Professional Documents

Culture Documents

Learn Quickly With Our PLC Training DVD Series

Learn Quickly With Our PLC Training DVD Series

Uploaded by

Santanu MahatoCopyright:

Available Formats

You might also like

- Five Things You MUST Know If You Want To Program PLCsDocument16 pagesFive Things You MUST Know If You Want To Program PLCsVladan MilojevićNo ratings yet

- PLC Programming Using RSLogix 500Document60 pagesPLC Programming Using RSLogix 500BodongKorenganNo ratings yet

- PLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingFrom EverandPLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingRating: 4 out of 5 stars4/5 (1)

- Actividad 3 English Activity V2Document3 pagesActividad 3 English Activity V2Diana catherine Romero pacheco0% (1)

- BUSINESS COMMUNICATION Assignment AIMADocument8 pagesBUSINESS COMMUNICATION Assignment AIMAAkash Choudhury67% (6)

- 1a.what Is A PLCDocument1 page1a.what Is A PLCardiyan inigoNo ratings yet

- Programmable Logic ControllerDocument4 pagesProgrammable Logic ControllerBlack PigeonNo ratings yet

- PLC Lader LogicDocument53 pagesPLC Lader LogicKamaraju DaviliNo ratings yet

- What Is A PLCDocument55 pagesWhat Is A PLCHugo GandaraNo ratings yet

- 05-Introduction To PLCDocument63 pages05-Introduction To PLCMohamed Gawad ARayaNo ratings yet

- PLC BasicsDocument53 pagesPLC Basicsssservice centreNo ratings yet

- A PLC-BasicDocument56 pagesA PLC-BasicMarc RodaviaNo ratings yet

- PLC History: What Is A PLC?Document53 pagesPLC History: What Is A PLC?Lin ChongNo ratings yet

- PLC Training Ladder, RS232Document64 pagesPLC Training Ladder, RS232Mahesh GonuguntlaNo ratings yet

- 0 - Intro - PLC Fundamentals Essentials For Control SystemsDocument5 pages0 - Intro - PLC Fundamentals Essentials For Control SystemsMinh Nguyen HoangNo ratings yet

- Materi PLC: Programmable Logic Controller (PLC) Adalah Sebuah Rangkaian Elektronik Yang DapatDocument15 pagesMateri PLC: Programmable Logic Controller (PLC) Adalah Sebuah Rangkaian Elektronik Yang DapatWidi MulyasanaNo ratings yet

- PLC Interview Questions With Answers Part 1Document54 pagesPLC Interview Questions With Answers Part 1Hagos AlemNo ratings yet

- PLC and Collaborative AutomationDocument4 pagesPLC and Collaborative AutomationChristopherElPadrinoCardenasNo ratings yet

- What Is A PLCDocument58 pagesWhat Is A PLCravigupta23No ratings yet

- Programmable Logic Controller Thesis PDFDocument6 pagesProgrammable Logic Controller Thesis PDFBestEssayHelpIndianapolis80% (5)

- Basic PLC: Programmable Logic Controller (PLC)Document32 pagesBasic PLC: Programmable Logic Controller (PLC)winda ramadhaniNo ratings yet

- Definicion de PLCDocument52 pagesDefinicion de PLCJuan Miguel Castro VargasNo ratings yet

- Guthi Vivek 2019107038Document3 pagesGuthi Vivek 2019107038Kushal KvssNo ratings yet

- What Is A Programmable Logic Controller (PLC) ?: Products by Size by Series Customized EnclosuresDocument11 pagesWhat Is A Programmable Logic Controller (PLC) ?: Products by Size by Series Customized EnclosuresTrisha SambranoNo ratings yet

- PLC NotesDocument61 pagesPLC NotesravipedapudiNo ratings yet

- PLC1 ADocument71 pagesPLC1 ASymon Justine SañoNo ratings yet

- PLC LearnDocument108 pagesPLC LearnImran Nawaz MehthalNo ratings yet

- PLC AutomationDocument47 pagesPLC AutomationAman AJNo ratings yet

- Programmed LogicDocument4 pagesProgrammed LogicScribdTranslationsNo ratings yet

- Research Paper On Programmable Logic ControllerDocument5 pagesResearch Paper On Programmable Logic Controllerefdwvgt4No ratings yet

- A Summary of PLCDocument2 pagesA Summary of PLCHoàng Minh ChíNo ratings yet

- PLC Fund 1794Document39 pagesPLC Fund 1794Joang TaoNo ratings yet

- Thesis Programmable Logic ControllerDocument5 pagesThesis Programmable Logic Controllerfjh1q92b100% (2)

- PLC PDFDocument3 pagesPLC PDFKushal KvssNo ratings yet

- Control System 5 RajibDocument7 pagesControl System 5 RajibSanjid ElahiNo ratings yet

- Introduction To Programmable Logic ControllersRev2Document43 pagesIntroduction To Programmable Logic ControllersRev2apelokayaNo ratings yet

- Chapter 1 (PLC)Document9 pagesChapter 1 (PLC)Kibria PrangonNo ratings yet

- DEE 3323.02 Pengenalan PLCDocument33 pagesDEE 3323.02 Pengenalan PLCnabilo20No ratings yet

- Project PLCDocument12 pagesProject PLCmajumderabhijit85No ratings yet

- PLC Trainer ThesisDocument4 pagesPLC Trainer Thesisfz6etcq7100% (2)

- Everything About Programmable Logic Cont PDFDocument4 pagesEverything About Programmable Logic Cont PDFFahim AkterNo ratings yet

- Programmable Logic Controller Name: Viloria, Maureen C. SR Code: J15-12667Document5 pagesProgrammable Logic Controller Name: Viloria, Maureen C. SR Code: J15-12667Danelle GeamalaNo ratings yet

- Comparing PLC and DCS: From The Automation List Department..Document6 pagesComparing PLC and DCS: From The Automation List Department..predic1No ratings yet

- Report On PLC & ScadaDocument30 pagesReport On PLC & ScadaRajmal Menariya60% (10)

- Programmable Logic Controller: What Is A PLC?Document22 pagesProgrammable Logic Controller: What Is A PLC?Shuaib AbdulmuhizNo ratings yet

- IntroductionDocument3 pagesIntroductionYamamoto Seet XNo ratings yet

- Comparing PLC and DCSDocument14 pagesComparing PLC and DCSamhosny64No ratings yet

- Programmable Logic Controller (PLC) Is A Digital Computer Used For The Automation of VariousDocument23 pagesProgrammable Logic Controller (PLC) Is A Digital Computer Used For The Automation of VariousSunil ChaudhariNo ratings yet

- Load Management SystemDocument40 pagesLoad Management Systematul mishraNo ratings yet

- Lect 001Document18 pagesLect 001lana_salahadinNo ratings yet

- PLC Workshop 1-2 DayDocument119 pagesPLC Workshop 1-2 DayOwais Khan100% (2)

- Articulo Ingles Programacion PLCDocument5 pagesArticulo Ingles Programacion PLCRafael Antonio Rubio ValeroNo ratings yet

- Beginners Guide To PLC ProgrammingDocument80 pagesBeginners Guide To PLC ProgrammingWilliam BuchananNo ratings yet

- Beginners Guide To PLC Programming How To Program A PLCDocument19 pagesBeginners Guide To PLC Programming How To Program A PLCAnonymous 0tqzNTWyyNo ratings yet

- PLC and Scada Systems: Programmable Logic Controller Supervisory Control and Data AcquisitionDocument35 pagesPLC and Scada Systems: Programmable Logic Controller Supervisory Control and Data AcquisitionjustinkikoNo ratings yet

- Chapter 1 NotesDocument3 pagesChapter 1 Noteshero_spaceboy3600No ratings yet

- Introduction To PLC ControllersDocument7 pagesIntroduction To PLC Controllersdhananjaymohapatra2009No ratings yet

- Mechatronics - PLC ReportDocument51 pagesMechatronics - PLC ReportEarl FloresNo ratings yet

- What Is Programmable Logic ControllerDocument4 pagesWhat Is Programmable Logic ControllerNgwe Soe HanNo ratings yet

- Industrial Training: Submitted For Partial Fulfillment of Award of B.Tech DegreeDocument35 pagesIndustrial Training: Submitted For Partial Fulfillment of Award of B.Tech DegreeNeha DhanukaNo ratings yet

- Programmable Logic Controller (PLC) Unitary PLCDocument2 pagesProgrammable Logic Controller (PLC) Unitary PLCLoveRahul100% (1)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Ourlog 9089Document4 pagesOurlog 9089Prin PinkyNo ratings yet

- Geophysics & Remote SensingDocument5 pagesGeophysics & Remote SensingHaris Eko SetyawanNo ratings yet

- (Mathematics in Industry 13) Wil Schilders (auth.), Wilhelmus H. A. Schilders, Henk A. van der Vorst, Joost Rommes (eds.) - Model order reduction_ theory, research aspects and applications-Springer-VeDocument463 pages(Mathematics in Industry 13) Wil Schilders (auth.), Wilhelmus H. A. Schilders, Henk A. van der Vorst, Joost Rommes (eds.) - Model order reduction_ theory, research aspects and applications-Springer-VeRaja Sekhar BattuNo ratings yet

- PM265 ch2Document47 pagesPM265 ch2M. AhmedNo ratings yet

- 2) Đề thi thử Chuyên Lê Hồng Phong - Nam Định (2023)Document8 pages2) Đề thi thử Chuyên Lê Hồng Phong - Nam Định (2023)trinhthingocanh2k5No ratings yet

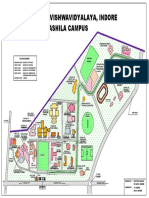

- Devi Ahilya Vishwavidyalaya, Indore Takshashila Campus: Vigyan BhawanDocument1 pageDevi Ahilya Vishwavidyalaya, Indore Takshashila Campus: Vigyan BhawankapasNo ratings yet

- Past Continuous TenseDocument5 pagesPast Continuous TensePathricia KasumNo ratings yet

- Wizard CodeDocument259 pagesWizard CodeAnonymous 243fCIzFKINo ratings yet

- Physical FeaturesDocument4 pagesPhysical FeaturesReshma SharmaNo ratings yet

- Maths Coursework Mark SchemeDocument4 pagesMaths Coursework Mark Schemef5d7ejd0100% (2)

- NOTH Menu Aug 22Document10 pagesNOTH Menu Aug 22Devin SwanepoelNo ratings yet

- Sitarambhai Naranji Patel Institute of Technology & Research Centre, Umrakh Electronics and Communication DepartmentDocument3 pagesSitarambhai Naranji Patel Institute of Technology & Research Centre, Umrakh Electronics and Communication DepartmentMitali TakawalaNo ratings yet

- Cicol NT Slurry: Constructive SolutionsDocument3 pagesCicol NT Slurry: Constructive SolutionstalatzahoorNo ratings yet

- 6th Grade Worksheet BundleDocument65 pages6th Grade Worksheet BundleLisa Ward0% (1)

- Starcraft - (1999) Hybrid - Chris Metzen PDFDocument10 pagesStarcraft - (1999) Hybrid - Chris Metzen PDFHawk RangerNo ratings yet

- 97 145Document2 pages97 145anon_251242493No ratings yet

- Council Agenda 28 October 2019 WebsiteDocument359 pagesCouncil Agenda 28 October 2019 WebsiteAlexander DarlingNo ratings yet

- Multithreaded Airport Simulation SystemsDocument6 pagesMultithreaded Airport Simulation Systemsphanikrishnajagadesh666No ratings yet

- Temperature SensorsDocument10 pagesTemperature Sensorsdevashish.jo11No ratings yet

- AOS Injury Classification Systems Poster 20200327 THORACOLUMBARDocument1 pageAOS Injury Classification Systems Poster 20200327 THORACOLUMBARRakhmat RamadhaniNo ratings yet

- For Which Value Of, Will The Lines Represented by The Following Pair of Linear Equations Be ParallelDocument54 pagesFor Which Value Of, Will The Lines Represented by The Following Pair of Linear Equations Be ParallelAmit SinghNo ratings yet

- What Is Underground Mining?Document2 pagesWhat Is Underground Mining?Taha YousafNo ratings yet

- Phosphoric Acid Industry - Problems & SolutionsDocument18 pagesPhosphoric Acid Industry - Problems & SolutionsRiyasNo ratings yet

- Vascular and Non-Vascular PlantsDocument3 pagesVascular and Non-Vascular PlantsLeonardo PigaNo ratings yet

- Gs This That Those - ExercisesDocument2 pagesGs This That Those - ExercisesWilvertein C ChambiNo ratings yet

- 1953-File Utama Naskah-6037-2-10-20200429Document20 pages1953-File Utama Naskah-6037-2-10-20200429taufik hidayatNo ratings yet

- Fussion3000 MackieDocument8 pagesFussion3000 MackieMarco BruceNo ratings yet

- Responsibility AccountingDocument14 pagesResponsibility AccountingJignesh TogadiyaNo ratings yet

Learn Quickly With Our PLC Training DVD Series

Learn Quickly With Our PLC Training DVD Series

Uploaded by

Santanu MahatoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Learn Quickly With Our PLC Training DVD Series

Learn Quickly With Our PLC Training DVD Series

Uploaded by

Santanu MahatoCopyright:

Available Formats

Learn quickly with our PLC Training DVD Series: on sale

$599.00 $379

Click here now for details!

What is a PLC?

A PLC (i.e. Programmable Logic Controller) is a device that was invented to replace the necessary

sequential relay circuits for machine control. The PLC works by looking at its inputs and depending upon

their state, turning on/off its outputs. The user enters a program, usually via software, that gives the

desired results.

PLCs are used in many "real world" applications. If there is industry present, chances are good that there

is a plc present. If you are involved in machining, packaging, material handling, automated assembly or

countless other industries you are probably already using them. If you are not, you are wasting money

and time. Almost any application that needs some type of electrical control has a need for a plc.

For example, let's assume that when a switch turns on we want to turn a solenoid on for 5 seconds and

then turn it off regardless of how long the switch is on for. We can do this with a simple external timer. But

what if the process included 10 switches and solenoids? We would need 10 external timers. What if the

process also needed to count how many times the switches individually turned on? We need a lot of

external counters.

As you can see the bigger the process the more of a need we have for a PLC. We can simply program

the PLC to count its inputs and turn the solenoids on for the specified time.

This site gives you enough information to be able to write programs far more complicated than the simple

one above. We will take a look at what is considered to be the "top 20" plc instructions. It can be safely

estimated that with a firm understanding of these instructions one can solve more than 80% of the

applications in existence.

That's right, more than 80%! Of course we'll learn more than just these instructions to help you solve

almost ALL your potential plc applications.

PLC Advantages and Disadvantages

Flexibility: One single Programmable Logic Controller can easily run many machines.

Correcting Errors: In old days, with wired relay-type panels, any program alterations required time

for rewiring of panels and devices. With PLC control any change in circuit design or sequence is as

simple as retyping the logic. Correcting errors in PLC is extremely short and cost effective.

Space Efficient: Today's Programmable Logic Control memory is getting bigger and bigger this

means that we can generate more and more contacts, coils, timers, sequencers, counters and so on. We

can have thousands of contact timers and counters in a single PLC. Imagine what it would be like to

have so many things in one panel.

Low Cost: Prices of Programmable Logic Controlers vary from few hundreds to few thousands. This

is nothing compared to the prices of the contact and coils and timers that you would pay to match the

same things. Add to that the installation cost, the shipping cost and so on.

Testing: A Programmable Logic Control program can be tested and evaluated in a lab. The program

can be tested, validated and corrected saving very valuable time.

Visual observation: When running a PLC program a visual operation can be seen on the screen.

Hence troubleshooting a circuit is really quick, easy and simple.

You might also like

- Five Things You MUST Know If You Want To Program PLCsDocument16 pagesFive Things You MUST Know If You Want To Program PLCsVladan MilojevićNo ratings yet

- PLC Programming Using RSLogix 500Document60 pagesPLC Programming Using RSLogix 500BodongKorenganNo ratings yet

- PLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingFrom EverandPLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingRating: 4 out of 5 stars4/5 (1)

- Actividad 3 English Activity V2Document3 pagesActividad 3 English Activity V2Diana catherine Romero pacheco0% (1)

- BUSINESS COMMUNICATION Assignment AIMADocument8 pagesBUSINESS COMMUNICATION Assignment AIMAAkash Choudhury67% (6)

- 1a.what Is A PLCDocument1 page1a.what Is A PLCardiyan inigoNo ratings yet

- Programmable Logic ControllerDocument4 pagesProgrammable Logic ControllerBlack PigeonNo ratings yet

- PLC Lader LogicDocument53 pagesPLC Lader LogicKamaraju DaviliNo ratings yet

- What Is A PLCDocument55 pagesWhat Is A PLCHugo GandaraNo ratings yet

- 05-Introduction To PLCDocument63 pages05-Introduction To PLCMohamed Gawad ARayaNo ratings yet

- PLC BasicsDocument53 pagesPLC Basicsssservice centreNo ratings yet

- A PLC-BasicDocument56 pagesA PLC-BasicMarc RodaviaNo ratings yet

- PLC History: What Is A PLC?Document53 pagesPLC History: What Is A PLC?Lin ChongNo ratings yet

- PLC Training Ladder, RS232Document64 pagesPLC Training Ladder, RS232Mahesh GonuguntlaNo ratings yet

- 0 - Intro - PLC Fundamentals Essentials For Control SystemsDocument5 pages0 - Intro - PLC Fundamentals Essentials For Control SystemsMinh Nguyen HoangNo ratings yet

- Materi PLC: Programmable Logic Controller (PLC) Adalah Sebuah Rangkaian Elektronik Yang DapatDocument15 pagesMateri PLC: Programmable Logic Controller (PLC) Adalah Sebuah Rangkaian Elektronik Yang DapatWidi MulyasanaNo ratings yet

- PLC Interview Questions With Answers Part 1Document54 pagesPLC Interview Questions With Answers Part 1Hagos AlemNo ratings yet

- PLC and Collaborative AutomationDocument4 pagesPLC and Collaborative AutomationChristopherElPadrinoCardenasNo ratings yet

- What Is A PLCDocument58 pagesWhat Is A PLCravigupta23No ratings yet

- Programmable Logic Controller Thesis PDFDocument6 pagesProgrammable Logic Controller Thesis PDFBestEssayHelpIndianapolis80% (5)

- Basic PLC: Programmable Logic Controller (PLC)Document32 pagesBasic PLC: Programmable Logic Controller (PLC)winda ramadhaniNo ratings yet

- Definicion de PLCDocument52 pagesDefinicion de PLCJuan Miguel Castro VargasNo ratings yet

- Guthi Vivek 2019107038Document3 pagesGuthi Vivek 2019107038Kushal KvssNo ratings yet

- What Is A Programmable Logic Controller (PLC) ?: Products by Size by Series Customized EnclosuresDocument11 pagesWhat Is A Programmable Logic Controller (PLC) ?: Products by Size by Series Customized EnclosuresTrisha SambranoNo ratings yet

- PLC NotesDocument61 pagesPLC NotesravipedapudiNo ratings yet

- PLC1 ADocument71 pagesPLC1 ASymon Justine SañoNo ratings yet

- PLC LearnDocument108 pagesPLC LearnImran Nawaz MehthalNo ratings yet

- PLC AutomationDocument47 pagesPLC AutomationAman AJNo ratings yet

- Programmed LogicDocument4 pagesProgrammed LogicScribdTranslationsNo ratings yet

- Research Paper On Programmable Logic ControllerDocument5 pagesResearch Paper On Programmable Logic Controllerefdwvgt4No ratings yet

- A Summary of PLCDocument2 pagesA Summary of PLCHoàng Minh ChíNo ratings yet

- PLC Fund 1794Document39 pagesPLC Fund 1794Joang TaoNo ratings yet

- Thesis Programmable Logic ControllerDocument5 pagesThesis Programmable Logic Controllerfjh1q92b100% (2)

- PLC PDFDocument3 pagesPLC PDFKushal KvssNo ratings yet

- Control System 5 RajibDocument7 pagesControl System 5 RajibSanjid ElahiNo ratings yet

- Introduction To Programmable Logic ControllersRev2Document43 pagesIntroduction To Programmable Logic ControllersRev2apelokayaNo ratings yet

- Chapter 1 (PLC)Document9 pagesChapter 1 (PLC)Kibria PrangonNo ratings yet

- DEE 3323.02 Pengenalan PLCDocument33 pagesDEE 3323.02 Pengenalan PLCnabilo20No ratings yet

- Project PLCDocument12 pagesProject PLCmajumderabhijit85No ratings yet

- PLC Trainer ThesisDocument4 pagesPLC Trainer Thesisfz6etcq7100% (2)

- Everything About Programmable Logic Cont PDFDocument4 pagesEverything About Programmable Logic Cont PDFFahim AkterNo ratings yet

- Programmable Logic Controller Name: Viloria, Maureen C. SR Code: J15-12667Document5 pagesProgrammable Logic Controller Name: Viloria, Maureen C. SR Code: J15-12667Danelle GeamalaNo ratings yet

- Comparing PLC and DCS: From The Automation List Department..Document6 pagesComparing PLC and DCS: From The Automation List Department..predic1No ratings yet

- Report On PLC & ScadaDocument30 pagesReport On PLC & ScadaRajmal Menariya60% (10)

- Programmable Logic Controller: What Is A PLC?Document22 pagesProgrammable Logic Controller: What Is A PLC?Shuaib AbdulmuhizNo ratings yet

- IntroductionDocument3 pagesIntroductionYamamoto Seet XNo ratings yet

- Comparing PLC and DCSDocument14 pagesComparing PLC and DCSamhosny64No ratings yet

- Programmable Logic Controller (PLC) Is A Digital Computer Used For The Automation of VariousDocument23 pagesProgrammable Logic Controller (PLC) Is A Digital Computer Used For The Automation of VariousSunil ChaudhariNo ratings yet

- Load Management SystemDocument40 pagesLoad Management Systematul mishraNo ratings yet

- Lect 001Document18 pagesLect 001lana_salahadinNo ratings yet

- PLC Workshop 1-2 DayDocument119 pagesPLC Workshop 1-2 DayOwais Khan100% (2)

- Articulo Ingles Programacion PLCDocument5 pagesArticulo Ingles Programacion PLCRafael Antonio Rubio ValeroNo ratings yet

- Beginners Guide To PLC ProgrammingDocument80 pagesBeginners Guide To PLC ProgrammingWilliam BuchananNo ratings yet

- Beginners Guide To PLC Programming How To Program A PLCDocument19 pagesBeginners Guide To PLC Programming How To Program A PLCAnonymous 0tqzNTWyyNo ratings yet

- PLC and Scada Systems: Programmable Logic Controller Supervisory Control and Data AcquisitionDocument35 pagesPLC and Scada Systems: Programmable Logic Controller Supervisory Control and Data AcquisitionjustinkikoNo ratings yet

- Chapter 1 NotesDocument3 pagesChapter 1 Noteshero_spaceboy3600No ratings yet

- Introduction To PLC ControllersDocument7 pagesIntroduction To PLC Controllersdhananjaymohapatra2009No ratings yet

- Mechatronics - PLC ReportDocument51 pagesMechatronics - PLC ReportEarl FloresNo ratings yet

- What Is Programmable Logic ControllerDocument4 pagesWhat Is Programmable Logic ControllerNgwe Soe HanNo ratings yet

- Industrial Training: Submitted For Partial Fulfillment of Award of B.Tech DegreeDocument35 pagesIndustrial Training: Submitted For Partial Fulfillment of Award of B.Tech DegreeNeha DhanukaNo ratings yet

- Programmable Logic Controller (PLC) Unitary PLCDocument2 pagesProgrammable Logic Controller (PLC) Unitary PLCLoveRahul100% (1)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Ourlog 9089Document4 pagesOurlog 9089Prin PinkyNo ratings yet

- Geophysics & Remote SensingDocument5 pagesGeophysics & Remote SensingHaris Eko SetyawanNo ratings yet

- (Mathematics in Industry 13) Wil Schilders (auth.), Wilhelmus H. A. Schilders, Henk A. van der Vorst, Joost Rommes (eds.) - Model order reduction_ theory, research aspects and applications-Springer-VeDocument463 pages(Mathematics in Industry 13) Wil Schilders (auth.), Wilhelmus H. A. Schilders, Henk A. van der Vorst, Joost Rommes (eds.) - Model order reduction_ theory, research aspects and applications-Springer-VeRaja Sekhar BattuNo ratings yet

- PM265 ch2Document47 pagesPM265 ch2M. AhmedNo ratings yet

- 2) Đề thi thử Chuyên Lê Hồng Phong - Nam Định (2023)Document8 pages2) Đề thi thử Chuyên Lê Hồng Phong - Nam Định (2023)trinhthingocanh2k5No ratings yet

- Devi Ahilya Vishwavidyalaya, Indore Takshashila Campus: Vigyan BhawanDocument1 pageDevi Ahilya Vishwavidyalaya, Indore Takshashila Campus: Vigyan BhawankapasNo ratings yet

- Past Continuous TenseDocument5 pagesPast Continuous TensePathricia KasumNo ratings yet

- Wizard CodeDocument259 pagesWizard CodeAnonymous 243fCIzFKINo ratings yet

- Physical FeaturesDocument4 pagesPhysical FeaturesReshma SharmaNo ratings yet

- Maths Coursework Mark SchemeDocument4 pagesMaths Coursework Mark Schemef5d7ejd0100% (2)

- NOTH Menu Aug 22Document10 pagesNOTH Menu Aug 22Devin SwanepoelNo ratings yet

- Sitarambhai Naranji Patel Institute of Technology & Research Centre, Umrakh Electronics and Communication DepartmentDocument3 pagesSitarambhai Naranji Patel Institute of Technology & Research Centre, Umrakh Electronics and Communication DepartmentMitali TakawalaNo ratings yet

- Cicol NT Slurry: Constructive SolutionsDocument3 pagesCicol NT Slurry: Constructive SolutionstalatzahoorNo ratings yet

- 6th Grade Worksheet BundleDocument65 pages6th Grade Worksheet BundleLisa Ward0% (1)

- Starcraft - (1999) Hybrid - Chris Metzen PDFDocument10 pagesStarcraft - (1999) Hybrid - Chris Metzen PDFHawk RangerNo ratings yet

- 97 145Document2 pages97 145anon_251242493No ratings yet

- Council Agenda 28 October 2019 WebsiteDocument359 pagesCouncil Agenda 28 October 2019 WebsiteAlexander DarlingNo ratings yet

- Multithreaded Airport Simulation SystemsDocument6 pagesMultithreaded Airport Simulation Systemsphanikrishnajagadesh666No ratings yet

- Temperature SensorsDocument10 pagesTemperature Sensorsdevashish.jo11No ratings yet

- AOS Injury Classification Systems Poster 20200327 THORACOLUMBARDocument1 pageAOS Injury Classification Systems Poster 20200327 THORACOLUMBARRakhmat RamadhaniNo ratings yet

- For Which Value Of, Will The Lines Represented by The Following Pair of Linear Equations Be ParallelDocument54 pagesFor Which Value Of, Will The Lines Represented by The Following Pair of Linear Equations Be ParallelAmit SinghNo ratings yet

- What Is Underground Mining?Document2 pagesWhat Is Underground Mining?Taha YousafNo ratings yet

- Phosphoric Acid Industry - Problems & SolutionsDocument18 pagesPhosphoric Acid Industry - Problems & SolutionsRiyasNo ratings yet

- Vascular and Non-Vascular PlantsDocument3 pagesVascular and Non-Vascular PlantsLeonardo PigaNo ratings yet

- Gs This That Those - ExercisesDocument2 pagesGs This That Those - ExercisesWilvertein C ChambiNo ratings yet

- 1953-File Utama Naskah-6037-2-10-20200429Document20 pages1953-File Utama Naskah-6037-2-10-20200429taufik hidayatNo ratings yet

- Fussion3000 MackieDocument8 pagesFussion3000 MackieMarco BruceNo ratings yet

- Responsibility AccountingDocument14 pagesResponsibility AccountingJignesh TogadiyaNo ratings yet