Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

396 viewsPipe Stress Analysis SEMINAR - COADE

Pipe Stress Analysis SEMINAR - COADE

Uploaded by

sateesh chandCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Offshore Piping Design: Technical Design Procedures & Mechanical Piping MethodsFrom EverandOffshore Piping Design: Technical Design Procedures & Mechanical Piping MethodsNo ratings yet

- Pipe Stress Manual CalcDocument62 pagesPipe Stress Manual Calcpipestress100% (8)

- Caesar Ii Pipe Stress Analysis TutorialDocument5 pagesCaesar Ii Pipe Stress Analysis TutorialRicardo A. Pol33% (6)

- Guide To Construction of Segmental BridgeDocument171 pagesGuide To Construction of Segmental Bridgenaqie_civil100% (9)

- Pipe Stress Analysis Intro PPS 180605Document34 pagesPipe Stress Analysis Intro PPS 180605Manjesh Kumar SinghNo ratings yet

- Concepts of Pipe Stress AnalysisDocument54 pagesConcepts of Pipe Stress AnalysisTejas Patel100% (12)

- 02 Stress Analysis of Piping System and Code Requirements ASME B31.3Document40 pages02 Stress Analysis of Piping System and Code Requirements ASME B31.3ballisnothing100% (2)

- Stress Analysis 1Document82 pagesStress Analysis 1Luis Ortiz100% (10)

- Questions For Stress AnalysisDocument3 pagesQuestions For Stress AnalysisSunday PaulNo ratings yet

- 01 - Hanger Sizing in CAESAR IIDocument40 pages01 - Hanger Sizing in CAESAR IIJimmy Alexander AvilaNo ratings yet

- Stress Analysis of Piping Systems and Pipelines - Harvard - UniversityDocument542 pagesStress Analysis of Piping Systems and Pipelines - Harvard - Universitykaruna346100% (11)

- DynamicsDocument28 pagesDynamicsLeandro Vargas100% (1)

- CaesarDocument32 pagesCaesarAndi Pramana80% (5)

- 2905 - Edgar EXPANSION JOINTS WITH CAESAR IIDocument45 pages2905 - Edgar EXPANSION JOINTS WITH CAESAR IIDivyesh Patel100% (1)

- Caesar Book MaterialDocument148 pagesCaesar Book MaterialCatur Oka Nurfansyah100% (11)

- Caesar II TrainingDocument22 pagesCaesar II TrainingPetar Jankovic50% (2)

- Stress Analysis of Piping Systems and Pipelines-Harvard UniversityDocument542 pagesStress Analysis of Piping Systems and Pipelines-Harvard UniversityRjeb mohamed100% (2)

- Calculated Stress in CAESAR II Software by Using Failure TheoryDocument6 pagesCalculated Stress in CAESAR II Software by Using Failure TheoryHùng Mạnh Nguyễn100% (1)

- Load Case CAESAR IIDocument6 pagesLoad Case CAESAR IIshakasspNo ratings yet

- Dynamic Module of CAESAR II PDFDocument68 pagesDynamic Module of CAESAR II PDFPrashant Agrawal100% (3)

- Load CombinationsDocument3 pagesLoad Combinationserikoh100% (1)

- Stress Analysis ReportDocument153 pagesStress Analysis ReportErarunv100% (6)

- Piping Stress Analysis SpecificationDocument1 pagePiping Stress Analysis SpecificationAdrian García Moyano100% (1)

- Importance & Impact of Stress Intensification Factor (SIF) : A PresentationDocument8 pagesImportance & Impact of Stress Intensification Factor (SIF) : A Presentationcasaean100% (1)

- Cryogenic Piping Stress AnalysisDocument6 pagesCryogenic Piping Stress AnalysismasilamaniNo ratings yet

- Trunnion Checking or Dummy Checking During Stress Analysis of A Piping SystemDocument2 pagesTrunnion Checking or Dummy Checking During Stress Analysis of A Piping SystemAmit SharmaNo ratings yet

- Fatigue Analysis W - CIIDocument10 pagesFatigue Analysis W - CIInaeand100% (1)

- Pipe Stress PDFDocument24 pagesPipe Stress PDFMichael Jones100% (1)

- Piping Stress AnalysisDocument159 pagesPiping Stress AnalysisSalah Eddine Ziani100% (1)

- Caesar II Modeling ExcisersDocument40 pagesCaesar II Modeling ExcisersBùi Văn Hợp100% (2)

- Screenshots of Pipe Stress Analysis in ActionDocument17 pagesScreenshots of Pipe Stress Analysis in ActionCepi Sindang Kamulan100% (2)

- Static & Dynamic Analysis of Piping SystemDocument105 pagesStatic & Dynamic Analysis of Piping Systemkarthikeashwar100% (4)

- Local Stresses WRC107Document19 pagesLocal Stresses WRC107naeand67% (3)

- NozzlePRO PDFDocument185 pagesNozzlePRO PDFRagupathy KulandaisamyNo ratings yet

- Stress Analysis NotesDocument127 pagesStress Analysis NotesArindomNo ratings yet

- Coade Pipe Stress Analysis Seminar Notes PDFDocument474 pagesCoade Pipe Stress Analysis Seminar Notes PDFAhmad Vawaid Sulthon100% (1)

- 16 Stress AnalysisDocument26 pages16 Stress AnalysisKusaila100% (1)

- Chemical Engineering - June 1997 - Pipe Design For Robust SystemsDocument9 pagesChemical Engineering - June 1997 - Pipe Design For Robust Systemshtaboada2008100% (1)

- Piping StressDocument30 pagesPiping Stresscharan100% (2)

- Sabp L 006Document8 pagesSabp L 006shafeeqm3086No ratings yet

- ASME Sec VIII Div 1Document120 pagesASME Sec VIII Div 1kanchanabalaji96% (23)

- KBR Piping Stress SpecificationDocument23 pagesKBR Piping Stress Specificationsamprof4vw83% (6)

- Asme Stress Linearization and Classification - A Discussion Based On A Case StudyDocument12 pagesAsme Stress Linearization and Classification - A Discussion Based On A Case Studysagar1503No ratings yet

- ASME Pressure Vessels Basic CalculationsDocument23 pagesASME Pressure Vessels Basic Calculationsdhasdj100% (17)

- Flare Piping Stress NalysisDocument7 pagesFlare Piping Stress Nalysisgpskumar22100% (1)

- Application of Peps in Stress Analysis of Nuclear Piping PDFDocument5 pagesApplication of Peps in Stress Analysis of Nuclear Piping PDFaaaaNo ratings yet

- Sabp L 006 PDFDocument8 pagesSabp L 006 PDFWNo ratings yet

- Paldex Seminar-2 - Stress AnalysisDocument75 pagesPaldex Seminar-2 - Stress AnalysisKumar Kote100% (1)

- Experiment # 2 Tension Testing of MetalsDocument3 pagesExperiment # 2 Tension Testing of MetalsJ. Fabián MenaNo ratings yet

- Stress Analysis of Oil and Gas Pipeline Parallel Laying When Traversing TunnelsDocument7 pagesStress Analysis of Oil and Gas Pipeline Parallel Laying When Traversing TunnelsTon PhichitNo ratings yet

- Piping, Fittings, and ValvesDocument9 pagesPiping, Fittings, and ValvesaasattiNo ratings yet

- FsafDocument24 pagesFsafpvmssonNo ratings yet

- SMiRT-23 Paper 093Document10 pagesSMiRT-23 Paper 093MAT-LIONNo ratings yet

- Pressure Cycling 2010051Document6 pagesPressure Cycling 2010051Sharath KrishnanNo ratings yet

- Detail Engineering MethodologyDocument11 pagesDetail Engineering MethodologyKumarJR86100% (1)

- Gasket FactorsDocument7 pagesGasket Factorsbalumagesh1979100% (2)

- Effect of Nozzle Stiffness On Nozzle Loads and StressesDocument12 pagesEffect of Nozzle Stiffness On Nozzle Loads and StressesJafer Sayed100% (1)

Pipe Stress Analysis SEMINAR - COADE

Pipe Stress Analysis SEMINAR - COADE

Uploaded by

sateesh chand0 ratings0% found this document useful (0 votes)

396 views463 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

396 views463 pagesPipe Stress Analysis SEMINAR - COADE

Pipe Stress Analysis SEMINAR - COADE

Uploaded by

sateesh chandCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 463

SECTION 1

-Peeescecesqoteccccccce

ooe@eenne een

#

Ae

¢

1.0

1a

ooce@ @ @ 0418889 @

12

ne)

°

°

° 13

e 14

1.5

°

°

°

o

°

&

°

°

e

e

°

°

Q

°

e

°

2

COADE Pipe Stress Analysis Seminar Notes

Section 1

Table of Contents

Introduction to Pipe Stress Analysis

‘Theory and Development of Pipe Stress Requirements

1.1.1 Basic Stress Concepts

LL2_ 3-D State of Stress in the Pipe Wall..

1.1.3 Failure Theories...

1.1.4 Maximum Stress Intensity Criterion

Fatigue Failure

1.2.1 Fatigue Basics.

1.2.2 Fatigue Curves.

1.2.3 Effect of Fatigue on Piping

1.2.4 Cyclic Reduction Factor ..

1.2.5 Effect of Systained Loads on Fatigue Strength ..

Stress Intensification Factors

Welding Research Council Bulletin 380

Code Compliance ..

1.5.1. Primary vs. Secondary Loads

1.5.2 Code Stress Equations

1.5.8 BB11 Power Piping

1.5.4 B81.3 Chemical Plant and Petroleum Refinery Piping

1.5.5 ASME Section III, Subsections NC & ND (Nuclear Class 2 & 3)

1.5.6 B314 Puel Gas Piping...

1.5.7 BS1.8 Gas Transmission and Distribution Piping Code

1.5.8- Canadian 2183/2184 Oil/Gas Pipeline Systems ...

15.9 RCOMC..

1.5.10 Stoomwezen .. -

1.5.11 Special Considerations of Code Compliance...

1.5.12 Evaluation of Multiple Expansion Range Cases

8

‘@ 9

o

°

a

o

o

e

°

9

9

eoeeecooceecceeeseereevece

COADE Pipe Stress Analysis Seminar Notes

1.0 Introduction to Pipe Stress Analysis

In order to properly design a piping system, the engineer must understand both a system's

behavior under potential loadings, as well as the regulatory requirements imposed upon it

by the governing codes.

A system's behavior can be quantified through the aggregate values of numerous physical

parameters, such as accelerations, velocities, displacements, internal forces and moments,

stresses, and external reactions developed under applied loads. Allowable values for each

of these parameters are set after review of the appropriate failure criteria for the system.

System response and failure criteria are dependent on the type of loadings, which can be

classified by various distinctions, such as primary vs. secondary, sustained vs. occasional,

or static vs. dynamic.

‘The ASME/ANSI B31 piping codes are the result of approximately 8 decades of work by the

American Society of Mechanical Engineers and the American National Standards Institute

(formerly American Standards Association) aimed at the codification of design and engineer-

ing standards for piping systems. The B31 pressure piping codes (and their successors, such

asthe ASME Boiler and Pressure Vessel Section [lI nuclear piping codes) prescribe minimum

design, materials, fabrication, assembly, erection, test, and inspection requirements for

piping systems intended for use in power, petrochemical/refinery, fuel gas, gas transmission,

and nuclear applications.

Due to the extensive calculations required during the analysis of a piping system, this field

of engineering provides a natural application for computerized calculations, especially

during the last two to three decades. The proliferation of easy-to-use pipe stress software

has hada two-fold effect: first, ithas taken pipe stress analysis out of the hands ofthe highly-

paid specialists and made it accessible tothe engineering generalist, butlikewiseithas made

everyone, even those with inadequate piping backgrounds, capable of turning out official-

looking results.

‘The intention of this course is to provide the appropriate background for engineers entering

the world of pipe stress analysis. The course concentrates on the design requirements

(particularly from a stress analysis point of view) of the codes, as well as the techniques to

be applied in order to satisfy those requirements. Although the course is taught using the

CAESAR TI Pipe Stress Analysis Software, the skills learned here are directly applicable

to any means of pipe stress analysis, whether the engineer uses a competing software

program or even manual calculational methods.

Why do we Perform Pipe Stress Analysis?

There are a number of reasons for performing stress analysis on a piping system. A few of

these follow: '

1 - In order to keep stresses in the pipe and fittings within code allowable levels.

2 - In order to keep nozzle loadings on attached equipment within allowables of

manufacturers or recognized standards (NEMA SM23, API 610, API 617, etc.).

COADE Pipe Stress Analysis Seminar Notes

Inorder to keep vessel stresses at piping connections within ASME Section VII

allowable levels.

o

»

In order to caleulate design loads for sizing supports and restraints.

In order to determine piping displacements for interference checks,

a

In order to solve dynamic problems in piping, such as those due to mechanical

vibration, acoustic vibration, fluidhammer, pulsation, transient flow, and relief

valve discharge.

o

’

7 ~~ Inorder to help optimize piping design.

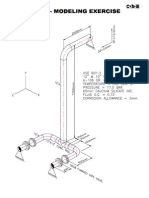

Typical Pipe Stress Documentation

Documentation typically associated with stress analysis problems consists of the stress

isometric, the stress analysis input echo, and the stress analysis results output. Examples

of these documents are shown in Figures 1-1 through 1-8 on subsequent pages.

‘The stress isometric(Figure 1-1)is asketch, drawn in an isometric coordinate system, which

gives the viewer a rough 3-D idea of the piping system. The stress isometric often

summarizes the piping design data, as gathered from other documents, such as the line list,

piping specification, piping drawing, Appendix A (Figure 1-2) of the applicable piping code,

etc. Design data typically required in order to do-pipe stress analysis consists of pipe

materials and sizes; operating parameters, such as temperature, pressure, and fluid

contents; code stress allowables; and loading parameters, such as insulation weight,

external equipment movements, and wind and earthquake criteria.

Points of interest on the stress isometric are identified by node points. Node points are

required at any location where it is necessary to provide information to, or obtain information

from, the pipe stress software. Typically, node points are located as required in order to:

1 - define geometry (system start, end, direction changes, intersection, etc.)

2 - note changes in operating conditions (system start, isolation or pressure reduc-

tion valves, etc.)

3 - dofine element stiffness parameters (changes in pipe cross section or material,

rigid elements, or expansion joints)

4 + designate boundary conditions (restraints and imposed displacements)

5 + specify mass points (for refinement of dynamic model)

6 + note loading conditions (insulation weight, imposed forces, response spectra,

earthquake g-factors, wind exposure, snow, etc.)

7 - retrieve information from the stress analysis (stresses at piping mid spans,

displacements at wall penetrations, atc.)

aeeccoekoes

C3o5eoce Hoe en ec eee

6

o

0

6

e

e

SOCe@@@ G8 57086980:

x

caseeeoeoerese

COADE Pipe Stress Analysis Seminar Notes

‘The input echo (Figure 1-3) provides more detailed information on the system, and is meant

to be used by the engineer in conjunction with the stress isometric.

‘The analysis output provides results, such as displacements, internal forces and moments,

stresses, and restraint loadings at each node point of the pipe, acting under the specified

loading conditions. CAESAR IZ provides results in either graphic or text format; Figures

1-4 and 1-5 present stress and displacement results graphically, The output also provides

a code check calculation for the appropriate piping code, ‘from which the analyst can

determine which locations are over stressed.

SsEni

oN

a

Computed thernal expansion of the vessel is a5

17.26BE-6 in/in/dag-F. at a temp of 828 dos.

Exchanger

Kode 108 is 26.88 ft. above vessel skirt

Diep. @ 282 = (820-78)dey.F(17 2688-6) in/ in/doge

(20.00) (izsrt. inet. = 3.121 in

X Diep. @ 128 = (828-78)(17.260E-G>(28.08+6.5-15)(12)

24.8 in,

Figure 1-1

co oee er ogeeceeeeeeesroeecrxre00

i Oo )

u

2 yy

| 3

= 4 x

4 none « so eo E 2 a

Ok

4 a ee Pew mm now UE

z \ om mw

a ”

g soa

| een

3 a a

Doom s 3

200 eee —,

a BY My Boepreayads famed ¥ pure 20 spe mH ay KaraTEIN 4 EargNY, PRI MRO THN FLISY MY BanIEND Res STV SPIO my LOY OF IY FEY mG

@] —Manvornemaiw sence suomnoTl ave {0 SWON ws WMA HT sascvts SNOT OVE

‘tae YSN oe “alos evn ”

exau neouire mnie: aw nv ova crate enna noronzee any sri OMT tvawet

, ‘nist Hensorad val 9000 IY ‘on tannerat vou nao ne onoa nec amewser

COADE Pipe

@eeoeoeeeeeeeocvree en

oeeeccvceeeecdg

COADE Pipe Stress Analysis Seminar Notes

CAESAR I1 VERS 3.18 JOBNANE:SSEM1 DEC 10, 1992 3:05 am

PIPE DATA

From 100 Te 105 bY= 3.800 ft.

PIPE

Dia= 20.000 in. Walt= .375 fn. Insul= 2.000 in.

GENERAL

Tim 700 F Pl= 125.0000 Ib./sq.in, Mat~ (1)LOW CARBON STEEL

E= 27,900,000 Ib./sq.in. v= .282 Density .2899 1D./cu.in.

RIGID Weight 3,290.00 1b,

DESPLACEMENTS

Node 100 X= .000 in. Y= 3.121 tn. OZ .000 in, RX -000

Ry= .000 RZ» .000

ALLOWABLE STRESSES

831.3 (1990) Se= 20,000 1b. /sq.in. Sh 16,500 1b./sq.in.

From 105 To 110 DY= 3.000 ft.

BEND at “To” end

Radius= 30,000 in. (LONG) Bend Angle 90.000 Angle/Node @1= 45.00 109

Angle/Node @2= .00 108

From 110 To 128 Dk= 12.000 ft.

BEND at “TO™ ena

Radius 30.000 in. (LONG) Bend Angle= 90.000 Angte/Node @l= 45.00 114

Angle/Node @2~ .00 113

From 115. To 120 DY= -18.000 ft.

DISPLACEMENTS

Node 120 DX» FREE DY= 1.800 in. DZ FREE RX= FREE RY™ FREE

RZ FREE

From 120 To 225 DY= -3.000 ft.

BEND at *70” end

Radius= 30,000 in. (LONG) Bend Angie= 90.000 Angle/Node @l~ 45.00 124

Angle/Node @2= .0G 123

From 125. To 130 x= 35.000 ft.

RESTRAINTS,

Node 130 +¥

From 130 To 135 OX= 35.000 ft.

RESTRAINTS.

Node 135 +¥

From 135 To 140 D¥m 35.000 ft.

RESTRAINTS

Node 140 +7

From 140 To 145 D¥= 20.000 Ft.

BEND at “To” end .

Radtus= 30.000 in. (LONG) Bend Angle= 90.000 Angle/Node @i~ 45.00 144

Angle/Node @2= .09 143 ‘

From 145 To 150 DY= -12.900 ft.

RESTRAINTS

Rode 150 ANC

Figure 1-8

COADE Pipe Stress Analysis Seminar Notes

cose 3 CEXP)OGHDL-D2 | FILE:SSIML EC 4.1992 12:47am

quir

ropes

cvssTa

xs

rove

muss

exrRL,

STRESS

‘simaot

Brin

axa

mb

mans.

Axia

STRESS

ODEs 123 (UERSTRESSED MODES .

Figure 1-4

CASE 1 COPEW-DIS-TL-PL FILE:SSEN2 DEC 4,952 12:49am. RESET

ur

peri

SPECrY

agate

ono

tan

HRDCEY

woe 25 ax, ises. x

Figure 1-5

16

os ee 0 eda

o

‘

wooo ee

,

ollo we oc rv e crc bee oeee

COADE Pipe Stress Analysis Seminar Notes

What are these Stresses?

‘The stresses calculated are not necessarily real stresses (such as could be measured by a

strain gauge, forexample), but are rather “code” stresses. Code stress calculations are based

‘upon specific equations, which are the result of 8 decades of compromise and simplification.

‘The calculations reflect:

1:

Inclusion or exclusion of piping loads, based upon convenience of calculation or

selected fa‘iure. In fact the result may not even represent an absolute stress

value, but rather a RANGE of values.

‘Loading type — these are segregated, and analyzed separately, as though they

occur in isolation, even though they actually are present simultaneously.

Magnification, due to local fitting configuration, which may in reality reflect a

decrease in fatigue strength, rather than an increase in actual stress.

Code committee tradition — every code is a result of a different set of concerns

and compromises, and therefore may appear to be on a different branch of the

evolutionary ladder. Because of this, every code gives different results when

calculating stresses.

A summary of significant dates in the history of the development of the piping codes is

presented below:

1815 - Power Piping Society provides the first national code for pressure piping.

1926 - ‘The American Standards Association initiates project B31 to govern

pressure piping.

1955 - Markl publishes his paper “Piping Flexibility Analysis”, introducing

piping analysis methods based on the “stress range”.

1957 - First computerized analysis of piping systems.

1968 - Congress enacts the Natural Pipeline Safety Act, establishing CFR 192,

which will in time replace B31.8 for gas pipeline transportation.

1969 Introduction of ANSI B31.7 code for Nuclear power plant piping.

1971 - Introduction of ASME Section III for Nuclear power plant piping.

1974 - Winter Addenda B31.1 moves away from the separation of bending and

torsional moment terms in the stress calculations and alters the intensi-

fication factor for moments on the branch leg of intersections.

1978 ANSI B31.7 is withdrawn,

1987 - — Welding Research Council Bulletin 330 recommends changes to the

B81.1, B31.3, and ASME Ili Class 2 and 3 piping codes.

COADE Pipe Stress Analysis Seminar Notes

1.1 Theory and Development of Pipe Stress Requirements

1.1.1 Basic Stress Concepts

Normal stresses: Normal stresses are those acting in a direction normal to the face of the

crystal structure of the material, and may be either tensile or compressive in nature. (In fact,

normal stresses in piping tend more to tension due the predominant nature of internal

pressure as a load case.) Normal stresses may be applied in more than one direction, and

may develop from a number of different types of loads. For a piping system, these are

discussed, below:

Longitudinal stress: Longitudinal, or axial, stress is the normal stress acting parallel to

thelongitudinal axis ofthe pipe. Thismay becaused by an internal force acting axially within

the pipe:

Figure 1.6

Suo= Fax/Am

Where

Sz = longitudinal stress, psi

Fay = internal axial force acting on cross-section, Ib

Am = metal cross-sectional area of pipe, in?

= dg? - aj2)/4

= Ragt

d, = outer diameter, in

d, = inner diameter, in

dm = mean diameter, = (dy + d))/2

18

Pecenscaee

Teoxreenooaretbsaoaag

oC

oo @eeoecocoecee @ GG

@oeosoovaeeeeascrcsee @eorvroevend0

yee eecceeecog

COADE Pipe Stress Analysis Seminar Notes

A specific instance of longitudinal stress is that due to internal pressure:

SL

Internal Pressure

SL

Figure 1-7

SL = PA/Am

Where:

P = design pressure, psig

A; = internal area of pipe, in?

= nd2/4 <

Replacing the terms for the internal and metal areas of the pipe, the previous equation may

be written as:

SL P dj? / (2 - 42), or:

S

1

Pal /4dut

For convenience , the longitudinal pressure stress is often conservatively approximated as:

S, = Pdj/4t

Another component of axial normal stress is bending stress. Bending stress is zero at the

neutral axis of the pipe and varies linearly across the cross-section from the maximum

compressive outer fiber tothe maximum tensile outer fiber. Calculating the stress aslinearly

proportional to the distance from the neutral axis:

Variation in Bending Stress Thru

Cross Section

Max compressive stress

1/2 mox compressive stress

Neutral Axis

Zero bending stress

1/2 mex tension siress

Mcx tension stress

Figure 1-8

&

COADE Pipe Stress Analysis Seminar Notes o

. °

SL = Mye/I

Where: .

Mp = bending moment acting on cross-section, in-Ib ©

© = distance of point of interest from neutral axis of cross-section, in °

I = moment of inertia of cross-section, in¢ o

=n (dod = &j4)/ 64 e

°

Maximum bending stress occurs where cis greatest — where itis equal to the outer radius: °

Smox = MpRo/I = My/Z

°

Where: °

Ry = outer radius of pipe, in Qc

Z = section modulus of pipe, ind e

= I/R o

Summing all components of longitudinal normal stress: _?

Sto= Fax/Am+Pdo/4t+Mp/Z e

e

Hoop stress: There are other normal stresses present in the pipe, applied in directions

orthogonal to the axial direction. One of these stresses, caused by internal pressure, is called e

hoop stress. This stress acts in a direction parallel to the pipe circumference. ee

8, ==] e

iD, :

BY

8

3,244 o-

o 7

Figure 1-9 e

‘The magnitude of the hoop stress varies through the pipe wall and can be calculated by an

‘Lame’s equation as: e

Sq = P(g 2 +12 152 /12)/(r92 - 112) °

°

e

da

° °

2.

2.

oF

COADE Pipe Stress Analysis Seminar Notes

‘Where:

Si = hoop stress due to pressure, psi

= inner radius of pipe, in

To = outer radius of pipe, in

1 = radial position where stress is being considered, in

‘The hoop stress can be conservatively approximated for thin-wall cylinders, by assuming

that the pressure force, applied over an arbitrary length of pipe, 1 (F = P dj )), is resisted

uniformly by the pipe wall over that same arbitrary length (Am, = 2t 1), or:

Sa = Pdl/2tl, or:

Su = Pdj/2t, or conservatively:

esse e@esoxeeec eae

y Sq = Pd/2t

Radial stress: Radial stress is the third normal stress present in the pipe wall. It acts in

the third orthogonal direction, parallel to the pipe radius. Radial stress, which is caused by

internal pressure, varies between a stress ‘equal to the internal pressure at the pipe’s inner

surface and a stress equal to atmospheric pressure at the pipe’s external surface. Assuming

that there is no external pressure, radial stress may be calculated as:

Figure 1-10

SR o= Pre -rj2 162/22) /(r2- 172)

Where:

Sr = radial stress due to pressure, psi ‘

Note that radial stress is zero at the outer radius of the pipe, where the bending stresses are

maximized. For this reason, this stress component has traditionally ‘been ignored during the

stress calculations,

Shear stresses: Shear stresses are applied in a direction parallel to the face of the plane

of the crystal structure of the material, and tond to cause adjacent planes of the crystal to

.

e

e

e

e

e

e

°

.

&

°o

9

e

e

e

o

9

e

e

°

‘COADE Pipe Stress Analysis Seminar Notes

slipagainst each other. Shear stresses may be caused by more than one type of applied load.

For example, shear stress may be caused by shear forces acting on the cross-section:

Shear Oistribution

Profile

Teo

Figure 1-11

tmx = VQ/Am

%max = maximum shear stress, psi

V_= shear force, Ib

Q = shear form factor, dimensionless (1.333 for solid circular section)

‘These shear stresses are distributed such that they are maximum at the neutral axis of the

pipe and zero at the maximum distance from the neutral aris. Since this is the opposite of

the case with bending stresses, and since these stresses are usually small, shearstresses due

to forces are traditionally neglected during pipe stress analysis.

Shear stresses may also be caused by torsional loads:

oe

Dewees cecVeect ree eee wee ees rsoaeersoae

eoeeoeevereeeaosceee coe een 8

oO

&

S

°

°

°

°

°

°

.

.

e

9

My = internal torsional moment acting on cross-section, in-Ib

¢ = distance of point of interest from torsional center (intersection of neutral axes)

of cross-section, in y

R= torsional resistance of cross-section, int

= 21

= pldat- 48/32

Maximum torsional stress occurs where c is maximized — at the outer radius:

Tmax = MpRo/21 = Mr/2Z

‘Summing the individual components of the shear stress, the maximum shear stress acting

on the pipe cross-section is:

tmx = VQ/An+My/2Z

Example Stress Calculations:

As noted above, a number of the stress components described above have been neglected for

convenience during calculation of pipe stresses. Most U.S. piping codes require stresses to

be calculated using some form of the following equations:

Longitudinal stress: S, = = My /Z+ Fax/Am+Pdo/4t

Shear stress: tT = Mp/2Zv

Hoop stress: Se = Pa/2t

Calculations are illustrated for a 6-inch nominal diameter, standard wall pipe (assuming the

piping loads are known):

Cross sectional

properties: Piping loads:

dy = 6.625 in Bending moment (Mp) = 4247 ft-lb

qd - 6.065 in Axial force (Fjx) = 33488 Ib ‘

t = 0.280in Pressure (P) = 600psi_ |

Zz . 8.496 in? Torsional Moment (Mz) = = 8495 ft-lb

Am = 6.5813 in?

113

COADE Pipe Stress Analysis Seminar Notes

Longitudinal stress:

Sp = 4247 x 12/8.496 + 33488/5.5813 + 600 x 6.625/4 (0.280)

= 18647 psi

Shear stress:

T = 8495 x 12/2 (8.496) = 5999 psi

‘Hoop stress:

Sq = 600 x 6.625 /2 (0.280) = 7098 psi

1.1.2 3-D State of Stress in the Pipe Wall

During operation, pipes are subject to al of these types of stresses. Examining a small cube

of metal from the most highly stressed point of the pipe wall, the stresses are distributed as

50:

Figure 1-13

‘There are an infinite number oforientations in which this cube could have been selected, each.

with a different combination of normal and shear stresses on the faces. For example, there

is one orientation of the orthogonal stress axes for which one normal stress is maximized,

and another for which one normal stress is minimized — in both cases all shear stress

components are zero. In orientations in which the shear stress is zero, the resulting normal

components of the stress are termed the principal stresses. For 3-dimensional analyses,

there are three of them, and they are designated as S; (the maximum), Sp, and Ss (the

minimum). Note that regardless of the orientation of the stress axes, the sum of the

orthogonal stress components is always equal, ie:

Sp +Sq+Sp=S; +S: +S;

‘The converse of these orientations is that in which the shear stress component is maximized

(there is also an orientation in which the shear stress is minimized, but this is ignored since

the magnitudes of the minimum and maximum shear stresses are the same); this is

appropriately called the orientation of maximum shear stress. The maximum shear stress

poe ee cceee sc ogee eee rere sores envree een

COADE Pipe Stress Analysis Seminar Notes

ina three dimensional state of stress is equal toone-halfof the difference between the largest

and smallest of the principle stresses (S; and Sg).

‘The values of the principal and maximum shear stress can be determined through the use

ofa Mobr’s circle. The Mohr's circle analysis can be simplified by neglecting the radial stress

component, therefore considering a less complex (i.e., 2-dimensional) state of stress. A

‘Mohr’s circle can be developed by plotting the normal vs. shear stresses for the two known

orientations (1., the longitudinal stressvs, the shear and the hoop stress vs, the shear), and

constructing a circle through the two points. The infinite combinations of normal and shear

stresses around the circle represent the stress combinations present in the infinite number

of possible orientations of the local stress axes.

A differential element at the outer radius of the pipe (where the bending and torsional

‘stresses are maximized and the radial normal and force-induced shear stresses are usually

zero) is subject to 2-dimensional plane stress, and thus the principal stress terms can be

computed from the following Mohr’s circle:

Figure 1-14

‘The center of the circle is at (Sy, + Sy)/2 and the radius is equal to [ (Sp - Sy)/ 212 + T2309,

‘Therefore, the principal stresses, S; and Sq, are equal to the center of the circle, plus orminus

the radius, respectively. The principal stresses are calculated as:

S. = Gy +Sx)/2+((Sp-Sq)/ 2] +2 2 and

“Se = GL +Sp)/2-((S_-Sw/ 22+ 22

As noted above, the maximum shear stress present in any orientation is equal to(S1 - S2)/2,

or:

i

umax = (Gr - SH)? +42 2

2

COADE Pipe Stress Analysis Seminar Notes

1.1.3 Failure Theories

To be useful, calculated stresses must be compared to material allowables. Material

allowable stresses are related to strengths as determined by material uniaxial tensile tests,

therefore calculated stresses must also be related to the uniaxial tensile test. This

relationship can be developed by looking at available failure theories.

Failure of

crass section

ja Stress,

©

ovtel

4 Strain

Tensite Test Resutts

unigtal Tensile Tensile Test

Test machine Speciaen

Figure 1-15

‘There are three generally accepted failure theories which may be used to predict the onset

of yielding in a material:

1 - GCTAHEDRAL SHEAR, or VON MISES THEORY

2 - MAXIMUM SHEAR, or TRESCA THEORY

3 - MAXIMUM STRESS or RANKINE THEORY

These theories relate failure in an arbitrary three dimensional stress state in a material to

failure in a the stress state found in a uniaxial tensile test specimen, since it is that test that

is most commonly used to determine the allowable strength of commonly used materials.

Failure of a uniaxial tensile test specimen is deemed to occur when plastic deformation

occurs; i.e., when the specimen yields.

Coeeccoteveevcece

yO @ @ ec

o

o

e

e

®

a

8

°

e

e

Oo

o

“

°

°

e

e

e

e

e

eo

e

9

o

°

e

9

9

9

Qe

°

eo

9

COADE Pipe Stress Analysis Seminar Notes

‘The three failure theories state:

Octahedral Shear - Von Mises Theory:

“Failure occurs when the octahedral shear stress in a body is equal to the octahedral.

shear stress at yield in a uniaxial tension test.”

‘The octahedral shear stress is caloulated as:

oct = VB [ (Sy - Sp)? + (Sp - Sg}? + (Sg - Sp)? V2

In a uniaxial tensile test specimen at the point of yield:

Si = Syiag Sg=S3=0

‘Therefore the octahedral shear stress in a uniaxial tensile test specimen at failure is

calculated as:

3 Zot = WS [ (Syieta = O08 + (0 - 0)2 + (O- Syieta)? 2?

= 22x Syiga/3

Therefore, under the Von Mises theory:

Plastic deformation occurs in a 3-dimensional stress state whenever the

octahedral shear exceeds 21/2 x Syieig / 3.

Maximum Shear Stress - Tresca Theory:

“Failure occurs when the maximum shear stress in a body is equal to the maximum.

shear stress at yield in a uniaxial tension test.”

‘The maximum shear stress is calculated as:

tmx = (81> S3}/2

Tn a uniaxial tensile test specimen at the point of yield:

Si = Syiea, Sp2=S3=0

So:

max = — Site 00/2 = Syieia/2 \

‘Therefore, under the Tresca theory:

Plastic deformation occurs in a 3-dimensional stress state whenever the

maximum shear stress exceeds Syjeia /2.

COADE Pipe Stress Analysis Seminar Notes

Maximum Stress - Rankine Theory

“Failure occurs when the maximum tensile stress in a body is equal to the maximum

tensile stress at yield in a uniaxial tension test.”

The maximum tensile stress is the largest, positive principal stress, S;. (By definition, S,

is always the largest of the principal stresses.)

Ina uniaxial tensile test specimen at the point of yield:

S1.= Syieia; S2=S3=0

Therefore, under the Rankine theory:

Plastic deformation occurs in a 3-dimensional stress state whenever the

maximum priacipal stress exceeds Syieta.

1.1.4 Maximum Stress Intensity Criterion

‘Mostof the current piping codes use aslight miodification ofthe maximum shearstress theory

for flexibility related failures. Repeating, the maximum shear stress theory predicts that

failure occurs when the maximum shear stressin a body equals Syigig/2, the maximum shear

stress existing at failure during the uniaxial tensile test. Recapping, the maximum shear

stress in a body is given by:

Tmax = (Si -Sa)/2

For the differential element at the outer surface of the pipe, the principal stresses were

computed earlier as:

Si = (Sp+Sp)/2+((Sp-Sp/ 22+ 22

So(or Ss) = (Su + Sw)/2-( (Sp -Sy)/ 222 + 2

‘As seen previously, the maximum shear stress theory states that during the uniaxial tensile

test the maximum shear stress at failure is equal to one-half of the yield stress, so the

following requirement is necessary:

tmax = ((Sp- Sy)? + 4 72] < Syiata

2 2

‘Multiplying both sides arbitrarily by two saves the time required to do two mathematical

operations, without changing this relationship. Multiplying by two creates the stress

intensity, whichis an artificial parameter defined simply as twice the maximum shear stress,

‘Therefore the Maximum Stress Intensity criterion, as adopted by most piping cades, dictates

the following requirement:

(Sz - Sy)? +4242 < Srila

eee eccee &o

oe5eeceo &

oO

e

e

e

e@eeoeeevneveeseooroe een 57e8008 8

cpeeecceeecag

COADE Pipe Stress Analysis Seminar Notes

Note that when calculating only the varying stresses for fatigue evaluation purposes (as

discussed in the following section), the pressure components drop out of the equation. Ifan

allowable stress based upon a suitable factor of safety is used, the Maximum Stress Intensity

criterion yields an expression very similar to that specified by the B31.3 code:

[S,2+45,2]12 < Sy

‘Where:

Sp = longitudinal normal stress due to bending, psi

S, = shear stress due to torsion, psi

Sq = allowable stress for loading case, psi

Example Stress Intensity Calculations:

Calculation of stress intensity may be illustrated by returning to our 6-inch nominal

diameter, standard wall pipe for which longitudinal, shear, and hoop stresses were

calculated. Reviewing the results of those calculations:

Longitudinal stress: S. = = :1547 psi

Shear stress: t = 5999 psi

Hoop stress: Sa = 7098 psi

Assuming that the yield stress of the pipe material is 30,000 psi at temperature, and a factor

of safety of 2/3 is to be used, the following calculations must be made:

USL Sw? +4122 < 2/3 x Syjaia, or:

((15547 - 7098)2 + 4 x 59992 J¥2 < 2/8 x 30000, or:

14674 < 20000

‘The 14674 psi is the calculated stress intensity in the pipe wall, while the 20000 is the

allowable stress intensity for the material at the specified temperature. In this case, the pipe

would appear to be safely loaded under these conditions.

COADE Pipe Stress Analysis Seminar Notes

1.2 Fatigue Failure

‘The failure modes discussed above were sufficient to describe catastrophic failure based upon

one time loadings. However, piping and vessels were also found to suffer from sudden failure

following years of successful service. The proposed explanation for this phenomenon was

fatigue failure of the material, resulting from propagation of cracks on the material crystal

structure level due to repeated cyclic loading.

2.1 Fatigue Basics

Steels and other metals are made up of organized patterns of molecules, known as crystal

structures. However, these patterns are not maintained throughout the steel producing an

ideal homogenous material, but are found in microscopic isoiated island-like areas called a

grains,

Inside each grain the pattern of molecules is preserved. From one grain boundary tothe next

the molecular pattern is the same, but the orientation differs. As a result, grain boundaries

are high energy borders. Plastic deformation begins within a grain that is both subject to

a high stress and oriented such that the stress causes a slippage between adjacent layers in

the same pattern. The incremental slippages (called dislocations) cause local cold-working.

On the first application of the stress, dislocations will move through many of the grains that

are in the local area of high stress. As the stress is repeated, more dislocations will move

through their respective grains. Dislocation movement is impeded by the grain boundaries,

so after multiple stress applications, the dislocations tend to accumulate at grain boundaries,

and eventually becoming so dense that the grains “lock up”, causing a loss of ductility and

thus preventing further dislocation movement. Subsequent applications of the stress cause

the grain to tear, forming cracks, Repeated stress applications cause the cracks to grow.

Unless abated, the cracks propagate with additional stress applications until sufficient cross

sectional strength is lost to cause catastrophic failure ofthe material. Figure 1-16 illustrates

this process.

a

i

, i

ceeceecadeneseceee rcs aenc

op eee

COADE Pipe Stress Analysis Seminar Notes

Molecuar parem

inunsttessed grain

—

a3 ‘Siping of one molecular

ELEY surface over another after

fist appcabon of tose

‘\ sino seed

Siglo

second appbcation of

=

Dislocations beginning

to internet and tangle

Atter many repedted applications of

sass the dislocations are

‘completely tangled and the gran is

‘locked’

With another application of the

stress, he rain “tears” and a

fatigue cracks inisated,

Figure 1-16

eeoeaeeeeoeveveenosee e@eococeeec sd

[ }

"Dislocation

Slit

Jest Stress Level

Tension

\

Tine

o

9 .

e

e

° vara Bein

9

6 Figure 1-17

.

e

° 1-21

eo

‘One Cycte

TEST LOADING CURVE

COADE Pipe Stress Analysis Seminar Notes

One important consideration is the fact that fatigue cracks usually are initiated at a free

surface, Corrosive attack on a material often produces pitting of metal surfaces. The pits

act as notches and produce a reduction in fatigue strength. In those specific cases when

corrosive attack occurs simultaneously with fatigue loading, a pronounced reduction in

fatigue properties results which is greater than that produced by prior corrosion of the

surface. When corrosion and fatigue occur simultaneously, the chemical attack greatly

accelerates the rate at which fatigue cracks propagate.

Unfortunately, fatigue failures can occur even when the stressin a material is below the yield

stress. This is because localized stress concentrations can cause plastic deformation in a

relativelly few grains despite the fact that the stress over a gross area of the section may be

farbelow the material yield stress. Ifthe section is subjected to a sufficient number of stress

cycles, cracks can initiate in highly stressed grains and then propagate throughout the

material, ultimately resulting in a fatigue failure of the section as a whole,

The fatigue capacity of a material can be estimated through the application of cyclic

extensive/compressive displacement loads with a uniaxial test machine, as shown in Figure

117,

Sample results for typical ferrous material (with a yield stress of 57,000 psi) are shown below:

Applied Cycitc Cycles to

Stress (psi) Failure

300.000 23

200.000 90

100,000 350

50,000 6,700

30,000 38,000

20,000 109.000

.2.2 Fatigue Curves

Aplot of the cyclic stress capacity of a material is called a fatigue (or endurance) curve. These

curves are generated through multiple cyclic tests at different stress levels. The number of

cycles to failure usually increases as the applied cyclic stress decreases, often until a

threshold stress (known as the endurance limit) is reached below which no fatigue failure

occurs, regardless of the number of applied cycles. The endurance limit (for thosemetals that,

possess one) is usually quantified as the value of the cyclic stress level which may be applied

for at least 108 cycles without failure. Typical ratios of the endurance limit to the ultimate

tensile strength of various materials are 0.5 for cast and wrought steels; about 0.35 for

several nonferrous metals such as nickel, copper and magnesium; and 0.2 to 0.3 for rough

or corroded steel surfaces (depending on the degree of stress intensification).

An endurance curve for carbon and low alloy steels, taken from the ASME Section VIII

Division 2 Pressure Vessel Code is shown in Figure 1-18.

onBee0093

@oos e686

Oo

ceoee coc G @

Yoeeec

eoeeeeeoerece en r57e ee osc eee aE

G@ioeeeocceeece

¢YCUC STRESS AMPLITUDE

COADE Pipe Stress Analysis Seminar Notes

cyous 7

Figure 1-18

Note that according to the fatigue curve, the material doesn’t fail upon initial loading, despite

enormously high stresses that appear to be well above the ultimate tensile stress of typical

carbon and low alloy steels. The reasons for this are:

1

The highly stressed areas under fatigue loading ‘are normally very localized.

Catastrophic failure under one-time loading will normally occur only when the

gross cross-section is overloaded.

Fatigue curves are usually generated through cyclic application of displacement,

rather than force, loading. Displacement loads are “self-limiting”. If a pipe is

overloaded with an imposed displacement, plastic stresses will develop, deform-

ing the pipe to its displaced position. At that point there will be no further

tendency for displacements to occur, and therefore no continuation of the load,

or further deformation leading to catastrophic failure. In the case of an applied

force (which is not a self- limiting load), deformation of the pipe does not cause

the force to subside, so deformation continues until failure.

‘The stress shown in a fatigue curve is a calculated stress, based upon the

assumption that Hooke’s law is applicable throughout the range of applied

loading; i.e., S = E ¢ , where:

E = modulus of elasticity of material, psi

e = strain in material, infin

1-23

oa TEES eae aaa TE

COADE Pipe Stress Analysis Semiziar Notes

In reality, once the material begins to yield, stress is no longer proportional to

the induced strain, and actually is much lower than that calculated.

1.2.3 Effect of Fatigue on Piping

A.R.C. Markl investigated the phenomenon of fatigue failure ofpiping during the 1940's and

1950's, and published his results in papers such as “Piping Flexibility Analysis”, published

in 1955, He tested a number of configurations (straight pipe, and various fittings, such as

pipe elbow, miter bend, unreinforced fabricated tee, welding tee, etc.) by using cyclic

displacements to apply alternating bending stresses. Plotting the cycles to failure for each

applied displacement, he found that the results of his experiments followed the form of

fatigue curves.

16 .

TYP) ay [

YF) Range of imposed displacements to

——— impose complete stress reversal

'S itn butt wold L

[lS [Siemens sarge tae

displacements

fms inplane

displacements Range of outpiane

as lave l displacements.

/~Rangs of inplana,

a ennesmanty ge ota

Figure 1-19

If an initially applied displacement load causes the pipe to yield, it results in plastic

deformation, producing a pre-stress in the system, which must be overcome by subsequent

stress applications, resulting in lower absolute stresses during later load cycles. Because of

the system “relaxation”, the initial values of the thermal stress are allowed to exceed the

material yield stress, with the aim being that the system “self-spring” during the first few

eyeles and then settle into purely elastic cycling This “self-springing” is also called Elastic

Shakedown, As shown in Figure 1-20, the maximum stress range may be set to 2S Yield (or

more accurately, the sum of the hot and the cold yield stresses) in order to ensure eventual

elastic cycling.

:

y

a

°

e

e

@

9

°o

e

e

e

fooeeescsca ee O80

oeseeoeveeveee

Se

oO

8

°

e

°

9

e

e

e

e

°

°

Oyo @ ee ceoeeecono

COADE Pipe Stress Analysis Seminar Notes

py:

2sy

Elastic Shakedown’

(Relaxation)

Time—>

Figure 1-20

Based upon this consideration, the initial limitation for expansion stress design was set to

the sum of the hot and the cold yield stresses — the maximum stress range which ensured

that the piping system eventually cycled fully within the elastic stress range. Incorporating

a factor of safety, this resulted in the following criterion:

Sp <= F(Syc+ Syn)

Where:

Sg = expansion stress range, psi

F = factor of safety, dimensionless

Syc = material yield stress at cold (installed) temperature, psi

Syq = material yield stress at hot (operating) temperature, psi

1.2.4 Cyclic Reduction Factor

Atsome point, in the vicinity of 7,000 cycles, the (Sye + Syp) limitation intersects the fatigue

carve for carbon and low alloy steel. The allowable stress range must therefore be reduced

to fit the fatigue curve for cyclic applications with 7,000 cycles or more: \

Sp <= F £(Syc + Syn)

1-25

COADE Pipe Stress Analysis Seminar Notes

Where:

f= cyclic reduction factor, as shown in the accompanying table

CYCLIG REDUCTION FACTOR TABLE

cycles N Factor f

a to: 7,000 1.0

‘ 7001 = 14,000 0.3

14.001 + 22,900 0.8

22,001 + 45,000 07

45.001 —- 100,000 0.8

100,001 == ~—-200,000 0.5

200.001 = ~—- 700,000 0.4

700,001 - 2,000,000 0.3

1.2.5 Effect of Sustained Loads on Fatigue Strength

In almost all cases the material fatigue curves are generated using a completely alternating

stress; i.e., the average stress component is zero. Research has shown that the magnitude

of the mean stress can have an effect on the endurance strength of a material, the trend of

which is shown below:

me

ay,

“Ye

ajay Tay Sey

Auarnating s1e38 24

1 ‘at

eles tlre

a

‘oF

1-26

eeeccoeecas

"@@emoo0@eeeo se e008

5

eeveccesecogeeoeee

i

COADE Pipe Stress Analysis Seminar Notes _/

Note that as the mean stress increases the maximum permissible absolute stress (S, +S.)

increases, while the permissible alternating stress decreases. The relationship between the

allowable alternating stress and the average stress is described by the Soderberg line, which

ates fairly well with test data for ductilematerials. The equation for the Soderberg line

is:

S,(Allowed) = S,(for R=-1) x 1- Sp/Syieia )

Where:

R= Smin/Smax

SB. = max Smin)/2

Sm = (Smnax+ Smin)/2

Note that during the development of the ASME Boiler and Pressure Vessel Code Section III

rules and procedures for analysis of nuclear piping, the Special Committee to Review Code

Stress Basis concluded that the required adjustments to a strain-controlled fatigue data

curve based on zero mean stress, occur only for a large mumber of cycles (i.e. N > 50,000 «

100,000) cycles for carbon and low-alloy steels, and are insignificant for 18-8 stainless steels

and nickel-chrome-iron alloys. Since these materials constitute the majority of the piping

materials in use, and since most cyclic loading events comprise much fewer than 50,000

cycles, the effects of mean stress on fatigue life are negligible for piping materials with

ultimate strengths below 100,000 psi. For materials with an ultimate strength equal to or

greater than 100,000 psi, such as high strength bolting, mean stress can have a considerable

effect on fatigue strength and should be considered when performing a fatigue analysis.

For a piping application, the implication of the Soderberg line on the fatigue allowable is

implementedin aconservativemanner. Thesustained stress (Le., weight, pressure, ete, can

be considered to be the mean component of the stress range after system relaxation, and as

such is used to reduce the allowable stress range:

Sp <= Ff(Sy, + Syy- Ssus)

127

COADE Pipe Stress Analysis Seminar Notes

1.3 Stress Intensification Factors

As noted previously, Mark’s fatigue tests generated endurance curves for various fitting

configurations, such as straight pipe, butt welded pipe, elbows, mitars, welding. tees,

unreinforced and reinforced fabricated tees, mostly using 4” nominal diameter, size-on-size

fittings. Markl noticed that the fatigue failures occurred not in the middle ofhis test spans,

but primarily in the vicinity of the fittings, and in those cases, they also occurred at lower

stress/cycle combinations than for the straight pipe alone.

Earlier theoretical work pointed to a possible explanation. It had been shown that elbows

tend to ovalize during bending, bringing the outer fibers closer to the neutral axis of the pipe,

thus reducing the moment of inertia (increasing flexibility) and the section modulus

(increasing developed stress).

Ovelization

of Bend

Figure 1-22

‘The stress intensification factors (the ratio of actual bending stress to the calculated bending

stress for a moment applied to the nominal section) for elbows was known to be:

is =

y=

Where:

ib =

ios

he

tos

R=

ros

0.75 / bes

0.9 / hs

out-of-plane intensification factor

in-plane intensification factor —

flexibility characteristic

tR/rt

pipe wall thickness, in

bend radius of elbow, in

mean radius of pipe, in

j

eoeeccheeececn

oe

COADE Pipe Stress Analysis Seminar Notes i

Markl found this to correlate fairly well with his test data and so adoptedit. Tests on mitered

bends correlated well with those for smooth bends, providing an equivalent bend radius R

was used in the above equation forh. Markl's estimates of equivalent bend radius are shown

below:

Re = r(1 +0. s/r cot D) (for closely spaced miters)

Ro = r(1+cotD)/2 (for widely spaced miters)

Where:

Re = equivalent bend radius, in

s = miter spacing at the centerline, in

D = one-half of angle between cuts

‘Mari found that the unreinforced fabricated tees could be modeled using the same formula

as that for single (widely spaced) miter bonds could be used, fa half angle of 45 degrees was,

used. This produces a flexibility characteristic of,

ho = tfr

@oo@e ee oce80e930

For butt welded tees (such as ANSI B16.9 welding tees) Markl again adapted the bend

equations, this time computing an equivalent radius (R,) and an equivalent thickness (te).

‘Markl’s equation for welding tees was:

hoo = c(tyRe/r2)

Where:

" ¢ = ratio of tee-to-pipe section modulii, dimensionless

= (te/t)32 (Markl’s recommendation)

ty = equivalent pipe wall thickness, in

= 1.60t (Markl’s recommendation)

Re = equivalent bend radius, in

= 1.35r (Markl’s recommendation)

Inserting these values into the expression for h yields: i

ho = 44t/r

‘This is precisely the expression used today for ANSI B16.9 welding tees.

e

e

e

e

e

°

°

e

e

rel

9

Qo

e

e

e

8

68

e

e

e

1-29

COADE Pipe Stress Analysis Seminar Notes :

For reinforced fabricated tees, Markl used the expression he had previously used for welding

tees, with different equivalent wall thickness and bend radius:

o( te Ry/r2)

(t/t) (Markl’s recommendation)

te = ttty

thickness of reinforcing pad or saddle, in

Ree

‘The following tables compare the stress intensification factors suggested by Mark's test

results versus the values calculated with his equations (results are for 4" nominal diameter,

standard schedule pipe):

Bend in-plane (15)

trie Test Calculated

0.062 4.49 5.7428

0.210 2.17 2.5476

9.129 4.38 3.5238

0.320 2,02 1.9238

0.319 2.10 1.9286

0,316 1.90 1.9381

0,328 1.70 1.8904

0.331 1.53 1.8809

0.324 1.36 1,909

0.332 1.28 1.8762

0.328 1.46 1.8904

Lod

1-80

{

eeerocsr,eeccae

e

e

e

°

e

+

°

°

e

e

°

o

°

e

e

e

2.

e

°

°

°

°

° Unreinforced tee (4):

tir Test Catcutated

°

0.0390 11.06 10.84

°

0.0455 6.12 7.06

e

0.0947 2.98 4.33

°

o.nat 2.34 2.89

°

°

. Reinforced tee:

« 3 in-plane (if) out-plane (io)

~ tpad Test Ceiculated Test calcutated

0.12 2.21 2.63 2.43 3.17

0.237 178 17 1.83 1.98

0.8 110 i. 1.08 1.18

‘These formulas for intensification factors were adopted (and expanded) by the piping codes.

Specific formulas and/or fittings recognized by the individual ASME/ANSI B31 codes are

usually shown in Appendix D of those codes (see Figure 1-23).

SPS a Pee re MRM ca a

COADE Pipe Stress Analysis Seminar Notes é

25

APPENDIX D

FLEXIBILITY AND STRESS INTENSIFICATION

FACTORS

ume on

PLERILITY Faron e AND STRESS TEMEOTEATION ACTER

Tees” Bealame tow Curent

rate 7 a ne

‘ama of Fe 4 Ex.

tuymemiemiy 3h weet £

‘Sitar eed mm SEED igre

ct a.

Me

[2

2

cf

i

ten a a tee a?

#

M 4

ahh

eee =

eee Seg

ae gee 7

a Ta.

Hee, OBOE =

— BRET smcromet

eerie ee. wort to . =

eit 1 a

po eto to ty 2 mwa

a AE A et , .

er et ot nn fe ' B

rma nee a ert onan ose 8 a

es

a

3

°

°

e

°

>

y

e

e

e

“.

e

e

e

e

©

%

oO

e

°

e

°

°

°

e

e

°

Le

eeeoeeeveseee occ e ee soe oOo

peeecceeecog

COADE Pipe Stress Analysis Seminar Notes

Subsequent research has demonstrated that Markl’s formulas, having been based on a

limited number configurations (significantly having omitted reduced outlet tees) and

disregarding any need to intensify torsional stress, are inaccurate in some respects.

‘The major problem with reduced intersections tees lies in the out-of-plane bending moment

on the header. Stresses due to these moments can never be predicted from the extrapolation

of size-on-size tests. Figure 1-24 below illustrates the origin of this problem.

Mob ‘Aroa ot high

Mob

bending

sresees SS

Size-on-size Recuced Intersection

Figure 1-24

Errors due to these moments can be non-conservative by as much as a factor of two or three.

Furthermore, when the r/R ratiois very small, the branch connection haslittle impact on the

header, so use of large stress intensification factors for the header can produce unreasonably

large calculated stresses.

R.W. Schneider of Bonney Forge pointed out this ineonsistency for reduced branch connec-

tions. His paper on the subject states that the highest stress intensification factors occur

when theratio of the branch to header radii is about 0.7, at which point the nonconservativism

(versus Mark's formulas) is on the order of two.

a7 10 \

fk \

Ratio of Actual i to Markl's i vs

Ratio of Branch to Header Radius

Figure 1-25

COADE Pipe Stress Analysis Seminar Notes i

1.4 Welding Research Council Bulletin 330

‘The Welding Research Council’s Bulletin 330, “Accuracy of Code Stress Intensification

Factors for Branch Connections” documented a major attempt to re-asseés the existing code

requirements for the intensification of stresses at tees and other branch connections. The

difficulty of this task was summed upin the bulletin by author E. C. Rodabaugh, whostated:

“We would rate the relative complexity of i-factors for pipe, elbows and branch connections

by the ratios 1:5:500, These comments on relative complexity, we think, are relevant at this

point because at least some readers will be looking for simple answers to what they perceive

to be a simple subject. They will not find any simple answers in this report.”

Summarizing the findings of WRC 830 in order of increasing importance:

D

2)

3d

4)

5)

6)

‘The following note should be added with regard tobranch connection flexibilities:

“in piping system analyses, it maybe assumed that the flexibility is represented

by arigidjoint et the branch-to-runcenterlines juncture. However, the Code user

should be aware that this assumption can be inaccurate and should consider the

use of a more appropriate flexbility representation.”

ASME 2/3 and B31.1 users can use the “Branch Connection” expressions for

unrein forced fabricated tees whenever r/R < 0.5.(Mark’s formulas specified that

the same stress intensification factorbe used onboth the branch and header legs

ofa tee, regardless of relative sizes, The codes noted above permit the reduction

ofthe stress intensification factor at the branch forrelative diameters. CAESAR IT

automatically considers the effects of reduced intersections on the stress inten-

sification factors for these codes unless directed otherwise by the user through

the setup file.)

B31.1 erred when including the calculations for branch connection stress

intensification factors; instead they should have included the calculations as

they appeared in ASME II]. (Further clarification of this note is given in note

10 herein.)

81.3 should include the stress intensification factors for branch connections as

per ASME II, (B31.3 uses Mark's original formulas, thus specifying the same

stress intensification factor for both the branch and header of a tee, regardless

of relative sizes.)

B31.3 should intensify the torsional moment at branch connections, with the

torsional intensification factor estimated as: i; = (/R)io.

B31.3 should eliminate the use of ij = 0.75i, + 0.25 for branch connections and

tees. It can give the wrong relative magnitude for header moments, and may

underestimate the difference between M, and Mj for r/R ratios between 0.3 and

0.95, and perhaps over-estimates the difference for r/R ratios below 0.2 and for

oR = 1.0.

Q

8

°

.

e

o

oe

e

e

°

8

8

°

°

°

°

°

°

°

°

*

@

°

.

°

°

oS

%.

e

°

°

Q

COADE Pipe Stress Analysis Seminar Notes ‘

2)

8)

9)

10)

For (r/R)

ib

For (r/R)

B31,3 andB31.1 should add restrictions to the stress intensification factor tables

indicating that they are valid for R/T’ < 50.

‘The codes should add notes that indicate that the stress intensification factors

are developed from tests and/or theories based on headers being straight pipe

with about two or more diameters length of pipe on either side of the branch.

The codes should also add notes to indicate that for branch connections/tees the

stress intensification factors are only applicable where the axis of the branch pipe

is within 5 degrees of normal to the surface of the header pipe.

‘The stress intensification factors for unreinforced fabricated tees, weldolets, and

sweepolets should be changed to:

< 0.9:

= 1.5CRV/T)29 (1/R)V2 (r/rp}, with ip(t/T) > 1.5,

= 0.9 (R/T (rirp), with in(V/T) > 1.0

= 0.8 GVT}2S (IR), with i, > 2.1

intensification factor for branch (to be linearly interpolated for r/R ratios

between 0.9 and 1.0)

R= mean radius of header pipe, in

'T = thickness of header pipe, in

Additional

= mean radius of branch pipe, in

= outer radius of branch pipe, in

= thickness of branch pipe, in

= intensification factor for run (header) pipe

\

ly, if a radius of curvature rps provided at the connection, which is not less than

the larger of /2, (T'+¥)/2, or T/2, then the calculated values of iy and iy may be divided by

2.0, but with the restriction that ip>1.5 and i>1.5.

Also, where reduced outlets are discussed, branch ends should be checked using Z = p(r2)t

and i(t/T) in place of i, with i(V/T) > 1.0.

You might also like

- Offshore Piping Design: Technical Design Procedures & Mechanical Piping MethodsFrom EverandOffshore Piping Design: Technical Design Procedures & Mechanical Piping MethodsNo ratings yet

- Pipe Stress Manual CalcDocument62 pagesPipe Stress Manual Calcpipestress100% (8)

- Caesar Ii Pipe Stress Analysis TutorialDocument5 pagesCaesar Ii Pipe Stress Analysis TutorialRicardo A. Pol33% (6)

- Guide To Construction of Segmental BridgeDocument171 pagesGuide To Construction of Segmental Bridgenaqie_civil100% (9)

- Pipe Stress Analysis Intro PPS 180605Document34 pagesPipe Stress Analysis Intro PPS 180605Manjesh Kumar SinghNo ratings yet

- Concepts of Pipe Stress AnalysisDocument54 pagesConcepts of Pipe Stress AnalysisTejas Patel100% (12)

- 02 Stress Analysis of Piping System and Code Requirements ASME B31.3Document40 pages02 Stress Analysis of Piping System and Code Requirements ASME B31.3ballisnothing100% (2)

- Stress Analysis 1Document82 pagesStress Analysis 1Luis Ortiz100% (10)

- Questions For Stress AnalysisDocument3 pagesQuestions For Stress AnalysisSunday PaulNo ratings yet

- 01 - Hanger Sizing in CAESAR IIDocument40 pages01 - Hanger Sizing in CAESAR IIJimmy Alexander AvilaNo ratings yet

- Stress Analysis of Piping Systems and Pipelines - Harvard - UniversityDocument542 pagesStress Analysis of Piping Systems and Pipelines - Harvard - Universitykaruna346100% (11)

- DynamicsDocument28 pagesDynamicsLeandro Vargas100% (1)

- CaesarDocument32 pagesCaesarAndi Pramana80% (5)

- 2905 - Edgar EXPANSION JOINTS WITH CAESAR IIDocument45 pages2905 - Edgar EXPANSION JOINTS WITH CAESAR IIDivyesh Patel100% (1)

- Caesar Book MaterialDocument148 pagesCaesar Book MaterialCatur Oka Nurfansyah100% (11)

- Caesar II TrainingDocument22 pagesCaesar II TrainingPetar Jankovic50% (2)

- Stress Analysis of Piping Systems and Pipelines-Harvard UniversityDocument542 pagesStress Analysis of Piping Systems and Pipelines-Harvard UniversityRjeb mohamed100% (2)

- Calculated Stress in CAESAR II Software by Using Failure TheoryDocument6 pagesCalculated Stress in CAESAR II Software by Using Failure TheoryHùng Mạnh Nguyễn100% (1)

- Load Case CAESAR IIDocument6 pagesLoad Case CAESAR IIshakasspNo ratings yet

- Dynamic Module of CAESAR II PDFDocument68 pagesDynamic Module of CAESAR II PDFPrashant Agrawal100% (3)

- Load CombinationsDocument3 pagesLoad Combinationserikoh100% (1)

- Stress Analysis ReportDocument153 pagesStress Analysis ReportErarunv100% (6)

- Piping Stress Analysis SpecificationDocument1 pagePiping Stress Analysis SpecificationAdrian García Moyano100% (1)

- Importance & Impact of Stress Intensification Factor (SIF) : A PresentationDocument8 pagesImportance & Impact of Stress Intensification Factor (SIF) : A Presentationcasaean100% (1)

- Cryogenic Piping Stress AnalysisDocument6 pagesCryogenic Piping Stress AnalysismasilamaniNo ratings yet

- Trunnion Checking or Dummy Checking During Stress Analysis of A Piping SystemDocument2 pagesTrunnion Checking or Dummy Checking During Stress Analysis of A Piping SystemAmit SharmaNo ratings yet

- Fatigue Analysis W - CIIDocument10 pagesFatigue Analysis W - CIInaeand100% (1)

- Pipe Stress PDFDocument24 pagesPipe Stress PDFMichael Jones100% (1)

- Piping Stress AnalysisDocument159 pagesPiping Stress AnalysisSalah Eddine Ziani100% (1)

- Caesar II Modeling ExcisersDocument40 pagesCaesar II Modeling ExcisersBùi Văn Hợp100% (2)

- Screenshots of Pipe Stress Analysis in ActionDocument17 pagesScreenshots of Pipe Stress Analysis in ActionCepi Sindang Kamulan100% (2)

- Static & Dynamic Analysis of Piping SystemDocument105 pagesStatic & Dynamic Analysis of Piping Systemkarthikeashwar100% (4)

- Local Stresses WRC107Document19 pagesLocal Stresses WRC107naeand67% (3)

- NozzlePRO PDFDocument185 pagesNozzlePRO PDFRagupathy KulandaisamyNo ratings yet

- Stress Analysis NotesDocument127 pagesStress Analysis NotesArindomNo ratings yet

- Coade Pipe Stress Analysis Seminar Notes PDFDocument474 pagesCoade Pipe Stress Analysis Seminar Notes PDFAhmad Vawaid Sulthon100% (1)

- 16 Stress AnalysisDocument26 pages16 Stress AnalysisKusaila100% (1)

- Chemical Engineering - June 1997 - Pipe Design For Robust SystemsDocument9 pagesChemical Engineering - June 1997 - Pipe Design For Robust Systemshtaboada2008100% (1)

- Piping StressDocument30 pagesPiping Stresscharan100% (2)

- Sabp L 006Document8 pagesSabp L 006shafeeqm3086No ratings yet

- ASME Sec VIII Div 1Document120 pagesASME Sec VIII Div 1kanchanabalaji96% (23)

- KBR Piping Stress SpecificationDocument23 pagesKBR Piping Stress Specificationsamprof4vw83% (6)

- Asme Stress Linearization and Classification - A Discussion Based On A Case StudyDocument12 pagesAsme Stress Linearization and Classification - A Discussion Based On A Case Studysagar1503No ratings yet

- ASME Pressure Vessels Basic CalculationsDocument23 pagesASME Pressure Vessels Basic Calculationsdhasdj100% (17)

- Flare Piping Stress NalysisDocument7 pagesFlare Piping Stress Nalysisgpskumar22100% (1)

- Application of Peps in Stress Analysis of Nuclear Piping PDFDocument5 pagesApplication of Peps in Stress Analysis of Nuclear Piping PDFaaaaNo ratings yet

- Sabp L 006 PDFDocument8 pagesSabp L 006 PDFWNo ratings yet

- Paldex Seminar-2 - Stress AnalysisDocument75 pagesPaldex Seminar-2 - Stress AnalysisKumar Kote100% (1)

- Experiment # 2 Tension Testing of MetalsDocument3 pagesExperiment # 2 Tension Testing of MetalsJ. Fabián MenaNo ratings yet

- Stress Analysis of Oil and Gas Pipeline Parallel Laying When Traversing TunnelsDocument7 pagesStress Analysis of Oil and Gas Pipeline Parallel Laying When Traversing TunnelsTon PhichitNo ratings yet

- Piping, Fittings, and ValvesDocument9 pagesPiping, Fittings, and ValvesaasattiNo ratings yet

- FsafDocument24 pagesFsafpvmssonNo ratings yet

- SMiRT-23 Paper 093Document10 pagesSMiRT-23 Paper 093MAT-LIONNo ratings yet

- Pressure Cycling 2010051Document6 pagesPressure Cycling 2010051Sharath KrishnanNo ratings yet

- Detail Engineering MethodologyDocument11 pagesDetail Engineering MethodologyKumarJR86100% (1)

- Gasket FactorsDocument7 pagesGasket Factorsbalumagesh1979100% (2)

- Effect of Nozzle Stiffness On Nozzle Loads and StressesDocument12 pagesEffect of Nozzle Stiffness On Nozzle Loads and StressesJafer Sayed100% (1)