Professional Documents

Culture Documents

Machinery

Machinery

Uploaded by

Rams RamsiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machinery

Machinery

Uploaded by

Rams RamsiCopyright:

Available Formats

MACHINERY AND EQUIPMENT

CHECKLIST

Machinery and equipment, known as plant, are major sources of hazards and workplace injuries. You must ensure all machinery

and equipment in your workplace is safe, used properly and maintained in good repair. This checklist will help you address some

common safety issues involving machinery and equipment. You should involve your workers in filling out this checklist.

If you mark any NO box on the checklist, you need to take action to make your workplace safer.

Date checklist completed:

Date checklist to be reviewed:

(annually or when there is a change or addition to machinery and equipment used in the workplace)

Name of person who completed checklist:

Position title: Company/workplace:

Safety devices

Are machine guards in place on all operating equipment? Yes No

Are belts, pulleys and other rotating parts properly guarded? Yes No

Are emergency stop buttons clearly marked and operational? Yes No

Work areas

Is there sufficient clearance space around all plant? Yes No

Are machinery and equipment areas kept clean and free from obstructions? Yes No

Is the ventilation adequate? Yes No

Are steps taken to reduce machinery noise (eg isolating the plant, mufflers, baffles)? Yes No

Are tools and portable equipment stored safely? Yes No

Safe operation

Are workers trained to operate machinery safely? Yes No

Do they hold any necessary certificates of competencies (eg forklift)? Yes No

Are workers supervised to ensure correct procedures are followed? Yes No

Is machinery and equipment regularly inspected for damage or wear? Yes No

Is machinery and equipment maintained according to the manufacturers’ instructions? Yes No

Personal protective equipment (PPE)

Do you provide adequate PPE (eg safety footwear, Yes No

eye protection, hearing protection) as required?

Do you and your workers maintain PPE in accordance with the manufacturers’ instructions? Yes No

You might also like

- 2014 CPC Final Practice Exam / AAPCDocument53 pages2014 CPC Final Practice Exam / AAPCJulio Lagrule100% (16)

- Neville, Oral and Maxillofacial Pathology, 2nd EdDocument857 pagesNeville, Oral and Maxillofacial Pathology, 2nd EdPatriciaSepúlvedaCruz67% (3)

- Micromax Specialists in Automation Machine Safety ChecklistDocument3 pagesMicromax Specialists in Automation Machine Safety Checklistjustine8448No ratings yet

- JHA No D0011 "Rust/Paint Chipping": Job Hazard Analysis and Tool Box Discussion FormDocument3 pagesJHA No D0011 "Rust/Paint Chipping": Job Hazard Analysis and Tool Box Discussion Formtjeng syuwenNo ratings yet

- SlamDocument8 pagesSlamClinton Eric HuntNo ratings yet

- 3 3bb0aDocument7 pages3 3bb0aEleandro JoaquimNo ratings yet

- Monthly HSSE Inspection ChecklistDocument5 pagesMonthly HSSE Inspection ChecklistEric TNo ratings yet

- Hot Work PermitDocument4 pagesHot Work PermitMichael RujuwaNo ratings yet

- MOG-HSEQ-F-178 Major Accidents Notification FormDocument2 pagesMOG-HSEQ-F-178 Major Accidents Notification FormSalim MuftahNo ratings yet

- Accident Incident Report SampleDocument4 pagesAccident Incident Report SampleNgoua CalixNo ratings yet

- Accident/Incident Investigation - Supervisor Training: N.C. Department of Labor Mine and Quarry BureauDocument44 pagesAccident/Incident Investigation - Supervisor Training: N.C. Department of Labor Mine and Quarry BureauSHANZAY21111111No ratings yet

- Thatta Cement Co. LTD.: HSE Compliance Checklist & Action Plan HIRA & EAI Implementation and Legal RequirementsDocument59 pagesThatta Cement Co. LTD.: HSE Compliance Checklist & Action Plan HIRA & EAI Implementation and Legal Requirementsck19654840No ratings yet

- Root Cause Analysis FormDocument2 pagesRoot Cause Analysis Formgunnery02No ratings yet

- Hazard ObservationDocument8 pagesHazard ObservationMarya HasniNo ratings yet

- Machinery Inspection ChecklistDocument3 pagesMachinery Inspection ChecklistrishibarathiNo ratings yet

- Pp0707-Wmp-f01 Waste Log - (Non-Hazardous Waste)Document1 pagePp0707-Wmp-f01 Waste Log - (Non-Hazardous Waste)Mohamed MounerNo ratings yet

- Material Handeling OCPDocument1 pageMaterial Handeling OCPAshwani KumarNo ratings yet

- Vehicle Tracking Policy - CMT Approved 01.09.16Document6 pagesVehicle Tracking Policy - CMT Approved 01.09.16sethup_1No ratings yet

- (Inspection Inprocess)Document15 pages(Inspection Inprocess)loserambujNo ratings yet

- Noise MonitoringDocument7 pagesNoise Monitoringshahrul rollNo ratings yet

- SK - SHE StatisticsDocument1 pageSK - SHE StatisticsIjaz HussainNo ratings yet

- JSA EmployeesDocument2 pagesJSA EmployeesburhanNo ratings yet

- Tools Safety and Machine GuardingDocument13 pagesTools Safety and Machine GuardingEfereutrio SolariotoNo ratings yet

- Agenda: Safety Committee Meeting Agenda and MinutesDocument2 pagesAgenda: Safety Committee Meeting Agenda and Minutessidadams2No ratings yet

- FMEADocument20 pagesFMEARonillo PormonNo ratings yet

- Working at HeightDocument2 pagesWorking at HeightMohammed KadhimNo ratings yet

- SCAT Chart - Systematic Cause Analysis Technique - SCAT ChartDocument4 pagesSCAT Chart - Systematic Cause Analysis Technique - SCAT ChartponggoooNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- Electrical Hazards ChecklistDocument3 pagesElectrical Hazards ChecklistMazen FakhefakhNo ratings yet

- Cranes and HoistsDocument3 pagesCranes and HoistsAditya Raj MishraNo ratings yet

- Weekly Inspection Report - xlsx5-3Document11 pagesWeekly Inspection Report - xlsx5-3bassim amrallaNo ratings yet

- Planned Job Observation: ChecklistDocument2 pagesPlanned Job Observation: ChecklistMOHAMMED RIYAN TNo ratings yet

- SAMPLE Machinery EHS Acceptance ChecklistDocument4 pagesSAMPLE Machinery EHS Acceptance ChecklistDhananjay Patil100% (1)

- Safety Inspection ChecklistDocument6 pagesSafety Inspection ChecklistVel MuruganNo ratings yet

- Health, Safety and Environment Policy ManualDocument3 pagesHealth, Safety and Environment Policy ManualVikas SinghNo ratings yet

- Report Log of Unsafe Acts, Unsafe Conditions and Almost AccidentsDocument3 pagesReport Log of Unsafe Acts, Unsafe Conditions and Almost AccidentsTatiana Garcia MendozaNo ratings yet

- Emergency Reporting Plan - BeloniaDocument4 pagesEmergency Reporting Plan - BeloniaMd Nurul Islam100% (1)

- 16 Tractor Inspection ChecklistDocument1 page16 Tractor Inspection ChecklistKoneti JanardhanaraoNo ratings yet

- Chapter 9. Failure Root Cause PreventionDocument23 pagesChapter 9. Failure Root Cause PreventionAbdirahman Ali mohamudNo ratings yet

- Training Global Calendar 2013 - LDDocument1 pageTraining Global Calendar 2013 - LDNicolas150956No ratings yet

- Construction Site Safety Control Measures For Covid-19Document34 pagesConstruction Site Safety Control Measures For Covid-19Achik WahabNo ratings yet

- SOP Traffic ManagementDocument9 pagesSOP Traffic ManagementSyed AhmadNo ratings yet

- Library of PD&T QMS Project HSE Moments: Presented By: On DateDocument8 pagesLibrary of PD&T QMS Project HSE Moments: Presented By: On DateSyahril Aizal AhmadNo ratings yet

- Access To and Egress From Workplace ProcedureDocument2 pagesAccess To and Egress From Workplace ProcedurednmuleNo ratings yet

- Basic 5SDocument117 pagesBasic 5SPrasad PrinceNo ratings yet

- 1 Site Safety Inspection ReportDocument1 page1 Site Safety Inspection ReportMohammed AbdulmuqeetNo ratings yet

- Safety Quiz - Answer PDFDocument1 pageSafety Quiz - Answer PDFRedzwan KadirNo ratings yet

- Fall Protection Program: Reviewed: May 2011Document20 pagesFall Protection Program: Reviewed: May 2011Marvin ReggieNo ratings yet

- Improving Compliance With ProceduresDocument66 pagesImproving Compliance With ProceduresAndrew DolbyNo ratings yet

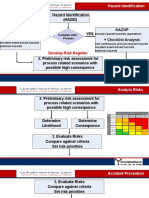

- Hazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisDocument7 pagesHazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisZeroRecoNo ratings yet

- Health: Key Performance Indicator Month of JANUARYDocument1 pageHealth: Key Performance Indicator Month of JANUARYSaddem Hadfi100% (1)

- Building Works at Hougang Town: Daily Housekeeping ChecklistDocument1 pageBuilding Works at Hougang Town: Daily Housekeeping ChecklistALFREDO JR. ARIOS CLARONo ratings yet

- Machinery Inspection ChecklistDocument3 pagesMachinery Inspection ChecklistYuva samaj sewa TrustNo ratings yet

- Workplace Safety Climate Survey: Yes - No Yes - No Yes - NoDocument2 pagesWorkplace Safety Climate Survey: Yes - No Yes - No Yes - NoBuddy KertunNo ratings yet

- Appendix-AC, Guide For Working at HeightsDocument23 pagesAppendix-AC, Guide For Working at HeightsApm FoumilNo ratings yet

- Incident Management ProcedureDocument19 pagesIncident Management ProcedureadorabletwhindingwiNo ratings yet

- Pt. Oversindo Services: Pt. Archroma Indonesia Project - CilegonDocument2 pagesPt. Oversindo Services: Pt. Archroma Indonesia Project - CilegonDeny NoizNo ratings yet

- PTW Tracking Log: Allied Engineering Construction Sdn. Bhd. Urc Engineering Sdn. BHDDocument1 pagePTW Tracking Log: Allied Engineering Construction Sdn. Bhd. Urc Engineering Sdn. BHDviniNo ratings yet

- Daily HSE ReportDocument5 pagesDaily HSE ReportSayeed MalikNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Architectural Design 7: Technological Institute of The Philippines 938 Aurora BLVD Cubao, Quezon CityDocument25 pagesArchitectural Design 7: Technological Institute of The Philippines 938 Aurora BLVD Cubao, Quezon CityKB SalvadorNo ratings yet

- CU 13. The Role of The Nurse EducatorDocument10 pagesCU 13. The Role of The Nurse EducatorWonie booNo ratings yet

- Malawi Government Cabinet ListDocument4 pagesMalawi Government Cabinet ListNation OnlineNo ratings yet

- Clinton Email Batch 2Document743 pagesClinton Email Batch 2DavidKihara100% (1)

- Respiratory Distress Learning Outcome RubricDocument2 pagesRespiratory Distress Learning Outcome Rubricdenise delgadoNo ratings yet

- PDFDocument28 pagesPDFlikun mishra0% (1)

- Basic HistopathologyDocument3 pagesBasic HistopathologyCIRILO MABBORANGNo ratings yet

- IV.3. Bioreactors in Tissue Engineering.Document30 pagesIV.3. Bioreactors in Tissue Engineering.Ingrid OlmedaNo ratings yet

- Barangay Certification: Barangay Malamsit Office of The Punong BarangayDocument4 pagesBarangay Certification: Barangay Malamsit Office of The Punong BarangayAwin BejarinNo ratings yet

- Disefectant Validation PfizerDocument13 pagesDisefectant Validation PfizerNgọc Lộc Cao NguyễnNo ratings yet

- SDS (ZP4300) MSDSDocument8 pagesSDS (ZP4300) MSDSNisa SutopoNo ratings yet

- Lasa NorumDocument17 pagesLasa NorumIFRS Citra HusadaNo ratings yet

- AHD Villlage SecretariatDocument28 pagesAHD Villlage Secretariatabhishek chowdaryNo ratings yet

- QRA Technical GuideDocument37 pagesQRA Technical GuideEmad ElgebesyNo ratings yet

- The End of Periodisation of Sports Training ADocument10 pagesThe End of Periodisation of Sports Training AÁdám GusztafikNo ratings yet

- Land Acquisition Act 2013Document53 pagesLand Acquisition Act 2013pankaj suryaNo ratings yet

- BTVN Coo Ngocj ThaorDocument2 pagesBTVN Coo Ngocj ThaorHuy Hợp NguyễnNo ratings yet

- BIOPIRACYDocument9 pagesBIOPIRACYiansolanoyu100% (1)

- Yog Gram Information in - EnglishDocument24 pagesYog Gram Information in - Englishdeeptigarg1983100% (3)

- Masterkure 260-V1-Asean-0614 - Concrete - Building EngineeringDocument4 pagesMasterkure 260-V1-Asean-0614 - Concrete - Building Engineeringkpher29No ratings yet

- Four Handed Dentistry and AssistantsDocument1 pageFour Handed Dentistry and AssistantsjohanNo ratings yet

- Chapter 1Document6 pagesChapter 1aksanaNo ratings yet

- ArticuloDocument8 pagesArticuloAkcyre PalominoNo ratings yet

- Medical PluralismDocument29 pagesMedical PluralismGian pagadduNo ratings yet

- Keto Meal Prep Lose Weight, Save Time, and Feel Your Best On The Ketogenic Diet by Liz WilliamsDocument227 pagesKeto Meal Prep Lose Weight, Save Time, and Feel Your Best On The Ketogenic Diet by Liz WilliamsKim Possible100% (2)

- Compliance CircularDocument1 pageCompliance CircularsadafNo ratings yet

- (Ebook) CISSP Business Continuity Planning - BCPDocument67 pages(Ebook) CISSP Business Continuity Planning - BCPIon VladNo ratings yet

- DMSO Health and Safety InformationDocument16 pagesDMSO Health and Safety InformationPapaindoNo ratings yet