Professional Documents

Culture Documents

WE-Aly-PLSec1-02-09-2010 Rev.1

WE-Aly-PLSec1-02-09-2010 Rev.1

Uploaded by

Ahmed AlyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WE-Aly-PLSec1-02-09-2010 Rev.1

WE-Aly-PLSec1-02-09-2010 Rev.1

Uploaded by

Ahmed AlyCopyright:

Available Formats

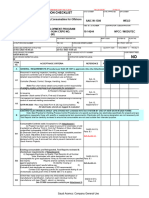

Date 2-Sep-10

Abu Dhabi Crude Oil Pipeline (ADCOP) Project

Discipline Welding Inspection Engineer

Third Party Inspection & Testing Services Daily Inspection Log Sheet GL Inspector Aly Abd Elmonem

RFI / Surv.

Sl No. Area / Location Description of Activity Inspection Result Comments/Recommendations

Ref.

- Daily Duites :-

1-Conducting different modes of inspection to get a good quality output.as: Welding parameter verification,consumables in used and

their certificates, pre-heating,equipment inspection and validation of performance,visual inspection of welds at 100% and monitoring

between passes at random checking on bevelling before fitup .

2-Monitoring pipeline installation activities,records any abnormalities found along the p/l path and reporting the situation to the concern

contractor supervisor.

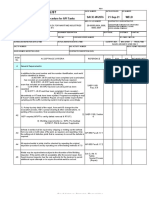

1- Production welds (M2 crew) :

3-Monitor welders performance for preventing any increase in their repair percentage at their welding assigned area.

a- Prev. welds : 276

Pipe Line Sec # 1 4-Reviewing the approved welding procedures, welder’s qualification list, contractor work of scope and procedures.

b- Today welds : 0

1 Construction Schedule 5- Checkinglist make for all welding equipments ,SMAW consumable conditions,and its traceability for repair welds, safety precaution ACC

c- Accu. Welds : 276

for perfoming these activites.

6-Give an advice to contractor team at site in any problems face during acheiving the welding activities.

7-Ensure that all activities done in site was done in line with the project specs . 2- Production welds (M2 crew) : Wait road crossing at KP46

8-Checking the cleaness of pipes ends from rust or any foriegn matrials before welding.

- Safety Observations:-

- No opservation was noted

You might also like

- QAQC Procedure For FabricationDocument7 pagesQAQC Procedure For FabricationRajesh K Pillai100% (6)

- Geometric Design Guidelines - 201209201654574591 PDFDocument67 pagesGeometric Design Guidelines - 201209201654574591 PDFVu BuiNo ratings yet

- ANET A3 - S Operation InstructionDocument37 pagesANET A3 - S Operation InstructionNaruto Uzumaki100% (1)

- Welding Inspection Handbook PDF 1623987530Document29 pagesWelding Inspection Handbook PDF 1623987530Dross AlssNo ratings yet

- 00 Saip 11Document21 pages00 Saip 11munnaNo ratings yet

- M 111 Tank Weld Repair ProcedureDocument8 pagesM 111 Tank Weld Repair ProcedureAAISATNo ratings yet

- Procedure For Tin - inDocument13 pagesProcedure For Tin - inAdil IjazNo ratings yet

- CV PidDocument6 pagesCV PidSibin DevasiaNo ratings yet

- NSH-SAOMPP-CMS-PI-001 Piping FabricationDocument13 pagesNSH-SAOMPP-CMS-PI-001 Piping FabricationNeil JavierNo ratings yet

- TDS - Galvanizing ProcessDocument7 pagesTDS - Galvanizing ProcessPappu Kishore Kumar100% (1)

- Baraneedharan Raju CV UpdatedDocument7 pagesBaraneedharan Raju CV UpdatedBaraneedharanNo ratings yet

- D Saic-W-2013 RepairDocument5 pagesD Saic-W-2013 RepairjineshNo ratings yet

- 01 Saip 01Document17 pages01 Saip 01munna100% (1)

- Inspection Engineer - Senior Welding - Arunkumar Andavar - CVDocument7 pagesInspection Engineer - Senior Welding - Arunkumar Andavar - CVArun KumarNo ratings yet

- MES - Construction Quality Manual - Rev - 0Document55 pagesMES - Construction Quality Manual - Rev - 0Ishaan ThakerNo ratings yet

- Project Vuilindlela - Piping Contractors - Quality and Techincal Audit RatingDocument2 pagesProject Vuilindlela - Piping Contractors - Quality and Techincal Audit RatingrcpretoriusNo ratings yet

- Resume of Zahid Ahmed PDFDocument5 pagesResume of Zahid Ahmed PDFzas_ayeshaNo ratings yet

- CQI-15 - Welding System Assessment 2nd EditionDL - Final - 2 - 2ndprinting Laser WeldingDocument3 pagesCQI-15 - Welding System Assessment 2nd EditionDL - Final - 2 - 2ndprinting Laser Weldingalfredo garciaNo ratings yet

- Bishwonath Mechanical &civil SupervisorDocument12 pagesBishwonath Mechanical &civil SupervisorshahbishwonathNo ratings yet

- Saic W 1308Document21 pagesSaic W 1308mathew.genesis.inspNo ratings yet

- QC Welding Inspector ImtiazDocument3 pagesQC Welding Inspector ImtiazImtiyaz MirzaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- 00 Saip 11Document21 pages00 Saip 11BIPIN BALAN100% (1)

- Saic W 2035Document2 pagesSaic W 2035ABDUL RAHMAN ALI MIRNo ratings yet

- WI-NG-6460-002-042 LV Cables Commissioning Rev01Document5 pagesWI-NG-6460-002-042 LV Cables Commissioning Rev01CEPCO karthikNo ratings yet

- Sac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API TanksDocument14 pagesSac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API Tankshusnain aliNo ratings yet

- NSH-SAOMPP-CMS-PI-008-painting and CoatingDocument17 pagesNSH-SAOMPP-CMS-PI-008-painting and CoatingNeil JavierNo ratings yet

- Rashid CV (Equipment Inspector-SEP-2017)Document3 pagesRashid CV (Equipment Inspector-SEP-2017)vajidqcNo ratings yet

- SAIC-W-2009 Revw-Control of Weld Consum - On PlotDocument1 pageSAIC-W-2009 Revw-Control of Weld Consum - On PlotAnonymous S9qBDVkyNo ratings yet

- Saic W 1307Document10 pagesSaic W 1307mathew.genesis.inspNo ratings yet

- Ahmed Ali Alshehri Mobile 00966-508-217284 Address: P.O.Box 70132 Zipcode:31952 Riyadh Street, Al-Khobar, Saudi ArabiaDocument9 pagesAhmed Ali Alshehri Mobile 00966-508-217284 Address: P.O.Box 70132 Zipcode:31952 Riyadh Street, Al-Khobar, Saudi ArabiaShah KhalidNo ratings yet

- Rashid New CV (WI-SEP-2017)Document3 pagesRashid New CV (WI-SEP-2017)vajidqcNo ratings yet

- Egatra: Quality ControlDocument6 pagesEgatra: Quality ControlAndreas Schlager100% (3)

- Abddou Med Amine cv-2-3Document5 pagesAbddou Med Amine cv-2-3امينNo ratings yet

- CV Shoaib Anwar - API 653 Inspector - 3aDocument6 pagesCV Shoaib Anwar - API 653 Inspector - 3ashoaib2scribedNo ratings yet

- QYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementDocument6 pagesQYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementAbdul Khaleem KhanNo ratings yet

- Ei-3008 - Sameer Mapari - Sap # 80001413Document14 pagesEi-3008 - Sameer Mapari - Sap # 80001413gayas416No ratings yet

- MPFM Hot Tap Procedure Rev B.2Document10 pagesMPFM Hot Tap Procedure Rev B.2Neil JavierNo ratings yet

- SAEP-1150 Inspection Coverage On ProjectsDocument54 pagesSAEP-1150 Inspection Coverage On ProjectsUsman AliNo ratings yet

- NSH SAOMPP CMS PI 007 ReinstatementDocument13 pagesNSH SAOMPP CMS PI 007 ReinstatementNeil JavierNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- SAIC W 2009 Revw Control of Weld Consum (EE) RLC FFDocument1 pageSAIC W 2009 Revw Control of Weld Consum (EE) RLC FFAnonymous S9qBDVkyNo ratings yet

- Ei-3109 - Vivek Kollat Babu - Sap # 80001443Document7 pagesEi-3109 - Vivek Kollat Babu - Sap # 80001443gayas416No ratings yet

- Saic L 2002Document13 pagesSaic L 2002chidambaramNo ratings yet

- Rfi TrackingDocument42 pagesRfi Trackinganand100% (2)

- NSH-SAOMPP-CMS-PI-004-tie in WorksDocument11 pagesNSH-SAOMPP-CMS-PI-004-tie in WorksNeil JavierNo ratings yet

- Ebs1 Aaaa00 Saqa Prqa 0016Document7 pagesEbs1 Aaaa00 Saqa Prqa 0016SERT-QA/QC- BUZNo ratings yet

- Rashid New CV (Feb-2017)Document3 pagesRashid New CV (Feb-2017)vajidqcNo ratings yet

- Muthukkumaran Anbalazhan - CVDocument4 pagesMuthukkumaran Anbalazhan - CVSaqib AliNo ratings yet

- Document Purpose & Personnel ResponsibilityDocument3 pagesDocument Purpose & Personnel ResponsibilityIlkin hasanovNo ratings yet

- MS For Cable Tray Installation (IFC, Rev.00)Document11 pagesMS For Cable Tray Installation (IFC, Rev.00)noelNo ratings yet

- Overhead Lines Commissioning Rev01Document5 pagesOverhead Lines Commissioning Rev01pradeepmv159No ratings yet

- Shaik Yousufuddin (Welding Inspector)Document3 pagesShaik Yousufuddin (Welding Inspector)Mohamed AdelNo ratings yet

- SD05wi1 Structural Inspection WorkpackDocument22 pagesSD05wi1 Structural Inspection WorkpackidrisNo ratings yet

- Guidelines For Fabrication of Steel GirderDocument17 pagesGuidelines For Fabrication of Steel Girderradhakrishnang100% (3)

- Construction Methodology For Slope Stability.Document19 pagesConstruction Methodology For Slope Stability.mehra.yogesh160No ratings yet

- Welding Inspection of Hmu Existing Flare Line Shutdown Tie-In Jobs PDFDocument5 pagesWelding Inspection of Hmu Existing Flare Line Shutdown Tie-In Jobs PDFRakesh RanjanNo ratings yet

- Vendor Approval For GFRC Rev.1Document16 pagesVendor Approval For GFRC Rev.1Ravi Shankar KolluruNo ratings yet

- Curriculum Vitae: Chandra Babu BattuDocument5 pagesCurriculum Vitae: Chandra Babu BattunkvonNo ratings yet

- Coating Procedure For Bituminous Material Rev 01Document5 pagesCoating Procedure For Bituminous Material Rev 01moytabura96No ratings yet

- Heat Transfer (EMEM-203) : Instructor Dr. Hatsari MitsudharmadiDocument8 pagesHeat Transfer (EMEM-203) : Instructor Dr. Hatsari MitsudharmadiAhmed AlyNo ratings yet

- G11 ASP Textbook ChaptersDocument47 pagesG11 ASP Textbook ChaptersAhmed AlyNo ratings yet

- 9 Cswip 3.1 Question Answers SPECIMEN WRITTEN EXAMINATION QUESTIONS Question Answers Solved Past Papers Cswip 3.1Document32 pages9 Cswip 3.1 Question Answers SPECIMEN WRITTEN EXAMINATION QUESTIONS Question Answers Solved Past Papers Cswip 3.1Mohammed Amjad AliNo ratings yet

- Mathod Statement of Duct InsulationDocument14 pagesMathod Statement of Duct InsulationAhmed AlyNo ratings yet

- M10 MCQDocument17 pagesM10 MCQashufriendluckyNo ratings yet

- Supply Chain Key Performance Indicators PDFDocument52 pagesSupply Chain Key Performance Indicators PDFErik VanNo ratings yet

- Communication Theory: Lasswell's ModelDocument9 pagesCommunication Theory: Lasswell's ModelKlaüss Vizcarra Lescano0% (1)

- Catalog WurthDocument3,535 pagesCatalog Wurthzdeniel2006No ratings yet

- Salt Corrosion Test PDFDocument16 pagesSalt Corrosion Test PDFPriyaranjanNayak100% (1)

- BC ProposalDocument6 pagesBC ProposalPooja BhavsarNo ratings yet

- Aurora Bearing 319 Catalog PDFDocument128 pagesAurora Bearing 319 Catalog PDFYeNo ratings yet

- Walk-In Evaporator Coils 101: Published byDocument6 pagesWalk-In Evaporator Coils 101: Published bynorfirdaus8310No ratings yet

- Who PQS E003 PV01.4Document20 pagesWho PQS E003 PV01.4Elvis GamesNo ratings yet

- Sicame - MR - Ashok Moni - RQ-2 - 22-11799-B - Keysight - 34901a - 10.06.2022Document1 pageSicame - MR - Ashok Moni - RQ-2 - 22-11799-B - Keysight - 34901a - 10.06.2022AshokNo ratings yet

- Intel Vs AMDDocument14 pagesIntel Vs AMDJo AshemNo ratings yet

- Public - Information - Brochure - Feb2012 Dfccil Land Acquisition Process PDFDocument12 pagesPublic - Information - Brochure - Feb2012 Dfccil Land Acquisition Process PDFmanish goyalNo ratings yet

- Business Requirement DocumentDocument8 pagesBusiness Requirement DocumentHUNTERNo ratings yet

- Book - Automotive Technology RoadmapDocument458 pagesBook - Automotive Technology RoadmapSunil Deshpande100% (1)

- Catalog URBDocument802 pagesCatalog URBLupan AlexandruNo ratings yet

- Coke Drum SpecDocument33 pagesCoke Drum SpecMahendra Rathore100% (1)

- NGN TTCL CaseDocument16 pagesNGN TTCL CaseNicholausJrNo ratings yet

- Five Steps To Business Intelligence Project SuccessDocument5 pagesFive Steps To Business Intelligence Project SuccessPamlaruku_Shin_4068No ratings yet

- Biswajit Sahoo - Android DeveloperDocument3 pagesBiswajit Sahoo - Android DeveloperSurendra ThotaNo ratings yet

- RF Microwave Catalog PDFDocument44 pagesRF Microwave Catalog PDFucnop100% (1)

- My To Days Paper of Cs 614 With SolutionDocument18 pagesMy To Days Paper of Cs 614 With SolutionchiNo ratings yet

- Federal Standard To Model PaintsDocument27 pagesFederal Standard To Model Paintsstriker190No ratings yet

- Quality Function DeploymentDocument34 pagesQuality Function Deploymentpuchy patataNo ratings yet

- Process Engineer Calderys IndonesiaDocument2 pagesProcess Engineer Calderys IndonesiaAde RachmanNo ratings yet

- (Download PDF) Digital Twin Driven Smart Manufacturing 1St Edition Fei Tao Online Ebook All Chapter PDFDocument42 pages(Download PDF) Digital Twin Driven Smart Manufacturing 1St Edition Fei Tao Online Ebook All Chapter PDFleslie.brooks363100% (14)

- Airraft HardwaresDocument38 pagesAirraft HardwaresDyesalyn B. CapitoNo ratings yet

- Contractual ProceduresDocument40 pagesContractual ProceduresyohanjNo ratings yet

- Small-Scale Mining in Malaysia & TechnologicalDocument20 pagesSmall-Scale Mining in Malaysia & Technologicalnaravichandran3662No ratings yet