Professional Documents

Culture Documents

US2254976

US2254976

Uploaded by

fatimasc0 ratings0% found this document useful (0 votes)

6 views3 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

6 views3 pagesUS2254976

US2254976

Uploaded by

fatimascCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 3

Patented Sept. 2, 1941

2,254,976

UNITED STATES PATENT OFFICE

2,258,976

‘MANUFACTURE AND PRODUCTION OF FINE

‘METAL AND ALLOY POWDERS

Alan Richard Powell, London, England, assignor

to Johnson, Maithey & Company, Limited,

‘London County, England, » British company

NoDrawing. Applloation October 27, 1938, Serial

Nop autaan. ‘in Great ‘Britain December 20,

4Ciaims, (CL 7505)

‘This invention relates to the production, in

the form of fine powders, of metals or alioys

capable of being produced 'by the conversion of

their compounds into metal by @ process of re-

duction or dissociation carried out at a tempera-

ture below the melting point of the metals or

alloys. If powdered reducible compounds of these

metals are subjected to reduction by heating in

the presence of reducing agents, or are dlssoc!-

ated by heating, the particles of the metals

formed coalesce to form larger aggregates which

it 1s impossible to comminute by mechanical

means by reason of thelr malleatility.

‘According to this invention the sald metals or

alloys thereof are obtained in the form of fine

powder by carrying out the dissoclation or re-

duction of one or more suitable compounds of

these metals in the presence of a suitable dis-

tributing or dispersing agent (hereinafter termed

distributing agent) which ts capable of helng

removed without detriment to the powdered met

al or metals ot alloys formed and then removing

the distributing agent,

‘Metals which can be produced in powdered

form by the process of this invention include cop-

per, silver, gold, iron, nickel, cobalt, and the

platinum group metals or alloys of two or more

of these metals or alloys of one or more of these

metals with one or more fusible metals (as for

example, tin, lead, zinc or cadmfum) which can

bbe,reduced below the melting point of the alloy

formed,

For example an oxide, hydroxide or carbonate

of one of the sald metals may be co-precipitated

with the oxide, hydroxide or carbonate of an-

other metal incapable of reduction or dissoci

tion, for example of the alkaline earths or mag-

nesium, the resulting mixed precipitate washed

free from soluble salts, dried and then subjected

to 2 dissociation or reduction treatment whereby

the said metal compound is converted to metal

which remains in a finely divided state evenly

distributed throughout the finely dlvided oxide

of the other metal constituting the distributing

agent. The distributing agent 1s then removed,

for example by leaching out with a suitable

solvent. In some cases, the finely divided metal

may be floated away from the distributing agent

by the use of a liquid of suitable specific gravity

or by the use of the usual oil flotation process.

Alternatively the distributing agents may be

impregnated with a solution of a suitable com-

6

25

30

35

40

50

being worked up in'the same way as the mixed

Precipitate referred to above.

‘The temperature and duration of the dissocl-

ation or reduction treatment influences the grain

size of the resulting metal powder, the powders

tending to be finer the lower the temperature

‘The proportion of distributing agent used also

tends to influence the size of the particles of the

resulting metal powder, the particles being small-

ez the larger the amount of aletributing agent

us

According to this invention it is possible to

obtain metal powders in such a state of fineness

that they will remain suspended in water for

relatively long periods.

‘The fine metal powders obtainable according to

this invention may be used for example for the

decoration of ceramic ware, for the production of

conducting surfaces on non-conducting materials,

for the preparation of metallic paints and also

in powder metallurey.

‘When using a mixture of two or more com-

Pounds of the said metals, as for example silver

‘nd copper nitrates, it is possible by selecting a

suitable temperature in the dissociation or re-

@uction treatment to obtain a powdered alloy

because by reason of the very fine state of sub-

division of the metals, diffusion takes place rap-

idly during the heating. It is thus possible

to obtain such alloys in the form of very fine

powders.

‘While in the case of tin, for example, powdered

metal cannot be obtained by the method accord-

ing to this invention, since at the temperature

necessary for reduction, namely at least 600°

centigrade, the metal melts and runs together,

T have found that by using a tin compound in

admixture with a metal compound capable of

reduction below the melting point of the alloy

formed, there is formed by the reduction treat

ment a powdered alloy; this is possible because

the melting point of the alloy formed from the

tin and the other metal or metals is higher than

that of tin. Other metals may also be added in

the form of reducible compounds, so that alloys:

are obtained in the form of fine ‘powders.

For example with copper or precious’ metal

compounds, tin compounds may be used in any

Proportion provided that the alloy produced melts.

‘at above the reduction temperature (the tem-

perature of the reduction treatment heitig above

600° centigrade) and cadmium and zine com-

Pound of the metal, the resulting mixture then 55 pounds may be used in amounts of not more than

2

about 10 per cent by weight (the temperature

of the reduction treatment belng for example be-

between 700° and 800° centigrade). If larger

amounts of cadmium or zine are used, vola~

tilisation occurs.

Tron, cobalt, nickel, gold and the platinum

metals, or alloys of these metals in any propor~

tion may also be obtained in the form of powders

by the process of this invention. Tn these cases

the reduction treatment 1s effected at a tem-

perature above the reduction temperature of the

Inetal compounds used. Alloys of ellver and cop-

per, alloys of gold and nickel, copper, iron or

platinum, or various carat gold alloys containing

hot more than 10 per cent of zine or cadmium

may likewise be prepared in the form of fine

powders.

‘The powdered alloys according to this inven-

tion are very useful for example for soldering

parts which are difficultly accessible and for

many other purposes.

‘The following examples will further illustrate

how the ssid invention may be carried out in

practice, but the invention 1s not restricted to

‘these examples.

Example 1

‘A mixture of silver nitrate and calcium or

magnesium nitrate (corresponding t» a ratio by

welght of Ag:CaO or MgO=1:1) is dissolved to

sive a 10 per cent aqueous solution and the solu-

tion poured into an amount of a holling solution

of sodium carbonate or caustic soda more than

sufficient to precipitate the corresponding car-

bonates or hydroxides. The resulting precipl-

tate is washed with hot water to remove soluble

salts, and dried. The resulting mixture is then

subjected to a dissociation or reduction treat-

ment as follows, For the purposes of dissocia-

tion, the mixture is heated in air at a tempera-

ture of from 300° to 900° centigrade. Higher

temperatures may be used but in this case the

silver melts and forms minute spheres. ‘The re-

‘duction treatment may be carried out by heating

the mixture, for example in an atmosphere of

hydrogen, at a temperature of from 200° to 900°

centigrade, ‘The product of either the dissocia~

tion or. reduction treatment is a finely divided

silver powder homogeneously dispersed through-

out the distributing agent, 1. e,, calcium or mag-

nestum carbonate or oxide. “The distributing

‘agent is then separated, for example by leaching

‘with a suitable dilute acid, such as acetic acid.

‘The resulting silver powder, especially when

the lower temperatures mentioned are used, is

extremely fine and will remain in suspension in

water for an appreciable time, and shows no

tendency to cake together when it is washed and

Example 2

Fine copper powder is prepared in @ manner

similar to that described in Example 1, but in

this case the metal oxide must de subjected to

a reducing treatment since copper oxide does

not dissociate on heating. The starting mate-

rials may be mixtures of copper and calcium

nitrates, copper and magnesium sulphates or

‘eopper and magnesium chlorides.

Example 3

For the production of an alloy of silver and

copper in the finely powdered form a mixture of

silver and copper nitrates in such @ proportion

1s to give the desired copper-silver ratio in the

2,954,076

alloy,

solution, which 1s mixed with

‘of a 10 per cent aqueous solution of

or magnesium nitrate, and the mixed solution

Poured into an amount of a boiling solution

sodium carbonate or caustic soda more than

sufficient to precipitate the corresponding car-

donates or hydroxides. ‘The resulting precipl-

tate is washed with hot water, dried and sub-

jected to a reduction treatment at a tempera-

ture of from 300°-900° centigrade, in an atmos~

phere of a reducing gas, as for example hydro-

gen, water gas, or producer gas, whereby all the

copper and silver compounds are reduced to the

corresponding metals. In this way a silver-cop-

per alloy is obtained in the finely powdered

form, intimately mixed with calcum or mag-

nestum oxides, ‘The distributing agent is then

removed, for example by leaching with a suitable

dilute acid such as acetic acid or sulphuric acid.

Example ¢

Fine gold and.fine platinum and other plati-

num metals may be obtained by impregnating an

excess of caleium or magnestum carbonates with

Solutions of the chlorides of the metals, drying

the resulting mixture end heating it in air or

In the presence of a reducing agent to produce,

an intimate mixture of the precious metal with

the distributing agent consisting of calcium or

magnesium carbonates and chlorides. ‘The dis-

tributing agent is then leached out with dilute

hydrochloric acid. ‘The precious metals are thus

obtained in an extremely finely powdered form.

Example §

‘To produce an alloy of gold and platinum in

the finely divided form, a mixture of the chlorides

of the two metals in the desired proportions is

dissolved in a small quantity of water and the

solution mixed with a large excess of calclum

for magnesium carbonates to produce a damp

powdery mixture, which is then dried and heated

in air at about 1000° centigrade for half to one

hour. After cooling, the calcium or magnesium

oxides and chlorides, which have acted as the

distributing agent, are removed by leaching with

dilute hydrochloric acid. ‘There !s thus obtained

an extremely finely powdered gold-platinum sl-

Joy which can be used in powder metallurgy.

Example 6 ,

Tron, copper and nickel sulphates (the ratio

by welght of the metals contained therein being

13:1) are dissolved in water to give a 10 per~

cent solution which 1s then mixed with an equal

‘volume of a 10 per.cent aqueous solution of

magnesium sulphate, and the mixed solution is,

Poured into a hot 20 per cent aqueous solution

of sodium carbonate containing more than sufl-

clent carbonate to precipitate the iron, copper,

nickel and magnesium as carbonates.

‘The precipitate s washed and dried and then

heated in an atmosphere of hydrogen at about

800° centigrade. ‘The product consists of a fine-

ly powdered alloy of iron, copper and nickel

Homogeneously distributed in magnesium oxide.

‘The latter is removed by extraction with dilute

sulphurle acid leaving the alloy in a very finely

divided state, ‘This may be used as a magnetic

powder.

‘A similar method may be used for production

of tron, nickel and cobalt in the form of fine

powders, In this case the mixture which is

5 poured into the sodium carbonate solution con-

10

25

35

40

4“

65

2,284,076

sists simply of iron, nickel or cobalt sulphate,

nitrate or chloride mixed with the corresponding

magnesium salt, or if the nitrate or chloride

solution is used, the corresponding calcium salt,

In this way it is possible to prepare iron, nickel 5

oF cobalt in a very fine powdered form suitable

for use in powder metallurgy.

Alloys of other metals may be produced in a

corresponding manner,

In the present specification and the appended

claims T mean by “conversion operation” the op-

eration of converting a compound of a metal or

‘a mixture of compounds of a plurality of metals

into the corresponding metal or alloy by reduc~

tion with 2 suitable reducing agent or by heat-

ing to such a temperature that the compound or

compounds is or are dissoclated to leave the free

metal or alloy. ‘This latter occurs only in the

ease of compounds of the precious metals, 1. ¢.

Sold, silver and the platinum group metals,

By “distributing agent” T mean e substance

which prevents the aggregation or sintering of

the particles of a metal or metals into relatively

coarse particles. Usually when a metal oxide is

reduced by hydrogen or other gaseous oF solid

reducing agents the fine particles of metal first

formed coalesce into much coarser particles or

Srow together to form relatively large erystals,

The purpose of the distributing agent is to pre-

vent this sintering or grain growth and to keep

the reduced metal in the form of a very fine

Powder,

By “capable of being removed without detri-

ment to the powdered metal or metals or alloys

formed” T mean that the substance used as a

Gistributing agent can be dissolved in solvents

which do not attack the finely powdered metal,

metals or alloy or ean be removed by mechan-

ical processes, such as flotation or treatment

with a heavy lquid, without contaminating the

finely powdered metal, metals or alloy produced

bby the conversion operation,

Where in the claims the expression “metal

compound” or “compound of a metal” is used

such expression fs intended to inelude one or 45

more metal compounds or the compounds of one

oF more metals, since, as pointed out in the ex-

amples, where a single metal compound is used

the product ts a single metal and where more

than one metal compound is used the product 1s 60

an alloy.

‘What I claim ts:

1. A process of producing in the form of fine

powder metal capable of being prodticed from

‘ts compounds by @ conversion operation at a 65

10

as

40

3

temperature below its melting point, which con-

sists in forming by coprecipitation from a solu

tion of suitable salts an intimate mixture of a

water-insoluble compound of the metal and a

Gistributing agent which prevents aggregation

of the particles of the metal and is capable of

being removed without detriment to the metal,

subjecting the coprecipitated mixture to the con-

version operation for converting the whole of the

metallic content into a fine metallic powder and

then removing the distributing agent,

2. A process of producing a fine metallic po

der which consists in subjecting a solution con-

taining a salt of a metal capable of being pro-

Guced from its compounds by a conversion ‘op.

eration at a temperature below its melting point

and a salt of a metal selected from the group

alkaline earths and magnesium, to a precipita-

tion operation to produce an intimate mixture

of an insoluble compound of the first-named

metal with @ distributing agent selected from

the group oxides, hydroxides, and carbonates, of

metals selected from the group magnesium and

the alkaline earths, subjecting said mixture to

the conversion operation at a temperature below

the melting point of the first-named metal, and

then removing the distributing agent.

3. A process of producing in the form of a fine

Powder a metal capable of being produced from

its compounds by a conversion operation at a

temperature below its melting point which con=

sists in forming by coprecipitation from a solu-

tion of suitable salts an intimate mixture of

‘8 water-insoluble compound of the metal and a,

distributing agent which prevents aggregation

of the particles of the metal and is capable of

being removed without detriment to the metal,

subjecting the coprecipitated mixture to the

conversion operation in the presence of a re-

ducing agent and then removing the distributing

agent

4. A process of producing a fine metallic pow-

Ger which consists in forming by a precipitation

operation an intimate mixture of a compound of

‘a metal capable of being produced from its com-

Pounds by a conversion operation at a tempera.

ture below its melting point with a distributing

agent which prevents aggregation of the parti

cles of metal and is capable of being removed

without detriment to the metal, subjecting the

Fesulting intimate mixture of insoluble metal

compound and distributing agent to the con-

‘version operation in the presence of a’ reducing

‘agent and then removing the distributing agent.

ALAN RICHARD POWELL.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Example of Business Plan Andrea Gold PeruDocument62 pagesExample of Business Plan Andrea Gold PerufatimascNo ratings yet

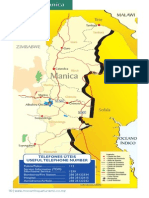

- Manica Folheto de TurismoDocument8 pagesManica Folheto de TurismofatimascNo ratings yet

- Small Scale Mining FilipinasDocument16 pagesSmall Scale Mining FilipinasfatimascNo ratings yet

- Estudo Mineracao ArtesanalDocument80 pagesEstudo Mineracao Artesanalfatimasc100% (1)

- CristalMiningCorp BusinessPlanDocument32 pagesCristalMiningCorp BusinessPlanfatimasc100% (1)

- Business Plan LiberiaDocument21 pagesBusiness Plan LiberiafatimascNo ratings yet

- Example of Business Plan Hassai Mine SudanDocument344 pagesExample of Business Plan Hassai Mine Sudanfatimasc100% (1)

- Determinaçao Voltamemetrica de OuroDocument2 pagesDeterminaçao Voltamemetrica de OurofatimascNo ratings yet