Professional Documents

Culture Documents

Fanuc 0i-M Manual

Fanuc 0i-M Manual

Uploaded by

rastaeggCopyright:

Available Formats

You might also like

- Okuma OSP P300S Operation ManualDocument415 pagesOkuma OSP P300S Operation Manualsunhuynh100% (4)

- Operating Manual: Mazatrol SmoothcDocument84 pagesOperating Manual: Mazatrol SmoothcLuis VargasNo ratings yet

- B-64487EN - 05 Operation and Maintenance Handbook 30iDocument974 pagesB-64487EN - 05 Operation and Maintenance Handbook 30iDmitryNo ratings yet

- Mazak Integrex J Series Parameter List MCode List Alarm ListDocument760 pagesMazak Integrex J Series Parameter List MCode List Alarm ListAju Augustine100% (2)

- Moriseiki Maintenance ClassDocument410 pagesMoriseiki Maintenance ClassLEONEL CARDENAS100% (10)

- Manual Guide +Document648 pagesManual Guide +Aloisio Gonzaga0% (1)

- vmc8501020 NCDocument153 pagesvmc8501020 NCNarendra Yadav100% (2)

- Programming Manual: Mazatrol Matrix NexusDocument350 pagesProgramming Manual: Mazatrol Matrix NexusMilton Righetto Nass100% (1)

- Mazak Alignment Procedure Integrex MK-IVDocument14 pagesMazak Alignment Procedure Integrex MK-IVMauro S Cabral100% (2)

- Mazak Integrex ATC Alignment ProcedureDocument29 pagesMazak Integrex ATC Alignment Procedureganesan 0011100% (1)

- Renishaw.-Installation Manual For Machine ToolsDocument220 pagesRenishaw.-Installation Manual For Machine ToolsPeter Nomikos100% (1)

- Fanuc Manual GuideDocument172 pagesFanuc Manual GuidemarianhainarosieNo ratings yet

- Okuma Howa Spindle Drive AlarmsDocument3 pagesOkuma Howa Spindle Drive AlarmsAnonymous wBxc1VGtNo ratings yet

- 65002e PDFDocument348 pages65002e PDFCristobal PerezNo ratings yet

- Okuma Osp p300s p300l Gauging Systems Instruction Manual Application Le61 497 R01a PDFDocument191 pagesOkuma Osp p300s p300l Gauging Systems Instruction Manual Application Le61 497 R01a PDFseb_dominiqueNo ratings yet

- Eiaiso640t MTDocument356 pagesEiaiso640t MTJPPNo ratings yet

- Yamaha Banshee Parts Manual 5FK6 - 2000Document55 pagesYamaha Banshee Parts Manual 5FK6 - 2000Felipe Antonio Pinto VillarroelNo ratings yet

- Fanuc CNC Parts: Rigid Tapping TroubleshootingDocument6 pagesFanuc CNC Parts: Rigid Tapping TroubleshootingTony AntonyNo ratings yet

- Programing Manual EIA ISODocument416 pagesPrograming Manual EIA ISORelu Chiru100% (2)

- SystemVarsAlpha List OkumaDocument16 pagesSystemVarsAlpha List Okumaseb_dominique100% (3)

- MazakDocument420 pagesMazakrguzmanabundis100% (1)

- Okuma OSP P300S Tool Magazine Instruction ManualDocument61 pagesOkuma OSP P300S Tool Magazine Instruction Manualsunhuynh100% (1)

- Mazak EIA - Programming Manula For Mazatrol Matrix PDFDocument531 pagesMazak EIA - Programming Manula For Mazatrol Matrix PDFMounir DouggazNo ratings yet

- Bnp-b3484 Centro Usinagem L31-MazakDocument227 pagesBnp-b3484 Centro Usinagem L31-MazakAntonio LucasNo ratings yet

- Parameter List: Mazatrol M PlusDocument136 pagesParameter List: Mazatrol M PlusОлег СуворовNo ratings yet

- MCV 510 - 1250B Operation and Maintenance Manual V2 - 2 PDFDocument346 pagesMCV 510 - 1250B Operation and Maintenance Manual V2 - 2 PDFGuillermo Ramirez100% (4)

- Kia SKT210SYDocument94 pagesKia SKT210SYrastaeggNo ratings yet

- Puma 450Document84 pagesPuma 450Cezar BalașeiNo ratings yet

- Mazak Matrixmillturn Eia Progmanual PDFDocument618 pagesMazak Matrixmillturn Eia Progmanual PDFCorey YoungNo ratings yet

- Applications Training For Integrex-100 400MkIII Series Mazatrol FusionDocument89 pagesApplications Training For Integrex-100 400MkIII Series Mazatrol FusionjaniNo ratings yet

- MAZAK MatrixMillTurn EIA ProgManualDocument618 pagesMAZAK MatrixMillTurn EIA ProgManuallastowlNo ratings yet

- NC Guide ProDocument4 pagesNC Guide ProBhupesh Kumar100% (2)

- MAZAK Matrix2 EIA ProgManualDocument502 pagesMAZAK Matrix2 EIA ProgManuallastowl50% (2)

- Fanuc 15 Model B - Alarm ListDocument32 pagesFanuc 15 Model B - Alarm Listakirenavi100% (1)

- Specifications: FANUC Series 16/18-MB/TB/MC/TC FANUC Series 16Document15 pagesSpecifications: FANUC Series 16/18-MB/TB/MC/TC FANUC Series 16avalente112No ratings yet

- GE Fanuc 18i Installation ManualDocument81 pagesGE Fanuc 18i Installation Manualapi-3771584No ratings yet

- DD 129283005 CDocument79 pagesDD 129283005 CTensaigaNo ratings yet

- Mori Seiki GPS System Relocation GPSRMS - OperationManual - NFP - Dongle2015 - EngDocument34 pagesMori Seiki GPS System Relocation GPSRMS - OperationManual - NFP - Dongle2015 - EngJuana Chivo100% (3)

- Meldas 64Document352 pagesMeldas 64Maria Cristina MendesNo ratings yet

- Fanuc O Series Lathe Parameter ManualDocument174 pagesFanuc O Series Lathe Parameter ManualАлексей Зубков100% (4)

- Maintenance Manual: Fanuc Ac Spinole ServoDocument152 pagesMaintenance Manual: Fanuc Ac Spinole Servovasiliy vasilievichNo ratings yet

- MR J2 Set Up Software BNP-B2208 PDFDocument70 pagesMR J2 Set Up Software BNP-B2208 PDFCristopher EntenaNo ratings yet

- BNP-A3040 Meldas5000 CNCDocument175 pagesBNP-A3040 Meldas5000 CNCchidambaram kasiNo ratings yet

- Maza Trol M 2 Operator ManualDocument5 pagesMaza Trol M 2 Operator Manualcamb2270100% (1)

- 65264EN Servo Tuning Alfa - FanucDocument58 pages65264EN Servo Tuning Alfa - FanucpkrkaranNo ratings yet

- FANUC Series 0i-MF Plus Die Mould FunctionsDocument18 pagesFANUC Series 0i-MF Plus Die Mould FunctionsAlex100% (1)

- N VX NV Post Processor Manual EngDocument29 pagesN VX NV Post Processor Manual EngrenatoNo ratings yet

- B 66102e - 10 - FanucDocument236 pagesB 66102e - 10 - Fanucbabak67167% (3)

- B-63530en 02Document550 pagesB-63530en 02ยุทธพงศ์ สืบตระกูล100% (3)

- 0i TF PLUS OP ENDocument374 pages0i TF PLUS OP ENTree889 GroundNo ratings yet

- Fusion640t Programming, Online, SummaryDocument7 pagesFusion640t Programming, Online, SummaryGuillermo Ramirez100% (1)

- CncLatheOkumaLb15 PDFDocument52 pagesCncLatheOkumaLb15 PDFSilvio GomesNo ratings yet

- V55 Maintenance 5Document5 pagesV55 Maintenance 5วรพงษ์ กอชัชวาลNo ratings yet

- Mitsubishi Alarm ListDocument19 pagesMitsubishi Alarm Listcoronaqc100% (1)

- Manual Guide I CNC Milling Made Easy ManualDocument126 pagesManual Guide I CNC Milling Made Easy ManualJasminNo ratings yet

- 5 - Manual Software DuplomaticDocument53 pages5 - Manual Software DuplomaticLuiz Gustavo Pastrello100% (1)

- Powermate 0 Maintenance Manual PDFDocument227 pagesPowermate 0 Maintenance Manual PDFmrtans100% (1)

- QT350 Alarm ListDocument102 pagesQT350 Alarm ListAbdul Leon50% (2)

- Classification of BudgetsDocument2 pagesClassification of Budgetskashishgarg429No ratings yet

- Scan 420Document1 pageScan 420Rahul ChoudharyNo ratings yet

- Hsslive March 2023 Key FY 436 Political ScienceDocument5 pagesHsslive March 2023 Key FY 436 Political Sciencemuhammedmuhtharmuhthar52No ratings yet

- 내 주는 강한 성이요Document14 pages내 주는 강한 성이요onlybronze46100% (1)

- User inDocument626 pagesUser ins_barriosNo ratings yet

- Nova MillDocument18 pagesNova MillrastaeggNo ratings yet

- BBCUserGuide-1 00Document524 pagesBBCUserGuide-1 00manitou1997No ratings yet

- iTNC 530: User's Manual HEIDENHAIN Conversational FormatDocument552 pagesiTNC 530: User's Manual HEIDENHAIN Conversational FormatrastaeggNo ratings yet

- CMZ Programming ManualDocument133 pagesCMZ Programming Manualrastaegg100% (6)

- Eagle Fanuc Oi Iss 2bDocument69 pagesEagle Fanuc Oi Iss 2brastaegg100% (1)

- HurcoLathe Max Start r0115-101Document108 pagesHurcoLathe Max Start r0115-101rastaeggNo ratings yet

- Hurco Lathe Conversational r0115-201Document84 pagesHurco Lathe Conversational r0115-201rastaeggNo ratings yet

- 4. Hướng dẫn sử dụng điều hòa tủ đứngDocument21 pages4. Hướng dẫn sử dụng điều hòa tủ đứngDuy ChuNo ratings yet

- Ethernet StandardDocument3 pagesEthernet Standardajju1378No ratings yet

- tfc02 PDFDocument22 pagestfc02 PDFAniigiselaNo ratings yet

- BST203 CDocument14 pagesBST203 CSutiknoNo ratings yet

- 3ah3 PDFDocument44 pages3ah3 PDFAndi GheorgheNo ratings yet

- Check Valve DescriptionDocument1 pageCheck Valve DescriptionmoodydoodyNo ratings yet

- NEW-3663 UserlDocument2 pagesNEW-3663 UserlksubbuNo ratings yet

- Computer Fundamental PDFDocument143 pagesComputer Fundamental PDFSudhir GulekarNo ratings yet

- Ashfaq Patel: Project Name: Water Jacket Core, Drilling SPM (Hinduja Foundry)Document2 pagesAshfaq Patel: Project Name: Water Jacket Core, Drilling SPM (Hinduja Foundry)Ayushee TiwariNo ratings yet

- FPGA (Field Programmable Gate Arrays)Document16 pagesFPGA (Field Programmable Gate Arrays)Syed Zulqadar HassanNo ratings yet

- Aircraft Electrical System Chapter 6 - Landing Gear PDFDocument19 pagesAircraft Electrical System Chapter 6 - Landing Gear PDFnjnvsrNo ratings yet

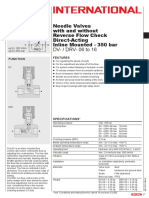

- Needle Valves With and Without Reverse Flow Check Direct-Acting Inline Mounted - 350 BarDocument4 pagesNeedle Valves With and Without Reverse Flow Check Direct-Acting Inline Mounted - 350 BarAmar KevricNo ratings yet

- Sauer Series 90 ManualDocument72 pagesSauer Series 90 ManualJCNo ratings yet

- Hydraulic Circuitry (W - BPV Junction Block) - (S - N B3BV11001 - B3BV11355) - S770Document5 pagesHydraulic Circuitry (W - BPV Junction Block) - (S - N B3BV11001 - B3BV11355) - S770Виктория РыбакNo ratings yet

- Geometrical & Mechanical Engineering Drawing-CAPE Unit II: Belt DrivesDocument3 pagesGeometrical & Mechanical Engineering Drawing-CAPE Unit II: Belt DrivesOlusegun OlugbadeNo ratings yet

- Asus A7N266-VM Motherboard ManualDocument116 pagesAsus A7N266-VM Motherboard Manualgm799763No ratings yet

- Body Control System: SectionDocument19 pagesBody Control System: SectionYehya ShaabanNo ratings yet

- Generation III Sonic Feeder Control System Manual 20576Document32 pagesGeneration III Sonic Feeder Control System Manual 20576julianmataNo ratings yet

- 02 Gen'l Info 456Document34 pages02 Gen'l Info 456Gabriely MuriloNo ratings yet

- Dahao A88 EngDocument166 pagesDahao A88 Engpaul197777777100% (2)

- GA Tug Boat - Ratu Fadila Atika Fadiat - 2006529032Document1 pageGA Tug Boat - Ratu Fadila Atika Fadiat - 2006529032ゖゖ ゖゖ ゖNo ratings yet

- Product Line Catalogue Ne Catalogue: Wrap Yourself in Comfort and Quiet Eco-Conscious Technologies From JapanDocument22 pagesProduct Line Catalogue Ne Catalogue: Wrap Yourself in Comfort and Quiet Eco-Conscious Technologies From Japanعبدالرحمن كرديNo ratings yet

- Endfedz Ef-Swl: HF End Fed Receive AntennaDocument4 pagesEndfedz Ef-Swl: HF End Fed Receive AntennaKane Wilson GonzalesNo ratings yet

- Usb 3.0 Docking & Clone Station For 2 Sata HddsDocument3 pagesUsb 3.0 Docking & Clone Station For 2 Sata HddsjpcmansoNo ratings yet

- TTV-IOM November 2006Document23 pagesTTV-IOM November 2006Ngô Khắc ToảnNo ratings yet

- Duties and ResponsibilitiesDocument5 pagesDuties and ResponsibilitiesJjiza MiclatNo ratings yet

- Tender Schedule For Electrical Work PDFDocument6 pagesTender Schedule For Electrical Work PDFnakul4491_88890127No ratings yet

- Ar650 Error CodesDocument4 pagesAr650 Error CodesforidigiNo ratings yet

- Technical Specifications Renault MASTER Z EDocument1 pageTechnical Specifications Renault MASTER Z Enawaz khanNo ratings yet

Fanuc 0i-M Manual

Fanuc 0i-M Manual

Uploaded by

rastaeggOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fanuc 0i-M Manual

Fanuc 0i-M Manual

Uploaded by

rastaeggCopyright:

Available Formats

FANUC Oi-M TRAINING MANUAL

This document is based on information available at the time of its publication. While efforts have been made to render accuracy to its content, the information contained herein does not purport to cover all details or variations in hardware and software, nor to provide every possible contingency in connection with installation, operation, programming, and maintenance. Features maybe described herein which are not present in all hardware and software systems.

Dugard Ltd assumes no obligation of notice to holders of this document with respect to changes subsequently made.

Dugard Ltd makes no representation or warranty, expressed, implied or statutory with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency or usefulness of the information in the manual .

•

DUGARD EAGLE FANUC OiM START UP PROCEDURE

• S\VITCH MACHINE ISOLATOR ON (ROUND BACK

OF MACHINE)

• ENSURE THAT THE OPERATOR DOOR IS CLOSED

• PULL E-STOP OUT

• PRESS CONTROL ON BUTTON, MACHINE WILL DISPLA Y SOFTWARE NUMBER AND A MESSAGE "NOT READY"

• WHEN "NOT READY" DISAPPEARS PRESS "POS"

• PRESS "ALL"

• ENSURE THAT "X,Y,Z" VALUES ARE IN EXCESS OF 1 OOMM FROM THE HOME POSITION

• MODE SELECTION SWITCH R4 TO THE ZERO

RETURi'\ POSITION

• PRESS-Z

• PRESS-X

• PRESS +Y

• NOTE: THE "Z" AXIS MUST BE REFERENCED FIRST.

SHUT DOWN PROCEDURE

• PRESS EMERGENCY STOP BUTTON

• PRESS NC CONTROL POWER OFF, (RED BUTTON)

• SWITCH ISOLATOR OFF, (ROUND BACK OF MACHINE)

MACIDNE AXIS

A) Vertical machining centers.

Z+

+

Y+

X+

B) Horizontal machining centers.

Y+

X+

rzC

+

- -

1, '

'·'i~{:' :"1"

:i-);;L:':;;),~f;!-,_-i:~;J-,.~:-i

\

ZERO RETURN

There is only one fixed reference point of each axis which is known as Zero Return. When powering on the machine it is necessary to manually establish this position using the appropriate Zero ReturnlReference push buttons.

On completion of this operation the machine will know its present position and subsequent functions can be performed.

The position of the zero return can vary between machine types in the 'X' and 'V' axes although the 'Z' axes point is at the top of the stroke, and invariably used as the tool change point.

NB: Some CNC machines are further refined by incorporating <Absolute Position Encoders', these never forget where their position is even after a power off.

- -

2.

..

>"., ... -", •. :,.,' .. : ...... .u

. 't,";, .;Z·'i;:;:':::.";'~;; -:

CO-ORDINATE SYSTEMS

CNC programming requires the use of rectangular co-ordinates. This is a point whose co-ordinate is expressed by using a linear value which is equal to the distance between a datum (i.e. XO YO) and the point in each axis.

RECT ANGULAR Co-ordinates (Also known as CARTESIAN co-ordinates)

POLAR Co-ordinates

Y4L78

- --

-r-t----+

X49.79

X+=Odeg. CCW=+ deg.

The co-ordinate system used results in a grid based around the datum (X axis zero, Y axis zero) of the component.

Y+

A= X35.0 Y25.0

B= X35.0 Y-15.0 G 30 A

c= X27.5 Y-3_O.O

D= X-12.5 Y-30.0 20

E= X-l2.5 Y-IO.O

F= X-20.0 Y-IO.O 10

G= X-20.0 Y25.0 30 10 20 30 40

x-

F 10

E

8

20 o

40

The positive sign is not required. If the negative sign is not programmed the machine will assume a positive figure.

The position of the datum will greatly affect the value of each of the coordinates. It is therefore vital that the datum of the component is established before attempting to write the program.

The datum(s) are freely definable by the programmer for a particular workpiece and may be either inside or outside the component to make co-ordinates easier to calculate.

- -.

The grid system also applies to the 'Z' axis.

Z+

~----~- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - J\

_-_ - - - _. - - - - - - - - - - - - - - .. - - - - B '------ - - - - - - - - - - - - --c

........ --------- 0

z-

x- ...... __ -------- ....... x+

FACE A=Z20 FACEB =ZO FACE C =Z-lO FACE D = Z-20

- --

5

There are two ways of commanding axis movement

I. ABSOLUTE (G90)

This system uses an absolute zero point on the component and all points are relative to this pre-determined datum. This method is by far the most widely used as the values relate directly to the component drawing and eliminates the need for mental arithmetic.

2. INCREMENTAL (G91)

This system is based on the point to point method. The actual distance between two points is specified along with its direction.

A

B

c

D

IIIIIIISIIIIIII

35 30 25 20 15 10 5

5

10 15 20 25 30 35

x- "~!I----------~~~ x+

ABSOLUTE INCREMENT AL

FROMBTOC X2S.0 X20.0

FROMCTOD X3S.0 XIO.O

FROMDTOA X-lS.O X-SO.O

FROM A TOB XS.O X20.0 Both methods of command are called within the program using preparatory (G) codes

as will be seen later. .'

The absolute method is a safer than incremental because one error in an incremental program will in effect. shift the entire program by the amount of the error.

- -

120 Y+

110

100

90

80

70 2

60

50

40

30

20 1

10 4

5

t-----A

---8

6

X+

10 20 30 40 50 60 70 80 90 100 110

I 2 3 4 5 6

A

GOO 090 X20.0 Y20.0

GOI 091 XIO.O Y50.0 FI20 XIO.O Y30.0

X50.0 Y20.0

X-IO.O Y-60.0

Y-40.0

X-70.0

B

GOO 090 X20.0 Y20.0

GOI O9lX20.0 Y50.0 FI20 XIO.O Y30.0

X50.0 Y20.0

X-IO.O Y-60.0

Y-SO.O

X-70.0

- -

ABSOLUTE CO-ORDINATE PROGRAMMING (G90)

In Absolute (G90) all dimensions are taken from a fixed point which is specified by the programmer.

y+

75

60

•

• i' '-_\j_~,.~t~"t~'-: l'

i-->"" _",.,:,'

.- --~~~~#~~;Jk~i¥~,\4¥~¥:;Mif&1~- ":§:-:,~,,~":-~~,

t

o

o

o

25

...

___ ---------

12 ~

- -

;-.;';,"-"',:',;';;,;"-

"\:;t.~~~t;;.;L~,;\' ;;;";;"'t)1}fl-;(:';;;

..__~

INCREMENTAL CO-ORDINATE PROGRAMMING (091)

In Incremental (091) all dimensions are taken from the last co-ordinate and not from a fixed point.

15

o

35

25

~-----50----~>~<~25

- --

X+

9

EXAMPLE 1

ABSOLUTE AND INCREMENTAL PROGRAMMING.

10 9 8 7 6 5 4 3 2 1 1 2 3 4 5 6 7 8 9 10

Y+

10 -, - 10

9 F 9

8 A - , 8

7 t • 7

6 f - - 1- - 1- 6

I

5 I -E- I I I 5

t- - - - 1- - -, - - , -t - - - - ,- - -,- r - - r -

I

4 I I I -G , I -0 4

r - - - r - - I - - I - - - - r - - -, - - T - - - -,

I

3 I - I I I I I - I - - - - 3

r- - - - - I - - - I - - -, - - I - - - - I - ,

2 I 2

L - - '. - - l - - ~ - - I - - I - - I - - - - L - - - - J - - -'- - c - J

I I

1 : i. I 1

L - L - - ,- - _1- - " - -

I

X ... X+

1 B - - - 1

. -- ,

2 I -'- 2

- I- - - --

3 - - - -J 3

4 L 4

5 c - _. -. - - 5

6 6

7 K -- - - -. - - - 7

I- I 1

8 I - I - - - - - - I - -'- -H 8

- , - - .- - I I - - -

9 - - - I - - - - - ,- 9

10 - L - - I - - - - 1 10

10 9 8 7 6 5 4 3 2 1 Y- 1 2 3 4 5 6 7 8 9 10 Absolute Incremental

A X Y AToB X Y

B X Y BToC X Y

C X Y CToD X Y

D X Y DToE X Y

E X Y EToF X Y

F X Y LToH X y

G X Y KToJ X y

H X Y JTo L X y

I X Y CToJ X Y - -

10

PREPARATORY FUNCTIONS ('G' CODES)

The use of a two digit 'G' code determines the command meaning on any given block of program. They effectively prepare the machine for a given command, e.g. RAPID or FEED from point' A' to point 'B', or should the machine arc in the clockwise or anticlockwise direction?

Most controls can list up to 90 different 'G' codes. However, the vast majority of these are not required unless using specialist programming techniques (machine manufacturers writing software).

The listing on the following page gives the most commonly used codes which are vital to the machines operation.

Each 'G' code belongs to a group.

A) Many 'G' codes can be programmed in a block as long as they are non conflicting. 'G' codes in the same group will conflict if programmed in the same block.

B) The group will also signify if the code is MODAL or NON-MODAL

A MODAL 'G' code is one which is effective until canceled by a 'G' code of the same group.

A NON-MODAL 'G' code is one which is effective only in the block in which it is programmed.

Group 00 'G' codes are NON-MODAL.

- -

\ \

GCODE GROUP DESCRIPTION

GOO 01 Positioning (Rapid feedrate)

GOI Linear Interpolation (Cutting feedrate)

G02 Circular interpolation Clockwise

G03 Circular interpolation Counter -clockwise

G04 00 Dwell, Exact stop

GOS High Speed Cycle Machining

G08 Advanced Preview Control

G09 Exact Stop

GIO Data setting

GIl Data settiI!& mode Cancel

GIS 17 Polar Cordinates Command Cancel

GI6 Polar Coordinates Command

GI7 02 X, V Plane assignment

GI8 Z,X Plane assignment

GI9 V,Z Plane ass~ent

G20 06 Inch Input

G2I Metric Input

G22 04 Stored stroke check function on

G23 Stored stroke check function off

G27 00 Reference zero return check

G28 Return to reference point

G29 Return from reference point

G30 Return to the second reference zero point

G31 Skip function

G39 Comer Offset Circular interpolation

G40 07 Cutter Radius Compensation (CRC) Cancel CDC

G41 CRC Left Side

G42 CRC~htSide

G43 08 Tool Length compensation '+'

G44 Tool Length compensation '-'

G49 Tool Length compensation cancel

G50 11 Scaling Cancel

G51 Scaling

G52 00 Local Coordinate System Setting

G53 Machine Coordinate S~tem Selection

G54 14 Workpiece Coordinate System I Selection

G55 Workpiece Coordinate System 2 Selection

G56 Workpiece Coordinate System 3 Selection

G57 Workpiece Coordinate System 4 Selection

G58 Workpiece Coordinate System 5 Selection

G59 Workpiece Coordinate System 6 Selection

065 00 Macro command

G66 Custom Macro Modal Call

067 Custom Macro Modal Call cancel - --- ---

o .= ,,~"- , '"' , ", - -.

t2

GCODE GROUP DESCRIPTION

G68 16 Co-ordinates Rotation

G69 Co-ordinates Rotation Cancel

G73 09 Peck Drilling Cycle

G74 Reverse Tapping Cycle

G76 Fine Boring

G80 Fixed Cycle Cancel

G81 Drilling Cycle

G82 Counterboring

G83 Peck Drilling Cycle

G84 Tapping Cycle

G85 Boring Cycle

G86 Boring Cycle

G87 Back Boring Cycle

G88 Boring Cycle

G89 Boring Cycle

G90 03 Absolute input

G91 Incremental Input

G92 00 Co-ordinate system setting

G94 05 Feed per minute

G95 Feed per Revolution

G98 04 Return to Initial Plane

G99 Return to 'R' Plane Notes:

Other groups besides the 00 group are modal (Stays active), and once they are commanded, they remain valid until another code in the same group is commanded and they are not influenced by the RESET push button switch.

G codes in the 00 group are non modal. It is possible to input many G codes in a block as long as two codes from the same group are NOT programmed. If two G codes from the same group are programmed the G code which is commanded later becomes valid, and the former becomes invalid.

- -

, ...,

Miscellaneous Function List

M-Code I Function Type I Remark

MOO Program stop

M01 Optional stop

I M02 End of program

I

r M03 Spindle CW

I

I M04 Spindle CCW

I M05 Spindle stop

f

M06 Auto tool change

M08 Coolant on

I M09 Coolant off

M10 4 th 5th axis servo off & clamp

M11 4 th axis servo on & unclamp

M12 5th axis servo on & unclamp

I M13 Spindle CW & coolant on

I

i M14 Spindle CCW & coolant on

; I

I M15 M13/M14 off

I

L M17 Coolant through spindle hole I Option

L- M18 M17 off I Option

I

l M19 Spindle orientation

L M23 Spindle CW & mist coolant on

I M24 Spindle CCW & mist coolant on I

I

i M25 I M23/M24 off

I M29 Rigid tapping

!

, M30 Program rewind I

1 I

I M31 I Air blow on I I

I

I M32 Air blow off I I

i

I M33 Spindle CW & air blow on Option

I

M34 Spindle CCW & air blow on Option

M35 M33/M34 off Option

M40 Neutral gear command

M41 Low gear command

M42 High gear command

M49 A TC automatic maintenance mode Arm Type

M49 Rotary MAG toot No. = Spindle tool No. Carousel Type

M50 POT vertical command Arm Type

M50 MAG forward (to spindle) Carousel Type

M51 Swing arm CCW 65 Arm Type

M51 Tool change position (spindle unclamp) Carousel Type

M52 Tool unclamp Arm Type

M52 Search change tool No. Carousel Type

- (

'.

C-1

1ft.

(

M-Code I Function I Type I Remark

M53 Swing arm down & turn 180· Arm Type

M53 Spindle clamp Carousel Type

M54 Tool clamp Arm Type

r--- M54 MAG backward (to home) Carousel Type

i

I

r M55 Swing arm back home Arm Type

I M55 Check spindle with MAG tool No. Carousel Type

:

t M56 Pot horizontal command Arm Type

i

I M56 M55 off Carousel Type

M60 Pot No.1 search and tool No. offset Arm Type

M63 Chip conveyor CW

M64 Chip conveyor CCW

M65 Chip conveyor off

M68 Cover coolant on

I M69 Cover coolant off

I

I

\

! M94 Mirror cancel

i M95 X mirror image on

l----

i M96 Y mirror image on

!

,--_.-

i M98 Main tape call sub I

;---~~--

I M99 Sub tape return

I

L_ - -

C-2

Eagle 600 Fanuc XP Supplement

Variations in M Codes

M7 Puts on through spindle coolant (M9 oft)

Ml2 Puts on side bed wash (also available via Machine panel switch),not M68/M69.

Toolchangerrecovery:~

Umbrella Type changer,

If the carousel stops mid cycle during tool change due to low air or collision of tools, Type in MDI "MI 002" cycle start.

This will return the carousel to its home position.

INITIALIZATION

GO Rapid mode

G 15 Polar Co-ordinates Command Cancel G17 X,Y, plane selection

G90 Absolute command

G94 Feed per minute

G21 Metric data input

G40 Cutter Radius compensation cancel G49 Tool length compensation cancel G50 Scaling Cancel

GSO Canned cycle cancel

G98 Return to initial point in canned cycle G54 Workpiece coordinates system 1 selection G69 Co-ordinate Rotation Cancel

When the power to the NC control is turned on, the control assumes its initialised state by automatically activating default selections for modal functions. These are as follows:-

In addition to control power on, the following also activate default selections for modal functions:-

1. Pressing the RESET button

2. The control executes an MJO (End of Programme).

- --

\5

LINEAR INTERPOLATION (GO I Gl)

The axis of the machine will move in linear at either Rapid or a programme specified Feedrate.

Any movement precceded by:-

GOO will occur at RAPID TRAVERSE. GOl will occur at a FEEDRATE.

NOTE:-

These commands are MODAL and will stay active until changed. A maximum of three axis can be programmed in one block.

Y+

. - .- ·GOO- .

X200 Y100 -;_~:--~.

G01--· .

X+

When programming two axis together in Rapid mode both axis motors operate at the same speed. A movement of 45 degrees is performed until the smaller distance is met followed by a straight line move to reach the target point.

GO

X50

Y20

X200 YIOO

When programming two axis together in Feed mode the axis motors speeds will be adjusted so the axis will meet at the target point at the same time. The feedrate is actually specified in mmlmin (G94). When in Inch mode, (G20), the fcedrate is specified as Inches per

minute.

The "'F" command is MODAL.

GO 1 X50 Y20 F250

X200 YlOO

- --

CUTTER RADIUS COMPENSATION C.R.C.

This feature compensates the actual machine cutter path to allow the use of cutters with a diameter different from the nominal size of the tool assumed when the programme was prepared. Cutter Radius Compensation (CRe) is activated by programming G41 if the cutter is to the ieft of the workpiece when viewed in the direction of travel or G42 if the cutter is to the right of the workpiece.

When CRC is active the control computes new intersection points at every change of direction, so that the contact point between the actual cutter is the same as it would be for the nominal sized cutter following the original programme path. CRC automatically computes the offset

command point for any intersection moves, including Circular and Helical arcs. CRe is turned otl by programmimg G40.

Since the offset register is used for both length and radius offsets, it is recommended that 1 to 20 are used for length and 21 onwards are used for radius.

To set a Tool radius offset simply enter the radius of the cutter into the selected offset number. The offset number is called in the programme using "D" followed by the offset number, this is placed in the same block as the G411G42.

OUTSIDE PROFll..E OUTSIDE PROFILE INSIDE PROFll..E INSIDE PROFILE

c.w. c.C.W. c.w. C.C.W.

=LEFT G4i = RJGHTG42 = RIGHT G42 = LEFT G41

G41

Direction of Travel

Direction of Travel

RULES

1. Cutter Radius Compensation, (C.RC.), must be applied and cancelled on a movement line.

2. The distance of the movement line, when applying and cancelling compensation, must be larger than the Tool Radius Value.

3. Compensation must be applied at between 90 1180 degrees to the first cutting line.

4. Internal Circular moves must be greater than the tool radius value.

-

OPTIONAL ANGLE CHAMFERING AND CORNER ROUNDING

Format

Explanations

• Chamfering

• Corner R

Chamfering and corner rounding blocks can be inserted automatically between linear interpolation and linear interpolation blocks

,C_ ,R

]

Chamfering

Corner R

When the above specification is added to the end of a block that specifies linear interpolation (GOl), a chamfering or corner rounding block is inserted.

Blocks specifying chamfering and corner rounding can be specified consecutively.

After C, specify the distance from the virtual corner point to the start and end points. The virtual corner point is the corner point that would exist if chamfering were not performed.

r--------.------------~--------. --

CD G91 G01 X100.0 ,C10.0;

[II X100.0Y100.0;

Inserted chamfering block

e

1

!

1

L___. ~ . _

After R, specify the radius for corner rounding.

r

-.- .. --.---- - "---'l

m G91 G01 X100.0 ,R10.0; ~ X1 00.0 Y1 00.0 ;

intersection

18

CIRCULAR INTERPOLATION (G2/G3)

Information required to interpolate an arc.

Plane Selection G 1 7/G 18/G 19

Direction of rotation G2/G3

End Point position X Y (Z)

Distance from start point to arc centre ... I I J (K)

or Radius R

Feedrate F (if not previously programmed) Y+

G2 rc.w.i

Y"

X+

X+

z ..

'9

Z+

G2(CW_)

- -

CIRCULAR INTERPOLATION

(G2, G3)

A circular interpolation G2/G3 block moves the machine from its current position to the command position along a circular arc. The rate of travel is uniform around the arc with tangential vector feedrate equal to the programmed feedrate.

A circular path may be generated in any of the major planes by programmimg the appropriate plane Select code. G17 for XY, G 18 for Zx, or G 19 for YZ. The arc may be specified by programmimg the centre point using I, J and K words to specify the distance from the start point to the arc centre for

X, Y and Z respectively. Alternatively the circle arc can be specified by programrnimg the circle radius using the "R" word. In this case the control computes the location of circle centre so that an arc of the specified radius connects the current position and the commanded endpoint. Programming a positive radius specifies the shorter of the two possible arcs connecting the current position and the commanded position. Programming a negative radius selects the longer arc.

Circular Interpolation may be programmed in two ways:

1. Programming G2 or G3 together with "I,J,K," words to define the centre point of arc.

2. Programming G2 or G3 together with an "R" word to define the radius of the arc.

Any arc length up to one full circle can be programmed in one block. A complete circle is specified by programming the endpoint to be the same as the current position. in this case the centre point method must be specified since the radius and one point does not uniquely determine the circle.

Preparatory Function Codes G2 andG3 are used for programming Circular Interpolation. These codes determine the direction of the circular path as viewed from the positive end of the axis that is perpendicular to the plane of the interpolation.

G2 code causes the tool to proceed in a clockwise, (C.W), path.

G3 code causes the tool to proceed in an Anti-clockwise, (C.C.W.) path

-

20

RADIUS

The "R" word may be used to define the radius of the arc rather than using the I, J, and K words to define the arc's centre point.

+

TWO POSSIBLE ARCS BETWEEN POINTS A & B IN CCW DIRECTION

Unless the length of the arc from the start point to the commnd point is exactly 180 degrees, there are two arcs with the same radius and direction connecting the two points, ( see figure above). A positive R word selects the arc less than 180 degrees, whereas a negative R word selects the arc greater than 180 degrees .

..

- ...

GENERAL PROGRAMMING CONSIDERA TIONS

1. Either the arc radius or centre point method may be programmed. Only one method, however, maybe programmed in a block.

If the centre location of the arc is the most critical dimension, the I, J, K method is preferable.

If the radius of the arc or the location of the endpoint of the arc is the most critical dimension, the R word method is preferable.

2. Arc's up to 360 degrees can be programmed in asingleblock when the : centre point method is used.

3. Arcs less than 360 degrees may be programmed in a single block when the radius specification method is used. The radius method is not recommended for arcs greater than 359 degrees.

4. An arc does not have to start or end on a quadrant line.

5. An Alarm condition results with the 1,J,K, word, centre point programming if the current position and the command position are different distances from the centre of the circle.

..

- -

2.2.

CDUGARDLTD

MACHINE TOOLS

(1)0

00

- --

2.3

x-

-55

1-

- -

HELICAL INTERPOLATION

This provides the operator with the facility to move another axis simultaneously whilst circular interpolation is being performed.

E.G.

G3 XO. Y30. 10.1-30. Z-S.

In the above example as the X and the Y axis interpolate complete the 360 degrees movement, the Zaxis will move down Srnm. Helical interpolation is used for thread milling.

- e·

2S

M M

CD '!

tri .,.

ci I I E:

\D N N E:

I I- If?

>- I- <[

<[ I

(\J l- I U

0:: VI l-

I"- <[

If) I- ~ (L

X VI 1.....

sr

If)

I

>- If)

(\J

\D sr

co I ~--...._

sr

X N (;

-: <,

/ -.

0 -,

0

/ 0 --q \

0 co

/ C\.! + fr:

I"- \

I \

I \D \

£: co

I ""Q

o \D I

OJ I

I !.._ >- \D

s:_ I" I

I- \D N

\ £: co I

sr

£: x

\ 0

-o I

G

\ /

\ ci /

\D

-, I /

>- ':£

-. 6 I /

N

<, .,.

x -:

<, ->

--...._ »>

---- -- -- - -

FIXED (CANNED) CYCLES

G81 DRILL CYCLE

G81

x

y

Z

R

F

Define Cycle

Hole Coordinates

Hole Depth

Rapid Plane

Feedrate

NOTE: -

Rapid plane is the distance the tool will stop above the top of the component, (ZO.) and will return to after the tool has reached the hole depth,

G83 PECK DRILL CYCLE

G83

x

y

Z

R

Q

F

Peck Depth

NOTE: -

In the G83 Cycle when the tool retracts from the hole after each peck it moves to the Rapid Plane

G73 IDGH SPEED PECK DRILL CYCLE

G73

x

y

Z

R

Q

F

Peck Depth

NOTE: -

In the G73 Cycle when the tool retracts from the hole after each peck it moves only a small amount to break the chip. The distance it moves up is preset in parameter no 5114 for Fanuc Oi

INITIAL AND RAPID PLANES USED IN FIXED CYCLES (G98/ G99)

G98

Returns the tool to the INITIAL Plane

When using the Fixed Cycles the control provides the ability to return to one of two planes.

G99

Returns the tool to the RAPID Plane.

The G98 / G99 Code is programmed on the same line as the Fixed Cycle code and is Modal.

G98 G99

Q _Initial point Q_---~

- - - -, l level

I I I

, I I

1 .. 1 _.. R point

, level

I

I

I Point Z G98 - INITIAL plane Return

- -

-_ -:,;':,' ;!:'-~:>,,::"

.',' " ----~-,-·:-;·~it;J~i~:t'~;

27

•·· .. ,·-'5

;;' __ ~;;}'ll:',. \-<~;iff';~:'.:;+

C)

N

C)

~1

M

~ I

0

L,

I

C) I!

C) C) I

C) C)

C) C) I

C) M

t.n ..---.

..---. C)

C)

C) I

C)

ru

I

0

C)

C)

C)

C)

ru

C)

C)

0 C) C)

C) >- C)

0 ..---.

C) C)

co x

C)

<=>

<=>

<=>

<=>

....... -

-

, J~

_- -·:i~,<:~r:J;i;Uic,-.,·

o

'-- ~1

• -

-,

0 -

•

0

c-

O

0

(Y)

0'----<

0

0

0

0 ru

V .. j-

~ ~

0

0

0

0

ru

l

0

0

-~ 0

0 - >-

ill

0

C> X

C>

-~

C> o o o

o tn

o N

o o o

tn ru

o o o

tn (Y)

I

---

I

I

r

-

-

FIXED (CANNED) CYCLES

G84 CONVENTIONAL TAPPING CYCLE

G84

x

y

Z

R

F

Define Cycle

Hole Coordinates

Hole Depth

Rapid Plane

Feedrate

NOTE: -

When using the tapping cycles the feedrate has to be calculated as follows: - FEED= RPM x PITCH

E.g. For an M8x1.25 tap rotating at 800rpm

FEED= 800x 1.25= 1000

G84 RIGID TAPPING CYCLE

This fixed cycle allows the use of rigid tap holders, providing precise thread generation and hole depth control while eliminating the need for expensive floating tap holders.

Since the code for rigid tapping and conventional tapping are the same, i.e. G84, to use rigid tapping an M29, (Rigid tapping mode), must be placed on the line before the fixed cycle.

E.g.:

N5 T5 M6 (TAP M8) S800M13

GO G80 G90 G54 XO. YO. G43 Z50. H5

M29 S800

G84 XO. YO. Z-IO. R6. FIOOO.

G84 RIGID TAPPING CYCLE

This is achieved by placing a Q on the G84 Line. Q= Peck Depth

The retraction distance is set in parameter no 5213

If parameter no: 5200 bit 5=0, then the tap will retract by the amount set in parameter no: 5213

Ifparameter no: 5200 bit 5=1, then the tap will retract back to the R plane at each retraction.

POLAR CO-ORDINATES

1800 ~~---------

G 15 Polar Co-ordinates Cancel

G 16 Polar Co-ordinates Command

If G 16 is programmed the "X" word becomes the radius or the length of the line and the "Y" word becomes the Angle at which that face, or hole is to be machined at.

X

RADIUS

y

ANGLE

NOTE:-

Polar Co-ordinates must be cancelled after it has been used. by programming a G 15. This converts the machine back 10 Rectangular Co-ordinates.

When using Polar Co-ordinates fora Bolt Hole Circle, if the centre .of the circle is not XO. YO. Then a G52, (Local Co-ordinates-System), must be programmed followed by the distance of the Bolt Hole Circle, from the Datum.

E.G.

For a Bolt Hole Circle positioned at XI03_ Y-76. The following would be programmed:

G52 XI03_ Y-76_

NOTE:-

After it has been used the Local Co-ordinates System must be cancelled by programmmg: -

G52 XO_ YO.

- -

31

____"'~ .......... _......;C;..;;..;. D;.._U.;._G;;;....;.!ARJ)~....;..;L.;.;.;.L;.;...D

~ MACHINE TOOLS

I~ 10.0

0; 0 I

10.00

50.00

, HOl(S j

I!W oUP

0

o

o

elM'S? orr ?SW HtH

o

100

- -

FORMATS FOR FIXED CYCLES

High Speed Peck Drilling Cycle

G73

Reverse tapping

G74

Fine Boring

G76

Drilling

G8l

Spot Facing

G82

Peck Drilling

G83

Tapping

G84

Boring Cycle 1

G85

Boring Cycle 2

G86

Back Boring Cycle 3

G87 X

Boring Cycle 4

G88

Boring Cycle 5

G89 WHERE:-

Q

F

X

y

z

R

X

y

z

R

F

X

Q

F

y

z

R

P

X

y

z

R

F

X

y

z

R

P

F

X

Q

F

R

y

z

X

y

R

F

z

(Feed in / Feed out)

X

y

R

F

z

(Feed in / Spindle Stop / Rapid out)

X

y

z

R

F

(Rapid in / Tool Shifts / Feed out I Tool Shifts / Rapid out)

y

z

Q

R

F

(Feed in / Dwell / Spindle Stop / Rapid out)

X

y

P

z

R

F

(Feed in / Dwell / Feed out)

X

y

z

R

P

F

X = X COORDINATE rosrnon y = Y COORDINATE rosrnon Z = FINAL DEPTII OF HOLE

Q = PECK DEPTH OR CLEARANCE IN BORE R = RAPID PLANE DEPTH

P=DWELL

F=FEEDRATE

- --

cD

·x+

TO SET X & Y DATUMS

Ensure the X & Y axis have been referenced.

Clock fixture location; (clock bore or edge find).

'1+

x-

CLOCK BoRE:

XO· 0 't o- 0

-B-y_

Press "position" on control panel, (poSN)

Press "ALL" soft key.

Make a note of X & Y values in uMACIDNE POSITION" & put them into the selected datum to be used, (ussuaUy G54). Ensure the radius of the Wobbler is added or subtracted to or from this value.

- -

SET TOOL LENGTH OFFSETS FANUCOiM

• ENSURE THAT THE MACHINE HAS BEEN REFERENCED

• TURN MODE SELECT SWITCH TO "MDI"

• NOW CALL THE REQUIRED TOOL INTO THE SPINDLE. EG. Tl M6 "EOB" THEN PRESS "CYCLE START"

• TURN MODE SELECT SWITCH TO "HANDLE" • REMOVE TOOL FROM SPINDLE

• TOUCH THE SPINDLE NOSE ON THE SETTING BLOCK

I I

I I

LJ

~ SETTING

..--

BLOCK

.... ..

,

, ", .... • PRESS "POS"

• PRESS "ALL"

• PRESS "Z"

• "Z" WILL FLASH ON "RELATIVE"

• PRESS "ORIGIN"

• THIS WILL SET THE "Z" RELATIVE TO ZERO

• MOVE THE "Z" AXIS CLEAR

• LOAD THE TOOL INTO THE SPINDLE

• TOUCH THE TOOL ONTO THE SETTING BLOCK

• PRESS "OFFSET / SETTING"

• PRESS "OFFSET"

• CURSOR TO THE REQUIRED "GEO (H)" NUMBER

• PRES S "Z"

• PRESS "INP.C."

• THIS WILL TRANSFER THE VALUE FROM THE RELATIVE SCREEN INTO THE "GEO (H)" OFFSET.

• THE TOOL IS NOW SET, REPEAT ABOVE UNTIL ALL TOOLS ARE SET.

SET WORK OFFSETS FANUCOiM

• TURN MODE SELECT SWITCH TO "MDI"

• NOW CALL ANY TOOL INTO THE SPINDLE FROM THE MAGAZINE, ENSURING THAT ALL THE TOOL LENGTH OFFSETS HAVE BEEN SET, AS PER THE PREVIOUS PROCEDURE.

• EG. T1 M6 "EOB" THEN PRESS "CYCLE START"

• MAKE A NOTE OF THE LENGTH OFFSET FOR THIS TOOL. EG. 101.73

• TURN MODE SELECT SWITCH TO "HANDLE"

• TOUCH THE TOOL ON THE COMPONENT.

I I

I I

-, ~

/ -,

C":

r-,

c

I I ~

COMPONENT • PRESS "OFFSET ISETTING.

• PRESS "WORK"

• CURSOR TO THE REQUIRED "Z" DATUM. EG. G55

• PRESS "Z" AND TYPE IN THE TOOL OFFSET VALUE. EG.101.73

• PRESS "MEASUR"

• THE "Z" DATUN IS NOW SET.

:0001 (DEMO PROGRAM) (FANlJ'C OIl

G21

G90 GI0 L2 PI X-161.S Y-113.S Z-276.

(TOOL OFFSETS)

G90 GI0 LI0 PI R90.07

G90 GI0 L12 PI R2S.

G90 GI0 LI0 P2 R134.32

G90 GI0 LI0 P3 R123.47

G90 GI0 L12 P3 R6.

G90 GI0 LI0 P4 R139.62

G90 GI0 L12 P4 R4.

G90 GI0 LI0 PS R93.11

G90 GI0 LI0 P6 R97.28

Ml Nl Tl M6

(SO MM DIA FACE MILL) T2

SSOOO M13

GO GS4 G40 X-80.Y40. G43 ZlS.Hl

Gl ZO.F3S00. X80.FlS00.

YO.

X-80.

Y-40.

X80.

GO Z100.M9 Ml

N2 T2 M6

(14.S MM DIA DRILL) T3

S800 M13

GO GS4 G40 G90 G98 XO.YO. G43 ZlS.H2

G83 XO.YO.Z-S.R2.Q6.F200. G80

GO Z100.M9 Ml

~3 T3 M6

(12 MM DIA CARBlPE SLOT DRILL) 1'4

SlS000 M13

GO G40 G90 X-60.Y-60. G43 ZlS.H3

Gl Z-S.F3S00.

_-

G41 X-42.D3 F1250. Y36.

G2 X-36.Y42.R6. G1 X36.

G2 X42.Y36.R6. G1 Y-36.

G2 X36.Y-42.R6. G1 X-36.

G2 X-42.Y-36.R6. G1 X-50.2 Y-30. G40 X-60.

GO Z2.

GO G40 G90 X-60.Y-60. G1 Z-15.F3500.

G41 X-50.D3 F2000. Y45.

G2 X-45.Y50.R5. G1 X45.

G2 X50.Y45.R5. G1 Y-45.

G2 X45.Y-50.R5. G1 X-45.

G2 X-50.Y-45.R5. G1 X-50.2 Y-40. G40 X-60.

GO Z2.

XO.YO.

G1 Z-3. Z-5.FIOO.

G41 X-7.5 D3 G3 17.5 F1000. G1 G40 XO.

GO Z100.M9

M1

N4 T4 M6

(SPOT DRILL AND CHAMFER) T5

S15000 M13

GO G40 G90 X-60.Y-60. G43 Z15.H4

G1 Z-8.4 F3500. G41 X-50.D4 F1500. Y45.

G2 X-45 ._Y:50. R5. Gl X45.

G2 K50. Y45 .R5. Gl --Y-45.

G2 -X45.Y-50.R5.

Gl X-4S.

G2 X-SO.Y-4S.RS. Gl X-SO.2 Y-40. G40 X-60.

GO Z2.

S3000 G4 Xl.

(SPOT DRILL) G4 Xl.

GO G40 G90 X-36.S8 YO.

G99 G81 X-36.S8 YO.Z-l.R2.F200. G80 M9

GO ZI00.MS Ml

NS TS M6

(S.IMM DIA DRILL) T6

S3S00 M13

GO G40 G90 G99 X-36.58 YO. G43 ZIS.HS

G83 X-36.S8 YO.Z-9.R2.Q2.F3S0. G80 M9

GO ZIOO.MS Ml

N6 T6 M6 (M6 TAP) S1000M13 T4

GO G40 G90 G99 X-36.S8 YO. G43 Z2S.H6

M29 S1000

G84 X-36.S8 YO.Z-6.R6.FIOOO. G80

G28 G91 ZO.MlS G28 YO.

G90

/M99

M30

.. -

;, \:;' ;

-,.~,·i:;:'· '

4-\

8. DATA INPUT/OUTPUT

OPERATION

B--63084EN/02

Memory card formatting

Before a file can be saved to a memory card, the memory card must be formatted.

Formatting a memory card

1 Press the rightmost soft key I c> I (continuous menu key) on the ALL

10 screen, described in Section 8.10.1.

2 Press soft key [M-CARD).

3 Place the CNC in the emergency stop state.

4 When a memory card is inserted, the state of the memory card is displayed as shown below.

Procedure

READIPUNCH(M-CARD)

01234 N12345

CNC RAM I Memory card

1512K byte I I

_2. OooM byte 50 RAM

File ( 11 1)l

I SRAMO_5A. FOB 524288 byte 971 01/23

1M" ....

Select: All data

S o TOOoo

EDIT •••• - - EMG- - 12: 15:00

[FORMAn [ SAVE 1 [ LOAD 1 [DELETE]

5 Press soft key [FORMAT). 6 A message prompting the user to confirm the operation is displayed.

Press soft key [EXEC] to execute the formatting operation.

7 As formatting is being performed, the message "FORMATTING" blinks.

) (

) (CAN) (EXEC) J

) (

8 Upon the completion of formatting, the message "COMPLETED" is displayed in the message field.

- 540-

B-63084EN/02

OPERATION

8. DATA INPUT/OUTPUT

Deleting files

Unnecessary saved files can be deleted from a memory card.

Deleting files

Procedure

) (

) (

) (CAN) (EXEC) J

1 Press the rightmost soft key I c:> I (continuous menu key) on the ALL

10 screen, described in Section 8.10.1.

2 Press soft key [M-CARD].

3 Place the CNC in the emergency stop state.

4 When a memory card is inserted, the state of the memory card is displayed as shown below.

READIPUNCH(M-CARD)

01234 N12345

CNC RAM l I Memorycard

[512K byte L 2. OOOM byte S- RAM

File ( 11

[!RAMO_SA. FOB 524288 byte97/01/23

Select: A" data

S 0 TOOOO

EDIT ..... - - EMG- - 12: 15: 00

[FORMAT] [ SAVE I [ LOAD I [DELETE]

5 Press soft key [DELETE].

6 With cursor keys [!] and [!] , select the file to be deleted from the memory card.

7 After checking the file selection, press soft key [EXEC].

8 As detection is being performed, the message "DELETING" blinks in the message field.

9 Upon the completion of deletion, the message "COMPLETED" is displayed in the message field.

- 541-

8. DATA INPUT/OUTPUT

OPERATION

~3084EN/o2

Message and restrictions

Messages

Message Description

INSERT MEMORY CARD. No memory card is inserted.

---------- -~~--~--- --~--

UNUSABLE MEMORY CARD The memory card does not contain device information.

f------~-~--- --_----_---------- - ... -_-~-"-~-----, .. --------------~-~~--_~---

FORMAT MEMORY CARD. The memory card is notformatted. Format the memory card before use.

-----_-- I----~-------- -----~

THE FILE IS UNUSABLE. The format or extension of the file to be loaded is invalid. Alternatively,

the data stored on the memory card does not match the CNC memory

size.

-~--_- ------~-----~--~~--_-_--~-------

REPLACE MEMORY CARD. Replace the memory card.

- __ - --- -----

FILE SYSTEM ERROR DDD I An error occurred during file system processing. DDD represents a file

system error code.

- I Save/load operation is enabled in the emergency stop state only.

SET EMERGENCY STOP STATE.

+------~- - ---

WRITE-PROTECTED Save operation: The protect switch of the memory card is set to the dis-

abled position.

Load operation: Parameter write is disabled.

VOLTAGE DECREASED. The battery voltage of the memory card has dropped.

(The battery requires replacement.)

-----.------------_-------~--- -----------_. __ --------_-------------

DEVICE IS BUSY. Another user is using the memory card. Alternatively, the device cannot

be accessed because automatic operation is in progress.

SRAM -+ MEMORY CARD? This message prompts the user to confirm the start of data saving.

-----------

MEMORY CARD -+ SRAM? This message prompts the user to confirm the start of data loading.

----------- --

DO YOU WANT TO DELETE FILE(S)? This message prompts the user to confrm the start of deletion.

--~---------------_--~------- ----~--------------

DO YOU WANT TO PERFORM FORMATTING? This message prompts the user to confirm the start of formatting.

~-_----.---

SAVING Saving is currently being performed.

_-

LOADING Loading is currently being performed.

f----

DELETING File deletion is currently being performed.

1-------- f-----

FORMATTING Memory card formatting is currently being performed.

r--------- ---

COMPLETED Save or load processing has been completed.

1------------------ ----_." -----

PRESS RESET KEY. Press the RESET key.

TURN OFF POWER. Tum the power off, then back on again. - 542-

B-63084EN/02

OPERATION

8. DATA INPUT/OUTPUT

File system error codes

Restrictions

• Memory card size

• Memory card specifications

• Attribute memory

• Compatibility of saved data

• Flash ROM card

• Operation during automatic operation

Code Meaning

102 The memory card does not have sufficient free space.

105 No memory card is mounted.

~---------.- .".--,--- - -_-._ -_. "

106 A memory card is already mounted.

'----

110 The specified directory cannot be found.

111 There are too many files under the root directory to allow a directo-

ry to be added.

-------~ --------- .... -- .. -- ...... --~-------------.--.---------~-- -_----_---_._._- .. _""----

114 The specified file cannot be found.

I

115 The specified file is protected.

._. __ ._-----_ .. _

117 The file has not yet been opened.

118 The file is already open.

--'"-.-----~- --

119 The file is locked.

1------------

122 The specified file name is invalid.

-~ I---- -

124 The extension of the specified file is invalid.

129 A non-corresponding function was specified.

_--_'_- .- -_-- ---_._,,_,. __ ._--,_._--

130 The specification of a device is invalid.

I-----~-~---- -_ .. _--_._ -_._.

131 The specification of a pathname is invalid.

133 Multiple files are open at the same time.

135 The device is not formatted.

--

140 The file has the readlwrite disabled attribute. The size of the memory card to be used must be larger than that of the RAM module mounted in the CNC. The size of the RAM module can be determined from the system configuration screen.

Use a memory card that conforms to PCMCIA Ver. 2.0, or JEIDA Ver. 4.1.

A memory card which has no attribute memory, or no device information in its attribute memory, cannot be used.

Data saved to a memory card is compatible only with CNCs that have the same hardware configuration and the same option configuration.

A flash ROM card can be used only for data loading.

During automatic operation, the contents of a memory card cannot be displayed, formatted, or deleted. To enable these operations, therefore, stop or suspend automatic operation.

- 543-

8. DATA INPUT/OUTPUT

OPERATION

B-63084EN/02

8.11

DATA INPUT/OUTPUT USING A MEMORY CARD

By setting the I/O channel (parameter No. 20) to 4, files on a memory card can be referenced, and different types of data such as part programs, parameters, and offset data on a memory card can be input and output in text file format.

The major functions are listed below.

• Displaying a directory of stored files

The files stored on a memory card can be displayed on the directory screen.

• Searching for a file

A search is made for a file on a memory card and, if found, it is displayed on the directory screen.

• Reading a file

Text-format ftles can be read from a memory card.

• Writing a file

Data such as part programs can be stored to a memory card in text file format.

• Deleting a file

A file can be selected and deleted from a memory card .

.-------- eNC --------~

Writing a file

Read.g.fi~ : I 1:-

Displaying a

directory

Searching for a file ._J r 1------------'

Deleting a file __j '--

Memory card

- 544-

B--63084EN/02

OPERATION

8. DATA INPUT/OUTPUT

Displaying a directory of stored files

Procedure

1 Press the EDIT switch on the machine operator's panel.

2 Press function key [PROGj .

3 Press the rightmost soft key I c> I (continuous menu key).

4 Press soft key [CARD]. The screen shown below is displayed Using page keys [!] and [!], the screen can be scrolled.

DIRECTORY (M-CARD)

No. FILE NAME

0001 01000

0002 01001

0003 00002

0004 02000

0005 02001

0006 03001

0007 03300

0008 03400

0009 03500

SIZE 123456 8458 3250 73456 3444 8483 406

2420 7460

) (DIR + ) (

00034 NOO045

DATE 97/07/10 97/07/30 97/07/30 97/07/31 97/07/31 97/08/02 97/08105 97/07/31 97/07/31

5 Comments relating to each file can be displayed by pressing soft key [DIR+].

DIRECTORY (M-CARD)

No. FILE NAME

0001 01000

0002 01001

0003 00002

0004 02000

0005 02001

0006 03001

0007 03300

0008 03400

0009 03500

) (DIR + ) (

00034 NOO045

COMMENT

(COMMENT ) (SUB PROGRAM )

(12345678 )

( )

( )

(SKIP-K )

(HI-SPEED )

( )

(TEST PROGRAM)

-

) ((OPRT») )

6 Repeatedly pressing soft key [DIR+] toggles the screen between the display of comments and the display of sizes and dates.

Any comment described after the 0 number in the file is displayed. Up to 18 characters can be displayed on the screen.

- 545-

8. DATA INPUT/OUTPUT

OPERATION

Searching for a file

Procedure

1 Press the EDIT switch on the machine operator's panel.

2 Press function key [4 .

3 Press the rightmost soft key I c> I (continuous menu key).

4 Press soft key [CARD). The screen shown below is displayed.

DIRECTORY (M-CARD)

No. FILE NAME

0001 01000

0002 01001

0003 00002

0004 02000

0005 02001

0006 03001

0007 03300

0008 03400

0009 03500

SIZE 123456 8458 3250 73456 3444 8483 406

2420 7460

00034 N00045

DATE

96/07/10 96107130 96107130 96107/31 96107131 96/08/02 96/08/05 96/07/31 96/07/31

-

) (OPRT) ) )

5 Press soft key [(OPRT»).

6 Set the number of the desired file number with soft key [F SRH).

Then, start the search by pressing soft key [EXEC). Iffound, the file is displayed at the top of the directory screen.

When a search is made for file number 19

DIRECTORY (M-CARD)

No. FILE NAME

0019 01000

0020 01010

0021 01020

0022 01030

- 546-

00034 N00045

COMMENT

(MAIN PROGRAM) (SUBPROGRAM-1 )

(COMMENT )

(COMMENT )

B-63084EN/02

OPERATION

8. DATA INPUT/OUTPUT

Reading a file

Procedure

1 Press the EDIT switch on the machine operator's panel.

2 Press function key [.ROG ].

3 Press the rightmost soft key 1[:::» (continuous menu key).

4 Press soft key [CARD}. Then, the screen shown below is displayed.

SIZE 123456 8458 3250 73456 3444 8483 406

2420 7460

00034 NOO045

DATE

96/07/10 96107130 96/07/30 96/07/31 96107131 96/08/02 96/08/05 96/07/31 96/07/31

DIRECTORY (M-CARD)

No. FILE NAME

0001 01000

0002 01001

0003 00002

0004 02000

0005 02001

0006 03001

0007 03300

0008 03400

0009 03500

-

l ( PROG ) (

) (DiR + ) (

-

) (OPRT) ) )

5 Press soft key [(OPRT)].

6 To specify a file number, press soft key [F READ]. The screen shown below is displayed.

DIRECTORY (M-CARD)

No. FILE NAME

0019 01000

0020 01010

0021 01030

00001 N00010

COMMENT

(MAIN PROGRAM) (SUBPROGRAM-1 ) (COMMENT )

READ

FILE NAME=20

PROGRAM No.=120

>

EDIT *** **** *** ****

15:40:21

(F NAME) ( 0 SET ) ( STOP ) ( CAN ) ( EXEC )

7 Enter file number 20 from the MDI panel, then set the file number by pressing soft key [F SET]. Next, enter program number 120, then set the program number by pressing soft key [0 SET]. Then, press soft key [EXEC].

• File number 20 is registered as 00120 in the CNC.

• Set a program number to register a read file with a separate 0 number. If no program number is set, the 0 number in the file name column is registered.

- 547-

8. DATA INPUT/OUTPUT

OPERATION

~084EN/02

8 To specify a file with its file name, press soft key [N READ] in step 6

above. The screen shown below is displayed. .

DIRECTORY (M-CARD)

No. FILE NAME

0012 00050

0013 TESTPRO

0014 00060

00001 N00010

COMMENT

(MAIN PROGRAM) (SUB PROGRAM-1) (MACRO PROGRAM)

EDIT

15:40:21

READ FILE NAME =TESTPRO

PROGRAM No. =1230

>

(F NAME) ( 0 SET ) ( STOP ) ( CAN ) ( EXEC )

9 To register file name TESTPRO as 0 1230, enter file name TESTPRO from the MDI panel, then set the me name with soft key [F NAM E). Next, enter program number 1230, then set the program number with soft key [0 SEl]. Then, press soft key [EXEC].

- 548-

B-63084EN/02

OPERATION

8. DATA INPUT/OUTPUT

Writing a file

Procedure

1 Press the EDIT switch on the machine operator's panel. 2 Press function key l.RaG ].

3 Press the rightmost soft key I c> I (continuous menu key).

4 Press soft key [CARD]. The screen shown below is displayed.

SIZE 123456 8458 3250 73456 3444 8483 406

2420 7460

00034 Noo045

DATE

96/07/10 96107130 96/07/30 96/07/31 96107/31 96/08102 96/08/05 96/07/31 96/07/31

DIRECTORY (M-CARD)

No. FILE NAME

0001 01000

0002 01001

0003 00002

0004 02000

0005 02001

0006 03001

0007 03300

0008 03400

0009 03500

-

) ( (OPRT») )

5 Press soft key [(OPRT)]. 6 Press soft key [PUNCH].

7 Enter a desired 0 number from the MDI panel, then set the program number with soft key [0 SET].

When soft key [EXEC] is pressed after the setting shown below has been made, for example, the file is written under program number 01230.

PUNCH

FILENAME = PROGRAM No. =1230

>

EDIT **** *** **** 15:40:21

(F NAME) ( 0 SET ) ( STOP) ( CAN ) ( EXEC )

8 In the same way as for 0 number setting, enter a desired file name from the MDI panel, then set the file name with soft key [F SEn. When soft key [EXEC] is pressed after the setting shown below has been made, for example, the file is written under program number 01230 and file name ABeD 12.

PUNCH

FILE NAME =ABCD12 PROGRAM No. =1230

>

EDIT

15:40:21

(F NAME) ( 0 SET ) ( STOP) ( CAN ) ( EXEC )

- 549-

8. DATA INPUT/OUTPUT

OPERATION

B-63084EN/02

Explanations

• Registering the same file name

• Writing all programs

• File name restrictions

When a file having the same name is already registered in the memory card, the existing file will be overwritten.

To write all programs, set program number = -9999. Ifno file name is specified in this case, file name PROGRAM.ALL is used for registration.

The following restrictions are imposed on file name setting:

<File name setting>

- 550-

x x x x x x x x ,

f

Not longer than 8 characters

DDD f

Extension not longer than 3 characters

~3084EN/02

OPERATION

8. DATA INPUT/OUTPUT

Deleting a file

Procedure

1 Press the EDIT switch on the machine operator's panel.

2 Press function key PROG •

3 Press the rightmost soft key I c> I (continuous menu key).

4 Press soft key [CARD]. The screen shown below is displayed.

SIZE 123456 8458 3250 73456 3444 8483 406

2420 7460

DIRECTORY (M-CARD)

No. FILE NAME

0001 01000

0002 01001

0003 00002

0004 02000

0005 02001

0006 03001

0007 03300

0008 03400

0009 03500

-

l ( PROG ) (

) (DIR + ) (

00034 NOO045

DATE

97107/10 97107/30 97107/30 97107/31 97107/31 97108/02 97108/05 97107/31 97107/31

-

) (OPRT) ) )

5 Press soft key [(OPRT)].

6 Set the number of the desired file with soft key [DELETE], then press soft key [EXEC]. The file is deleted, and the directory screen is displayed again.

When file number 21 is deleted

DIRECTORY (M-CARD)

No. FILE NAME

0019 01000

0020 01010

0021 01020

0022 01030

00034 NOO045

COMMENT

(MAIN PROGRAM) (SUBPROGRAM-1 )

(COMMENT )

(COMMENT )

File name 01020 is deleted.

DIRECTORY (M-CARD)

No. FILE NAME

0019 01000

0020 01010

0021 01020

0022 01030

00034 N00045

COMMENT (MAIN PROGRAM) (SUBPROGRAM-1 )

(COMMENT )

(COMMENT )

File number 21 is assigned to the next file name.

- 551-

You might also like

- Okuma OSP P300S Operation ManualDocument415 pagesOkuma OSP P300S Operation Manualsunhuynh100% (4)

- Operating Manual: Mazatrol SmoothcDocument84 pagesOperating Manual: Mazatrol SmoothcLuis VargasNo ratings yet

- B-64487EN - 05 Operation and Maintenance Handbook 30iDocument974 pagesB-64487EN - 05 Operation and Maintenance Handbook 30iDmitryNo ratings yet

- Mazak Integrex J Series Parameter List MCode List Alarm ListDocument760 pagesMazak Integrex J Series Parameter List MCode List Alarm ListAju Augustine100% (2)

- Moriseiki Maintenance ClassDocument410 pagesMoriseiki Maintenance ClassLEONEL CARDENAS100% (10)

- Manual Guide +Document648 pagesManual Guide +Aloisio Gonzaga0% (1)

- vmc8501020 NCDocument153 pagesvmc8501020 NCNarendra Yadav100% (2)

- Programming Manual: Mazatrol Matrix NexusDocument350 pagesProgramming Manual: Mazatrol Matrix NexusMilton Righetto Nass100% (1)

- Mazak Alignment Procedure Integrex MK-IVDocument14 pagesMazak Alignment Procedure Integrex MK-IVMauro S Cabral100% (2)

- Mazak Integrex ATC Alignment ProcedureDocument29 pagesMazak Integrex ATC Alignment Procedureganesan 0011100% (1)

- Renishaw.-Installation Manual For Machine ToolsDocument220 pagesRenishaw.-Installation Manual For Machine ToolsPeter Nomikos100% (1)

- Fanuc Manual GuideDocument172 pagesFanuc Manual GuidemarianhainarosieNo ratings yet

- Okuma Howa Spindle Drive AlarmsDocument3 pagesOkuma Howa Spindle Drive AlarmsAnonymous wBxc1VGtNo ratings yet

- 65002e PDFDocument348 pages65002e PDFCristobal PerezNo ratings yet

- Okuma Osp p300s p300l Gauging Systems Instruction Manual Application Le61 497 R01a PDFDocument191 pagesOkuma Osp p300s p300l Gauging Systems Instruction Manual Application Le61 497 R01a PDFseb_dominiqueNo ratings yet

- Eiaiso640t MTDocument356 pagesEiaiso640t MTJPPNo ratings yet

- Yamaha Banshee Parts Manual 5FK6 - 2000Document55 pagesYamaha Banshee Parts Manual 5FK6 - 2000Felipe Antonio Pinto VillarroelNo ratings yet

- Fanuc CNC Parts: Rigid Tapping TroubleshootingDocument6 pagesFanuc CNC Parts: Rigid Tapping TroubleshootingTony AntonyNo ratings yet

- Programing Manual EIA ISODocument416 pagesPrograming Manual EIA ISORelu Chiru100% (2)

- SystemVarsAlpha List OkumaDocument16 pagesSystemVarsAlpha List Okumaseb_dominique100% (3)

- MazakDocument420 pagesMazakrguzmanabundis100% (1)

- Okuma OSP P300S Tool Magazine Instruction ManualDocument61 pagesOkuma OSP P300S Tool Magazine Instruction Manualsunhuynh100% (1)

- Mazak EIA - Programming Manula For Mazatrol Matrix PDFDocument531 pagesMazak EIA - Programming Manula For Mazatrol Matrix PDFMounir DouggazNo ratings yet

- Bnp-b3484 Centro Usinagem L31-MazakDocument227 pagesBnp-b3484 Centro Usinagem L31-MazakAntonio LucasNo ratings yet

- Parameter List: Mazatrol M PlusDocument136 pagesParameter List: Mazatrol M PlusОлег СуворовNo ratings yet

- MCV 510 - 1250B Operation and Maintenance Manual V2 - 2 PDFDocument346 pagesMCV 510 - 1250B Operation and Maintenance Manual V2 - 2 PDFGuillermo Ramirez100% (4)

- Kia SKT210SYDocument94 pagesKia SKT210SYrastaeggNo ratings yet

- Puma 450Document84 pagesPuma 450Cezar BalașeiNo ratings yet

- Mazak Matrixmillturn Eia Progmanual PDFDocument618 pagesMazak Matrixmillturn Eia Progmanual PDFCorey YoungNo ratings yet

- Applications Training For Integrex-100 400MkIII Series Mazatrol FusionDocument89 pagesApplications Training For Integrex-100 400MkIII Series Mazatrol FusionjaniNo ratings yet

- MAZAK MatrixMillTurn EIA ProgManualDocument618 pagesMAZAK MatrixMillTurn EIA ProgManuallastowlNo ratings yet

- NC Guide ProDocument4 pagesNC Guide ProBhupesh Kumar100% (2)

- MAZAK Matrix2 EIA ProgManualDocument502 pagesMAZAK Matrix2 EIA ProgManuallastowl50% (2)

- Fanuc 15 Model B - Alarm ListDocument32 pagesFanuc 15 Model B - Alarm Listakirenavi100% (1)

- Specifications: FANUC Series 16/18-MB/TB/MC/TC FANUC Series 16Document15 pagesSpecifications: FANUC Series 16/18-MB/TB/MC/TC FANUC Series 16avalente112No ratings yet

- GE Fanuc 18i Installation ManualDocument81 pagesGE Fanuc 18i Installation Manualapi-3771584No ratings yet

- DD 129283005 CDocument79 pagesDD 129283005 CTensaigaNo ratings yet

- Mori Seiki GPS System Relocation GPSRMS - OperationManual - NFP - Dongle2015 - EngDocument34 pagesMori Seiki GPS System Relocation GPSRMS - OperationManual - NFP - Dongle2015 - EngJuana Chivo100% (3)

- Meldas 64Document352 pagesMeldas 64Maria Cristina MendesNo ratings yet

- Fanuc O Series Lathe Parameter ManualDocument174 pagesFanuc O Series Lathe Parameter ManualАлексей Зубков100% (4)

- Maintenance Manual: Fanuc Ac Spinole ServoDocument152 pagesMaintenance Manual: Fanuc Ac Spinole Servovasiliy vasilievichNo ratings yet

- MR J2 Set Up Software BNP-B2208 PDFDocument70 pagesMR J2 Set Up Software BNP-B2208 PDFCristopher EntenaNo ratings yet

- BNP-A3040 Meldas5000 CNCDocument175 pagesBNP-A3040 Meldas5000 CNCchidambaram kasiNo ratings yet

- Maza Trol M 2 Operator ManualDocument5 pagesMaza Trol M 2 Operator Manualcamb2270100% (1)

- 65264EN Servo Tuning Alfa - FanucDocument58 pages65264EN Servo Tuning Alfa - FanucpkrkaranNo ratings yet

- FANUC Series 0i-MF Plus Die Mould FunctionsDocument18 pagesFANUC Series 0i-MF Plus Die Mould FunctionsAlex100% (1)

- N VX NV Post Processor Manual EngDocument29 pagesN VX NV Post Processor Manual EngrenatoNo ratings yet

- B 66102e - 10 - FanucDocument236 pagesB 66102e - 10 - Fanucbabak67167% (3)

- B-63530en 02Document550 pagesB-63530en 02ยุทธพงศ์ สืบตระกูล100% (3)

- 0i TF PLUS OP ENDocument374 pages0i TF PLUS OP ENTree889 GroundNo ratings yet

- Fusion640t Programming, Online, SummaryDocument7 pagesFusion640t Programming, Online, SummaryGuillermo Ramirez100% (1)

- CncLatheOkumaLb15 PDFDocument52 pagesCncLatheOkumaLb15 PDFSilvio GomesNo ratings yet

- V55 Maintenance 5Document5 pagesV55 Maintenance 5วรพงษ์ กอชัชวาลNo ratings yet

- Mitsubishi Alarm ListDocument19 pagesMitsubishi Alarm Listcoronaqc100% (1)

- Manual Guide I CNC Milling Made Easy ManualDocument126 pagesManual Guide I CNC Milling Made Easy ManualJasminNo ratings yet

- 5 - Manual Software DuplomaticDocument53 pages5 - Manual Software DuplomaticLuiz Gustavo Pastrello100% (1)

- Powermate 0 Maintenance Manual PDFDocument227 pagesPowermate 0 Maintenance Manual PDFmrtans100% (1)

- QT350 Alarm ListDocument102 pagesQT350 Alarm ListAbdul Leon50% (2)

- Classification of BudgetsDocument2 pagesClassification of Budgetskashishgarg429No ratings yet

- Scan 420Document1 pageScan 420Rahul ChoudharyNo ratings yet

- Hsslive March 2023 Key FY 436 Political ScienceDocument5 pagesHsslive March 2023 Key FY 436 Political Sciencemuhammedmuhtharmuhthar52No ratings yet

- 내 주는 강한 성이요Document14 pages내 주는 강한 성이요onlybronze46100% (1)

- User inDocument626 pagesUser ins_barriosNo ratings yet

- Nova MillDocument18 pagesNova MillrastaeggNo ratings yet

- BBCUserGuide-1 00Document524 pagesBBCUserGuide-1 00manitou1997No ratings yet

- iTNC 530: User's Manual HEIDENHAIN Conversational FormatDocument552 pagesiTNC 530: User's Manual HEIDENHAIN Conversational FormatrastaeggNo ratings yet

- CMZ Programming ManualDocument133 pagesCMZ Programming Manualrastaegg100% (6)

- Eagle Fanuc Oi Iss 2bDocument69 pagesEagle Fanuc Oi Iss 2brastaegg100% (1)

- HurcoLathe Max Start r0115-101Document108 pagesHurcoLathe Max Start r0115-101rastaeggNo ratings yet

- Hurco Lathe Conversational r0115-201Document84 pagesHurco Lathe Conversational r0115-201rastaeggNo ratings yet

- 4. Hướng dẫn sử dụng điều hòa tủ đứngDocument21 pages4. Hướng dẫn sử dụng điều hòa tủ đứngDuy ChuNo ratings yet

- Ethernet StandardDocument3 pagesEthernet Standardajju1378No ratings yet

- tfc02 PDFDocument22 pagestfc02 PDFAniigiselaNo ratings yet

- BST203 CDocument14 pagesBST203 CSutiknoNo ratings yet

- 3ah3 PDFDocument44 pages3ah3 PDFAndi GheorgheNo ratings yet

- Check Valve DescriptionDocument1 pageCheck Valve DescriptionmoodydoodyNo ratings yet

- NEW-3663 UserlDocument2 pagesNEW-3663 UserlksubbuNo ratings yet

- Computer Fundamental PDFDocument143 pagesComputer Fundamental PDFSudhir GulekarNo ratings yet

- Ashfaq Patel: Project Name: Water Jacket Core, Drilling SPM (Hinduja Foundry)Document2 pagesAshfaq Patel: Project Name: Water Jacket Core, Drilling SPM (Hinduja Foundry)Ayushee TiwariNo ratings yet

- FPGA (Field Programmable Gate Arrays)Document16 pagesFPGA (Field Programmable Gate Arrays)Syed Zulqadar HassanNo ratings yet

- Aircraft Electrical System Chapter 6 - Landing Gear PDFDocument19 pagesAircraft Electrical System Chapter 6 - Landing Gear PDFnjnvsrNo ratings yet

- Needle Valves With and Without Reverse Flow Check Direct-Acting Inline Mounted - 350 BarDocument4 pagesNeedle Valves With and Without Reverse Flow Check Direct-Acting Inline Mounted - 350 BarAmar KevricNo ratings yet

- Sauer Series 90 ManualDocument72 pagesSauer Series 90 ManualJCNo ratings yet

- Hydraulic Circuitry (W - BPV Junction Block) - (S - N B3BV11001 - B3BV11355) - S770Document5 pagesHydraulic Circuitry (W - BPV Junction Block) - (S - N B3BV11001 - B3BV11355) - S770Виктория РыбакNo ratings yet

- Geometrical & Mechanical Engineering Drawing-CAPE Unit II: Belt DrivesDocument3 pagesGeometrical & Mechanical Engineering Drawing-CAPE Unit II: Belt DrivesOlusegun OlugbadeNo ratings yet

- Asus A7N266-VM Motherboard ManualDocument116 pagesAsus A7N266-VM Motherboard Manualgm799763No ratings yet

- Body Control System: SectionDocument19 pagesBody Control System: SectionYehya ShaabanNo ratings yet

- Generation III Sonic Feeder Control System Manual 20576Document32 pagesGeneration III Sonic Feeder Control System Manual 20576julianmataNo ratings yet

- 02 Gen'l Info 456Document34 pages02 Gen'l Info 456Gabriely MuriloNo ratings yet

- Dahao A88 EngDocument166 pagesDahao A88 Engpaul197777777100% (2)

- GA Tug Boat - Ratu Fadila Atika Fadiat - 2006529032Document1 pageGA Tug Boat - Ratu Fadila Atika Fadiat - 2006529032ゖゖ ゖゖ ゖNo ratings yet

- Product Line Catalogue Ne Catalogue: Wrap Yourself in Comfort and Quiet Eco-Conscious Technologies From JapanDocument22 pagesProduct Line Catalogue Ne Catalogue: Wrap Yourself in Comfort and Quiet Eco-Conscious Technologies From Japanعبدالرحمن كرديNo ratings yet

- Endfedz Ef-Swl: HF End Fed Receive AntennaDocument4 pagesEndfedz Ef-Swl: HF End Fed Receive AntennaKane Wilson GonzalesNo ratings yet

- Usb 3.0 Docking & Clone Station For 2 Sata HddsDocument3 pagesUsb 3.0 Docking & Clone Station For 2 Sata HddsjpcmansoNo ratings yet

- TTV-IOM November 2006Document23 pagesTTV-IOM November 2006Ngô Khắc ToảnNo ratings yet

- Duties and ResponsibilitiesDocument5 pagesDuties and ResponsibilitiesJjiza MiclatNo ratings yet

- Tender Schedule For Electrical Work PDFDocument6 pagesTender Schedule For Electrical Work PDFnakul4491_88890127No ratings yet

- Ar650 Error CodesDocument4 pagesAr650 Error CodesforidigiNo ratings yet

- Technical Specifications Renault MASTER Z EDocument1 pageTechnical Specifications Renault MASTER Z Enawaz khanNo ratings yet