Professional Documents

Culture Documents

BHEL TDC For Fittings

BHEL TDC For Fittings

Uploaded by

Guru KguruOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BHEL TDC For Fittings

BHEL TDC For Fittings

Uploaded by

Guru KguruCopyright:

Available Formats

Bharat Heavy Electricals Limited (A Govt.

of India Undertaking)

Piping Centre, 80, G. N. Chetty Road, CHENNAI- 600 017

Phone: 91 (044) 28161245, Fax 044 28161 341 e-mail: prs@bhelmpc.co.in

REF: ENQ NO: 4101000043

DT: 30.04.2010

Sub: Procurement ofBW fittings.

Ref: Enquiry No:PC:4101000043 dt 30.04.2010

Please find the following tender documents for reference.

1. List of items and sample drawings.

2. TDC:TDG: 102:04.

Pre qualification is the criteria for consideration for other than BHEL approved vendors. After qualifying for registration, the new vendors may be considered for future requirements, in line with BHEL system and policy. Such vendors will not be considered for this enquiry.

This is a limited tender and only vendors who are contacted through e-mail/courier may submit their offers.

New vendors may download vendor registration forms from BHEL web site www.bhel.com and relevant data for formal registration.

Dy1bp;':e

BHEL I Piping Centre 80,GN Road, T.Nagar Chennai -600017 Ph: 044-28161243

(f) ~ ill !::

u, o f(f)

::i

r(jJ '<t 0 CO N N CO ill N

f- a -c--' N .,- LO

O.s

'"""

..J

0 0 -e+ .,-

..- N 0... ..J ..J

..J N 0 0 0

0 0... ..- S

..J N 0... N

N S 0 '<t N S N

N 0 (") 0... 0...

0... '<t N 0... N S '<t S

S (") N S <:( co

N 0... (f) '<t N '<t

'<t <:( S '<t (") <:( (")

(") (f) (") l'- N (f) N

C N N '<t N N <:( <:(

a <:( (")

(") « ~ (f) 0 (f)

:g_ (f) >< N (")

(f) ..- "'!

'C ..- <.0 <:( l'- ><

0 (") to (f) <.0 >< N (") N

(/) X (") X l'- N

Q) v-' LO LO 0 co N ><

0 .,- (") N >< -e-' 0 ill

l'- ;:0 (") <.0 LO <.0

E ;:0 N >< l'- 0 0 (") (")

>< r-, N 0 0 >< N

~ (") ill (")

X N LO ..J S N

(") l'- '<t ..J S (")

'r" LO 0 W 0 0 N N

co <r (") N

0 0 0 o CO CO 0 ><

0 ..J ..J

0 ill ill ill ill ill "'!

cr: cr: ill 0 0 cr: l'-

LO LO LO

ill ill f- '<t '<t 0 Z '<t

0 0 a ill 0

::J ::J cr: cr: cr: 0

0 0 ill ..J ..J ..J 0 ill

ill ill S S S S S cr:

cr: cr: co co co co co 0

ill "0 "0 'E "0 CJ) "0 "0

'e--' '- ro '- N '- '-

0 <.0 m m m <.0 m m

c 0 "0 "0 "0 "0 0 "0 "0

Cl l'- C C C C r-;- C C

C I m m m m m m

'~ 0 iii iii iii ...... ...... iii iii

N (/) N

m (") '- '- '- '- (") '- '-

'- I Q) Q) Q) Q) I Q) Q)

0 0 0.. 0.. 0.. 0.. 0 0.. 0..

co (/) (/) (/) (/) co (/) (/)

""" I

-c -c <:( <:( '<t <:( <:(

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

ro 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

'C (") 0 N ..- N co CJ) l'-

Q) LO co LO (") l'- l'- co (")

ro LO LO ex) l'- CJ) CJ) LO CJ)

~ l'- l'- LO '<t '<t '<t l'- l'-

'r" 'r" 0 N N N N N

..- ...... LO LO LO LO LO LO

N N N N N N N N

CJ) CJ) ill CJ) ill CJ) CJ) CJ)

0

Z

U5 0 0 0 0 0 0 0 0

'r" N (") '<t LO <.0 l'- ex)

()

c

ill 'Iiil ~~~~,~:i;~~I~~:~~~~~:~~~~'C:~~~~O~e,;':~; ·~~~nnai

• I \ Wel~:d=~it:1:!ngs~~~ India~ Boiler Reg~~~tions~

1.0 CODES:-

The fittings shall meet Indian Boiler Regulations (IBR) and the following requirements in addition to the standards specified in the Purchase Order (PO).

TDG: 102 Rev 04 Date: 27.02.2009 Page: 1 of 4

2.0 RAW MATERIALS:-

a) All pipes used for fittings shall meet the respective specification. The test certificate shall be furnished.

b) All mother pipes used for fittings shall be subjected to a hydraulic test as per SA 530 or UT as per ASTM E 213 at the mill

c) All plates used for fittings shall be UT tested as per S1 of SA578 and acceptance norms shall be as per Level B of SA578

d) The raw material forging shall be ultrasonically tested as per SA 388 and the acceptance norm shall be as per 3.3.4 of ASME Sec VIII Div 2.

e) Steel for SA 182 F 11, F 12 &F22 if indigenously procured, to be from following manufacturers approved under IBR for creep resistant steels: i ) Alloy Steel Plant Durgapur, ii )Tata Iron & Steel company, Jamshedpur & iii) Mahindra Ugine Steel Company, Mumbai.

f) Carbon content of SA 234 WPB, WPC, SA 105 fittings shall be restricted to 0.25% max

3.0 PROCESS:-

a) Process of manufacture shall conform to applicable standards.

b) All fittings shall be of seamless unless otherwise specified in the purchase order.

c) In case of welded fittings, WPS,PQR & welder qualification shall be approved by BHEL - PC, prior to start of welding.

d) All fittings shall have smooth surfaces, workman like finish and free from loose scales and defects like laps, seams, folds, cracks, pitting etc .. Repair by welding is NOT permitted.

e) Dimensions shall be as per ASME 816.9 or 816.28,8utt Weld edges shall be as given in Purchase Order. The ends of reducers shall have a straight portion of Minimum 13mm.

f) Unless otherwise specified in the P.O SA 234 WP 11/12/22 fittings shall be supplied as per class1, SA 182 F11/12 shall be supplied as class 2, SA 182 F22 shall be of class 3 only.

4.0 HEAT TREATMENT:-

4.1 All fittings shall be heat treated as below.

SA 234 WP 8 - As per specification

SA 105, SA234 WP C - Normalised

SA234 WP111 WP12/ WP22 - Normalised & Tempered

SA182 F111 F12/ F22 - Normalised & Tempered

Stainless Steel :-

SA 182 F3041 316/3211 347 SA 403 WP304/ 316/ 321/ 347

- Solution annealed

- Solution annealed

4.2 Fittings confirming to SA 234 WP91 and SA182 F91shall be normalised at1040 t01070deg C (for wall thickness larger than 75 mm, accelerated cooling may be done to obtain a fully martensitic structure) and tempered at 760:t 10 deg C

5.0 TESTING: -

(a) All ferrous fittings shall be tested by MPI as per ASTM E-709 and SS fittings shall be

LPI tested as per AS E 165.

S. Jayakumar, Engg

P. Elangovan, QA

Approved by K. Vedaprasad, QC

K. Ganeshan, MPL ~J

•Bhar3t.~HeaViElectriCa-.·.IS~·.L·I' .. m .... it.e .. d .. '. Piping cenT.re~-Chen.r.'. a. i Technical Delivery Conditions Conditions for Butt

L Welded -:- Fittings a~ p~r India~_Boi~~_~~e~_l:llat!~_~~_.

TOG: 102 Rev. 04 Date: 27.02.2009 Page: 2 of 4

(b) One fitting of each specification, heat, heat treatment lot and size shall be subjected to Tension Test as per applicable standard.

(c) All fittings of wall thickness above 6mm or NB 200mm and above shall be Ultrasonically Tested as per SA 388; acceptance norms shall be 3.3.4 of ASME section VIII Div.2.

(d) Hardness test shall be carried out on each fittings of WP91 I F91. For other fittings hardness shall be checked on 10% of the fittings.

(e) In case of welded fittings; all the welds shall be 100% RT tested and acceptance norms shall be UW 51 of ASME Sec VIII DIV-1

(f) The following supplementary tests shall be carried out for specifications namely SA105, SA 182 F11! F12! F22! F91, SA 234 WPC! WP111 WP12 / WP22 /WP91 ( No supplementary test applicable for SA 234 WPB )

a) Product analysis - one! heat! size.

b) Tension test - one / heat / heat treatment lot! size.

(g) Metallography:- Metallography shall be carried out on one per heat, per size, per heat treatment lot of WP91 / F91 fittings. Acceptance norms - The Material shall be free from any micro fissures. Microstructure shall show tempered martensite and also to be examined for any grain growth. Photomicrograph with 500x ( Min) magnification along with Metallography report to be provided. The actual magnification shall be indicated.

6.0 POSITIVE MATERIAL IDENTIFICATION ( PMI) FOR ALLOY STEEL FITTINGS.

Each alloy steel fitting shall be checked for the correctness of the material during manufacturing and final inspection using X-ray fluorescence principle or spark emission spectrography.

7.0 PAINTING, COLOUR CODING, MARKING, PACKING & END PROTECTION

7.1 PAINTING: All fittings (except stainless steel and galvanised) shall be painted on the external surface as given below

a) surface preparation: Blast cleaning

b) Primer coat: 50 microns of Red oxide zinc phosphate confirming to IS 12744

c) Final coat : 70 microns of Synthetic enamel paint confirming to IS2934 .

d) Shade: (i) smoke grey - shade no 692 of IS5 for all carbon steel fittings (ii) Sea green -- shade no 217 of IS5 for all Alloy steel fittings

The internal surface shall be protected with rust preventive coating or rust inhibitor. Stainless steel and Galvanised fittings need not be painted.

7.2 COLOUR CODING; All fittings shall be colour coded circumferentially at ends as

given below

P. Elangovan, QA

=

Red Blue

SA 234 WPB / WPBW WPC/ SA105

=

S. Jayakumar, Engg

Approved by

r-. K. Vedaprasad, QC ()"

K. Ganeshan, MPL '{

~'"

Bharat Heavy ElectricalsLim;ied~P;ping Centre-,ChEmnai Technical Delivery Conditions Conditions for Butt Welded - Fittings as per Indian Boiler Regulations.

I . . ~.~_ .. _ .... _. ... .._ ...

WP11 / SA 182 F11 = Green & White

WP121 SA182 F12 Black & Red

WP22 I SA 182 F22 ._ Blue & Red

WP91 I SA 182 F91 - Brown & Red

TOG: 102 Rev. 04 Date: 27.02.2009 Page: 3 of 4

SA 182 I SA 403 F I WP 304 316 321 347

=

Blue & Yellow Black & Green Blue & Brown Yellow & Black

=

=

=

7.3 MARKING:

7.3.1 The fittings dispatched to BHEL Stores shall be punched I etched with Material code, Heat number, material specification, maker's emblem, Inspectors seal and Statutory authorities seal (as applicable) .

In addition, the above details along with size shall be paint stenciled on the fittings.

If the thickness of the fitting is less than 6 mm, punching is not permitted and the above details shall be paint stenciled only. Fittings of size up to 2" (50mm) shall be tied together and the above details shall be punched / etched in a separate tag and tied to it

7.3.2 The fittings dispatched directly to project site as DTS shall be punched and paint stenciled with OU code (14 digit work order du detail) as given by purchase in addition to marking done as per para 7.3.1.

7.4 PACKING AND END PROTECTION: Machined ends of the fittings shall be well protected using end caps and fittings shall be suitably packed in box / crate to avoid transit & other damages.

8.0 INSPECTION & CERTIFICATION: -

, All fittings are to be Inspected at the manufacturer's works by the Inspection agencies / authorities as per IBR and as indicated in the P.O. Inspection certificate in IBR Form III C shall be submitted along with the Work Test Certificate countersigned by the above authorities and shall include the following.

1. Test Certificate Number & date.

2. BHEL P.O Number & Amendment Number

3. BHEL P.O. Serial Number

4. BHEL TOC Number

5. Size-wise Quantity

6. Specification, Grade & Year of code.

7. Heat/Melt Number

8. Starting material details.

9. Steel making process

10. Laddie Analysis of Raw Material and product analysis of fitting.

*11. Positive Material Identification (PMI) report for Alloy steel fittings.

*12. Supplementary Test(Product analysis, Tension test.) results.

*13. Heat Treatment Chart.

*14. NDE report. (VISUAL.MPI, LPI,UT)

*15. Tensile Test Report

*16. Hardness est Report

S. Jayakumar, Engg

Approved by

r-: K. Vedaprasad, QC

K. Ganeshan, MPLg(

P. Elangovan, QA

11'08 :f62Rev~04 I Date: 27.02.2009

I Page: 4 of 4

-~~---'---"

Bharat Heavy Electricals Limited, Piping Centre, Chennai

Technical Delivery Conditions Conditions for Butt Welded - Fittings as per Indian Boiler Regulations.

17. Metallography Report along with photomicrograph with 500x ( min)

magnification.

*18. Dimensional conformance.

*19. RT test report / Results (for welded fittings)

*20. Guarantee of HTP shall be given as follows> "Fittings are capable of withstanding without failure, leakage or impairment of their serviceability a hydrostatic test pressure equal to that prescribed for the specified matching pipe of equivalent material".

"Details furnished in the Tests certificate in lieu of chart/report is acceptable.

9.0 RECORDS OF REVISION :-

Rev 01 : a) Fully revised for better clarity. : b) Para 2.0 e added.

Rev 02 : a) Para 2.0 (c): UT acceptyance norms revised from level A to B. Rev 03 : a) Fully revised for better clarity.

: b) Para 4.2,6.0,8.0 (11) added.

c) Para 2 (d) ,4.1, 5 (d) are revised.

Rev 04: a) Para 5.0 (g), 7.0 and 8.0 (17) are revised.

*****

s. Jayakumar, Engg P. Elangovan, QA P-f~

_j iF'L I DATE ALTERED :

w

:x:

(D e:1 CHD & APPD :

u, ...J

w

0 :x:

>- (D

>->-u..

ffi.=o

"-0>-

Ow",

O<ll::w

Q.(5o::

w~1!!

f"0<~ NOTES: ~

",oW

->-F 2

~~o 1) DESIGN PRESSURE 70.6 Kg/Cm (g)

~~ ....

=>9:_; 2) DESIGN TEMPERATURE : 475 ·C

00«

g8~

(J)U')::::E 3) WORKING MEDIUM STEAM

;E~~

zcn~ 4) FOLLOW TDC No. : TDG-102 (LATEST REVISION)

0\3>-

zz~ 5) ALL DIMENSIONS ARE FINISHED DIMENSIONS

~t;>-

~:::JZ 6) DESIGN, MANUFACTURING, INSPECTION, TOLERANCES AND TESTING

w:::;;«

F!::~ SHALL BE AS PER IBR ANSI B16.9 AND SA 234.

Z

0 7) FLOW AREA SHALL NOT BE LESS THAN 80% OF NOMINAL FLOW AREA.

F=

:::>

« 8) t-min SHALL NOT BE LESS THAN 0.875 TIMES OF THE WALL THICKNESS

(J

(i.e 0.875 x THICKNESS )

'.f'/

/()/

'>\:/

/

;./

/."

~"r - /

"' /

EDGE PREPARATION

AS PER DRG NO: """'''-,"" ""y«--,

3- 80- 300-19825

,

STYLE-P, d1=454 /{()~/ \

(TYP) \

/ \

Qj/

./ \

/ I

I 1

I

OD508x27

:-·,OC" ~~J

BW LR 90DEG ELBOW 92 524 976 0000 406 000

- A

OD508x27 SA 234 WP22 CL1 1

VAR 0 MA TERIAL CODE i1::_t:: UNIT WT. (KG)

DESCRIPTION I- o z

No. UJ MA TERIAL SPECN :? :::> QUANTITY

BHARAT HEAVY ELECTRICALS LIMITED NAME SIGNATURE DATE

~ DRN N.MEGANA THAN _sd_ 23/03/2010

PIPING CENTRE CHD N.MEGANA THAN _sd_ 24/03/2010

CHENNAI 600 017 APPD K.V.RAMANI _sd_ 25/03/2010

DEPT ALL PROJECnON SCALE WEIGHT (Kg) REF TO ASSY I OLD DWG

C]@

CODE DIMENSIONS N.T.S 406.000

ARE IN MM

TITLE DRAWING NO : ([V

ASME 816.9 BW LR 90DEG ELBOW 4-80-321- 70629 IClC)

OD508x27

_j I'; I DATE ALTERED :

w

:r:

m (i'

u, d CHO & APPD :

° :r:

~>-~

ffi~o

<LOt-

OWUl

g:~~

w~1t!

F"'~ NOTES: ~

UlOW

->-F Kg/Cm2(g)

~.=o 1) DESIGN PRESSURE 70.6

~~t-

::>Q:;_J 2) DESIGN TEMPERATURE 475 'C

00<

g8~

UlUl:::l; 3) WORKING MEDIUM STEAM

;E~~

ZLD~ 4) FOLLOW TOC No. TOG-102 (LATEST REVISION)

°6>-

zz< 5) ALL DIMENSIONS ARE FINISHED DIMENSIONS

:::I; ;=

~~~ 6) DESIGN, MANUFACTURING, INSPECTION, TOLERANCES AND TESTING I

w:::l;<

Ft::~ SHALL BE AS PER IBR ANSI B16.9 AND SA 234.

Z I 7) t-min SHALL NOT BE LESS THAN 0.875 TIMES OF THE WALL THICKNESS

0

F (l.e 0.875 x THICKNESS )

::>

« I

u EDGE PREPARATION

,/AS PER DRG NO:

I -: 3- 80- 300-19825

/

/

I .: STYLE-P, d1=743

/1~

'7: '////////// ""f

! !

_U~·U"U_Y~·~~'.·'~·u

I .//./ .// I

! !

~! LDj

1'01 1'01

xi Xl

I ~! 1'01

~i -1---- ;------ ----- t- ~i

1'1 OJI I

01 oj

01 OJ

I

! ,

i ! I

J

f '/////// 1 I

it! /

i

,/ .s;/ .// ./ ·//J'_LL. t

,w_,_~_,u'm'n'u_,, ___ u,

EDGE PREPARATION/ 1

£.; I

AS PER DRG NO: I '

..... / 610 I

f

3-80-300-19825 ' __ ~'><- __ "~A~.wU~~UU>.~~'__W_'~.'_~_~~W~U"" .. --Y---··~" _'W''-_~ ___ ~"V_" ___ "_ ~ __ ~~~ .. ~,_".v~, ___ .j

STYLE-P, dl=649

OD813x35/0D711 x31 92 117 553 0000 410 000

- A

I L=610 SA 234 WP22 CLl 1

VAR £:) MA TERIAL CODE <L I- UNIT WT. (KG)

I ....... -

DESCRIPTION I- !:( z

No. V) MATERIAL SPECN < ::> QUANTITY

BHARAT HEAVY ELECTRICALS LIMITED NAME SIGNATURE DATE

~ DRN N.MEGANA THAN _sd_ 22/03/2010

PIPING CENTRE CHO N.MEGANATHAN _sd_ 24/03/2010

CHENNAI 600 017 APPD K.V.RAMANI _sd_ 25/03/2010

DEPT ALL PROJECllON SCALE WEIGHT (Kg) REF TO ASSY / OLD DWG

C]@)

CODE DIMENSIONS N.T.S 410.000

ARE IN MM

TITLE DRAWING NO :

ASM B16.9 BW CON REDUCER 4-80-320- 70619 I ()ei

OD813x35/0D711 x31

CRH-NRV a z

f- Ii z

f- « a

0

G +

:;{ V! u,

0

o: 1.6

h- x

{I} co

~ T

u.... }-

(J Z II

011 () u.s

~ w

f:'I 0 0::

Oi w

z: CO (~ I

0 3: {Ii

;"."':

k;

2::

'"

W

'"

W

~

:;,

;~

'"

'"

~

(Ij 6

.0-. fE

:;;;

;':

~

~I !-

z

~ lL

>-< '"

«

:: <L

:;.:_

UJI ~ iE

'"

J') 8

W (~

N fl' ~

£.D iJ\ '"

w Co <!

Q

z; Z 0

Z -«; Si

Co C "'"'

~ z 0

...q;. , u, :0

:::'" G 0 Pi)

V',L.! vi W (3 ....:I 14

,_, Q ~ fu Pi)

'" 0: is: ~ ~

t...; a '" :>-<

a 0 a w :;:, >- :z;

:..u Q c:: <: Pi)

~2 _, V) U

_, Pi)

a -c ~ ~

-« ~ % w

'" 0:; ;2

<f) z 8 :j

if>

t.D ~ « t:; z

zQ .r; w

:::,c V) V> c: 8

DUCt:

~~e 2; :3

::; ~ a

.~ - L

Z

::s ~ PO iii

'" 0

0 ""' co

Z til _,

'" ~

£c<

N 0 5

"" z X Q rp

0

c,

f;.J

Q:::

(5

e

L

E LJ

cc P...I

E (:)

'" Z I

I ,

'" 0 i I

f- ~I

/\1 -<

L

(I) .....:11

2: ~ :>-<1

w

~ a H

-s- 0 enl

Vii w rt:

WJ (I) 9

t-

O

Zl >- 0 0

_J ~

_J '0

« A

0 VI

{7j (f) 'J}

>- Vi

t/) w

I w Z

(L z i3

w ::.:

ro u ~

0 I

0 w e-r-

l- e _J _J

l- e;;: _J <t

I W « =s:

G > 3:

;:;' "<, cr

0 0:: 9

~ w a

cr u..

L0 :::>

0

Lc (/) (0

0 -s;

w H

0 :2 IS

0 ~

5 0 0 01- Tii\l £

~.to+

E

E

01 0J

I .,.:

I v

~ z

~ W

I

if,' 3: &8 §

E-< gl w

en {l)

:::>

Z 0

• x 0 ¢ E t: E f:

0

w

~

0::

W

Q:_, >

0; ::J~ w "

L...l CL 0

)::! ~ ~! 0:: w

1::1 0::

0 :::0

001 ~ ~l z if- I-

,- <1 ;:: -c I

_) 121 ::El () u.; '"

.,,(~l u, :-:; «

<i

¢! CLI ~i z >- x

1 z ..J I-

ew 0 ..J {/1

xi zi o <{

~~ , gl u, 0 LU

EI ;;:; o,

<1 a 0 >- c:

g:i "'I 0::1 <{ K z

0] ~ 'r1 0 z

>-i w 0

__;; '" l-l w rn o

°1 0

;;;': C, if} a u.

u~ ~ l- I- a

o::i II ::) ;:::- ¥

1-; ~! 0

w; mi 0 ;::

::iii ~ J; ;1

<i l.Jj (>51 0 ;:;' II

6; :'.'1 0::

51 0 l-

I s:

'''..-4 ~

ZI 5 0 53dld GO ;JO" ci- IP iil <;'0+

~--++--------------

SOt OJ 6-0 S3dld 03l10ll!NO~ s-<- tP 1>

Qt l::iQj O'O~

X E ~

'" I C

eo W 0 tr'j

" ~ t<)

"" ..J ,\

0) 2 -'i S2 v:

n u; t.n

! z u.:: ';"'1 (n

~l L {fi W

CO o UJ L; Z

<!- Z X

0 ::E c:: '" U

<..) ¥ =;0

.» ~ t: ~

W CL U ....!

0 a:- i- ;j! ;:;'

0 <: 3:

0 u, ::::! 3:

i in c::

3'i c:: p

,_. 0

CD 0 b

0

OJ

N

0. IHOIVdlS .=0 GO

..-<

i o o C0

!

You might also like

- Grade 8.8 Bolt Loading Capacities TableDocument2 pagesGrade 8.8 Bolt Loading Capacities TableVijai Shankar SinghNo ratings yet

- Weld IncoDocument1 pageWeld IncomprabhurajalingamNo ratings yet

- Sa 299Document3 pagesSa 299Web LogueandoNo ratings yet

- C% MN% Si% P% Max S% Max: The Ladle Analysis of The Steel Shall Be Given As BelowDocument2 pagesC% MN% Si% P% Max S% Max: The Ladle Analysis of The Steel Shall Be Given As BelowThennarasu VelloreNo ratings yet

- Aws D10.8 1996 PDFDocument19 pagesAws D10.8 1996 PDFCGRRNo ratings yet

- Inspection of CastingDocument23 pagesInspection of CastingRaghu SanthNo ratings yet

- 39 Ni CR Mo 3Document2 pages39 Ni CR Mo 3Lokesh Krishnappa100% (2)

- AISI 4130: Incoloy Alloys, Fast QuoteDocument5 pagesAISI 4130: Incoloy Alloys, Fast QuoteSantanu SahaNo ratings yet

- Sa 387Document29 pagesSa 387Ali VarmazyarNo ratings yet

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocument2 pagesSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Standard Specification For Steel Sheet Zinc Coated Galvanized or Zinc Iron Alloy Coated Galvannealed by The Hot Dip ProcessDocument4 pagesStandard Specification For Steel Sheet Zinc Coated Galvanized or Zinc Iron Alloy Coated Galvannealed by The Hot Dip ProcessarchahmedassafNo ratings yet

- Flanges - Standard Dim For Flanges Used in InvestaDocument2 pagesFlanges - Standard Dim For Flanges Used in InvestaBharat TailorNo ratings yet

- L80 - Continental AlloysDocument2 pagesL80 - Continental Alloystoxa0707No ratings yet

- Sa 320 PDFDocument13 pagesSa 320 PDFRaju SkNo ratings yet

- Submerged Arc Welding: by L D PoyyaraDocument35 pagesSubmerged Arc Welding: by L D Poyyaraanon_293243615No ratings yet

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- b2020-Tdc-Fas-004 Fasteners r3Document2 pagesb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNo ratings yet

- Defects in Seamless TubesDocument4 pagesDefects in Seamless TubesAgniva DuttaNo ratings yet

- TDC Fasteners TDC 5 166 NutsDocument4 pagesTDC Fasteners TDC 5 166 NutsGohilaRajNo ratings yet

- Astm A537-A537m-95-2000Document4 pagesAstm A537-A537m-95-2000NadhiraNo ratings yet

- How To Read STD IS 2062 (2011)Document17 pagesHow To Read STD IS 2062 (2011)AkshayNo ratings yet

- Sa 213Document11 pagesSa 213gst ajahNo ratings yet

- Astm A53Document2 pagesAstm A53DeepakNo ratings yet

- Data Sheet Material 2.4819Document3 pagesData Sheet Material 2.4819BoberNo ratings yet

- Specification For Pressure Vessel Plates, Alloy Steel, Chromium-MolybdenumDocument6 pagesSpecification For Pressure Vessel Plates, Alloy Steel, Chromium-MolybdenumAnilNo ratings yet

- Astm 533Document4 pagesAstm 533JOSEPH REFUERZONo ratings yet

- ASTM A182 - Standard Specification For Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings and Valves and Parts For High Temperature ServiceDocument16 pagesASTM A182 - Standard Specification For Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings and Valves and Parts For High Temperature ServiceKok WaiNo ratings yet

- As MeDocument235 pagesAs Meshashi_uitNo ratings yet

- Chemical Composition - Zinc PDFDocument2 pagesChemical Composition - Zinc PDFIslam SahafayatNo ratings yet

- Steel Pipes Tubes Eng PDFDocument21 pagesSteel Pipes Tubes Eng PDFsintaprisilliaNo ratings yet

- Sa 266Document5 pagesSa 266Alejo ZabalaNo ratings yet

- ASTM A633 GR E Data Sheet 2012 04 01Document2 pagesASTM A633 GR E Data Sheet 2012 04 01FrancescoGuglielmo100% (1)

- (First Revision) : Indian StandardDocument8 pages(First Revision) : Indian StandardBhanu Pratap ChoudhuryNo ratings yet

- Astm B423Document4 pagesAstm B423pritam sarkarNo ratings yet

- ASTM A335 Pipe Specification1 PDFDocument8 pagesASTM A335 Pipe Specification1 PDFRoberto EliasNo ratings yet

- Sa 283Document3 pagesSa 283AnilNo ratings yet

- ASTM A480-A480M-04aDocument24 pagesASTM A480-A480M-04aNadhiraNo ratings yet

- ASTM Specs FittingsDocument10 pagesASTM Specs FittingskhaireddinNo ratings yet

- Spec No / Name Unsno/ Numeric Norm Form Class Condition: Material Database ReportDocument16 pagesSpec No / Name Unsno/ Numeric Norm Form Class Condition: Material Database ReportRafeek ShaikhNo ratings yet

- Comparison of Flange Face Finish As Per B16-5Document1 pageComparison of Flange Face Finish As Per B16-5Vivi OktaviantiNo ratings yet

- 304 304L Data Sheets 1 28 13 PDFDocument12 pages304 304L Data Sheets 1 28 13 PDFneerajtrvNo ratings yet

- Is 1030 1998 PDFDocument8 pagesIs 1030 1998 PDFRitesh AnandNo ratings yet

- Steel, Strip, High-Carbon, Cold-Rolled, Spring Quality, General Requirements ForDocument5 pagesSteel, Strip, High-Carbon, Cold-Rolled, Spring Quality, General Requirements ForProduction DepartmentNo ratings yet

- Is 513 Amendment-1Document2 pagesIs 513 Amendment-1sanjeev00747488No ratings yet

- ASTM A537 Standard SpecificationDocument4 pagesASTM A537 Standard SpecificationLeon SanchezNo ratings yet

- Sa 105 PDFDocument10 pagesSa 105 PDFkumarNo ratings yet

- Astm A31 (1995)Document4 pagesAstm A31 (1995)gsb2100% (1)

- SB 151 PDFDocument6 pagesSB 151 PDFAnilNo ratings yet

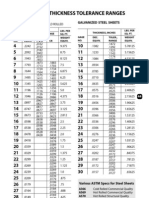

- H.R. Flat Bar: Astm-Aisi Thickness Tolerance RangesDocument1 pageH.R. Flat Bar: Astm-Aisi Thickness Tolerance RangesMaria Eliza Renee DominguezNo ratings yet

- Astm A-351 GR CF8MDocument2 pagesAstm A-351 GR CF8MVictor Castellanos AlegriaNo ratings yet

- S235jr Carbon SteelDocument2 pagesS235jr Carbon Steelcheligp1981No ratings yet

- Welding & SR Requirements - Pressure Parts - BoilerDocument7 pagesWelding & SR Requirements - Pressure Parts - BoilerNavneet SinghNo ratings yet

- Pressure Vessel Steels - Astm A516Document6 pagesPressure Vessel Steels - Astm A516septo982No ratings yet

- XR7040 SMDocument57 pagesXR7040 SMJeff BrintonNo ratings yet

- Hohengarten Ex 063Document43 pagesHohengarten Ex 063Jay YarowNo ratings yet

- Technics SUV6 Int SMDocument10 pagesTechnics SUV6 Int SMMitica NechiforNo ratings yet

- Oedipus Rex OrderDocument49 pagesOedipus Rex OrdergoorangesNo ratings yet

- Formula BookDocument55 pagesFormula Bookrsmssm2003No ratings yet

- OpTransactionHistory18 08 2014Document1 pageOpTransactionHistory18 08 2014Guru KguruNo ratings yet

- J3kA4Yv8XDLZtAKs7w001580565829 PDFDocument1 pageJ3kA4Yv8XDLZtAKs7w001580565829 PDFGuru KguruNo ratings yet

- Jawjawaharlal Nehru Technological University Hyderabadaharlal Nehru Technological University HyderabadDocument2 pagesJawjawaharlal Nehru Technological University Hyderabadaharlal Nehru Technological University HyderabadGuru KguruNo ratings yet

- Detail Syllabus For Static Equipment DesignDocument9 pagesDetail Syllabus For Static Equipment DesignGuru KguruNo ratings yet

- Gurunadharao Kanugula: Field of Experience in Static & Package EquipmentsDocument10 pagesGurunadharao Kanugula: Field of Experience in Static & Package EquipmentsGuru KguruNo ratings yet

- 11 Facts About Ancestral Property You Must KnowDocument1 page11 Facts About Ancestral Property You Must KnowGuru KguruNo ratings yet

- RX-V365 Om RLDocument104 pagesRX-V365 Om RLGuru KguruNo ratings yet

- Service Delivery Professional: Core CompetenciesDocument1 pageService Delivery Professional: Core CompetenciesGuru KguruNo ratings yet

- Doola Theerinda LanjaDocument10 pagesDoola Theerinda Lanjamad usudan56% (9)

- 2012 Monthly Calendar Landscape 02Document12 pages2012 Monthly Calendar Landscape 02rajuthekingNo ratings yet

- Asme Weld Efficiencies NotesDocument28 pagesAsme Weld Efficiencies NotesSiva SubramaniNo ratings yet

- En 10204Document1 pageEn 10204Guru KguruNo ratings yet