Professional Documents

Culture Documents

Iron Production

Iron Production

Uploaded by

headacrOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iron Production

Iron Production

Uploaded by

headacrCopyright:

Available Formats

Iron Production - Techniques and History , Bo Justusson

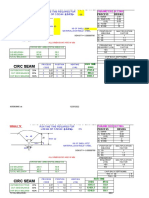

Basic Steps Iron is produced from ore in two steps. There are many alternate methods

First ore is mixed with charcoal (or coke) that has been used throughout history

in a blastfurnace and heated to high for those two steps. When charcoal

temperature to get iron. Then this iron is was used, countries with both iron ore

further processed to reduce carbon and and large forests (like Sweden) had

slag, and to add alloys. an advantage.

Iron ore and charcoal (or coke) are

Blast- charged from the top. Air is blown in

furnace at the bottom. The coal burns to CO

which reacts with the ore and reduces

it.

In principle:

Fe3O4 + CO --> Fe + CO2

The waste rock in the ore is lighter

than iron and floats as slag. The

melted iron and slag are tapped at the

bottom.

(GIF-image 3k)

Blast-furnaces have been used since

the 12th century. Their size has

increased. Charcoal was first used,

but from around 1800 coke could be

used.

To obtain high quality iron and steel

Iron and from the the blast-furnace iron (pig

Steel iron), it is heated and treated with air

or pure oxygen. Left aBessemer

converter where air is blown in at

bottom and passes through melted

iron.

Below a Siemens-Martin

furnace where air goes into a pre-

heater (regenerator) and passes above

the melted iron and then onto another

regenerator which gets heated. The

direction of the air flow is changed

after a time to make use of the heat!

Both methods were invented around

1860.

(GIF-images 4k+4k)

You might also like

- Extraction of IronDocument4 pagesExtraction of IronNadita100% (1)

- Jigs and Fixtures - Multiple Choice Questions (MCQ) and Answers 1-Jigs and Fixtures Are Used ForDocument5 pagesJigs and Fixtures - Multiple Choice Questions (MCQ) and Answers 1-Jigs and Fixtures Are Used For312817116012 Ganesh Ram100% (1)

- MRO Stop Industrial Fastener CatalogDocument53 pagesMRO Stop Industrial Fastener CatalogMROstop.comNo ratings yet

- Manufacturing Engineering - I: Diploma Mechanical Engineering Semester: 3Document7 pagesManufacturing Engineering - I: Diploma Mechanical Engineering Semester: 3solaank16No ratings yet

- 01 - Hardening Tempering and Heat TreatmentDocument124 pages01 - Hardening Tempering and Heat Treatmentj43951048No ratings yet

- Metals and Its Applications-1Document112 pagesMetals and Its Applications-1amaandeshmukh4No ratings yet

- Learning CenterDocument8 pagesLearning CenterpdiconpNo ratings yet

- Notes on Blast Furnace ProcessDocument6 pagesNotes on Blast Furnace ProcessrizwanofficialmailNo ratings yet

- 1.steel MakingDocument15 pages1.steel MakingArunava BasakNo ratings yet

- Blast Furnace Slides, IIT RoorkeeDocument25 pagesBlast Furnace Slides, IIT RoorkeeKrishnaNo ratings yet

- On Steel MakingDocument58 pagesOn Steel Makingallan arthur bare100% (2)

- Blast Furnace SayanDocument19 pagesBlast Furnace Sayansayan2017nimtalaNo ratings yet

- The Processes of Iron and Steel MakingDocument53 pagesThe Processes of Iron and Steel MakingNur FarzanaNo ratings yet

- MMS Unit VDocument8 pagesMMS Unit VAdula RajasekharNo ratings yet

- Lara SmeltingDocument1 pageLara SmeltingCeline LaraNo ratings yet

- Ironmaking - Part 2Document42 pagesIronmaking - Part 2Aryan MishraNo ratings yet

- Points To Remember: at The End of The Topic, You Will Know AboutDocument31 pagesPoints To Remember: at The End of The Topic, You Will Know AboutShoaib SamimNo ratings yet

- Extracting Iron: The Blast FurnaceDocument2 pagesExtracting Iron: The Blast FurnacearwaNo ratings yet

- Iron Working ProcessesDocument2 pagesIron Working ProcessesZaldi GeaNo ratings yet

- 4 Extraction of Iron in A Blast Furnace PDFDocument1 page4 Extraction of Iron in A Blast Furnace PDFShashank pandeyNo ratings yet

- STEEL MAKING PROCESS-dikonversiDocument17 pagesSTEEL MAKING PROCESS-dikonversiM RamdansNo ratings yet

- BisquefiringDocument4 pagesBisquefiringRicardo PelosoNo ratings yet

- Pengekstrakan BesiDocument5 pagesPengekstrakan BesiNajwa Ghazali100% (1)

- Lec 26Document28 pagesLec 26Sergio zihadNo ratings yet

- Iii. Ironmaking: Blast Furnace, A VerticalDocument7 pagesIii. Ironmaking: Blast Furnace, A VerticalGrezy MagnoNo ratings yet

- Engineering Material - : Chapter TwoDocument41 pagesEngineering Material - : Chapter TwoAla ZiNo ratings yet

- Iron Making MM-15020 5 Sem B Tech Department of Metallurgy and Materials Engineering V.S.S.U.T, BurlaDocument83 pagesIron Making MM-15020 5 Sem B Tech Department of Metallurgy and Materials Engineering V.S.S.U.T, BurlaAshishNo ratings yet

- Steel Plate Manufacturing ProcessDocument1 pageSteel Plate Manufacturing ProcessMetline IndustriesNo ratings yet

- Chemistry Project: Purification of IronDocument8 pagesChemistry Project: Purification of IronShivam JaggiNo ratings yet

- Universiti Malaysia Perlis Laboratory Report Metal Extraction Technology PDT 262 SEMESTER 2 (2016/2017)Document17 pagesUniversiti Malaysia Perlis Laboratory Report Metal Extraction Technology PDT 262 SEMESTER 2 (2016/2017)amirolNo ratings yet

- Methods of Melting: Anil Kumar. GarikapatiDocument16 pagesMethods of Melting: Anil Kumar. GarikapatiAnil Kumar GarikapatiNo ratings yet

- Manufacturing Process I Lecture No. 8: FurnacesDocument11 pagesManufacturing Process I Lecture No. 8: Furnacesmahi rajNo ratings yet

- Smelting Is A Form Of: Blast FurnaceDocument31 pagesSmelting Is A Form Of: Blast FurnaceLalaine Arabit100% (1)

- Chemistry With Boos Chapter 1.5, 4.1 and 4.2Document1 pageChemistry With Boos Chapter 1.5, 4.1 and 4.2jos huaNo ratings yet

- Extraction of Iron (Nehru Garden, JalandharDocument4 pagesExtraction of Iron (Nehru Garden, Jalandharapi-3731257No ratings yet

- Iron Ore 01Document8 pagesIron Ore 01api-3731257No ratings yet

- Metallurgy of IronDocument18 pagesMetallurgy of IronEliasNo ratings yet

- Cupola FurnaceDocument32 pagesCupola Furnaceadelina ednandaNo ratings yet

- Lesson 4 - Production of MetalsDocument16 pagesLesson 4 - Production of MetalsOwen GichangiNo ratings yet

- By:-Chirag Sharma Amit SankheDocument27 pagesBy:-Chirag Sharma Amit SankheChirag SharmaNo ratings yet

- Institute of Space Technology Islamabad-Pakistan: (Assignment No. 03)Document9 pagesInstitute of Space Technology Islamabad-Pakistan: (Assignment No. 03)Umair MumtazNo ratings yet

- Blast FurnaceDocument91 pagesBlast FurnaceSarbajitManna100% (1)

- Iron Carbon Phase DWG2Document44 pagesIron Carbon Phase DWG2Shailesh DeshmukhNo ratings yet

- Coal MinininDocument21 pagesCoal Minininmohamed ZakirNo ratings yet

- Casting ProccessDocument20 pagesCasting ProccessBalmes CastroNo ratings yet

- Lecture-4-Intro. To Melting Furnaces-Lecture NotesDocument43 pagesLecture-4-Intro. To Melting Furnaces-Lecture NotesManchi MaheetNo ratings yet

- Tamahagane Production, Control of SlagDocument5 pagesTamahagane Production, Control of SlagMobius108No ratings yet

- Flux, Iron, Coke Blast Furnace Pig Iron Solid SolidDocument18 pagesFlux, Iron, Coke Blast Furnace Pig Iron Solid SolidMD. ZUBAIR ISLAMNo ratings yet

- 34 Steel Mills: Steelmaking ProcessDocument7 pages34 Steel Mills: Steelmaking Processjanimalik19891988No ratings yet

- Engg - Materials - Lect - 5Document9 pagesEngg - Materials - Lect - 5Smruthi SuvarnaNo ratings yet

- The Bessemer Process PDFDocument3 pagesThe Bessemer Process PDFJosua Aditya PratamaNo ratings yet

- A Closer Look at Iron Smelting or Extractive MetallurgyDocument17 pagesA Closer Look at Iron Smelting or Extractive MetallurgypakistanihaxorNo ratings yet

- MetallurgyDocument90 pagesMetallurgyErmias GuragawNo ratings yet

- IM&SM 1999 - ChinaDocument5 pagesIM&SM 1999 - ChinaAlberto ConejoPadreNo ratings yet

- Extraction of IRON FROM ORE - Putligarh (G) - AmritsarDocument6 pagesExtraction of IRON FROM ORE - Putligarh (G) - Amritsarapi-3731257No ratings yet

- Notes For 3rd Exam (Ferrous Metallurgy)Document2 pagesNotes For 3rd Exam (Ferrous Metallurgy)Fabie BarcenalNo ratings yet

- Lect 10Document22 pagesLect 10e22mecu0009No ratings yet

- Iron Processing: Iron Processing, Use of A Smelting Process To Turn The Ore Into A Form From Which ProductsDocument9 pagesIron Processing: Iron Processing, Use of A Smelting Process To Turn The Ore Into A Form From Which ProductsDevina DianmahendraNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- HVOF-pump ImpellerDocument4 pagesHVOF-pump ImpellerjohnyNo ratings yet

- Welder Id CardDocument1 pageWelder Id CardRahul DwivediNo ratings yet

- Sepction - 2Document4 pagesSepction - 2k koradiaNo ratings yet

- Extrusion Is A Process Used To Create Objects of A Fixed Cross-SectionalDocument8 pagesExtrusion Is A Process Used To Create Objects of A Fixed Cross-SectionalHaRi See RamNo ratings yet

- Equipments Used in Cement Process IndustryDocument22 pagesEquipments Used in Cement Process IndustrySindarth Raveendrakrishnan100% (2)

- Manufacturing EngineeringDocument62 pagesManufacturing EngineeringMuhammad IrvanNo ratings yet

- Buku Ajar 6Document16 pagesBuku Ajar 6Cynthia Sasmita DewiNo ratings yet

- Lesson Plan mp2Document2 pagesLesson Plan mp2Saravanan RajendranNo ratings yet

- Modeling The Piston Casting With Filling and Solidification of Al Alloy in Permanent Mould Using Magma Simulation SoftwareDocument74 pagesModeling The Piston Casting With Filling and Solidification of Al Alloy in Permanent Mould Using Magma Simulation SoftwareRaja Santhosh100% (1)

- Casting PDF IIT Ropar by Dr. Anupam AgrawalDocument37 pagesCasting PDF IIT Ropar by Dr. Anupam Agrawalhimanshu singhNo ratings yet

- Typical PFD of Residue Catalytic CrackingDocument2 pagesTypical PFD of Residue Catalytic CrackingKmt_AeNo ratings yet

- Bevel Gears & Gear Sets: Quality With Value GuaranteedDocument1 pageBevel Gears & Gear Sets: Quality With Value GuaranteedSergio Ballestas100% (2)

- BBC Price List Showroom 03-06-21Document1 pageBBC Price List Showroom 03-06-21Kwabena StyleNo ratings yet

- Spesifikikasi Alatan TanganDocument4 pagesSpesifikikasi Alatan TanganMohd Dinie HafiqNo ratings yet

- Dissertationen Humboldt Uni BerlinDocument7 pagesDissertationen Humboldt Uni BerlinWriteMyPaperCoCanada100% (1)

- Welding CalculationDocument5 pagesWelding CalculationBWQNo ratings yet

- Mefc 103 Module PreliminariesDocument6 pagesMefc 103 Module PreliminariesVELASCO JULIE-ANN G.No ratings yet

- Epoxy Painting MethodDocument3 pagesEpoxy Painting MethodKaram MoatasemNo ratings yet

- Tube To Tube Welding Procedure Control No.:Revision No.: 0 Date: Page: 1 of 1 1.0 ScopeDocument1 pageTube To Tube Welding Procedure Control No.:Revision No.: 0 Date: Page: 1 of 1 1.0 ScopesbmmlaNo ratings yet

- Additeve-Manufacturing Am-420s 20-53 3046hogDocument2 pagesAdditeve-Manufacturing Am-420s 20-53 3046hoggersomNo ratings yet

- Brazing ProcedureDocument2 pagesBrazing ProcedureNoel Delos SantosNo ratings yet

- ET ZC235 Manufacturing Processes: BITS PilaniDocument113 pagesET ZC235 Manufacturing Processes: BITS PilaniAasheesh Chander AgrawalNo ratings yet

- DIVER's CHECKLIST PDFDocument3 pagesDIVER's CHECKLIST PDFangelieNo ratings yet

- SECO Milling Tools CatalogDocument730 pagesSECO Milling Tools CatalogmichaelguzziNo ratings yet

- Heat TreatmentDocument32 pagesHeat TreatmentMradul ChaudharyNo ratings yet

- Information Sheet 1.1-8: Welding Techniques & Procedures Learning ObjectivesDocument1 pageInformation Sheet 1.1-8: Welding Techniques & Procedures Learning ObjectivesRose Ann Pegarro AlamanNo ratings yet

- Jadual Pembahagian WimDocument3 pagesJadual Pembahagian WimMuhd RafiqNo ratings yet

- Paints PDFDocument28 pagesPaints PDFPrasad RaikarNo ratings yet