Professional Documents

Culture Documents

Elect Manhole Handhole Metric

Elect Manhole Handhole Metric

Uploaded by

Rom Guaren0 ratings0% found this document useful (0 votes)

139 views7 pagesBRICK COLLAR LINED UP WITH CEMENT MORTAR 115 REINF. AT 150 EW top, SIDES and BOTTOM - SLOPE 1:40 TO SUMP y---GROUND ROD and CLAMP. MANHOLE AND COVERS ARE DESIGNED FOR MAXIMUM WHEEL LOAD IN ACCORDANCE WITH AASHTO HS20-44.

Original Description:

Original Title

elect_manhole_handhole_metric

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBRICK COLLAR LINED UP WITH CEMENT MORTAR 115 REINF. AT 150 EW top, SIDES and BOTTOM - SLOPE 1:40 TO SUMP y---GROUND ROD and CLAMP. MANHOLE AND COVERS ARE DESIGNED FOR MAXIMUM WHEEL LOAD IN ACCORDANCE WITH AASHTO HS20-44.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

139 views7 pagesElect Manhole Handhole Metric

Elect Manhole Handhole Metric

Uploaded by

Rom GuarenBRICK COLLAR LINED UP WITH CEMENT MORTAR 115 REINF. AT 150 EW top, SIDES and BOTTOM - SLOPE 1:40 TO SUMP y---GROUND ROD and CLAMP. MANHOLE AND COVERS ARE DESIGNED FOR MAXIMUM WHEEL LOAD IN ACCORDANCE WITH AASHTO HS20-44.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 7

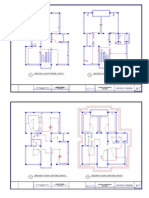

300 X 300 X 250

DEEP SUMP

180) | DUCT ENTRANCE

a |i

LI:

ts,

150 |

t 25 PULLING-IN IRON

150]

PLAN

FOR MANHOLE FRAME & COVER, SEE

FED. SPEC. A-A~60005 FIG. 4,” SIZE 28

150 AND FIG. 12, SIZE 28 RESPECTIVELY

300

| BRICK COLLAR LINED UP

WITH CEMENT MORTAR

{_

| fi DUCT ENTRANCE

~_

25 PULLING-IN IRON << LAP REINF. 600mm (TYP.)

150 | 150

5 REINF. AT 150 EW

jOP, SIDES & BOTTOM | WATERSTOP_AT ALL

SLOPE 140-7 BE CONSTR. JTS. (TYP.)

TO SUMP

250 fe GROUND ROD & CLAMP

SECTION A-A

NOTES:

1. FOR DETAILS OF CABLE RACKS,

DUCT ENTRANCE AND PULLING—IN

MANHOLE DIMENSIONS. IRONS, SEE PLATE UG-7.

PE at ger High Pr 2. MINIMUM CONCRETE COMPRESSIVE

71800} 2800 308 STRENGTH SHALL BE 21 MPa

2 1800__| 2500 2000 .

STANDARD ELECTRICAL MANHOLE (NONTRAFFIC)

TYPES 1 & 2

SKETCH DATE JUNE 2002 | STYLE UG-1

300 X 300 X 250 DEEP

SUMP

200 |

A A

L _!

$25 PULLING-IN IRON. —+ TT BISTERTRANCE. LocaTION To BE

200 200

FOR MANHOLE FRAME & COVER, SEE FED.

SPEC. A-A~60005, FIG. 1, SIZE 30A AND

FIG. 8, SIZE 30A, RESPECTIVELY

BRICK COLLAR LINED UP WITH

CONCRETE OR BLACK ; ESS CEMENT MORTAR

TOP ROADWAY ==

5 @ 150 EM, T&B ——~ : {

# = 150 MIN,

#4 © 180 EW EF fet eo EE

925 PULLING-IN IRON

200, | Bo — DUCT ENTRANCE

SLOPE 1:40 TO SUMP T mR

WATERSTOP AT ALL: Sid LAP REINF. 600 (TYP.)

CONSTR. JTS. (TYP.) =a 7]

#4 6 230 188 [=——cROUND ROD & CLAMP

250 t Nores

SECTION A-A -

1. MANHOLE AND COVERS ARE DESIGNED

FOR MAXIMUM WHEEL LOAD IN

ACCORDANCE WITH AASHTO HS20-44,

2. FOR DETAILS OF CABLE RACKS,

MANHOLE DIMENSIONS DUCT ENTRANCE AND PULLING~IN

TWre| A B _{e @r HiGH PT) IRONS, SEE PLATE UG~7.

3_|-1e00—|1600, 2000 7

4 | 1600_| 2600 2000 3. MINIMUM. CONCRETE COMPRESSIVE

STRENGTH SHALL BE 21 MPa.

STANDARD ELECTRICAL MANHOLE (TRAFFIC)

TYPES 3 & 4

SKETCH DATE JUNE 2002 | STYLE UG-2

925 PULLING-IN IRON

200

at

<)

+ 300 X 300 X 250 DEEP SUMP

{s

ooo ey

200

DUCT ENTRANCE.

TO BE AS INDICATED.

200

PLAN

600 OPENING

oy Z 18mm, PLATE~PROVIDE

F/s0 X15 @ 150 8

16 X 16 BAR 8

13,

cuear-l|-

“— 100 X 20

(SEE_NOTE 3) BARS

VER DETAI

200)

UFTING HOLES

200

LOCATION

FOR MANHOLE FRAME, SEE

FED SPEC, A~A-60005, FIG 3, SIZE

24A, STYLE B, 100mm’ FLANGE.

CONCRETE PAVING ———

#5 @ 150 EW. oN

TOP, BOTTOM & SIDES

25 PULLING-IN IRON = —~TIJ

200

SLOPE 1:40.

TO SUMP

WATERSTOP AT ALL

CONSTR. JTS. (TYP.)

m0 re

GROUND ROD & cue“

BRICK COLLAR LINED UP

WITH CEMENT MORTAR.

LAP REINF. 600 (TYP.)

NOTES:

MANHOLE AND COVERS ARE

DESIGNED FOR MAXIMUM WHEEL

LOAD OF 22700 kg OR DUAL

WHEEL LOAD OF 41000 kg,

2. FOR DETAILS OF CABLE RACKS,

DUCT ENTRANCE AND PULLING-IN

IRONS, SEE PLATE UG-7.

3. COVER SHALL BE MADE OF

STRUCTURAL STEEL CONFORMING

SECTION A-A TO ASTM A 36/A 36M.

MANHOLE DIMENSIONS 4. MINIMUM CONCRETE COMPRESSIVE

TET A B__[C (AT HIGH PTY] STRENGTH SHALL BE 21 MPa.

5 1800 1800 2000

| 1800 [2500 2000

STANDARD ELECTRICAL MANHOLE (AIRFIELD)

TYPES 5 & 6

SKETCH DATE JUNE 2002 | STYLE UG-3

13mm FLOOR PLATE RASED

13mm PLUG WELD

PATTERN

I,

8 wail B 65 X_10_SEAL

4 Alt va WELDED TO ONE

Lipt o 4 SIDE OF THE DOOR

Z ip Ih a SEAL DETAIL

HINGE—WELDED TO FRAME

COVER

PLAN OF COVER

HANDLE-

COVER

TR A

5 2

BBE PE se

730% 130 HINGE

—™ t sau'ssS Zenon

SS DETAIL ABOVE

45 X 40X13 wee rm FLOOR SECTION

13mm PLUG WELD

16 ANCHOR ROD SY

sents SOIC. 64 x 64 x 79

ni

(SFR S08) DUCT ENTRANCE 300 x 300 x 300

SECTION OF FRAME 1505 DEEP SUMP

13mm PLUG WELDS

© 200 0.C. WAX A

i)

DUCT ENTRANCE 150. A 150

a

A q 025 1

wo fe a 150 LM <|Pttine- SI

i q 25 IN 1RONS—

4 < PULLING-IN IRON E 4

sLoPe 1.40 ff yA fp 5

Fo SUMP 1 4 © 300 ANCHORS Z

1. SOS 150] (COVER NOT SHOWN)

zm AND BOTTOM

E PLAN

SCL 10] CONSTR. TS. (IYP.) ‘NOTES:

1. FOR DETALS OF CABLE RACKS,

DUCT ENTRANCE AND PULLNG-IN

SECTION A-A IRONS, SEE PLATE UG-7.

HANOHOLE DIMENSIONS ‘2. MINIMUM CONCRETE COMPRESSIVE

TYPE A STRENGTH ‘SHALL BE 21 MPa,

7 1000

z 1250

STANDARD ELECTRICAL HANDHOLE (NONTRAFFIC)

TYPES 1 & 2

SKETCH DATE JUNE 2002 | STYLE UG-4

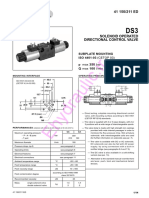

#13 PLUG WELD

B +

613 PLUG WELD

AT 150 Oc.

HINGE-WELDED TO FRAME

& COVER

A

#13 PLUG WELD

AT 150 0.6,

‘SUMP:

REMOVABLE W 200 X 59. 75 X 10 X 1400 PL

NOTE: STIFFENERS SHOWN

DUCT ENTRANCE. LOCATION TYP. BOTH SIDES

TO BE AS INDICATED “ON

THE PROJECT DRAWING a

170

L 152 x 89 x 7.9 al 75 X 10 X 200 PL

135 STEEL ROD

150 x X 1400 PL: ayn PLAN 13mm PL 100 .

a. \toy

fone Lge qr

eral Ws 150] Jsolee

ST 75_X 9.5,

32 X 3 ANCHOR

4 TYPE 53, 330 LONG L 89 x 89 x 6.4)

TYPE 4, 480 LONG @ 450 o..

190 ty ® 250 (SEE NOTE 4)

W. & EF,

z SECTION C-C

300

4 @ 250 EW. &

warersTOr A tt ‘SIDES & BOTTOM

CONSTR. JTS. (TYP.) 13 mm P.EJ, ALL AROUND {ZPIING OR GRADE

SECTION A-A

NOTES: Ss

1. ENTRANCE OF DUCTS INTO HANDHOLE MAY i ae i

BE MADE ON SIDE FACES OR CORNERS 250, Fag pt SOW E 59 ba sf 32 X 3

AS REQUIRED. 3 x ANcHOR 450

2. FOR DETAILS OF CABLE RACKS, DUCT a

ENTRANCE. AND PULLING-IN IRONS, 130 SUP Oy ft AT 300 Ew.

SEE PLATE UG~7. 0 00 F. SIDES &

3. HANDHOLE AND COVER IS DESIGNED FOR E y ET] Borrow

WAXIMUM SINGLE WHEEL LOAD OF boo

22700 kg OR DUAL WHEEL LOAD OF

41000 bg. Sf srouND Roo

4. COVER SHALL BE MADE OF STRUCTURAL & CLAMP feavonniz [ owensions |

"STEEL CONFORMING TO ASTM A 36/A 36M. SECTION B-B ae _

5. MINMUM COMPRESSIVE STRENGTH OF 4 1250

CONCRETE SHALL BE 21 MPa.

STANDARD ELECTRICAL_HANDHOLE (TRAFFIC/AIRFIELD)

TYPES 3 & 4

SKETCH DATE JUNE 2002 | STYLE UG-5

CONCRETE RING

‘AROUND BOX

‘STAINLESS STEEL

HEX BOLT AND

WASHER.

PULL SLOT COVER

SKID

RESISTANT

SURFACE

BOX_AND

SECTIONAL

BOX WHEN

REQUIRED

HANDHOLE SIZING

[300mm x 300mm x 600mm DEEP

6 _[800mm_x 500mm X 600mm DEEP

7_[800mem_ x 600mm X 600mm OEP

8

9

[600mm X 100Omm X 600mm DEEP]

[200mm X 125mm X_60dmm DEEP|

HANDHOLE REQUIREMENTS

1. HOUSING SHALL BE A POLYMER CONCRETE REINFORCED WITH A HEAVY WEAVE FIBERGLASS

REINFORCING WITH COMPRESSIVE STRENGTH OF NO LESS THAN 70 MPa.

2. COVER AND BOX SHALL WITHSTAND A SERVICE LOAD OF NO LESS THAN 6800 kg OVER A

250 x 250 AREA.

‘3. PROVIDE STAINLESS STEEL BOLTS AND INSERTS.

4. PROVIDE WITH (2) 64mm MOUSEHOLES.

5. PROVIDE LABEL “ELECTRICAL” FOR POWER HANDHOLES OR "TELEPHONE" FOR TELEPHONE

HANDHOLES, OR AS INDICATED.

150mm

STANDARD ELECTRICAL HANDHOLE (NONTRAFFIC)

(COMPOSITE/FIBERGLASS) TYPES 5, 6, 7, 8 & 9

SKETCH DATE JUNE 2002 | STYLE

UG-6

75 CONCRETE WALL-

_ E 40 (MIN) J

=165.X 65 X 5 PLATE

032 SLEEVE, ~ [Mte® LOCKWASHER 4 | oy.

at 417064 WASHER

oJ 100

FILLET WELD

64 RAD

025 v-sot— €

ALTERNATE METHOD

DETAIL OF PULLING-IN IRON

WALL OF MANHOLE

fe 180 MIN.

180 MIN.

feet

TYPICAL CABLE RACK

INSIDE Face]

OF MANHOLE—~*|

45

St 1

75

TYPICAL _DUCT ENTRANCE

210

025

230

CAST IN PLACE

NOTE

‘ALL METAL PARTS SHALL

BE HOT DIP GALVANIZED

SKETCH DATE

DETAILS

(PULLING-IN IRONS, CABLE RACK AND DUCT ENTRANCE)

JUNE 2002 | STYLE

UG-7

You might also like

- All About M KiiiDocument90 pagesAll About M Kiiisudhiruday31No ratings yet

- Kahramaa Sample DrawingDocument10 pagesKahramaa Sample DrawingRico Perial71% (7)

- Pinakafinal BD Plan Floor PlanDocument3 pagesPinakafinal BD Plan Floor PlanJohn Carlo Telan Panganiban100% (1)

- Western Electric Vacuum Tube Data 1941Document212 pagesWestern Electric Vacuum Tube Data 1941wa4gvt5044100% (1)

- Aa 036531 001Document1 pageAa 036531 001narutothunderjet2160% (1)

- Watermain STD Dwgs-101101Document37 pagesWatermain STD Dwgs-101101Pn EkanayakaNo ratings yet

- Mid Section of Super Structure: C L of SpanDocument6 pagesMid Section of Super Structure: C L of SpanMohsin SyedNo ratings yet

- 20 Mva Transformer-Belaganj, Naugachia, Supaul, Jainagar, Phulparas-Layout1Document1 page20 Mva Transformer-Belaganj, Naugachia, Supaul, Jainagar, Phulparas-Layout1Anoop DikshitNo ratings yet

- STD - 011 Typical Det of Lintel Beam Chajja-ModelDocument1 pageSTD - 011 Typical Det of Lintel Beam Chajja-ModelIrshad KhanNo ratings yet

- Celdas Wemco de 60 m3 - Planos IdDocument17 pagesCeldas Wemco de 60 m3 - Planos IdFrancisco Gil100% (1)

- 5881 EL34conversionDocument11 pages5881 EL34conversionfightingforyeshuaNo ratings yet

- Reinforced ER: NcreteDocument5 pagesReinforced ER: NcreteBright IndiaNo ratings yet

- Brief Schedules - (Building Designers' Manual)Document39 pagesBrief Schedules - (Building Designers' Manual)nivram75100% (2)

- Yamaha AX700U Service ManualDocument17 pagesYamaha AX700U Service Manualparabellum44No ratings yet

- 6 - CABLE-1-ModelDocument1 page6 - CABLE-1-ModelAbhas GuptaNo ratings yet

- Steel Line Blanks & Spacer Dimension TableDocument5 pagesSteel Line Blanks & Spacer Dimension TableSeungmin PaekNo ratings yet

- Ad 036633 001Document1 pageAd 036633 001narutothunderjet216No ratings yet

- Ring Joint RTJDocument6 pagesRing Joint RTJzulikram100% (1)

- KTA - TB-HV-DWG-0001.REV.2 HVAC Equipment For Office Building - DWG PDFDocument9 pagesKTA - TB-HV-DWG-0001.REV.2 HVAC Equipment For Office Building - DWG PDFHo Ngoc Thanh QuangNo ratings yet

- DR 2GL Se 4206Document1 pageDR 2GL Se 4206bobmarley20161934No ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- Indalco TablesDocument7 pagesIndalco TablesAdhish Gupta100% (1)

- Glossary - FULL (A-Z) - ТеплотехникаDocument320 pagesGlossary - FULL (A-Z) - ТеплотехникаEugene FedoseyevNo ratings yet

- 4CX250 K and MDocument6 pages4CX250 K and Magus reza aristiadiNo ratings yet

- Data Sheets PDFDocument7 pagesData Sheets PDFshareyhouNo ratings yet

- MS25083 KDocument5 pagesMS25083 Kahs23No ratings yet

- Notes: P.T. Badak N.G.L. Bontang L.N.G. PlantDocument10 pagesNotes: P.T. Badak N.G.L. Bontang L.N.G. PlantAdidtya Budhi SaputraNo ratings yet

- I - LouversDocument10 pagesI - Louversgpskumar22No ratings yet

- Appleton Electric Apltonc00003 D17 D2 D3 D5 D16Document5 pagesAppleton Electric Apltonc00003 D17 D2 D3 D5 D16AliHabesNo ratings yet

- For Tender: Beca Philippines LTD Pacifictech Solutions IncDocument1 pageFor Tender: Beca Philippines LTD Pacifictech Solutions Incchristian reyesNo ratings yet

- Bond LogDocument8 pagesBond LogpsmanasseNo ratings yet

- WT 1,2,3Document3 pagesWT 1,2,3JockoJoleNo ratings yet

- D Pi 175Document2 pagesD Pi 175reza329329No ratings yet

- The Williamson AmplifierDocument44 pagesThe Williamson Amplifierfrox123No ratings yet

- 5 8kV 250A 500A Konnetor Teknik OzelliklerDocument14 pages5 8kV 250A 500A Konnetor Teknik OzelliklerFrancisco Campaña PerezNo ratings yet

- S3 01concretedetails PDFDocument1 pageS3 01concretedetails PDFAmr HalabyNo ratings yet

- Stancor Ultra-Linear Williamson Amplifier W A-8054 XFMRDocument6 pagesStancor Ultra-Linear Williamson Amplifier W A-8054 XFMRVaslejeanNo ratings yet

- 560 000 ST S 001 - 1Document1 page560 000 ST S 001 - 1JA_RRYNo ratings yet

- Pipe Reinforcing at SupportDocument12 pagesPipe Reinforcing at SupportSeungmin Paek100% (3)

- Tower1 sht2Document1 pageTower1 sht2Nandini SNo ratings yet

- Lug Sup'tDocument2 pagesLug Sup'tSeungmin PaekNo ratings yet

- Transformer BushingDocument11 pagesTransformer BushingNunna BaskarNo ratings yet

- Stiffening Ring Cal For Exteneral Press.Document11 pagesStiffening Ring Cal For Exteneral Press.inspectormhp100% (1)

- Microsoft Word MecvinaDocument37 pagesMicrosoft Word MecvinaRam RamirezNo ratings yet

- 41150Document14 pages41150zayerirezaNo ratings yet

- 01-203 RW Mechanical DrawingsDocument6 pages01-203 RW Mechanical Drawingsnazar750No ratings yet

- Standard For Ship Piping 2Document227 pagesStandard For Ship Piping 2khanhhue67% (3)

- Problem Set 1Document9 pagesProblem Set 1Ron Julienne RebugioNo ratings yet

- Water Tank To Column Detail: Advanced Diploma of Building Design Footing Layout Student Accommodation S01Document7 pagesWater Tank To Column Detail: Advanced Diploma of Building Design Footing Layout Student Accommodation S01hmaisano1100% (1)

- Sample CalculationDocument35 pagesSample CalculationYoesbar Sofyan100% (1)

- Scientific American, Vol. XXXVII.—No. 2. [New Series.], July 14, 1877 A Weekly Journal Of Practical Information, Art, Science, Mechanics, Chemistry, And ManufacturesFrom EverandScientific American, Vol. XXXVII.—No. 2. [New Series.], July 14, 1877 A Weekly Journal Of Practical Information, Art, Science, Mechanics, Chemistry, And ManufacturesNo ratings yet

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

![Scientific American, Vol. XXXVII.—No. 2. [New Series.], July 14, 1877

A Weekly Journal Of Practical Information, Art, Science,

Mechanics, Chemistry, And Manufactures](https://imgv2-2-f.scribdassets.com/img/word_document/187114288/149x198/c199ff44cf/1579708199?v=1)