Professional Documents

Culture Documents

ProVent Design and Usage

ProVent Design and Usage

Uploaded by

Sean WiseCopyright:

Available Formats

You might also like

- Proceedings CIB W062 2018 SymposiumDocument354 pagesProceedings CIB W062 2018 SymposiumdplumbingNo ratings yet

- Drainagesystemslecturei 091022013358 Phpapp02Document62 pagesDrainagesystemslecturei 091022013358 Phpapp02Abdul Raoof100% (1)

- HVAC Load Calculations GuideDocument66 pagesHVAC Load Calculations GuideHESuarez88% (41)

- Ansi Color CodingDocument2 pagesAnsi Color CodingHESuarez100% (1)

- Corporate Venture Studios DirectoryDocument12 pagesCorporate Venture Studios Directorymoctapka0880% (1)

- Plumbing and Sanitary Systems Topic 1 Module 1 LectureDocument55 pagesPlumbing and Sanitary Systems Topic 1 Module 1 Lecturechristian001 Latag100% (1)

- Se Sovent Design Manual 101o New011007Document24 pagesSe Sovent Design Manual 101o New011007jomy_pj8106No ratings yet

- Wet Scrubber Selection GuideDocument8 pagesWet Scrubber Selection GuideHESuarez100% (2)

- Wet Scrubber BulletinDocument8 pagesWet Scrubber BulletinHESuarez100% (1)

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- Soal Olimpiade Matematika Grade 4Document3 pagesSoal Olimpiade Matematika Grade 4wakidsNo ratings yet

- Negative Averment AffidavitDocument3 pagesNegative Averment Affidavitamenelbey80% (5)

- New Password 3: A Reading and Vocabulary Text: Linda ButlerDocument1 pageNew Password 3: A Reading and Vocabulary Text: Linda ButlerRastko Manojlovic0% (3)

- ProVent IPC Comparison Manual LetterDocument12 pagesProVent IPC Comparison Manual Letterjack j100% (1)

- Lecture 4 Water Pipe Sizing PDFDocument26 pagesLecture 4 Water Pipe Sizing PDFAlchea Aldeguer100% (1)

- Plumbing ReviewerDocument46 pagesPlumbing ReviewerYsabelle Marie FuentesNo ratings yet

- R1 Designing A School Public ToiletDocument18 pagesR1 Designing A School Public ToiletIrish Barte100% (1)

- Case Study Siphonic Roof Drains MarshallDocument2 pagesCase Study Siphonic Roof Drains MarshalldanateoNo ratings yet

- Hydromax™ Siphonic Drainage 17-2-12Document83 pagesHydromax™ Siphonic Drainage 17-2-12Dan O Villarreal100% (1)

- Sizing Sump Pits and Sump PumpsDocument2 pagesSizing Sump Pits and Sump PumpsnNo ratings yet

- IRR On Proper Sewage HandlingDocument51 pagesIRR On Proper Sewage HandlingDexter G. BatalaoNo ratings yet

- Tips of Fountain Design Part 2 - 3 - Blog of Fountain Design and Water ShowsDocument2 pagesTips of Fountain Design Part 2 - 3 - Blog of Fountain Design and Water ShowsAnh Đức NguyễnNo ratings yet

- Sizing Water SystemsDocument16 pagesSizing Water SystemsRadoNoun100% (1)

- Pool Circulation PDF Document Aqua Middle East FZCDocument18 pagesPool Circulation PDF Document Aqua Middle East FZCAdolfsmith69No ratings yet

- ACO Floor Drains and Clean Out CatalogDocument9 pagesACO Floor Drains and Clean Out CatalogJohnny TsehayeNo ratings yet

- Plumbing Fittings Types With Their ApplicationDocument12 pagesPlumbing Fittings Types With Their ApplicationBiju MenonNo ratings yet

- Chapter 11 Water Distribution SystemsDocument32 pagesChapter 11 Water Distribution SystemsEarl John LugatimanNo ratings yet

- Plumbing Specifications - NgacDocument57 pagesPlumbing Specifications - Ngacmon MagbualNo ratings yet

- 12 DrainageDocument22 pages12 Drainageansara89No ratings yet

- Hot and Cold Water Supply FinalDocument40 pagesHot and Cold Water Supply FinalAmit Kumar YadavNo ratings yet

- 224105, Residential Plumbing FixturesDocument15 pages224105, Residential Plumbing Fixturessrp. mohammedNo ratings yet

- Building Services - Water SupplyDocument33 pagesBuilding Services - Water SupplyRitikaNo ratings yet

- Siphonic System - Design RulesDocument26 pagesSiphonic System - Design RulesCarla Bianca Meliton ConsueloNo ratings yet

- Rainwater Harvesting Workshop Manual-UK-RHA - 2012Document36 pagesRainwater Harvesting Workshop Manual-UK-RHA - 2012Erin Lim100% (1)

- Frequently Asked Questions: Geberit SupertubeDocument9 pagesFrequently Asked Questions: Geberit Supertubemohaideen kasimNo ratings yet

- 01-2021-02-15 - EL - RES - Ato Mamush Plumbing Services Design ReportDocument15 pages01-2021-02-15 - EL - RES - Ato Mamush Plumbing Services Design Reportdawitggg0% (1)

- PLUMBING Final HandoutprofDocument33 pagesPLUMBING Final HandoutprofReinier CarrascoNo ratings yet

- Mebs6000 1011 05 DrainageDocument72 pagesMebs6000 1011 05 Drainagesmartysky100% (1)

- Ebook Lakes LagoonsDocument24 pagesEbook Lakes LagoonskhairullamustafaNo ratings yet

- CPDT Bulletin - 2022Document9 pagesCPDT Bulletin - 2022Ivan DNo ratings yet

- Design and Construction of Swimming Pools-Ib-P-Bc2017 014Document10 pagesDesign and Construction of Swimming Pools-Ib-P-Bc2017 014Luffy11No ratings yet

- Siphonic Roof Drainage Systems The Road To PrimingDocument0 pagesSiphonic Roof Drainage Systems The Road To PrimingDedy KristiantoNo ratings yet

- Plumbing Engineering Design Course: Engineer Haithm KhalilDocument34 pagesPlumbing Engineering Design Course: Engineer Haithm KhalilAhmed Hassan100% (1)

- Plumbing Materials and Various ToolsDocument8 pagesPlumbing Materials and Various ToolsJayson G. GunioNo ratings yet

- Geberit Drainage BrochureDocument6 pagesGeberit Drainage BrochureCzar LRNo ratings yet

- PVC Design Guide ApprovedDocument222 pagesPVC Design Guide Approvedgabox7No ratings yet

- Swimming Pool CodeDocument53 pagesSwimming Pool CodeAnonymous dK9Qi2XjNo ratings yet

- Water Supply in High Rise BuildingsDocument8 pagesWater Supply in High Rise BuildingsVaishnavi Parmar100% (1)

- Pipe SpecialsDocument20 pagesPipe SpecialsLance Joseph OdtojanNo ratings yet

- Specifications For Underground Water Storage Tanks For Fire ProtectionDocument5 pagesSpecifications For Underground Water Storage Tanks For Fire ProtectionkirmaniNo ratings yet

- Pipe Sizes and ScheduleDocument2 pagesPipe Sizes and Schedulechupacid0% (1)

- Xpelair CataloguesDocument39 pagesXpelair Cataloguestafadzwa simbiNo ratings yet

- BUILDING PLUMBING SYSTEM Part 2Document10 pagesBUILDING PLUMBING SYSTEM Part 2Nyein Aye MyatNo ratings yet

- Mebs6000 0809 03 Cold and Hot Water Design PDFDocument78 pagesMebs6000 0809 03 Cold and Hot Water Design PDFKamaruz DanialNo ratings yet

- Arch 502 - Pipes FittingsDocument70 pagesArch 502 - Pipes FittingsjerilonNo ratings yet

- Chapter 9 Vents and VentingDocument24 pagesChapter 9 Vents and VentingPotter XxNo ratings yet

- Topic 6 Plumbing & Sanitary (2012) Stud-1Document30 pagesTopic 6 Plumbing & Sanitary (2012) Stud-1LuisLoNo ratings yet

- Chilled Water Pipe DESIGNDocument22 pagesChilled Water Pipe DESIGNTanjim FakirNo ratings yet

- Water SupplyDocument17 pagesWater SupplyHarsh VermaNo ratings yet

- Technical Specifications For Fire Suppression System PipesDocument14 pagesTechnical Specifications For Fire Suppression System PipesHarikrishnaNo ratings yet

- SgTank Sectional Water Storage TankDocument33 pagesSgTank Sectional Water Storage TankRichard LeongNo ratings yet

- Plumbing Materials, Fittings, FixturesDocument21 pagesPlumbing Materials, Fittings, FixturesRayan Ahmad BarodiNo ratings yet

- DM Auto Irrigation Systems SpecificationsDocument71 pagesDM Auto Irrigation Systems SpecificationsbargothiNo ratings yet

- Deckshield IDDocument2 pagesDeckshield IDMinhHyNo ratings yet

- Enraf Insertion Stilling Wells-2 - 240426 - 122200Document5 pagesEnraf Insertion Stilling Wells-2 - 240426 - 122200edgar vidalNo ratings yet

- SE SOVENT DESIGN MANUAL 101o New011007Document24 pagesSE SOVENT DESIGN MANUAL 101o New011007Любов АндреєваNo ratings yet

- SE SOVENT DESIGN MANUAL 101o New011007Document24 pagesSE SOVENT DESIGN MANUAL 101o New011007VishnuNo ratings yet

- The Akatherm Akavent System: Design GuidelinesDocument16 pagesThe Akatherm Akavent System: Design Guidelinesdaud heruNo ratings yet

- QuickStream PE - Manual Wavin PresiuneDocument40 pagesQuickStream PE - Manual Wavin PresiuneIonut SomneaNo ratings yet

- Design Briefs Advanced VAV SystemsDocument27 pagesDesign Briefs Advanced VAV SystemsHESuarezNo ratings yet

- Thermal Storage Wall Design ManualDocument43 pagesThermal Storage Wall Design ManualAn Energy-Efficient Solar-Heated GreenhouseNo ratings yet

- Thermal Energy StorageDocument3 pagesThermal Energy StorageHESuarezNo ratings yet

- EDR Multifamily Design Guide For Energy EfficiencyDocument25 pagesEDR Multifamily Design Guide For Energy EfficiencyHESuarezNo ratings yet

- Commercial Kitchen Design GuideDocument31 pagesCommercial Kitchen Design Guidebasha99100% (2)

- EDR DesignBriefs PumpsystemtroubleshootingDocument39 pagesEDR DesignBriefs PumpsystemtroubleshootingLuis CarlosNo ratings yet

- EDR CommissioningHandbookCompleteDocument125 pagesEDR CommissioningHandbookCompletegeralva55No ratings yet

- Psychrometric CourseDocument94 pagesPsychrometric CourseHESuarez50% (2)

- Fire SPRKLR Train ManDocument81 pagesFire SPRKLR Train ManHESuarez100% (1)

- Maximizing Wet Scrubber PerformanceDocument7 pagesMaximizing Wet Scrubber PerformanceHESuarez100% (1)

- Cross Connection ManualDocument122 pagesCross Connection ManualHESuarezNo ratings yet

- A Hand Book For The Mechanical Designer Ventilation Duct FanDocument107 pagesA Hand Book For The Mechanical Designer Ventilation Duct Fanrawneeh100% (6)

- Bpump PDFDocument20 pagesBpump PDFgpskumar22No ratings yet

- VAV Design GuideDocument326 pagesVAV Design GuideHESuarez100% (3)

- Fire StopDocument55 pagesFire StopHESuarezNo ratings yet

- Grinnell Grooved Fire ProDocument144 pagesGrinnell Grooved Fire ProHESuarez100% (1)

- Rainwater Collection SystemDocument28 pagesRainwater Collection SystemHESuarezNo ratings yet

- Stair PressurizationDocument7 pagesStair PressurizationHESuarez100% (1)

- How To Use Adobe Illustrator CS3Document11 pagesHow To Use Adobe Illustrator CS3HESuarezNo ratings yet

- Blaze Master Installation and Specification ManualDocument33 pagesBlaze Master Installation and Specification ManualHESuarez100% (1)

- Trouble-Shooting Chart For PUMPSDocument1 pageTrouble-Shooting Chart For PUMPSAnwar SyedNo ratings yet

- Evap. Cooling Design ManualDocument109 pagesEvap. Cooling Design Manualkunj74No ratings yet

- Pylontech - US2000C, US3000CDocument1 pagePylontech - US2000C, US3000CYC CarieloNo ratings yet

- The Science of EtymologyDocument274 pagesThe Science of Etymologynatzucow100% (5)

- Rose Doe v. The City of New York, Et. Al.Document57 pagesRose Doe v. The City of New York, Et. Al.Daily Caller News FoundationNo ratings yet

- Sikamelt 700Document2 pagesSikamelt 700Ionut StoicaNo ratings yet

- Folding Standards: GeneralDocument9 pagesFolding Standards: GeneralNaadiyah JauharaNo ratings yet

- Guide JCT 2005 Design Built Rev 2009Document44 pagesGuide JCT 2005 Design Built Rev 2009seanbeagNo ratings yet

- Vrealize Automation 70 ConfigurationDocument386 pagesVrealize Automation 70 ConfigurationsatishNo ratings yet

- Fusion Financials Implementation GuideDocument174 pagesFusion Financials Implementation Guidemaddiboina100% (1)

- University of Santo Tomas Senior High School Documentation of Ust'S Artworks Through A Walking Tour Brochure and Audio GuideDocument30 pagesUniversity of Santo Tomas Senior High School Documentation of Ust'S Artworks Through A Walking Tour Brochure and Audio GuideNathan SalongaNo ratings yet

- May 6, 2016 Strathmore TimesDocument28 pagesMay 6, 2016 Strathmore TimesStrathmore TimesNo ratings yet

- Organisation of Prosecuting AgenciesDocument24 pagesOrganisation of Prosecuting AgenciesPAULOMI DASNo ratings yet

- Penggunaan Metode Waterfall Untuk Pengembangan Sistem Monitoring Dan Evaluasi Pembangunan PedesaanDocument26 pagesPenggunaan Metode Waterfall Untuk Pengembangan Sistem Monitoring Dan Evaluasi Pembangunan PedesaanII8I40O24 Oktaviana Rinda SariNo ratings yet

- Bissell 1967Document82 pagesBissell 1967engr_usman04No ratings yet

- Portable Lamps & Converters: W 276 LEDDocument2 pagesPortable Lamps & Converters: W 276 LEDRaghu paryNo ratings yet

- Republic vs. Castelvi, 58 SCRA 336 (1974)Document4 pagesRepublic vs. Castelvi, 58 SCRA 336 (1974)Gabriel HernandezNo ratings yet

- 2024 03 06 Introduction Lecture Series Climate Protection SS2024Document45 pages2024 03 06 Introduction Lecture Series Climate Protection SS2024Abdullah Khan QadriNo ratings yet

- Erectile Dysfunction: QuestionsDocument24 pagesErectile Dysfunction: QuestionsSayed NourNo ratings yet

- Unpacking Instructional Leadership QuestionnairesDocument7 pagesUnpacking Instructional Leadership QuestionnairesRENIEL MARK BASENo ratings yet

- State v. Carveiro, Ariz. Ct. App. (2015)Document5 pagesState v. Carveiro, Ariz. Ct. App. (2015)Scribd Government DocsNo ratings yet

- Lesson 4: Water SafetyDocument12 pagesLesson 4: Water SafetyHelena FarroNo ratings yet

- 04 Rodrigo Roa Duterte, Fifth State of The Nation Address, July 27, 2020 - Official Gazette of The Republic of The PhilippinesDocument23 pages04 Rodrigo Roa Duterte, Fifth State of The Nation Address, July 27, 2020 - Official Gazette of The Republic of The PhilippinesJoseph SalazarNo ratings yet

- Members 800Document62 pagesMembers 800Sandeep JainNo ratings yet

- Modi Cabinet 3.0 Ministers NamesDocument6 pagesModi Cabinet 3.0 Ministers NamesRicha sharmaNo ratings yet

- Tailieuchung Boi Duong Hoc Sinh Gioi Luong Giac NXB Dai Hoc Quoc Gia 2014-2-8519Document116 pagesTailieuchung Boi Duong Hoc Sinh Gioi Luong Giac NXB Dai Hoc Quoc Gia 2014-2-8519Vincent TuấnNo ratings yet

- The Eden Club Rules & RegulationsDocument16 pagesThe Eden Club Rules & RegulationsRodney AtkinsNo ratings yet

- Aquatic HabitatDocument6 pagesAquatic Habitatofurumchinyere9No ratings yet

ProVent Design and Usage

ProVent Design and Usage

Uploaded by

Sean WiseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ProVent Design and Usage

ProVent Design and Usage

Uploaded by

Sean WiseCopyright:

Available Formats

ProVent® System Components

Cast-in-Place Sleeve

StackVent

EZ-Flex Connector

ProVent Stack

EZ-Flex Connector

BaseVent

Copyright2006-07 ProVent Systems. Inc Page 2

Table of Contents

Introduction to ProVent Systems Page 4

Rules for ProVent Stacks and StackVent Fitting Page 5

Rules for the ProVent BaseVent Fitting Page 6

Rules for Branch Openings Page 7

Chart 1: Fixture Unit Values by Type of Fixture Page 8

Chart 2: Maximum Loading by Branch Page 9

Chart 3: Maximum Loading by Stack Page 9

Chart 4: Maximum Loading by Building Drain Page 9

StackVent Dimensions Page 10

BaseVent Dimensions Page 11

Drawings to Illustrate Rules for Use of StackVent Pages 12-17

Drawings to Illustrate Rules for Use of BaseVent Pages 18-24

Drawings to Illustrate Rules for Branch Openings Pages 25-30

Drawings 31a-f: Other Examples of ProVent Fixture Branches Page 31

Drawing 32: Example of Side-by-Side Layouts Page 32

Drawings 33 a-b: Example of Single Unit Layouts Page 33

Drawings 34 a-c: Example of Back-to-Back Layouts Pages 34-35

Copyright2006-07 ProVent Systems. Inc Page 3

Introduction to ProVentTM Systems

A PVC Plastic Single Stack

Waste and Vent System

The ProVent System™ is a plumbing engineered single stack system that finally offers the industry a PVC

equivalent to the cast iron Sovent® system. Introducing the ProVent Stack Fitting™ and a ProVent Base Fit-

ting™. This major change from cast iron fittings allows the installation of a complete PVC single stack drain-

age and vent system.

If you use PVC but you want the benefits of a Sovent®-style system, you can now use the ProVent System.

Also, because the ProVent System is not subject to corrosion, you can safely use it in coastal regions.

The ProVent System™ is particularly effective in multi-story buildings such as hotels, condos and apartments

where it creates considerable cost savings as well as enhanced performance and longevity. It increases the

capacity of the plumbing stack, eliminates separate vent piping and minimizes pipe penetrations.

The ProVent Stack and the ProVent Base Fittings reduce the maximum flow velocity, increase the stack waste

water capacity and control the interior air pressures that can cause siphonage and blowouts of fixture traps.

ProVent Systems™ Fittings were designed to further enhance acoustic performance by increasing wall thick-

nesses and providing sound absorbing ribs that greatly reduces the water noise associated with plastic pip-

ing. This new system creates a sound-tested “Whisper-Quiet PVC Plumbing System”.

This type of single stack system has been used for over forty years, with proven performance throughout the

world. In addition to these proven benefits, the ProVent System provides the following:

Flexible couplings that connect the piping from the Base to the Stack Fitting provide for a pipe expansion and

contraction system that works.

A StackVent system that fots plumbing walls and will fit drop ceilings without requiring special recess boxes.

Easier installation due to its light weight (7.5 pounds) and elimination of the need for hangers (when used

with ProSet Systems fire-rated penetrations) .

The plumbing approvals for using this new system are granted under the Alternate Materials & Methods or

the Alternate Professional Engineers Design criteria in the Plumbing Codes based on ASSE 1043, ASTM D-

2665 & NSF 14 Test & Design Standards.

Copyright2006-07 ProVent Systems. Inc Page 4

TM

1. Rules for the ProVent Stack and StackVent Fitting

Note: The Charts referred to below are contained on pages 6 and 7.

1.1 The ProVent stack must be sized by the total number of fixture units (D.F.U.) discharging into it. Chart 1

provides the number of fixture units by individual fixture. The sum of the fixture units for all fixtures dis-

charging into the stack equals the total fixture units. Chart 3 provides the required stack size by total fixture

units. The stack size shall continue full size through the roof.

1.2 A ProVent Stack Fitting is required to be used at each floor level when the horizontal soil or waste branch

collected is either the same size or one pipe size smaller than the vertical ProVent Stack Fitting.

1.3 Waste branches that are two (2) pipe sizes smaller than the stack can be connected with a sanitary tee

or wye directly into the ProVent stack (between ProVent Stack Fittings).

1.4 If there are no branch connections at a floor level, there is no need to use the ProVent Stack Fitting. In-

stead, a double in-line offset must be used in its place. The vertical interval between the Stack Fitting and

the in-line offset shall not exceed 20 feet and no more than two (2) consecutive double in-line offsets can be

used.

1.5 Offsets in the stack of more than 60 degrees require a ProVent Base Fitting with a pressure relief vent

line tied in to the top vertical portion of the stack. Branch piping can be connected to the offset soil piping.

A 45 degree stack offset is not considered an offset. Waste branches (1) one pipe size smaller can be con-

nected to the pressure relief vent line with the exception of washing machine wastes. It is recommended

that Washing machine wastes should be isolated from other fixtures. If they must be combined, call for

technical support.

1.6 The building drain size is determined by the total fixture unit load (Chart 4) from the combination of

stacks and other soil or waste branches that discharge into it (Charts 1, 2 and 3).

1.7 Stacks may offset above the highest fixture served. When the horizontal offset exceeds twenty (20) feet,

the diameter of the horizontal offset and the vent through the roof must be increased one pipe size

1.8 Combinations of vent stacks may be tied together above the highest fixture served before going through

the roof. The combined vertical stack must be increased (1) one pipe size larger than the combined stacks.

If the distance between the two (2) stacks that connect is greater than twenty (20) feet, the horizontal

branch must be one (1) pipe size larger than the downstream stack.

Note: The corresponding drawings are shown as examples of the rules. However, there may be other op-

tions not shown in the drawings.

Copyright2006-07 ProVent Systems. Inc Page 5

TM

2. Rules for the ProVent BaseVent Fitting

Note: The Charts referred to below are contained on pages 6 and 7.

2.1 A ProVent Base Fitting must be installed at the base of each vertical stack before it enters the horizontal

building drain. If the vertical distance to the closest ProVent Stack Fitting exceeds twenty feet (20’-0") an

inline offset must be installed within five feet (5’-0") above the ProVent Base Fitting. The building drain size

is calculated by using Chart 4 in accordance with the fixture unit values (D.F.U.) for all fixtures discharging

into it as shown in Chart 1.

2.2 The ProVent Base Fitting has a pressure relief vent opening that extends up then makes a 180 degree

turn downward using pipe and fittings that connect to the horizontal building drain at a point no less than 10

pipe diameters downstream from the center line of the vertical stack to the centerline of the branch wye. The

pressure relief vent line may run parallel to the horizontal drain and must connect above the centerline of the

drain. Branch soil or wastes are allowed when they are connected above the horizontal drain line.

2.3 A ProVent Base Fitting must be used on any stack offsets of more than 60 degrees with the pressure re-

lief vent connection running from the base fitting back into the top vertical portion of the stack drop.

2.4 Soil and waste branches can be connected into the building drain between the stack and the relief vent

when the connections are made above the center line of the building drain. The branch fixture unit loading

should be in accordance with the pitch of the pipe as shown in Chart 3.

2.5 Waste branches at least (1) one pipe size smaller can be connected to the pressure relief horizontal vent

line. Washing machine drains should not connect to the pressure relief vent line.

2.6 Soil or waste branches may connect directly into the vertical stack directly below the ProVent Base Fitting

only when the connections are made using fittings such as a combination wye and 1/8 bend.

2.7 Conventional waste & vent plumbing systems can connect downstream from the pressure relief vent to

pick up remote fixtures. Conventional revents can tie back into the ProVent vertical stack with vent sizing

based on the additional fixture units vented or can be separately vented through the roof in accordance with

locally accepted plumbing code vent sizing.

Note: The corresponding drawings are shown as examples of the rules. However, there may be other op-

tions not shown in the drawings.

Copyright2006-07 ProVent Systems. Inc Page 6

3. Rules for Branch Openings

Note: The Charts referred to below are contained on pages 6 and 7.

3.1 All branch piping sizes and loads should be in accordance with Chart 3. Branch piping should have a mini-

mum of 1/8" per foot pitch.

3.2 Branches that change directions three (3) times by 90 degrees should increase one pipe size at the offset

nearest the stack. This increase does not apply if one (1) of the changes can be made with two (2) forty five

degree fittings or a short sweep 90 degree fitting.

3.3 If two (2) 3.5 gpf public water closets are connected to the same branch, the first connection can be 3"

then increased to 4" at the second connection. This increase is not required for the 1.6 gpf flush water clos-

ets. Check manufacturers installation instructions for pressure assisted type water closets that may require

special fittings for back to back installations.

3.4 4" Size branches shall not exceed a developed length of 27 feet. 3" Size branches shall not exceed a de-

veloped length of 15 feet. 2" Size branches shall not exceed a developed length of 15 feet. 2" branches for

washing machines should not exceed 5 feet. These lengths include any horizontal pipe offsets but the

length of the vertical drop arms is not included. Horizontal to horizontal branch connections should be made

with wye combinations or heel outlet fittings.

3.5 Vertical branches should not exceed 40". A 45 degree offset can extend the drop pipe to 40" from the

top 45 degree fitting to the fixture outlet. When a vertical drop into a horizontal waste exceeds 10 feet both

must increase one (1) pipe size.

3.6 1-¼" size fixture traps can be connected back to back into one 2" vertical drop. 1-½" size fixture traps

require separate 2" drops. 1-1/2" and larger traps can use a single vertical drop by increasing the drop one

(1) pipe size. Note: Horizontal waste branches without vertical drops are sized per chart 2.

3.7 An alternate to increase developed lengths can be done by using a revent line or by telescoping smaller

to larger pipe sizes or by using an Air Admittance Valve where applicable and permitted. The revent line shall

be routed vertically and horizontally and tie in above the flood rim level using a wye branch looking up.

Note: The corresponding drawings are shown as examples of the rules. However, there may be other op-

tions not shown in the drawings.

Copyright2006-07 ProVent Systems. Inc Page 7

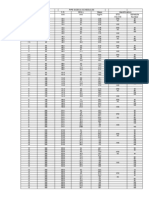

Chart 1: Fixture Unit Values by Type of Fixture

Fixture Fixture Units

Bathrooms

Water Closet: Flush Valve 6

Water Closet: Tank Operated 4

Urinal: Pedestal 6

Urinal: Non-Pedestal 2

Bidet 2

Bathtub (with or w/o shower) 2

Shower (per showerhead) 2

Lavatory 1

Bathroom Group 1: Lavatory, Bathtub (with or w/o shower), Flush Valve Water 8

Closet

Bathroom Group 2: Lavatory, Bathtub (with or w/o shower), Tank Operated Water 5

Closet

Kitchens

Sink (with or w/o waste disposal) 2

Sink (scullery) 2

Dishwasher 2

Laundry Room

Washing Machine 3

Laundry Tray (One or Two Compartments) 2

Specialty Fixtures

Sink: Flushing Rim with Valves 6

Sink: Service (P-Trap) 2

Sink: Service (Standard Trap) 3

Lavatory: Surgeon 2

Lavatory: Hairdresser, Beauty Parlor 2

Miscellaneous

Floor Drain: 2” 2

Drinking Fountain 1

Copyright2006-07 ProVent Systems. Inc Page 8

Maximum Loading by Branch, Stack and Building

in Fixture Units

Chart 2: Maximum Loading by Branch

Slope Slope

2% (1/4” per foot) 1% (1/8” per foot)

Drain Size Fixture Units Fixture Units

2” 6 5

3” 16 13

4” 90 72

Chart 3: Maximum Loading by Stack

Stack Size Fixture Units

3” 64

3” (over 7 stories) 102

4” 504

5” 1,010

6” 2,200

8” 3,900

Chart 4: Maximum Loading by Building Drain

Slope Slope

2% (1/4” per foot) 1% (1/8” per foot)

Drain Size Fixture Units Fixture Units

3” 42 36

4” 216 180

5” 350 280

6” 850 680

8” 2,700 2,160

10” 3,900 3,120

12” 5,800 4,640

Copyright2006-07 ProVent Systems. Inc Page 9

StackVent Dimensions

A B* C D E* F G H I

3" 7-3/4" 18" 3-1/2" 3-1/2" 9" 9" 6-1/2" 5-3/4" 4-1/4"

4" 9-3/4" 22-1/2" 4-1/2" 4-1/2" 10-1/2" 12" 8" 7" 5-1/4"

* For effective height after installation, subtract 3” from this measurement since the top spigot end inserts 3”

up into the ProSet Sleeve

Copyright2006-07 ProVent Systems. Inc Page 10

BaseVent Dimensions

A B1 B2 C D E

3" x 2" 9-1/2" 11" 9-1/4" 4" 2-3/4" 6"

4" x 3" 11-1/2" 13-1/2" 11" 5" 4" 7"

Copyright2006-07 ProVent Systems. Inc Page 11

Stack and StackVent Fitting Rule 1.2

A ProVent Stack Fitting is required to be used at each floor level when the horizontal soil or waste branch

collected is either the same size or one pipe size smaller than the vertical ProVent Stack Fitting.

Extend ProVent stack f ull

size through the roof

4” ProVent Stack

StackVent

Floor Drain

4” WC

StackVent

Floor Drain

4”

3”

4”

BaseVent

Drawing 1.2

Copyright2006-07 ProVent Systems. Inc Page 12

Stack and StackVent Fitting Rule 1.3

Waste branches that are two (2) pipe sizes smaller than the stack can be connected with a sanitary tee or

wye directly into the ProVent stack (between ProVent Stack Fittings).

4” ProVent

Stack

2” Waste - 2 Pipe

sizes Smaller

StackVent

2” Waste: 2 Pipe

Sizes Smaller

4” ProVent

Stack

Drawing 1.3

Copyright2006-07 ProVent Systems. Inc Page 13

Stack and StackVent Fitting Rule 1.4

If there are no branch connections at a floor level, there is no need to use the ProVent Stack Fitting. Instead,

a double in-line offset must be used in its place. The vertical interval between the Stack Fitting and the in-

line offset shall not exceed 20 feet and no more than two (2) consecutive double in-line offsets can be used.

ProVent

Stack

StackVent

20’ 0”

Max.

Inline Offsets: Two (2) 1/8 Bends

& One (1) 1/4 Bend.

20’ 0”

Max.

20’ 0”

Max.

StackVent

ProVent

Stack

BaseVent

Drawing 1.4

Copyright2006-07 ProVent Systems. Inc Page 14

Stack and StackVent Fitting Rule 1.5

Offsets in the stack of more than 60 degrees require a ProVent Base Fitting with a pressure relief vent line

tied in to the top vertical portion of the stack. Branch piping can be connected to the offset soil piping. A 45

degree stack offset is not considered an offset. Waste branches (1) one pipe size smaller can be connected

to the pressure relief vent line with the exception of washing machine wastes. It is recommended that

Washing machine wastes should be isolated from other fixtures. If they must be combined, call for technical

support.

StackVent

BaseVent

A

One pipe size smaller

than relief vent

B

B Not

4” or 3” Considered

Waste 45o

an Offset

Detail: “B-B”

4” 4”

Detail:

Drawing 1.5

Copyright2006-07 ProVent Systems. Inc Page 15

Stack and StackVent Fitting Rule 1.7

Combinations of vent stacks may be tied together above the highest fixture served before going through the

roof. The combined vertical stack must be increased (1) one pipe size larger than the combined stacks. If

the distance between the two (2) stacks that connect is greater than twenty (20) feet, the horizontal branch

must be one (1) pipe size larger than the downstream stack.

Vent Throug h Roof

5”

If distance between

stacks is more than

4” 20 f eet, increase

one pipe size

4”

4”

4”

Drawing 1.7

Copyright2006-07 ProVent Systems. Inc Page 16

Stack and StackVent Fitting Rule 1.8

Stacks may offset above the highest fixture served. When the horizontal offset exceeds twenty (20) feet, the

diameter of the horizontal offset and the vent through the roof must be increased one pipe size

Vent Throug h Roof Vent Throug h Roof

5” 4”

20’ or less, no pipe

More than 20’, size increase

Increase one pipe size

4”

5”

4”

4”

4”

4”

Drawing 1.8

Copyright2006-07 ProVent Systems. Inc Page 17

BaseVent Fitting Rule 2.1

A ProVent Base Fitting must be installed at the base of each vertical stack before it enters the horizontal

building drain. If the vertical distance to the closest ProVent Stack Fitting exceeds twenty feet (20’-0") an

inline offset must be installed within five feet (5’-0") above the ProVent Base Fitting. The building drain size

is calculated by using Chart 4 in accordance with the fixture unit values (D.F.U.) for all fixtures discharging

into it as shown in Chart 1.

StackVent

ProVent

Stack

StackVent

Inline Offset:

ProVent Two (2) 1/8 Bends

Stack

& One (1) 1/4 Bend.

More

than 20’

20’ 0”

Max.

BaseVent BaseVent Max. of 5’

Drawing 2.1

Copyright2006-07 ProVent Systems. Inc Page 18

BaseVent Fitting Rule 2.2

The ProVent Base Fitting has a pressure relief vent opening that extends up then makes a 180 degree turn

downward using pipe and fittings that connect to the horizontal building drain at a point no less than 10 pipe

diameters downstream from the center line of the vertical stack to the centerline of the branch wye. The

pressure relief vent line may run parallel to the horizontal drain and must connect above the centerline of the

drain. Branch soil or wastes are allowed when they are connected above the horizontal drain line.

Cleanout

as required

BaseVent

Detail: “A-A”

3” Stack: Min. 30”

4” Stack: Min. 40”

Drawing 2.2

Copyright2006-07 ProVent Systems. Inc Page 19

BaseVent Fitting Rule 2.3

A ProVent Base Fitting must be used on any stack offsets of more than 60 degrees with the pressure relief

vent connection running from the base fitting back into the top vertical portion of the stack drop.

BaseVent

Greater than 60o

Greater than 60o

Detail: “A-A”

Drawing 2.3

Copyright2006-07 ProVent Systems. Inc Page 20

BaseVent Fitting Rule 2.4

Soil and waste branches can be connected into the building drain between the stack and the relief vent when

the connections are made above the center line of the building drain. The branch fixture unit loading should

be in accordance with the pitch of the pipe as shown in Chart 3.

Detail: “A-A”

BaseVent

Detail: “B-B”

1-1/2”

LAV

A

WC

1-1/4” A

2”

3” 4” BaseVent

B

3”

B

A Incorrect (Does not enter main

building drain above its center line)

Drawing 2.4

Copyright2006-07 ProVent Systems. Inc Page 21

BaseVent Fitting Rule 2.5

Waste branches at least (1) one pipe size smaller can be connected to the pressure relief horizontal vent line.

Washing machine drains should not connect to the pressure relief vent line.

BaseVent

Connect tub

waste to PRL

3” Pressure

Relief Line A

A

TUB

2”

B

B

4”

Detail: “A-A”

Branch Waste Line

Min. Elev. Requts.

Branch

Waste Line

Pressure Relief Line (PRL)

Detail: “B-B”

Drawing 2.5

Copyright2006-07 ProVent Systems. Inc Page 22

BaseVent Fitting Rule 2.6

Soil or waste branches may connect directly into the vertical stack directly below the ProVent Base Fitting

only when the connections are made using fittings such as a combination wye and 1/8 bend.

Detail: “A-A”

BaseVent

Double combo wy e (long or short

sweep) and 1/8 bend

(single combo used f or one side)

Drawing 2.6

Copyright2006-07 ProVent Systems. Inc Page 23

BaseVent Fitting Rule 2.7

Conventional waste & vent plumbing systems can connect downstream from the pressure relief vent to pick

up remote fixtures. Conventional revents can tie back into the ProVent vertical stack with vent sizing based

on the additional fixture units vented or can be separately vented through the roof in accordance with locally

accepted plumbing code vent sizing.

StackVent

Vent Throug h Roof

Sanitary

Tee

Or route back

to ProVent Stack

ProVent

Stack

BaseVent

1-1/2”

LAV

WC

1-1/4” TUB

3” PRL

2” 2”

2”

Connection outside

single stack zone

Conventional ProVent

Plumbing System Plumbing System

Drawing 2.7

Copyright2006-07 ProVent Systems. Inc Page 24

Branch Opening Rule 3.1

All branch piping sizes and loads should be in accordance with Chart 2. Branch piping should have a minimum

of 1/8" per foot pitch.

(See Chart 2)

Branch Opening Rule 3.2

Branches that change directions three (3) times by 90 degrees should increase one pipe size at the offset

nearest the stack. This increase does not apply if one (1) of the changes can be made with two (2) forty five

degree fittings or a long sweep 90 degree fitting.

900 Ell 900 Ell

2” 2” 2” 3”

Sanitary

Tee

StackVent

0

Long sweep

90 Ell 900 Fitting

900 Ell

2” 2”

2” 2”

ProVent

Stack

900 Ell

Drawing 3.2

Copyright2006-07 ProVent Systems. Inc Page 25

Branch Opening Rule 3.3

If two (2) 3.5 gpf public water closets are connected to the same branch, the first connection can be 3" then

increased to 4" at the second connection. This increase is not required for the 1.6 gpf flush water closets.

Check manufacturers installation instructions for pressure assisted type water closets that may require special

fittings for back to back installations.

Two 3.5 gpf WCs

ProVent

Stack

WC

3” Two 1.6 gpf WCs

WC

4”

3”

3”

3”

StackVent

ProVent

Stack

Drawing 3.3

Copyright2006-07 ProVent Systems. Inc Page 26

Branch Opening Rule 3.4

4" Size branches shall not exceed a developed length of 27 feet. 3" Size branches shall not exceed a devel-

oped length of 15 feet. 2" Size branches shall not exceed a developed length of 15 feet. 2" branches for

washing machines should not exceed 5 feet. These lengths include any horizontal pipe offsets but the

length of the vertical drop arms is not included (see Rule 3.5 for restrictions on vertical drops). Horizontal to

horizontal branch connections should be made with wye combinations or heel outlet fittings.

Prov ent

Stack

3”

15’ Max

27’ Max

StackVent 4” * 15’ Max

Prov ent

Stack 3” * 15’ Max

2”

* A maximum distance of 27 ft. is allowed on a 4” soil branch.

However, it is recommended that the use of 3” pipe be maximized

for 1.6 GPF toilet systems.

Drawing 3.4

Copyright2006-07 ProVent Systems. Inc Page 27

Branch Opening Rule 3.5

Vertical branches should not exceed 40". A 45 degree offset can extend the drop pipe to 40" from the top 45

degree fitting to the fixture outlet. When a vertical drop into a horizontal waste exceeds 10 feet both must

increase one (1) pipe size.

40” or less 40” or less

2” Ov er 40”

2” 2”

2”

2” 3”

10’ or less Ov er 10’

2” 3”

Horizontal Waste Horizontal Waste

Drawing 3.5

Copyright2006-07 ProVent Systems. Inc Page 28

Branch Opening Rule 3.6

1-¼" size fixture traps can be connected back to back into one 2" vertical drop. 1-½" size fixture traps re-

quire separate 2" drops. 1-1/2" and larger traps can use a single vertical drop by increasing the drop one

(1) pipe size. Note: Horizontal waste branches without vertical drops are sized per chart 2.

Sink

LAV or EWC

2”

1-1/4” 1-1/2”

1-1/2” 1-1/2”

1-1/4”

1-1/2” 1-1/4” 2” 2”

1-1/4”

2” 2”

LAV or EWC

2”

2”

Washing

Machine

2”

Washing

Machine

4” 4”

2” 3”

Max: 5’

on 2” Max: 15’

on 3”

2”

Washing

Machine

2”

2”

3”

3”

Max: 15’

on 3”

Drawing 3.6

Copyright2006-07 ProVent Systems. Inc Page 29

Branch Opening Rule 3.7

An alternate to increase developed lengths can be done by using a revent line or by telescoping smaller to

larger pipe sizes or by using an Air Admittance Valve where applicable and permitted. The revent line shall be

routed vertically and horizontally and tie in above the flood rim level using a wye branch looking up.

4” ProVent Stack

Max: 15’

LAV

StackVent 2” *

Max: 15’

TUB

2” *

Pressure

Equali zing Line

(rev ent line)

StackVent

Ov er 15’

TUB

Optional Air

Admittance Valv e

Ov er 15’

BaseVent LAV

* The maximum branch size is two sizes smaller than the stack size

Drawing 3.7

Copyright2006-07 ProVent Systems. Inc Page 30

Other Examples of ProVent Fixture Branches

Lavatories: Vertical Branch Lavatories: Horizontal Branch

1-1/2”

2”

LAV 2”

LAV

2” LAV

1-1/4” 2” 1-1/2”

1-1/2”

LAV 1-1/4” LAV

1-1/2”

2”

LAV

1-1/2”

Drawing 31a Drawing 31b

Sinks: Vertical Branch Sinks: Horizontal Branch

1-1/2”

2” 1-1/2”

2”

2”

1-1/2”

2” 1-1/2”

2”

1-1/2”

Drawing 31c Drawing 31d

Washing Machines: Vertical Branch Washing Machines: Horizontal Branch

2”

2”

3”

3”

4”

Max: 5’

Max: 15’

4”

Drawing 31e Drawing 31f

Copyright2006-07 ProVent Systems. Inc Page 31

Example: Side by Side Layouts

1-1/2” LAV

1-1/4”

2”

ProVent

Typical Side by Side

WC

Stack

TUB

TUB

StackVent

WC

1-1/2” LAV

1-1/4”

2”

20’ 0”

Max.

Inline Offset - Two (2) 1/8 Bends

& One (1) 1/4 Bend. If 20 f oot

maximum is exceeded between

inline offset and BaseVent, add

inline offset 5’-0” abov e BaseVent

Detail: “A-A”

ProVent

Stack

1-1/2” LAV

20’ 0”

1-1/4” Max.

2”

Detail: “B-B” Typical Side by Side

WC

BaseVent Base of Stack

TUB

Drawing 32 TUB

A

3” PRL A WC

1-1/2” LAV

B 2”

SAN

1-1/4”

2”

B

3”

Copyright2006-07 ProVent Systems. Inc Page 32

Example: Single Unit Layouts

1-1/2” LAV ProVent

Stack

WC Typical Single Unit

1-1/4”

2”

3”

TUB 2”

2”

2”

StackVent

Drawing 33a

ProVent

Stack

BaseVent

1-1/2” LAV Typical Single Unit

Base of Stack

1-1/4”

2” WC

TUB

3” PRL

2”

2” A

A

B 3” Stack: Min. 30”

B 4” Stack: Min. 40”

Drawing 33b

Detail: “A-A” Detail: “B-B”

Copyright2006-07 ProVent Systems. Inc Page 33

Example 1: Back to Back Layouts

1-1/2” ProVent

Stack

LAV

2”

Typical Back to Back

1-1/4”

2”

2”

WC LAV

3” 1-1/2”

2”

1-1/4”

3”

TUB

WC

Heel Inlet

1/4 Bend

StackVent TUB 2”

Drawing 34a ProVent

Stack

1-1/2”

BaseVent

LAV 2”

Typical Back to Back

1-1/2”

Base of Stack

1-1/4”

LAV

Connect tub 2”

waste to PRL WC

1-1/4”

TUB

2”

2”

3”

TUB

3” PRL 3” Stack: Min. 30”

2” 4” Stack: Min. 40”

Drawing 34b

Copyright2006-07 ProVent Systems. Inc Page 34

Example 2: Back to Back Layouts

(Alternative Layout for Upper Floors)

ProVent

1-1/2” Stack

Alternate Back to Back

LAV

1-1/4”

2”

LAV

1-1/4”

WC 1-1/2”

2” 2”

3”

TUB 3”

WC

2”

StackVent TUB 2”

Heel Inlet ProVent

1/4 Bend Stack

Drawing 34c

Copyright2006-07 ProVent Systems. Inc Page 35

IMPORTANT NOTICE

This manual shows the basic plumbing rules that have been used for over 40 years for both the copper and cast iron Sovent

systems. The same rules apply for this PVC plastic ProVent System that includes both the ProVent Stack and Base fittings.

ProVent Systems may include conventional plumbing that must be installed in accordance with local plumbing codes. The

vents from conventional plumbing may be tied into the ProVent stack as indicated within this manual.

ProVent Systems can assist in job design and inspections under certain understood conditions with the contractor or plumb-

ing engineer. Job quotations may or may not include these services where required. Contact us for further information.

All additional piping, fittings, pipe supports, firestopping and other items that are supplied by others, should be in strict ac-

cordance with good piping practices and all applicable codes having jurisdiction.

When the rules used in this manual are adhered to without any deviations the system is known to function properly. How-

ever, any unknown deviation may reduce the integrity of this system. Therefore, the user must assume all responsibility for

the integrity and performance of the completed DWV plumbing system and for adherence to all the rules included in this

manual.

ProVent Systems cannot assume responsibility for the performance of the complete DVW system other than for the perform-

ance of the individual components supplied by ProVent Systems, as stated in the “Limited Parts Warranty”, below.

LIMITED PARTS WARRANTY

Sellers products are carefully inspected for manufacturing defects; however, it is not always possible to detect hidden defects. Said products are warranted only

to the extent that seller will replace without charge, products proved to have manufacturing defects within 6 months of the date of delivery thereof and provided

seller has been given an opportunity to inspect the product alleged to be defective and the installation or use thereof. NO WARRANTY IS INCLUDED AGAINST

ANY EXPENSE FOR REMOVAL, REINSTALLATION OR OTHER CONSEQUENTIAL DAMAGES ARISING FROM ANY DEFECT. THE WARRANTIES SET OUT ABOVE

ARE THE ONLY WARRANTIES MADE BY SELLER AND ARE EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE

WARRANTIES OR MERCHANTABILTY AND FITNESS FOR A PARTICULAR PROPOSE.

You might also like

- Proceedings CIB W062 2018 SymposiumDocument354 pagesProceedings CIB W062 2018 SymposiumdplumbingNo ratings yet

- Drainagesystemslecturei 091022013358 Phpapp02Document62 pagesDrainagesystemslecturei 091022013358 Phpapp02Abdul Raoof100% (1)

- HVAC Load Calculations GuideDocument66 pagesHVAC Load Calculations GuideHESuarez88% (41)

- Ansi Color CodingDocument2 pagesAnsi Color CodingHESuarez100% (1)

- Corporate Venture Studios DirectoryDocument12 pagesCorporate Venture Studios Directorymoctapka0880% (1)

- Plumbing and Sanitary Systems Topic 1 Module 1 LectureDocument55 pagesPlumbing and Sanitary Systems Topic 1 Module 1 Lecturechristian001 Latag100% (1)

- Se Sovent Design Manual 101o New011007Document24 pagesSe Sovent Design Manual 101o New011007jomy_pj8106No ratings yet

- Wet Scrubber Selection GuideDocument8 pagesWet Scrubber Selection GuideHESuarez100% (2)

- Wet Scrubber BulletinDocument8 pagesWet Scrubber BulletinHESuarez100% (1)

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- Soal Olimpiade Matematika Grade 4Document3 pagesSoal Olimpiade Matematika Grade 4wakidsNo ratings yet

- Negative Averment AffidavitDocument3 pagesNegative Averment Affidavitamenelbey80% (5)

- New Password 3: A Reading and Vocabulary Text: Linda ButlerDocument1 pageNew Password 3: A Reading and Vocabulary Text: Linda ButlerRastko Manojlovic0% (3)

- ProVent IPC Comparison Manual LetterDocument12 pagesProVent IPC Comparison Manual Letterjack j100% (1)

- Lecture 4 Water Pipe Sizing PDFDocument26 pagesLecture 4 Water Pipe Sizing PDFAlchea Aldeguer100% (1)

- Plumbing ReviewerDocument46 pagesPlumbing ReviewerYsabelle Marie FuentesNo ratings yet

- R1 Designing A School Public ToiletDocument18 pagesR1 Designing A School Public ToiletIrish Barte100% (1)

- Case Study Siphonic Roof Drains MarshallDocument2 pagesCase Study Siphonic Roof Drains MarshalldanateoNo ratings yet

- Hydromax™ Siphonic Drainage 17-2-12Document83 pagesHydromax™ Siphonic Drainage 17-2-12Dan O Villarreal100% (1)

- Sizing Sump Pits and Sump PumpsDocument2 pagesSizing Sump Pits and Sump PumpsnNo ratings yet

- IRR On Proper Sewage HandlingDocument51 pagesIRR On Proper Sewage HandlingDexter G. BatalaoNo ratings yet

- Tips of Fountain Design Part 2 - 3 - Blog of Fountain Design and Water ShowsDocument2 pagesTips of Fountain Design Part 2 - 3 - Blog of Fountain Design and Water ShowsAnh Đức NguyễnNo ratings yet

- Sizing Water SystemsDocument16 pagesSizing Water SystemsRadoNoun100% (1)

- Pool Circulation PDF Document Aqua Middle East FZCDocument18 pagesPool Circulation PDF Document Aqua Middle East FZCAdolfsmith69No ratings yet

- ACO Floor Drains and Clean Out CatalogDocument9 pagesACO Floor Drains and Clean Out CatalogJohnny TsehayeNo ratings yet

- Plumbing Fittings Types With Their ApplicationDocument12 pagesPlumbing Fittings Types With Their ApplicationBiju MenonNo ratings yet

- Chapter 11 Water Distribution SystemsDocument32 pagesChapter 11 Water Distribution SystemsEarl John LugatimanNo ratings yet

- Plumbing Specifications - NgacDocument57 pagesPlumbing Specifications - Ngacmon MagbualNo ratings yet

- 12 DrainageDocument22 pages12 Drainageansara89No ratings yet

- Hot and Cold Water Supply FinalDocument40 pagesHot and Cold Water Supply FinalAmit Kumar YadavNo ratings yet

- 224105, Residential Plumbing FixturesDocument15 pages224105, Residential Plumbing Fixturessrp. mohammedNo ratings yet

- Building Services - Water SupplyDocument33 pagesBuilding Services - Water SupplyRitikaNo ratings yet

- Siphonic System - Design RulesDocument26 pagesSiphonic System - Design RulesCarla Bianca Meliton ConsueloNo ratings yet

- Rainwater Harvesting Workshop Manual-UK-RHA - 2012Document36 pagesRainwater Harvesting Workshop Manual-UK-RHA - 2012Erin Lim100% (1)

- Frequently Asked Questions: Geberit SupertubeDocument9 pagesFrequently Asked Questions: Geberit Supertubemohaideen kasimNo ratings yet

- 01-2021-02-15 - EL - RES - Ato Mamush Plumbing Services Design ReportDocument15 pages01-2021-02-15 - EL - RES - Ato Mamush Plumbing Services Design Reportdawitggg0% (1)

- PLUMBING Final HandoutprofDocument33 pagesPLUMBING Final HandoutprofReinier CarrascoNo ratings yet

- Mebs6000 1011 05 DrainageDocument72 pagesMebs6000 1011 05 Drainagesmartysky100% (1)

- Ebook Lakes LagoonsDocument24 pagesEbook Lakes LagoonskhairullamustafaNo ratings yet

- CPDT Bulletin - 2022Document9 pagesCPDT Bulletin - 2022Ivan DNo ratings yet

- Design and Construction of Swimming Pools-Ib-P-Bc2017 014Document10 pagesDesign and Construction of Swimming Pools-Ib-P-Bc2017 014Luffy11No ratings yet

- Siphonic Roof Drainage Systems The Road To PrimingDocument0 pagesSiphonic Roof Drainage Systems The Road To PrimingDedy KristiantoNo ratings yet

- Plumbing Engineering Design Course: Engineer Haithm KhalilDocument34 pagesPlumbing Engineering Design Course: Engineer Haithm KhalilAhmed Hassan100% (1)

- Plumbing Materials and Various ToolsDocument8 pagesPlumbing Materials and Various ToolsJayson G. GunioNo ratings yet

- Geberit Drainage BrochureDocument6 pagesGeberit Drainage BrochureCzar LRNo ratings yet

- PVC Design Guide ApprovedDocument222 pagesPVC Design Guide Approvedgabox7No ratings yet

- Swimming Pool CodeDocument53 pagesSwimming Pool CodeAnonymous dK9Qi2XjNo ratings yet

- Water Supply in High Rise BuildingsDocument8 pagesWater Supply in High Rise BuildingsVaishnavi Parmar100% (1)

- Pipe SpecialsDocument20 pagesPipe SpecialsLance Joseph OdtojanNo ratings yet

- Specifications For Underground Water Storage Tanks For Fire ProtectionDocument5 pagesSpecifications For Underground Water Storage Tanks For Fire ProtectionkirmaniNo ratings yet

- Pipe Sizes and ScheduleDocument2 pagesPipe Sizes and Schedulechupacid0% (1)

- Xpelair CataloguesDocument39 pagesXpelair Cataloguestafadzwa simbiNo ratings yet

- BUILDING PLUMBING SYSTEM Part 2Document10 pagesBUILDING PLUMBING SYSTEM Part 2Nyein Aye MyatNo ratings yet

- Mebs6000 0809 03 Cold and Hot Water Design PDFDocument78 pagesMebs6000 0809 03 Cold and Hot Water Design PDFKamaruz DanialNo ratings yet

- Arch 502 - Pipes FittingsDocument70 pagesArch 502 - Pipes FittingsjerilonNo ratings yet

- Chapter 9 Vents and VentingDocument24 pagesChapter 9 Vents and VentingPotter XxNo ratings yet

- Topic 6 Plumbing & Sanitary (2012) Stud-1Document30 pagesTopic 6 Plumbing & Sanitary (2012) Stud-1LuisLoNo ratings yet

- Chilled Water Pipe DESIGNDocument22 pagesChilled Water Pipe DESIGNTanjim FakirNo ratings yet

- Water SupplyDocument17 pagesWater SupplyHarsh VermaNo ratings yet

- Technical Specifications For Fire Suppression System PipesDocument14 pagesTechnical Specifications For Fire Suppression System PipesHarikrishnaNo ratings yet

- SgTank Sectional Water Storage TankDocument33 pagesSgTank Sectional Water Storage TankRichard LeongNo ratings yet

- Plumbing Materials, Fittings, FixturesDocument21 pagesPlumbing Materials, Fittings, FixturesRayan Ahmad BarodiNo ratings yet

- DM Auto Irrigation Systems SpecificationsDocument71 pagesDM Auto Irrigation Systems SpecificationsbargothiNo ratings yet

- Deckshield IDDocument2 pagesDeckshield IDMinhHyNo ratings yet

- Enraf Insertion Stilling Wells-2 - 240426 - 122200Document5 pagesEnraf Insertion Stilling Wells-2 - 240426 - 122200edgar vidalNo ratings yet

- SE SOVENT DESIGN MANUAL 101o New011007Document24 pagesSE SOVENT DESIGN MANUAL 101o New011007Любов АндреєваNo ratings yet

- SE SOVENT DESIGN MANUAL 101o New011007Document24 pagesSE SOVENT DESIGN MANUAL 101o New011007VishnuNo ratings yet

- The Akatherm Akavent System: Design GuidelinesDocument16 pagesThe Akatherm Akavent System: Design Guidelinesdaud heruNo ratings yet

- QuickStream PE - Manual Wavin PresiuneDocument40 pagesQuickStream PE - Manual Wavin PresiuneIonut SomneaNo ratings yet

- Design Briefs Advanced VAV SystemsDocument27 pagesDesign Briefs Advanced VAV SystemsHESuarezNo ratings yet

- Thermal Storage Wall Design ManualDocument43 pagesThermal Storage Wall Design ManualAn Energy-Efficient Solar-Heated GreenhouseNo ratings yet

- Thermal Energy StorageDocument3 pagesThermal Energy StorageHESuarezNo ratings yet

- EDR Multifamily Design Guide For Energy EfficiencyDocument25 pagesEDR Multifamily Design Guide For Energy EfficiencyHESuarezNo ratings yet

- Commercial Kitchen Design GuideDocument31 pagesCommercial Kitchen Design Guidebasha99100% (2)

- EDR DesignBriefs PumpsystemtroubleshootingDocument39 pagesEDR DesignBriefs PumpsystemtroubleshootingLuis CarlosNo ratings yet

- EDR CommissioningHandbookCompleteDocument125 pagesEDR CommissioningHandbookCompletegeralva55No ratings yet

- Psychrometric CourseDocument94 pagesPsychrometric CourseHESuarez50% (2)

- Fire SPRKLR Train ManDocument81 pagesFire SPRKLR Train ManHESuarez100% (1)

- Maximizing Wet Scrubber PerformanceDocument7 pagesMaximizing Wet Scrubber PerformanceHESuarez100% (1)

- Cross Connection ManualDocument122 pagesCross Connection ManualHESuarezNo ratings yet

- A Hand Book For The Mechanical Designer Ventilation Duct FanDocument107 pagesA Hand Book For The Mechanical Designer Ventilation Duct Fanrawneeh100% (6)

- Bpump PDFDocument20 pagesBpump PDFgpskumar22No ratings yet

- VAV Design GuideDocument326 pagesVAV Design GuideHESuarez100% (3)

- Fire StopDocument55 pagesFire StopHESuarezNo ratings yet

- Grinnell Grooved Fire ProDocument144 pagesGrinnell Grooved Fire ProHESuarez100% (1)

- Rainwater Collection SystemDocument28 pagesRainwater Collection SystemHESuarezNo ratings yet

- Stair PressurizationDocument7 pagesStair PressurizationHESuarez100% (1)

- How To Use Adobe Illustrator CS3Document11 pagesHow To Use Adobe Illustrator CS3HESuarezNo ratings yet

- Blaze Master Installation and Specification ManualDocument33 pagesBlaze Master Installation and Specification ManualHESuarez100% (1)

- Trouble-Shooting Chart For PUMPSDocument1 pageTrouble-Shooting Chart For PUMPSAnwar SyedNo ratings yet

- Evap. Cooling Design ManualDocument109 pagesEvap. Cooling Design Manualkunj74No ratings yet

- Pylontech - US2000C, US3000CDocument1 pagePylontech - US2000C, US3000CYC CarieloNo ratings yet

- The Science of EtymologyDocument274 pagesThe Science of Etymologynatzucow100% (5)

- Rose Doe v. The City of New York, Et. Al.Document57 pagesRose Doe v. The City of New York, Et. Al.Daily Caller News FoundationNo ratings yet

- Sikamelt 700Document2 pagesSikamelt 700Ionut StoicaNo ratings yet

- Folding Standards: GeneralDocument9 pagesFolding Standards: GeneralNaadiyah JauharaNo ratings yet

- Guide JCT 2005 Design Built Rev 2009Document44 pagesGuide JCT 2005 Design Built Rev 2009seanbeagNo ratings yet

- Vrealize Automation 70 ConfigurationDocument386 pagesVrealize Automation 70 ConfigurationsatishNo ratings yet

- Fusion Financials Implementation GuideDocument174 pagesFusion Financials Implementation Guidemaddiboina100% (1)

- University of Santo Tomas Senior High School Documentation of Ust'S Artworks Through A Walking Tour Brochure and Audio GuideDocument30 pagesUniversity of Santo Tomas Senior High School Documentation of Ust'S Artworks Through A Walking Tour Brochure and Audio GuideNathan SalongaNo ratings yet

- May 6, 2016 Strathmore TimesDocument28 pagesMay 6, 2016 Strathmore TimesStrathmore TimesNo ratings yet

- Organisation of Prosecuting AgenciesDocument24 pagesOrganisation of Prosecuting AgenciesPAULOMI DASNo ratings yet

- Penggunaan Metode Waterfall Untuk Pengembangan Sistem Monitoring Dan Evaluasi Pembangunan PedesaanDocument26 pagesPenggunaan Metode Waterfall Untuk Pengembangan Sistem Monitoring Dan Evaluasi Pembangunan PedesaanII8I40O24 Oktaviana Rinda SariNo ratings yet

- Bissell 1967Document82 pagesBissell 1967engr_usman04No ratings yet

- Portable Lamps & Converters: W 276 LEDDocument2 pagesPortable Lamps & Converters: W 276 LEDRaghu paryNo ratings yet

- Republic vs. Castelvi, 58 SCRA 336 (1974)Document4 pagesRepublic vs. Castelvi, 58 SCRA 336 (1974)Gabriel HernandezNo ratings yet

- 2024 03 06 Introduction Lecture Series Climate Protection SS2024Document45 pages2024 03 06 Introduction Lecture Series Climate Protection SS2024Abdullah Khan QadriNo ratings yet

- Erectile Dysfunction: QuestionsDocument24 pagesErectile Dysfunction: QuestionsSayed NourNo ratings yet

- Unpacking Instructional Leadership QuestionnairesDocument7 pagesUnpacking Instructional Leadership QuestionnairesRENIEL MARK BASENo ratings yet

- State v. Carveiro, Ariz. Ct. App. (2015)Document5 pagesState v. Carveiro, Ariz. Ct. App. (2015)Scribd Government DocsNo ratings yet

- Lesson 4: Water SafetyDocument12 pagesLesson 4: Water SafetyHelena FarroNo ratings yet

- 04 Rodrigo Roa Duterte, Fifth State of The Nation Address, July 27, 2020 - Official Gazette of The Republic of The PhilippinesDocument23 pages04 Rodrigo Roa Duterte, Fifth State of The Nation Address, July 27, 2020 - Official Gazette of The Republic of The PhilippinesJoseph SalazarNo ratings yet

- Members 800Document62 pagesMembers 800Sandeep JainNo ratings yet

- Modi Cabinet 3.0 Ministers NamesDocument6 pagesModi Cabinet 3.0 Ministers NamesRicha sharmaNo ratings yet

- Tailieuchung Boi Duong Hoc Sinh Gioi Luong Giac NXB Dai Hoc Quoc Gia 2014-2-8519Document116 pagesTailieuchung Boi Duong Hoc Sinh Gioi Luong Giac NXB Dai Hoc Quoc Gia 2014-2-8519Vincent TuấnNo ratings yet

- The Eden Club Rules & RegulationsDocument16 pagesThe Eden Club Rules & RegulationsRodney AtkinsNo ratings yet

- Aquatic HabitatDocument6 pagesAquatic Habitatofurumchinyere9No ratings yet