Professional Documents

Culture Documents

SDL800 Manual

SDL800 Manual

Uploaded by

SubdriverOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SDL800 Manual

SDL800 Manual

Uploaded by

SubdriverCopyright:

Available Formats

SOL 800 Laser Diode Driver

Userls Manual

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may resutt in hazardous radiation exposure.

Spectra Diode Labs

Copy right Spectra Diode labs 19B7 February 1990

Part Number: 0439 - 0173

SOL 800 Laser Diode Driver User's Manual

Contents

1.0

User Salely Figure:

1.1 CDRH Safety Labels

2.0 2.1 2.2 2.3

Initial Inspection and Tum-On Unpacking

Setting the Line Voltage and Selecting a Fuse and Power Cord lnttral Turn-On

3.0 Product Description

4.0 Specifications

5.0 Front Panel Description

51 Power

52 Detector Calibration

5.3 Current l.irrut

5.4 Setpoint Temperature

5.5 Digital Display

5.6 Bias Level.

57 Control Mode Select. rnA I mW

5.8 Analog Input

59 Laser Control: Error, On. Setup ..................

5.10 Laser and Detector

5.11 Laser Head

Figures:

5.1 Front Panel 5.2 5.3 5,4

Output Cable Assembly

Laser HeadlHeatsink, SDL-800·H Laser HeadlHeatsink, SDL-800·C

6.0 6.1 6.2 6.3 6.4

Rear Panel DescrIption _ ..

Recorder Outputs

TE Cooler Driver

Remote Interlock .. Power Modute FIgUres:

6.1 Rear Panel

...................................... 14

16

6.2

Power Module

2

3 3 3 3

4

5

7 7 7 8 8 9 9 9 9 10 10 10

7 11 12 13

14 14 14 15 15

7.0 Application Notes 17

7.1 Noise Susceptibility 17

7.2 Measuring the Vohage Across a Laser Diode 17

73 Using the TE Cooler to Control Wavelength. 17

7.4 Using Other Monitor Photodiodes .. 17

B.O Error Condhions 18

8.1 Error Light Blinking Rapidly 18

8.2 Error Light Blinking Slowly 18

83 Error Light On Steadily 18

9.0 Petformance Verification and calibration 19

9.1 SOL 800 Check-out Procedu re 19

9.2 SOL BOO Calibration Procedure 21

10.0 Service 23

101 Disassembling the SDL 800 23

10.2 Reassembly 24

10.3 The Main Board 25

Figure:

101 Main Board Assembly 26

11.0 WalTa nty Information 27

12.0 Parts List 28

13.0 Schematic Diagrams 32

13.1 Power Supply

13.2 Front Board

13.3 Main Board Contents

SDL-800 Laser Diode Driver User's Manual

1.0

User Safely

I GROUND THE POWER SUPPLY

To minimize shock hazard, the power supply must be connected to an electrical ground. The power supply is equipped with a three-conductor AC power cable which must be plugged into an approved three-contact electrical outlet.

I VERifY LINE VOLTAGE SELECTOR SEmNG

Before connecting the line cord, verify that the line voltage setting in the power module agrees with local line voltage. (See Section 6.4 and Figure 6.2)

I REMOVING THE COVER

WARNING:

Dangerous voltages exlS1lnSIde the power supply, even with the power switched off.

Only qualified service personnel sllould remove the cover.

I SERVICING

There are no user replaceable parts inside the power supply. Refer all servicing to qualified personnel. (See Section 10.0)

I FCC COMPLIANCE

WARNING:

This equipment generates, uses, and can radiate radio frequency energy and If not Installed and used In accordance with the Instruction manual, may cause Interference to radio communications. It has been tested and found to comply with the limits for a class A computing device persuant to Subpart J 0' Part 1S 0' fCC I\IIes, which are designed to provide reasonable protection against such Interference when operated In a commercial environment. Operation of this equipment In residential areas Is likely to cause Interference, In which case, the user, at his own expense, will be required to take whatever measures may be required to correct the Interference.

I LASER SAFETY WARNINGS

The laser light emitted from laser diodes is invisible and may be harmful to the human eye. Avoid looking directly into the laser diode or into the collimated beam along its optical axis when the device is in operation.

Operating a laser diode outside of its maximum ratings may cause device fail UTe or a safety hazard.

See laser data sheets and the SDL Operator's Manual (for laser diodes) for additional information,

Figure 1.1

CDRH SAFETY LABELS

Serial Number Label

(

Spectra Diode labs

F==-"'c" '~:-., ,'-',1 ,~1I';\J.1""'" 't',' '.

Mll::,fl S~ _._.

I

Danger Label

SDL 800 Rear Panel

1.0

User Safety

SDL-BOO Laser Diode Driver User's Manual

2,0

Initial Inspection and Turn-On

21 UNPACKING

Upon receipt, carefully inspect the shipping container for damage, Carriers will not accept claims for damage unless all shipping materials are saved.

2.2 SETTING THE LINE VOLTAGE AND SELECTING A FUSE AND POWER CORD

See section 6.4 for a description of the power module. Verify that the line voltage selector and fuse are set properly. At the present lime, all units arc shipped with a U.S.A. style power cord. You may need to obtain a power cord compatible with local power distribution outlets.

2.3 INITIAL TURN ON

Read This Manual Before Connecting A Laser Diode to the SOL-BOO

CAUTION:

Lasers may be damaged by Improper S(!ttlng of the current limit and bias controls or by Improper use of the analog Input, See sections 5.3, 5.6, and 5.8. Check the line voltage selector and fuse before connecting power,

The remote interlock plug must be installed in the rear panel. It is installed when shipped. If it is not in place, the SDL gOO ERROR light will remain on and the unit will be inoperable.

Use Section 9.110 verify proper operation upon receipt.

The SOL-ROO Laser Diode Driver may be used to power laser diodes requiring up to lOOO mA of drive. Current control or optical power monitor modes may be selected. An adjustable current Emit helps protect the diode from accidental overdrive. The SDL 800 contains a thermoelectric cooler driver which is compatible with SDL laser products.

Features which help protect laser diodes arc: power line filtering, low line voltage detection, open circuit detection, high speed current limit. built-in dummy setup diode, missing monitor photodiode detection and automatic shorting of the laser diode terminals during output switching.

1\ front panel key switch and rear panel remote interlock connector are provided to assist s<t[c usc of the SDL 800 and associated laser diode.

Rear panel connectors allow monitoring the laser current and power. and provide direct access to the thermoelectric cooler driver for special control applications.

Several laser diode mounts with cable and matching connector are available.

3.0

Product Description

III

SDL·BOO Laser Diode Driver User's Manual

4.0 Specifications

-

CURRENT CONTROL MODE Display Mode

Range

Resolution

Accuracy

Bias Level Range

Analog Input Range 1 Scale FaClor

Scale Factor Accuracy Bandwidth

Stability, Short Term Temperalure Coefficient

OPTICAL POWER CONTROL MODE Display Mode

Range

Resolution

Accuracy

Display Mode Range Resolution Accuracy

Detector Calibralion Range Bias Level Range

Analog Input

Range Scale FaClor

Scale Factor Accuracy Bandwidth

Temperature Coefficient

CURRENT LIMIT Display Mode Range Resolution

Accuracl

TEMPERATURE Display Mode Range Resolution Accuracy3

Setpoinl Temp. Adjustment Range Thermoelectric Cooler Current

Ext. TEC Drive (rear panel)

Range Scale Factor

Accuracy of Scale Factor

AVERAGE CURRENT 010 1000 mA

1 mA

± 5 mA plus 0.5% of reading 10 to 1000 mA

010 1000 mA

1 mAlmV, 1 V Full Scale

± 10 rnA plus 3% 01 reading

Typically, 100 kHz for load impedance <20.

Typically, 5 JlA p-p Typically, 100 ppml°C

AVERAGE POWER o to 200 mW

1mW

± 1 mW plus 5% of reading PEAK POWER

o to 200 mW

1mW

± 4 mW plus 5% 01 reading 2 10 20 IlA'mW

2 to 200 mW

o to 200 mW

0.2 mW/mV, 1 V Full Scale ± 2 mW plus 3% of reading

> 100 kHz for load impedance" 2 n Typically, 100 pprn/'C

CURRENT LIMIT 10 to 1000 mA

1 rnA

± 5 rnA plus 0.5% of reading, only specified for currents> 25 rnA

ACTUAL or SETPOINT ·20 to 40 °C

0.1 DC

± 1 °C from -to io 30"C ± 2°C from ·20 to 40°C ·10 OCto 30 °C

o 10 1.5 A continuous

o to 3 V lVIV

± 10mV

MONITOR OUTPUTS Output Impedance Current

Scale Factor

Accuracy of Scale Factor Power

Scale Factor

Accuracy of Scale Factor

4.0 Specifications

REMOTE INTERLOCK Open Circuit Voltage Short Circuit Current Open Interlock

5V± 10% <1 mA

Tums laser OFF

1 mV/mA ±1mA

1 mV/mW ±1mW

GENERAL

Operating Temperalure Storage Temperature Power

10t040¢C -40 to 75°C

100. 120. 220. 240 VAC +5%, -10%,481066 Hz

Size

6"Hx13"Wx12"D

(150 mm x 330 mm x 300 mm)

Weight

Bib. (4 kg)

NOTES:

t, The sum of bias and analog currents will limit at the current limit setting

2. Total error between displayed current limit and displayed average cutrem in current limit mode may be as high as the sum of the accuracies for these two values.

3. The thermistor presently used by SOL has a ±5% tolerance at 25 "C. ±8% at .t 0 DC, and ±6% at 30 DC. Corresponding temperature errors are ±1.2, ±1.5. and± 1.5 DC.

SDL 800 ENCLOSURE DIMENSIONS

o 0 lZZJl g o 10:0 Q) I

........ -...- I

SDLBOO

6.00 (ISO mm)

o

Q) Q) 0

•

•

L

13.00 (330 mm)

L

12.00 (300 mm)

_J

-

SOL-SOD Laser Diode Driver User's Manual

Figure 5.1

SDL BOO FRONT PANEL

5.0

Front Panel Description

..

5.1 POWER

This switch controls the line power. It is a key switch and the key is removable only in the OFF position to allow safe use of the SDL 800. A separate switch, the laser control. IS used to control power 10 the laser diode.

5.2 DETECTOR CAL

This control calibrates the optical power mode for use with monitor photodiodes with a range of calibration factors from 2 to 20 ].lNmW,

CAUTION:

If the control is improperly set, the laser diode may be driven to current limit when power feedback is selected.

Four methods may be used to set the detector calibration control:

1. The calibration factor mav be set directlv from the SDL data sheet.

This is the simplest way, 'but is su bjcct to limits in reading the scale on the front panel.

2. The laser diode may be operated in current mode at the operating current given on the data sheet while monitoring power and adjusting the detector calibration control to read the correct power. Note that the diode should be operated at the temperature specified on the data sheet. This method eliminates scale reading but is subject to variation in output power with temperature and time.

3. The laser may be operated in current mode while monitoring optical power and adjusting the detector calibration control to match the acmal output power as indicated by an external calibrated power detector. This method is accurate but requires a calibrated power meter. Make sure the power meter intercepts all the output from the laser. The detector should intercept a solid angle of approximately 85°.

4. With no laser connected. a I ill resistor in series with an ammeter may be connected to the front panel DETECTOR B]\'C connector. Divide the ammeter reading in ~A by the data sheet monitor photodiode value in ,UNmW. Adjust the detector calibration control until the average power reading matches the calculated answer. For example, a reading of 2,500 )J.A (2.5 rnA) and 10 )J.NmW corresponds to 250 mW. This method accurately sets the control to match the MPD calibration number but requires a resistor and an ammeter.

5.3 CURRENT LIMIT

Drive current for both the dummy setup diode and the laser diode will not exceed the value set by this control. This control should be set before switching power from the dummy load to the laser diode. The setpoint may be read on the display by selecting the CURRENT LIMIT, rnA display mode.

The ERROR light wiil start to blink when the actual current is within about 10 rnA of the current limit value. A suggested setting is the data sheet value for operating current plus 10 rnA. If the operating current is not specified, a low initial setting is recommended. If current limit is activated, the ERROR light will blink.

CAUTION:

The current limit setting should be changed when changing lasers.

5.4 SETPOINT TEMP

This control sets the temperature the thermoelectric cooler controller will attempt to maintain. The setpoint value is read out on the main display by selecting the SETPOINT TEMP, °C display mode. In order to work accurately, this control must be used with the thermistor described in Section 4.0, Note 3.

5.0

Front Panel Description

-

SDL-SOO Laser Diode Driver User's Manual

5.0

Front Panel Description

5.5 DIGITAL DISPLAY

This display allows observation of one of the parameters indicated to the right of the display. The active parameter is indicated by a lighted LED annunciator. Parameters are selected by pressing one of two buttons located to the right of the display window which move the annunciator up or down one line per press.

5.6 BIAS LEVEL

This lfl-turn control adjusts the bias level for either operating current or power, depending on the control mode selected. The bias level varies from a to full scale.

CAUTION:

When changing control mode, the bias level should be turned CCW to Its minimum value because the required setpoint for one control mode will differ from the setpeint for the other mods,

NOTE: The bias current may be set to indicate a negative value of up to -10 rnA all some units. This current does nor actually flow through the laser diode.

5.7 CONTROL MODE SELECT, rnA I mW

This button changes the control mode between current and optical power. The optical power mode may be entered only when the laser diode is "on" and if a monitor photodiode is present. An annunciator is located to the left of rnA and mW.

One will be lighted to indicate the active mode. (See caution regarding BIAS LEVEL in Section 5.6).

NOTE: If the display is reading peak power and the control mode is switched from rnA to mW, a transient will be seen on the display. It is caused by the MPD test and does not indicate a laser diode pulse.

5.8 ANALOG INPUT

This BNe connector allows an external signal to be added to the bias level. It is direct coupled and may be used to set the bias level remotely or to sweep the drive. The 0 to 1 volt input range corresponds to a to full scale for the active control mode.

CAUTION:

The analog Input may overdrive the laser If excessive voltage is applied.

Current limit operates on the sum of the bias level and analog inputs and will protect the laser diode if properly set.

5.9 LASER CONTROL: ERROR, ON, SETUP

This button selects whether the internal dummy load or the laser diode is connected to the drive circuitry. One of three indicator lights located to the left of each label will be lighted.

I SETUP means the internal load is connected.

I ON means the laser is connected. If the SETUP light is blinking when the ON light is lit, power will be applied to the laser diode after a 10 second delay. The delay is provided to comply with safety requirements,

I ERROR means some error, such as current limit, has occurred or is occuring, Some errors prevent switching the output to ON. See Section 8.0 for more information on error conditions.

5.10 LASER and DETECTOR

These two BNC connectors duplicate the laser output and monitor photodiode input connections of the LASER HEAD connector. They allow alternative access to the laser drive and detector amplifier circuits. The LASER BNC can be used to drive a laser through a coaxial cable. The DETECTOR B!\i'C can be used as an input connector for an external phorodiode.

CAUTION:

These connectors are connected directly across the laser diode and monitor photodiode terminals of the LASER HEAD connector.

511 LASERHEAD

This connector allows connecting optional heatsinks or cables to the SDL 800. It carries laser drive, thermoelectric cooler drive, monitor photodiode and thermistor signals. The matching plug installs with the key in the metal shell facing up. The output cable wire color code is shown below. Optional heatsinks inelude the SDL-800-H (for HI, ill, and H7 packages) and the SDL--8oo-C (for Cvblock packages.) See Figures 5.3 and 504 on the following pages.

5.0

Front Panel Description

SOL-BOO Lasar Died. Driver User's Manual

5_0

Front Panel Description

IiII

Figure 5.2

OUTPUT CABLE ASSEMBLY

Cable length: 70 inches

COLOR FUNCTlOI'

EU<' THERM1STOR (I)

BRN' TIlERMlSTOR 121

IUD LASERIAI

ORN LASERIC)

YEl.' TE.e ~ .. )

GRN' nc()

BLU' MPDIAI

VIO' MPOICI 'These wires are not connected when using the SDl-SOO-C haatsink

Figure 5.3

LASER HEAD I HEATSINK SDl·800·H

® ~ \

CD !

r 1/4·20 ihr8aded Mounting HD~e

! /

L ., .

I?'--\-

0)

/ (j)

I I

L. _-

,.

.~ See Fig",.. 5.2

QUTI'UT CAB~E ASSEMBLY

ITEM

OTY

DESCRIPTION

1

2 3 4 5 6 7 8 9 10 11

HEATSINK BODY (SDL 800·0100) CABLE ASSEMBLY (SDL 900·6002) STRAIN RELIEF IHEYCO 3210) LASER DIODE

FRONT MOUNTING PLATE (SDL soc-oi 01) SOCKET ASSEMBLY. 8 PIN (AUGAT 9112·AG6) DIODE. IN414S (CATriOOE TO PIN 5)' WASHER 2·56

P.H., 2·56 X 114'

P,H., 6·32 X 5116'

F.H .. 8·32 X 112"

1 1 1 4 2 2 4

SIZE: 2.S·H x 2,5"W x 3.0'0 (S4mm x S4mm x 76mm) WEIGHT: 1.4 Ibs (.64 kg)

INSTALLATION NOTE

W9ar a ground9d wrist strap when handling IhBlas", dkxie. Conl"lfJd /h ... Ias ... r hBad 10 !he SOL· BOO, (p/r.Jgg9d in) 10 ground Ih .. beea. T.ghlBn IasBr mounting sc"',... 10 insu", sd9qual" haa/· sinking.

'The IN4148 diode is installed to reducs possible state discharge transiar-ts.

5.0

Front Panel Description

SOL-BOO Lase, Diode Drive, User's Manual

5.0

Front Panel Description

Figure 5,4

LASER HEADIHEATSINK SDL·800-C

'14·20 Th'a.aoa Mounting Hole

\

(r- I

(pJ-_j--

cb CD

s..Flf1I/"'S.2

OUTPUT CABLE ASSEMBLY

\

CD

CD

ITEM

aTY

DESCRIPTION

1

2 3 4 5 6 7 e 9 10 11

1 4

HEATSINK BODY (SOL 800-(100) CABLE ASSEMBLY (SOL 800-6002) SmAIN RELIEF (HEYC03210) LASER OIODE

FRONT MOUNTING PLATE (SOL 800-01 02) INSULATED TERMINAL

DIOOE,IN4148 (CATHODE TO LUG)' SOLDER LUG, 6-32

P.H., 2-56 x 114'

P .H., 6-32 X 3116'

F.H., 8-32 x 1 t.:!'

SIZE: 2.5"1-1 x 2.5"'N x 3.0"0 (64mm x 64mm X 76mm) WEIGHT: 1.41bs (.64 kg)

INSTA11ATIONNOTE:

W .. er a groundlld ",tis, strap whfJn handling th .. laser diod .. , Allach IhfJla ... r diad .. to Ill .. I"" .. r lt9ad betor. .. sold .. ring rha /sad. Connact!ha lasa, hsad to tha SDL.aOO, (pluggfld in) to ground rll .. lt9ad. USB a grounded k>w pow'" soldering iron (40 Watts 0, less is f9CO(7Im .. nded) and do not IBt smok e from rhe flux ge/ on the lase, diods.

'The IN4148 diode is installed to ,educe possible static discharge transients.

Flgl.lre6.1

SDL 800 REAR PANEL

These connectors allow monitoring the laser diode drive current and output power (if the laser is equipped with a monitor photodiode.) Both signals have an output impedance of about SeX) n and are designed to be used with high input impedance measuring equipment The outputs are short circuit protected.

6.0

Rear Panel Description

61 RECORDER OUTPUTS

I CURRENT: This ENe output provides a voltage proportional to the current flowing through either the internal dummy load or the laser diode. The scale factor is I mY /mA.

I POWER: This ENe output provides a voltage proportional to the monitor photodicde signal. Assuming the detector calibration adjustment on the front panel is set correctly, the scale factor is 1 mV/mW

6.2 TE COOLER DRIVER

A BNC connector and a toggle switch are associated with the TE cooler drive circuit.

The BNC connector allows an external signal to be applied to the thermoelectric cooler drive circuit when the TE cooler source switch lS placed in the EXTERNAL position. A signal between 0 and 3 volts "ill be buffered with unity gain and applied to the TE cooler connections of the LASER HEAD connector. Posiuve

SDL·800 Laser Diode Driver User's Manual

6.0

Rear Panel Descri pti 0 n

&Ell

voltage results in cooling action. Negative input voltages result in a TE drive voltage of about O. Heating action must be provided by the power dissipated by the laser diode.

The toggle switch connects the thermoelectric cooler driver either to the internal temperature control signal when in INTERNAL position or to an external drive signal when in the EXTERNAL position.

CAUTION:

Operating a TE cooler-equipped laser diode with the switch in the EXTERNAL position may cause the laser diode to overheat. Cooling will not occur in the EXTERNAL position unless an appropriate input signal is provided.

6.3 REMOTE INTERLOCK

This connector is provided 10 comply with safely requirements. The plug supplied is jumpered internally and it must be in place for the power supply to drive a laser. If it is desired 10 usc the interlock feature. remove the jumper in the connector and replace it with ,I circuit which will be closed in the "safe" position and open when the interlock is broken.

6.4 POWER MODULE

The power module allows changmg line cords to match local outlets. holds the main line fuse and allows matching line voltage to one of 4 choices by removing a small circuit board in the module. Use a pair of pliers to extract the voltage selecting circuit board if it needs to be changed.

WARNING:

Verity that the line voltage selection and fuse are correct for your installation before applying power to the unit. Make all required changes with power removed from the equipment.

1 and 1/2 Amp fuses are provided with each unit.

lJOe Voltage = 120

Voltage Selection Circuit Board

uns Voltage = 100

ru" 0'

t·:·~.·. ~;~:':-:-:""

CHECK FuSE 00 L

220 3sn, >03HO

CHECK FUSE 0(';('; 100 3S0, >:JlH:J

,,::.;.,. .

"""",0,

Power Cord

(Supplied Wilh SDL 800)

SDL-800 Laser Diode Driver Users Manual

7.0 Application Notes

7.1 NOISE SUSCEPTIBILITY

Noise may be seen on the monitor outputs when using an oscilloscope. The internal noise is typically under I mV pop. Noise may be coupled into the circuits from external sources located near the power supply. One cause is ungrounded conductive surfaces on which the SOL 800 may be placed. Another cause is ground loops which are formed between the rear panel safety ground connection of the power cable, rear panel cable connections, the laser head case, or the drive cable shield.

7.2 MEASURING THE VOLTAGE ACROSS A LASER DIODE

When using the LASER HEAD connector, the voltage across the laser diode may be observed at the LASER BNC connector. The drive current flowing through the standard output cable induces an error of about 0.1 m V /rnA of laser current.

CAUTION:

This procedure Is mentioned but not recommended because the LASER BNC connector Is directly across the taser, Use extreme care when using this procedure. Installing a 10 kn resistor between the center BNC

terminal and the measuring equipment Is a precautionary measure.

7.3 USING THE TE COOLER TO CONTROL WAVELENGTH

The wavelength of SOL laser diodes varies about 0.3 nmf'C of temperature shift. The SETPOINT TEMP control may be used to wavelength tune a laser. Alternatively, the EXTERNAL TE cooler drive input (rear panel) may be connected to a usersupplied circuit which controls wavelength directly. One way to implement a wavelength senscr is to subtract the outputs of two photodiodes recording light through two optical bandpass filters. One should have a center frequency higher than that desired and the other, lower. The passbands should overlap.

7.4 USING OTHER MONITOR PHOTODIODES

Other photodiodes may be connected to the DETECTOR BNC or the appropriate leads of the output cable (see Figure 5.2) The photodiode should be rated for at least 5 V reverse bias and have a rise time into 50 n of less than 50 nsec. The effective output in JlNmW must fall in the range of the DETECTOR CAL control to ensure front panel display accuracy.

Consult SOL for other applications.

The ERROR light associated with the output control button is activated by the conditions shown below. The errors may be simulated using the procedures in Section 9.1.

8. t ERROR LIGHT BLINKING RAPIDLY

This condition will occur as long as the driver is in current limit (Transient current limiting will cause the ERROR light to blink for about 1 second)

8.2 ERROR LIGHT BLINKING SLOWLY

This condition will occur for two reasons:

I. Open Laser Circuit - An attempt is made to switch from SETUP to ON with no laser diode. The output will remain in SETUP. One exception occurs if the bias current is set to O. In this case the open circuit detector triggers only if the drive signal forward biases the laser diode. Reverse biasing is eliminated without generating an error.

2. Missing Monitor Photodiode - An attempt is made to switch from current mode to power mode while in SETUP, or while in ON without a monitor photodiode. The mode control will remain in current mode (mA).

8.3 ERROR LIGHT ON STEADILY

This condition will occur for two reasons:

I. Low Main Power Supply Voltage - The AC power input drops below about 80% of nominal. The output control will switch from ON to SETUP if necessary, and the output drive will switch off. The unit "locks up" until the line voltage increases.

2. Remote Interlock Plug Missing (interlock circuit open) - Results in same consequences as reason # 1. Replace the interlock plug to restore normal operation. See paragraph 6.3 and 9.1-13.

8-0

Error Conditions

SDL-8DD Laser Diode Driver User's Manual

9.0 Performance Verification and Calibration

..

9.1 SDl800 CHECK-OUT PROCEDURE

This procedure verifies the basic operation of the power supply. Each item listed below should be performed by the operator prior to use of the driver with a laser diode. If a reading appears to be in error, check the Specifications, (Section 4.0, page 5) for the allowable error.

I. Power Up - After verifying the selection of proper line voltage and fuse, and inserting the remote interlock plug, plug in the unit and turn the POWER key switch to ON. The digital display and the CURRENT LIMIT and SETUP annunciators should light.

2. Display - Turn the CURRENT LIMIT adjust control knob from full CCW to full CWo The display should vary from about 0 to about WOO (rnA) as the knob is rotated.

3. Current Mode - Adjust CURRENT LIMIT to about 1000 rnA then switch the display to AVERAGE CURRENT. Vary the BIAS lEVEL control approximately to turns from CCW to full CWo The display should vary from about 0 to 1000 (mA).

4. CUrrentllm~ - With the BIAS lEVEL full CW, vary the CURRENT LIMIT from full CCW to full CWo The ERROR light should blink. The average current should vary from about 0 to 1000 (rnA).

5. Photodetector Amplifier and DETECTOR CAL - Switch the display to AVERAGE POWER. With no laser connected, the display should read about 0 (mW). Connect a 1 ill, 1/4 W resistor across the DETECTOR BNC connector. With the DETECTOR CAL knob full CCW, the display should read about 1250 (mW). Rotate the DETECTOR CAL knob full CWo The display should read about 125 (mW).

6. Peak Power - Connect a I ill, 1(4 W resistor across the DETECTOR BNC connector. Switch display to PEAK POWER. Rotate the DETECTOR CAL knob full CCW, pause, then rotate it quickly full CWo The display should drop from about 1250 to about 125 (mW) over a period of about one second.

7. Selpalnt Temp - Switch the display to SETPOINT TEMP. Vary the SETPOINT TEMP control from full CCW to full CWo The display should vary from about -10.0 to 30.0 (eC).

8. Actual Temp - Switch the display to ACTUAL TEMP. With no laser installed, the display should read about -35.5 "C. Connect the output cable to the LASER HEAD connector. Short the black and brown leads together. The display should read about 68 DC. Connect a 10 ill resistor to the black and brown leads (remove short first), The display should read about 25 "C .

9, TE Cooler Drive - Connect the output cable to the LASER HEAD connector. Connect a JO kn resistor between the black and brown leads and a 1 n, 10 W resistor between the green and yellow leads. Connect a voltmeter with a 10 volt scale, negative to green and positive to yellow, Set the display to ACTUAL TEMP and record the reading. Switch the rear panel TE drive switch to INTERNAL.

Switch the display to SETPOINT TEMP and adjust the SETPOINT TEMP control to about -10 "C. The voltmeter reading should be about L6 V, Adjust the serpoint to 5° above the ACTUAL value. The voltmeter should read about -50 mV. Adjust the setpoint to the ACTUAL reading, Vary the setpoint slightly about the ACTUAL reading.

The voltmeter reading should ramp up and down between the two voltage readings observed above.

10. MISSing Monitor PhotodJode Error· With no laser connected, press the control mode button to switch from mA to mW. The ERROR light should blink.

11. Tum-on Delay and Open Circuit Error - With no laser connected, press the output control button to switch from SETUP to ON. The SETUP light should blink for about 10 seconds. followed by slow blinking from the ERROR light for about 2 seconds. The BIAS LEVEL must be adjusted to a positive average current in SETUP before the open circuit will function.

12. Low Line Voltage Error - If available, connect the unit to power from a variable AC source (e.g., autotransformer). Lower the supply voltage from nominal. At about 80% of nominal line Voltage, the ERROR light should come on steadily (it may cycle off and on slowly at threshold). The threshold varies with load conditions inside the SDL 800,

13. Remote Interlock - Remove the REMOTE INTERLOCK plug. The ERROR light should come on steadily. Replace the remote interlock plug.

9.0 Performance Verification and Calibration

SOL -BOO Laser Diode Driver Users Manual

9.0 Performance Verification and Calibration

-

9.2 SDL 800 CALIBRATION PROCEDURE

Four adjustments are provided for calibration of the SDL 800. In addition to the four internal adjustments, the DETECTOR CAL knob must be repositioned to match the panel scale whenever the knob is removed. All adjustments should be made after the unit has been on for at least 1(1 hour.

WARNING:

Dangerous voltages are present In this product even when the power switch is OFF. Only experienced service personnel should attempt calibration.

I. Two Vah Reference - Connect a voltmeter with accuracy of at least I mY when reading 2 volts to Test Point 2 (TP2) and TP3. Adjust the 2 Y AD] control to set the measured voltage to 2 Y ± 1 mY.

2. Current Limit Adjust - Using the digital display, set the CURRENT LIMIT to 2()() rnA ±5 rnA. Record the exact value. Switch the display 10 AVERAGE CURRENT and increase the BIAS LEVEL control until the ERROR light blinks. then one tum CW more. This step forces the current limit loop to operate.

Adjust the CURRENT LIMIT OFFSET control until the average current matches the current limit serpoint within I rnA.

3. Power Offset Adjust - Turn the DETECTOR CAL control knob full CCW. Connect a voltmeter with accuracy of at least 0.1 rnV when reading 100 mY to TPI and TP3.

Adjust the POWER OFFSET control for a reading of 0 ± 0.5 mY.

4. Detector calibration Adjust - Turn the DETECTOR CAL control knob full CCW. Move the DETECTOR CAL jumper to the TEST position. Connect a voltmeter with accuracy of at least 1 mY when reading 1 Y and 0.1 mY when reading 100 mY to TPI and TP3 Record the reading.

Turn the DETECTOR CAL knob full CWo Adjust the internal DE· TECTOR TRIM control until the reading is exactly one-tenth the value recorded when the knob was full CCW. ±O.I mY.

Return the DETECTOR CAL jumper to its normal position (NORM.)

5. DETECTOR CAL Knob Adjust - Remove the DETECTOR CAL jumper and connect an ammeter in series with the inboard and middle pins. Divide the current reading in IlA by 10 (JiNmW) and record the result.

If replacing the DETECTOR CAL knob, rotate the bare shaft until the average power displayed matches the number recorded above. Carefully install the knob with white-line indicator aligned to "10" on the panel. Without rotating the shaft. tighten the setscrews of the knob. When checking the knob, rotate the knob until the average power display matches the number recorded above, then check for knob indicator alignment to the "10" on the panel.

Return the DETECTOR CAL jumper to its normal position.

NOTE: Because the set screws dig into the shaft when installed, it is not possible to make small corrections to the knob after the firs! installation. The screws will locate themselves illIo their previous positions as they are tightened.

9.0 Performance Verification and Calibration

SOL-BOO Laser Diode Driver Use(s Manual

10.0 Service

WARNING:

Dangerous voltages are present in this product even when the power switch Is OFF. Only experienced service personnel should attempt repaIrs.

Use a low power soldering Iron and rosin core flux only.

101 DISASSEMBLING THE SOL 800

1. forcatlbratlon:

The SDL 800 is held together by four (4) screws on the bottom. Tum the instrument over on a soft surface and remove the four screws which pass through the feet. (The feet will also corne off).

Turn the instrument right-side-up on the soft surface. (The plastic enclosure consists of a top. bottom and two sides, with the top and bot- 10m sandwiching the sides.) With the 4 screws removed. working carefully around the enclosure one corner at a time, gradually pull the top cover from the side rails. It will take several cycles around the corners to remove the top.

After the top has been lifted off, all calibration may be performed without further disassembly.

2. for further servICe:

After removing the top cover as described above, carefully lift the front board up out of its connector.

WARNING:

DO NOT disconnect the wire from the front panel to the main board.

Remove the four (4) screws in the comers of the main board. Lay the front board on top of the main board. Grasp the transformer and rock the rear panel slightly 10 ease it out of the groove in the plastic enclosure. Hold the transformer and front of the main board and lift the assembly out of the plastic enclosure.

To remove the front board from the front panel remove the three (3) small knobs and the one (I) larger knob from their respective shafts. Remove the five (5) screws holding the front board to the front panel. Lift the board away from the panel.

WARNING:

DO NOT disconnect the wire from the front panel to the main board.

10.2 RE-ASSEMBLY

Reassembly proceeds in the reverse order of disassembly. When placing the assembly in the enclosure ensure that the rear panel drops into the groove on both sides as it is lowered into the enclosure. When reassembling the front panel, install all screws loosely and position board for smooth button operation, then tighten the screws. Route the green safety wire so that it is not between the front board and the main board.

10.0 Service

SDL·800 Laser DiOde Driver users Manual

10.0 Service

10.3 THE MAIN BOARD (See Figure 10.1)

1. Jumpers (the main board has 6 jumpers ):

J6 Isolates (V+) power. Current through J6 with no laser connected and current limit at 0 should be about 10 mAo

J7 Isolates (V.) power. Current under same conditions above should be about 80 mAo

J8 Isolates (5V) power. Current under same conditions above should be about 300 rnA.

J9 Isolates the current loop from the other feedback loops. J 1 0 Supplies a substitute signal 10 the photodiode amplifier.

J 11 Allows connecting a known voltage to the front panel DVM circuit Connect the voltage between TP3 and the middle pin of J II with the jumper removed.

2. Test POints (the main board has 3 test points):

TPI Used to calibrate the photodiode circuits TP2 Used to adjust the 2 volt reference

TP3 The ground reference for all analog circuitry.

FIgure 10.1

MAIN BOARD ASSEMBLY SDL 800

J9

J8 J7 J6

TP 1

POWER OFFSET

CURRENT 2 V TP 3 TP 2

LIMIT ADJ

OFFSET

J 11

DETECTOR TRIM

Jl0 DETECTOR CAL JUMPER

SOL-800 laser Diode Driver User's Manual

11.0 Warranty Information

Unless otherwise specified, all Spectra Diode Labs products are unconditionally warranted to be free from defects in workmanship and materials for a period of 90 days from date of shipment. The warranty does not apply to devices which have been damaged due to operating conditions outside the limits shown on the appropriate data sheet This warranty is in lieu of all other warranties, expressed or implied, and does not cover incidental or consequential loss.

Liability under this warranty is limited to repairing, replacing, or giving credit for the purchase price of any equipment which proves to be defective during the warranty period, provided prior authorization for such return has been given by an authorized representative of Spectra Diode Labs. In-warranty repaired or replacement equipment is warranted only for the remaining unexpired portion of the original warranty period applicable 10 the repaired or replaced equipment.

This warranty does not apply 10 equipment or components not manufactured by Spectra Diode Labs. When SDL products manufactured by others arc included in Spectra Diode Labs equipment, the original manufacturer's warranty is extended to Spectra Diode Labs' customers.

This warranly does nOI apply to equipment or components which inspection by Spectra Diode Labs shall disclose to have become defective or unworkable due to abuse, mishandling, misuse, accidental alteration, negligence, improper installation or other causes beyond Spectra Diode Labs' control.

When products manufactured by others are used in conjunction with Spectra Diode Labs equipment, this warranty is extended only to the equipment manufactured by Spectra Diode Labs.

The above warranty is valid for units purchased and used in the UNITED STATES ONLY. Products with foreign-end destinations are subject to a warranty surcharge,

Note: This list contains a oesaipion of each replaceable part along with one manufacturer name and part number. Substitutions may be made only if the part is equivalent or sopetior 10 the part in the list.

Due to availability of parts, SDL reserves the right to make such parts substitutions.

SOL 800 Main Material list

IDENTIFIER DE:SCRr~ION MFG KFGPART

AI PC ASS);' :t'.AIN SOL 800-2001

A2 PC ASS¥ rRONT ant. 80o-~OO2

B1J'I"I'O}.l SWTCH .37:5 CUT-IW>! W-lCN-17

Jl ,J'2 ,J) CONN 8:NC BLXH D )JoIPHENOl. )1-2221

COR~ PWR USA 2.3m BELDEN 1125-1

f1'_'SE 1/2;\ 25'OV JAG LF ]12. soc

FUSE lA ~"50V J)"G LF 311001

INSUL BUSH!NG 4-40 »<RLI( SIB-Q,,)

INSUL HTSN:K TO-220 SPC 1200-07FG-513

JACK PHONE 5WCRrr 142A

!<NOB u.RGE; ELXC J{RD\.I CP 3009-292

l(NOB SM.lI.LL EL.EC HRDW CP )0-08"'182-10

!1A,h-JA.L- SOL 80'0-0-006-

HOD:JLE LINt: SPRAGIJI: ~OO-J1r4G-2

eLI P M'rG ~OO'[)u: CORCOM 45-16.76

PLUG PHONE SW'CRr!' 750

SWITCH :KI'i CPST en 'i2 0 1-11-4-C-2-

CaNT "IN OJ-N-O"

TR..l..NSFO'RKEP. SOL Dt:l8JB 12.0 Parts List

SOL -800 laser DKJde Driver US9~S Manual

12.0 Parts list

SOL 800 Assen-blies Material List

AI

AIC3<I

AIC9..l3

Aiel!! "'_ICI~.tj..I-:j(I

A 1(3<; 1'.10.,4,10-14,19.20 i..ij.4,lt..2S..1<:J.Jl )I..34.)7,)t! AIO!,lUiJ:!:jJ AIQ,.7,16~'i A)CFij,1l

AlCRI..I AlCFlIIJ..l31"1·19 AK'RV,

AICR)i

AICR'UI

Auo-n

i\\JI~

AIH-~

AIJD

Aln:

AUt"

AI1H·2C

AIKJ

Atl,1

At\trl

A1l}!;io.J'::.t4 A,]()J-";','iB

AIQ1

Aim

AlIU

AIR._~6;

AIRIQ.~.!!~ "'IRII.I:!.1~_1JJ!l1.93_~ AIRi,F

Alkw_"I_;; AtRll'il4!l>-~O_T:',&'I A\~4-l_'"J

A 1 Rl7J:'

AIR_'-::

Al~~.sJ. AIR1.H,I~.27,J:'.38 4O,41_4~_~U.9.f,6 34,R9.9~~

Alfl:LI

PESCRIWOl'."

I"C ASsY MAL ... ·

CAP Al HOJL"P 6..J\' OJ" AI. 1»'J)lrf' 16\' CAl' CE~ llPI" sov CAl' CERm-P lOOV (.AJt CER uvP SOv CAJ' CER .IL,.. SCI\

CAJ'TA iUF SO\' CAPTA IOL"FlSV DlODE]..\ tOO\.' DIODE SKY lA A(l\ DIODE sw lOOMA JOO\ DIODE. ZJI..'R]'1\' sv:

DIODE Z.~R 6V 5'11' DIODE Z-";R 12\" 5~ cox ..... PC) M coxv PC (£) M cosx esc F PC RECl"T DJ:-'; !I SOCXETTO·U(j SOCKETDjp~ SOCKET. SHl'!'roT RElAY SPDT 5\' INDIOL.'H

HEA TSI~"K. TO-2.."'1J TRA:"iS ~";P:-'; GP 'J1I.ANS p~"Gr TR.A.I'..lS PfI,,,, 'iOW ~SP:"o'fDARL

RES 11 .. sw W\L' '" I;o.;D RES I_OOK .1t; .tzs .... · RLS-l.lJ5K .I~ nsw RES9JlK .I~ ,1lSW

R.E.S 1'0;':'.1% ,l:!S\I,

RF..s 1~9K ,1%.125\1. P.E.S4011%-.1~ R£S.~I~,I!5W RES15(1)!; I~ 115'11t ru:::..sJ,'nK I~~ ,l15W

RE.S 19.6X 1<:Ii- .ll'i ....

RF5 2O_OK 1% ,125'0\-·

RES UK I ~ _I25W

MBi ~mi·PARlf

SDL JOO.",II

MEPCo 3476GFlIJZM6P3IMBS

PI\J'riASOi'olC EITn6R1S3SW

J<E\(IT CJ12CllllX2~CA

KEM:ET Cl22021KlG5CA

!<EMIT 022CIZ:Z.lQUSCA

SPRAGL.:E lC2(lZSUlo.M~El

!<EMET TI!lBICl:S""~

1CEMl'T mOE106.M02SAS

MOT ,"-""I

GI I~~

L:!'.TTRD J~l4fi

M'1j ,"'l2I!A

MOT INS9Of;

MOT 1I'~21')

....... +-lO)Ia.~{l

A~l' 101567-4

AM. "_'l

AMP ~12l):l'·1

M01EX ID-I8-2Dll

n ~...1!;--Q'-I

AMP j31220-:!

A.",in AZII-1C'-U'lJ

MlUER. 'nJ.M

IIIKJ'LD "Nl-V1-I)I)H

MOT MP"S4~~

MOl M.f"S.tlU

MDT MJEt'mO

n rmzs

DALE ~'S-'!'l OHM

DALE: RN5_KHrJl!l

DALE R_~!OO_~IR

D,lJ.E R..""5.5-C93-HB

DAll R."'l_'j_5.Cl-4-Uifl

DALE R.~5C16~:l'B

All RJI.'K4020F

All Rf.,,1{4990F

AH RNX150If

All R.....;K..'i1211

All .P..N'K.lilb2F

All R.."'lK2C02F SDL 800 Assemblies Material List

JDE~TIFJE~

AIR. R':"~,~.f-!i,'IO ,\1 Rn:..;,t,.' AlFU.~.:-~

AIR'),', r\\IH,:v,.J"_M AIR.40.~~ ,\IFiI.5_IIl,:J.4_611_7'::''''' ,\I"'''S.~S.I .. _'_I,I.'_\ -:'f,

Al R..~.11 ,16,JO.) I ,j).')~.42~W,9~ AIR"\)

AIRoI'l

Al I<. HI

?\IRfl

r\lRl

\IR-\ ,\LR~~,I,;_-:1iiC -\:..;t

.\. ~ l, "l , <\!l··

-"l_'r, Ail"l~ ALl'1: ,".H") All'J5_~_1 \ /1,] rn.r,\ll-V·.Wl!

DESCRIPT)()"

RES.38-Jl\. 1<::: _m\), RESbS,lK 1<;', L!.W. R!'...s316I(jQ l!5W RES n 5'< ,:::5'" RES 100 ~~~ :!5W RES 3Jl) 5~c .15"'" RES IK vs ::.~ ..... liS 4 7K ~r; ::"~\I, REs 10K 'Sq2_~1,I,. RES 150K ~-":'~5\1, RF$ ~~K ~<; 2...w. RJ:::.."i. IX ~r; .sw RL')lxl-~'" 1\.\. RJ'$.W!O"" ?ow

RE .... ~·l"V v K v,x X_, ("( I\J RE." ~.;yv..", 1':-1( x" SI r RE s TR,\1R U.: I',"-~ swrrcu srrrr ec-

,'I' ,,(

rc ,",,'\1.(, '\~L\ TC A:";L(;;-i\\.1

Ie: ARlVi) ,\':\- ~ I(",DECDR),[ r-; Ie l'PROC F'(j~!() ICO!'A'II\

ICOP A~fl""

Ie or A_I,.r PRe' ICO:!" A~II' I'K I,,'·;t Ie v RIT ~5\

IC\' tUH.1K H'

All

All

AB

~[r('o MEPeu :o.4B'CO MEPCO MfPC() MH(O MH(,() ;Y;U'CO

All

AI!

DAl.I

Ali

"u

lHll'R:-":~ AI.CO

..,.,.-'1'

'\,",,1.

Muf

RLA

11

sr» :-"A·Il,W:'-1.Y-, xiot

r .... l:

I':o.n "'All -, 'v l l

~!fG. PART II

R. lOIIJ~f

R. lo:.t.SJ1l"

R."'1U-l~31 CJU5-:n .. ~'-, CIUSL11X~~'::< CFUS-:loJO-S'7.CR1'S·n:_·~~ C~ ... ,:,,);_-y, CR2S---10K·Vr CiU5·1:5-0K·:,-r:-, UU~-4-70Jo;-Y~, U~I02~

IW1~J<

C\\·:;I' VI 7I1f',,\;':.'

3:6Bl"'" 3JUf·j·I!''': !'>~~·j(·II.."[)·""RA

nJ-l[)<;lnn' t".iCl-1:.l'JtJlIC'·

L\,1.:l1]."" ~c.lJ!))J}' nV'I)I' o"p~..,c,1' l_\t\~,< '/ ,~_(

1 \1;'1 .. ( ~Cl-.'

12.0 Parts List

SDL-SOO Laser Diode Driver User's Manual

12,0 Parts List

SDL 800 Assemblies Material List

IDENTIFIER :D£SCRIPTloN MFG !'IFCi PART ,

~~ PC A.SSV FRONT BDO-2002

A:IlC) CAP eER .1UF 50\" SPRAGUE lC20t5U104M050a

A2C4, '5 CAP M'lL .1UF :250',' NICH QXM2E104K

Po;l:Cl,2 CAP n i our- :tSV I<E>!ET T150EI06M025AS

i\20S) -13 LED RED Tl.' 5 GI HUfP-3316

11.2052 L[C REO .56 "8. B." G1 MAJiEi940

A2DSl LED I\.[D .56 "1. :e , ,~ GI KJ\.N6-950

A.2J] CONN PC 60 F AMP lO2S.fI4-4

A2Jl r:ll COHN PC I. r SAKT[:C E-SS-120-T/O]

A2R4, 5,9-15 I\.[S 100 5\ .25W KEPCO CR25-100-5l

A,2R7 I 8,16-18 1\.[5 ]30 51 .25101 MEPCO CR25-3JD-5'

A2Rl-3 PO'l' 10K 1 T 20' AB 20G048PHl3MB

A2R6 POT 10K lOT BOURNS 35405-76-10)

A1Rlg IU:S 116K 1\ .12Sw AB RNKJ1£3F

A;1RlO RES 470K 51: .25io; KE:PCO CR25-nOtr;-S'

A2S~'1-4 SWITCH PSH SPST CtIT-1iAM ~S8-10(i

JI.:t!Ul r c DIlR DIGIT HOT MC1413P

AO!l"2 rc DVR SGtIT MOT MC}4'5l1BCP

}I.~t·3 t c DVM HOT MC144J3P Wire COlor

13.1 OUTPUT CABLE (Refer to Figure 5.2)

Function

Black Brown Red Orange Yellow Green Blue Violet

Thermistor lead 1 Thermistor lead 2 laser Anode (0 V)

laser Cathode (negative)

Thermoelectric Cooler Posrtive lead (pos~ive) Thermoelectric Cooler Negative lead (0 V) Monrtor Photodiode Anode (negative) Monitor Photodiode Cathode (0 V)

Comments in parentheses refer to the polarrty of the vohage on a wire. The overall cable shield should be connected to the laser anode lead. The monitor photodiode shield should not be connected. (II is connected at the a-pin connector.)

13.2 DRIVER ElECTRONICS

Three schematics are shown for the SDL 800: the power supply, the front board and the main board. The actual power supply is located on the main board and rear panel.

13.0 Schematic Diagrams

I >

I U f-

~

tf)_

ffi~

~ o o,

l: __ __j

I I ___j

L

·

:~: ... -------1

C\J M'C

:;~

·.;:::m ro_ E I: (1)0 .c'" uu. (/)

,

~--br---,_oc. ~S S,l~-

'"-+-+-----01 ... - 0:2'

~, ;

~-'~

;;--

:;'----~

'i' .... >---

i~ t------

ii! ~ ~~~ _

LN.._ESS OT\-ER\JISE t-UTED.

f'T'.,p TRANSISTORS 2N~i26

I'F'N TRANSISTffiS 2N4124 RESISTrn5 1/8 \JAn Si': 1..tPREFIXED PIN I'U'13ERS ARE .J12

DETECnTCF C ... L.

- - - ---./\/V'v -

02, s o

.E

P rDlITCI1 ~g

~'

! ---,-220P

'i

,..-----

1

7A

AELAY

~--------

--<:)-1

B

,

1

CRS l1'oS401

I~

CR6 1f\1;4Dl

~l

R£l'UTE <t INTERLOCK 1

J13-4

vee vee 128 C32

I'r" ]'NT """ ffi

58_ 13 PSI

!li"

''''T 2' P" nAL -

23 "-

II' p," K

12

RUM PSD Tlt£R ! ~

I'1'f1l'l"'l' H PSi' PAS 1-'C6B7DS

PA7 PM 20

PAS PA'

PS3 PAZ

PSA

PBS

P!l6

PS7 "

I I I

009

17"'W278

+

I'

3 2 1 0

ocrrr-rr-S-T--·~~I~'--J 24A TO D~

8=

_.__-.-~"lK

.J13-S

1£ ca:t.ER

JJ13-S

PC,

PCD GNIJ

Schematic 13.3 Main Board

You might also like

- Instruction Book Qc1112 and Qc2112 ESF 2960 0380 00 ENDocument79 pagesInstruction Book Qc1112 and Qc2112 ESF 2960 0380 00 ENКонстантин Гетьман100% (1)

- M-sr-130 Rev 6 Ul - sn413 - XXXDocument38 pagesM-sr-130 Rev 6 Ul - sn413 - XXXIM100% (1)

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- LDC205C ManualDocument38 pagesLDC205C ManualbrindhabrinjiNo ratings yet

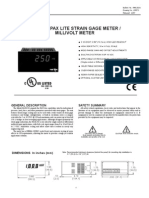

- Model Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedDocument8 pagesModel Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedJosé Tomas CisnerosNo ratings yet

- SAKO SKI780 ManualDocument74 pagesSAKO SKI780 ManualJordi Garcia100% (1)

- Zeeta308d PDFDocument25 pagesZeeta308d PDFGeorcchi CheeckNo ratings yet

- Function GeneratorDocument37 pagesFunction GeneratorRoberto Angel Lora MartinezNo ratings yet

- 59714602rvC - OPMANPXS5 822 822WBDocument19 pages59714602rvC - OPMANPXS5 822 822WBCalidad CocoNo ratings yet

- Instruction Manual: Model RSP Sanitary Electronic Pressure TransmitterDocument16 pagesInstruction Manual: Model RSP Sanitary Electronic Pressure TransmitterHectorNo ratings yet

- SV - 03678 - en - Na 2Document16 pagesSV - 03678 - en - Na 2eduardodluffy268No ratings yet

- Controlador de CorrienteDocument12 pagesControlador de Corrientecjaziel66No ratings yet

- Plasma TV: Service ManualDocument38 pagesPlasma TV: Service ManualD TodounpocoNo ratings yet

- GRL100B 6F2S0835 2.7Document392 pagesGRL100B 6F2S0835 2.7Nazi SweetNo ratings yet

- Manual SA-MAX500 Manual de Servicio PDFDocument133 pagesManual SA-MAX500 Manual de Servicio PDFAbel GaunaNo ratings yet

- Dual Display Digital Multimeter User ManualDocument15 pagesDual Display Digital Multimeter User ManualEric CostaNo ratings yet

- Pasolink PlusDocument316 pagesPasolink PlusescalimetroNo ratings yet

- Data Sheet: Overload Relays, RMP-111D ANSI Code 32Document7 pagesData Sheet: Overload Relays, RMP-111D ANSI Code 32LUATNo ratings yet

- LG LCD Monitor M1917a-K, F, GZD - eDocument33 pagesLG LCD Monitor M1917a-K, F, GZD - evideosonNo ratings yet

- TR DMO200 Manual v4 User GuideDocument36 pagesTR DMO200 Manual v4 User Guideวิรวัฒน์ ปัททุมNo ratings yet

- ADP3338 Data SheetsDocument16 pagesADP3338 Data SheetstarpinoNo ratings yet

- 0201Document80 pages0201Ashenafi Gebremeskel MezgeboNo ratings yet

- LG 50pg4000Document34 pagesLG 50pg4000jooscar83No ratings yet

- Users Manual: MultimeterDocument20 pagesUsers Manual: MultimeterchepebotellaNo ratings yet

- Sony CDPX777ES CD SMDocument41 pagesSony CDPX777ES CD SMczeslawastachowialpNo ratings yet

- 7SG117 Argus 7: Answers For EnergyDocument10 pages7SG117 Argus 7: Answers For EnergygovindarulNo ratings yet

- SDS 4000 PDFDocument76 pagesSDS 4000 PDFAdan SolanoNo ratings yet

- TTi Model QPX1200 DC Power Supply Service ManualDocument49 pagesTTi Model QPX1200 DC Power Supply Service ManualT3brzNo ratings yet

- Tornado - 401 USER MAnDocument11 pagesTornado - 401 USER MAnvipulNo ratings yet

- HIGH POWER FREQUENCY-STABILIZED 300mW DIODE LASER FOR RAMAN SPECTROSDocument17 pagesHIGH POWER FREQUENCY-STABILIZED 300mW DIODE LASER FOR RAMAN SPECTROSRussell Decotis100% (1)

- MS2108A English ManualDocument24 pagesMS2108A English ManualiconeykregNo ratings yet

- Superdil Laser Diode Controller: Instruction ManualDocument7 pagesSuperdil Laser Diode Controller: Instruction Manualअमरेश झाNo ratings yet

- RMC 131d Data Sheet 4921240104 UkDocument8 pagesRMC 131d Data Sheet 4921240104 Ukdavid loughlinNo ratings yet

- Insulation Tester: Rs-232 DataloggerDocument42 pagesInsulation Tester: Rs-232 DataloggervlkodlakschwartzNo ratings yet

- BEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke DetectorDocument15 pagesBEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke Detectoryesid rodriguezNo ratings yet

- ADVR 12 Manual enDocument6 pagesADVR 12 Manual enSyed Mohammad Naveed0% (1)

- 1260 ManualDocument215 pages1260 ManualGaurav AcharyaNo ratings yet

- Ajustable Precision Zenner Shunt Regulador LM 431Document13 pagesAjustable Precision Zenner Shunt Regulador LM 431Freddy InimaNo ratings yet

- Toshiba GRB150BDocument143 pagesToshiba GRB150BbookreaderAUNo ratings yet

- RC4558 Dual General-Purpose Operational Amplifier: 1 Features 3 DescriptionDocument31 pagesRC4558 Dual General-Purpose Operational Amplifier: 1 Features 3 DescriptionCarloz FriazNo ratings yet

- 59718608rva OpMan822-HRDocument10 pages59718608rva OpMan822-HRCalidad CocoNo ratings yet

- An Analog Current Controller Design For Laser Diodes: Todd P. MeyrathDocument7 pagesAn Analog Current Controller Design For Laser Diodes: Todd P. MeyrathAfzal345No ratings yet

- TM-6001 (20181025)Document34 pagesTM-6001 (20181025)vũ trầnNo ratings yet

- ICL8069 - Low Voltage Reference - Intersil CorporationDocument6 pagesICL8069 - Low Voltage Reference - Intersil Corporationwlen2012No ratings yet

- Datasheet Sar100 Robust Gyro Sensor Ts1440 r4Document13 pagesDatasheet Sar100 Robust Gyro Sensor Ts1440 r4Marlon Isaac CortesNo ratings yet

- Flex Current Clamps User Manual: Version 1.1 Code No. 20 751 302Document12 pagesFlex Current Clamps User Manual: Version 1.1 Code No. 20 751 302Carlos A VillalobosNo ratings yet

- Power Meter E51C2Document29 pagesPower Meter E51C2atereñoneNo ratings yet

- RMC 131d Data Sheet 4921240104 UkDocument8 pagesRMC 131d Data Sheet 4921240104 UkAilton NevesNo ratings yet

- LG 42PJ250-SA Chassis PB02ADocument70 pagesLG 42PJ250-SA Chassis PB02AamaralfassNo ratings yet

- Adxrs610 Yaw Rate GyroDocument12 pagesAdxrs610 Yaw Rate GyroTarek Car MillaNo ratings yet

- Led LCD TV: Service ManualDocument54 pagesLed LCD TV: Service Manualsypo11100% (1)

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Heetah: Owners ManualDocument36 pagesHeetah: Owners ManualSubdriverNo ratings yet

- How To Upgrade Your TurntableDocument8 pagesHow To Upgrade Your TurntableSubdriverNo ratings yet

- Casio VZ-8M Owners Manual PDFDocument171 pagesCasio VZ-8M Owners Manual PDFSubdriverNo ratings yet

- MK6100 - Quick Start Guide - UK FR SP DE IT NL PT PDFDocument136 pagesMK6100 - Quick Start Guide - UK FR SP DE IT NL PT PDFSubdriverNo ratings yet

- M300 ManualDocument23 pagesM300 ManualSubdriverNo ratings yet

- Kimmon KP 2014 ManualDocument44 pagesKimmon KP 2014 ManualSubdriverNo ratings yet