt Tesla Bedini!!!!!Document30 pagesMueller Experiments Kromrey Brandt Tesla Bedini!!!!!d4nk4rNo ratings yet

- HIGH FREQUENCY PLASMOID IN VORTEX AIRFLOW (A.I. Klimov)Document8 pagesHIGH FREQUENCY PLASMOID IN VORTEX AIRFLOW (A.I. Klimov)THE NIKOLA TESLA INSTITUTE100% (1)

- Bearden - Electret - What It Is and How It Works (2005) PDFDocument4 pagesBearden - Electret - What It Is and How It Works (2005) PDFUn Chubacca YetiNo ratings yet

- Tesla Symp06 CorumDocument7 pagesTesla Symp06 CorumNO,NO,NO 2 status QUONo ratings yet

- THE BIGGEST LITTLE ANTENNA IN THE WORLD - US Navy's VLF Antenna at Cutler MaineDocument57 pagesTHE BIGGEST LITTLE ANTENNA IN THE WORLD - US Navy's VLF Antenna at Cutler MaineTHE NIKOLA TESLA INSTITUTE100% (2)

- Secrets of Cold War Technology by Gerry VassilatosDocument324 pagesSecrets of Cold War Technology by Gerry VassilatosproofaddictNo ratings yet

- Vladimir UtkinDocument93 pagesVladimir UtkinTata Lissokit100% (4)

- Radiant EnergyDocument199 pagesRadiant EnergyicewarNo ratings yet

- Tom Bearden PPA Increasing COP by Addnl Extractn From Flow1aDocument34 pagesTom Bearden PPA Increasing COP by Addnl Extractn From Flow1akishbudNo ratings yet

- A G PatentsDocument12 pagesA G PatentsartleaderNo ratings yet

- Adams Pulsed Electric Motor PDFDocument13 pagesAdams Pulsed Electric Motor PDFnima_matrix20028550No ratings yet

- A Special Selection From Infinite Energy Magazine: Selected Articles From Issues 1 - 45 March/April 1995 - September/October 2002Document117 pagesA Special Selection From Infinite Energy Magazine: Selected Articles From Issues 1 - 45 March/April 1995 - September/October 2002DsgmmmmNo ratings yet

- 2013 Theory of Antirelativity Eric DollardDocument13 pages2013 Theory of Antirelativity Eric DollardJR2017100% (3)

- The N Machine by Bruce DePalmaDocument10 pagesThe N Machine by Bruce DePalmaSebastienKlementNo ratings yet

- How An Electrical Circuit Is REALLY Powered - Bearden For DummiesDocument8 pagesHow An Electrical Circuit Is REALLY Powered - Bearden For Dummiesberencsi2616No ratings yet

- Anti GravityDocument0 pagesAnti Gravitydewidewi76No ratings yet

- A Special Case of Voltage Gain - Olicer Nichelson - VOLTGNDocument2 pagesA Special Case of Voltage Gain - Olicer Nichelson - VOLTGNDra_en_Ku_mi__5308No ratings yet

- Eric Dollard On Telluric WavesDocument30 pagesEric Dollard On Telluric Waveselectrosci67% (3)

- 401 731 1 SM PDFDocument7 pages401 731 1 SM PDFsempreaprender3701No ratings yet

- Longitudinal Waves in ElectromagnetismDocument7 pagesLongitudinal Waves in Electromagnetismarg0naut0% (1)

- Evgray Research - Vibrator Circuit by Gary PorterDocument18 pagesEvgray Research - Vibrator Circuit by Gary Porterlittledigger100% (1)

- T7-0ts Instruction ManualDocument2 pagesT7-0ts Instruction ManualĆoravka Gluvić-MutavićNo ratings yet

- Black WavesDocument15 pagesBlack WavesGUESTXXXNo ratings yet

- The Telefunken - Nikola Tesla and The Sayville WirelessDocument6 pagesThe Telefunken - Nikola Tesla and The Sayville WirelessTHE NIKOLA TESLA INSTITUTENo ratings yet

- Communicate After InternetDocument4 pagesCommunicate After InternetJake MitchellNo ratings yet

- Free Electric Energy in Theory and PracticeDocument77 pagesFree Electric Energy in Theory and Practicesdio06No ratings yet

- Plasma Tubes With Internal and External ElectrodesDocument4 pagesPlasma Tubes With Internal and External ElectrodesHayley As Allegedly-Called YendellNo ratings yet

- Pulsed Discharge Plasma For Pollution ControlDocument25 pagesPulsed Discharge Plasma For Pollution ControlTHE NIKOLA TESLA INSTITUTENo ratings yet

- AlzofonDocument20 pagesAlzofonOrphiac IncNo ratings yet

- Replication and Study of Kapagene GeneratorDocument8 pagesReplication and Study of Kapagene GeneratoremiroNo ratings yet

- Imaginary ConstructsDocument2 pagesImaginary ConstructsVinyasiNo ratings yet

- Theoretical Elements of Electro-Dynamic MachineryDocument116 pagesTheoretical Elements of Electro-Dynamic Machineryanonkid100% (7)

- Pt.3 - Algebra - Eric Dollard SFTS PowerpointDocument234 pagesPt.3 - Algebra - Eric Dollard SFTS PowerpointSh3nrA80% (5)

- Final DocumentDocument60 pagesFinal Documentatri786No ratings yet

- Testament of Eric P DollardDocument6 pagesTestament of Eric P Dollardacuonaut100% (1)

- Zero Point Energy Per Stereo Radian and the Distribution of Gravitational Acceleration of Planets Throughout the Solar System.: The Origin and Cause of GravitationFrom EverandZero Point Energy Per Stereo Radian and the Distribution of Gravitational Acceleration of Planets Throughout the Solar System.: The Origin and Cause of GravitationNo ratings yet

- Electromass: The Same Principles at Every ScaleFrom EverandElectromass: The Same Principles at Every ScaleRating: 3 out of 5 stars3/5 (1)

- Stanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinFrom EverandStanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinNo ratings yet

- Conversations on Electric and Magnetic Fields in the CosmosFrom EverandConversations on Electric and Magnetic Fields in the CosmosNo ratings yet

- Mathematical Solution Unifying the Four Fundamental Forces in NatureFrom EverandMathematical Solution Unifying the Four Fundamental Forces in NatureNo ratings yet

- The Magnetic Pulse of Life: Geomagnetic Effects on Terrestrial LifeFrom EverandThe Magnetic Pulse of Life: Geomagnetic Effects on Terrestrial LifeNo ratings yet

- Radio Designers HandbookDocument1,540 pagesRadio Designers Handbookkishbud100% (3)

- Joseph Newman The Energy MachineDocument54 pagesJoseph Newman The Energy Machinekishbud100% (8)

- Charles Steinmetz - Elementary Lectures On Electric Discharges, Waves and ImpulsesDocument172 pagesCharles Steinmetz - Elementary Lectures On Electric Discharges, Waves and Impulsesdawsecs100% (1)

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Radiation Light and Illumination - 1918Document330 pagesRadiation Light and Illumination - 1918oung12012469No ratings yet

- Steinmetz Outline of Theory of Impulse Currents 1916Document31 pagesSteinmetz Outline of Theory of Impulse Currents 1916kishbudNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Tesla Coil TunerDocument4 pagesTesla Coil TunerkishbudNo ratings yet

- Tesla CoilDocument5 pagesTesla CoilJim78% (9)

- Tesla-Inventions, Researches and WritingsDocument522 pagesTesla-Inventions, Researches and Writingsslavkobatich100% (1)

- Brevets Nicola Tesla CompletDocument499 pagesBrevets Nicola Tesla CompletkozlhooNo ratings yet

- Thermodynamics 2Document7 pagesThermodynamics 2riez24No ratings yet

- N 10 Electricalexperi 06 GernDocument84 pagesN 10 Electricalexperi 06 Gerntomtom545100% (2)

- Tom Bearden PPA Increasing COP by Addnl Extractn From Flow1aDocument34 pagesTom Bearden PPA Increasing COP by Addnl Extractn From Flow1akishbudNo ratings yet

- Bill Ramsay Rodin Coil Test Result ExplanationsDocument4 pagesBill Ramsay Rodin Coil Test Result Explanationskishbud100% (1)

- Kromrey Converter US3374376Document8 pagesKromrey Converter US3374376kishbud100% (1)

- Pharmacists Give Themselves Cancer From Dispensing Toxic Chemotherapy ChemicalsDocument4 pagesPharmacists Give Themselves Cancer From Dispensing Toxic Chemotherapy ChemicalskishbudNo ratings yet

- Scalar Wave TechnologyDocument13 pagesScalar Wave Technologykishbud100% (1)

- Cipaca Lake and Neuropothy CausesDocument8 pagesCipaca Lake and Neuropothy CauseskishbudNo ratings yet

- Coconut Cooking Oil Is A Powerful VirusDocument9 pagesCoconut Cooking Oil Is A Powerful ViruskishbudNo ratings yet

- 528Hz FrequencyDocument16 pages528Hz Frequencykishbud100% (1)