Professional Documents

Culture Documents

60mm Mortars, PMA (Part-1)

60mm Mortars, PMA (Part-1)

Uploaded by

Patrick CostaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

60mm Mortars, PMA (Part-1)

60mm Mortars, PMA (Part-1)

Uploaded by

Patrick CostaCopyright:

Available Formats

60mm mortars

Part 1

By Clyde Barrow

The following is part one of a series on building a 60mm mortar patterned after the type used by the U.S.in WWII. This same design with minor alterations, is still in production and standard issue in most NATO countries. The complete setup weighs about 40 pounds and breaks down into three sections; baseplate,bipod and barrel. This allows for quick setup/takedown and easy transport. The mortar bombs, either high explosive or smoke type, weigh just under

3 lbs. each. The 60rrm mortar is the cheapest and simplest method available for a two or three man squad to inflict artillery level damage to fixed targets at ranges of 300 yards to ~ mile or more. Although the design specs presented can be altered for use in producing an 81mm mortar, the increased weight required limits the larger unit to use as a vehicle mounted weapon. For reasons of mobility, we will concentrate on the 60mm uni t.

Once Fired 60MMInert Mortar Rounds

Practice Bombs

60mm practice rounds are available from Sand R Company, RD 2 Box 71, Arkport, NY 14807. Price i5$6.00 each plus shipping charges (3 lbs.each). Practice rounds were identical to live ammo except that they carried a small smoke charge instead of an explosive. They were used for target practice only.

The examples from Sand R have been "demi 11 ed It by unscrew; ng the nosepi ece and drilling a 7/16" diameter hole through the fuse assembly. The nose pieces are included although impact has smashed the plunger into a permanently "fired" position. These rounds look as if they have been in storage on the ocean floor since WWII. They are heavily caked in rust, although they don't look too bad after a good bath ;n naval jelly (rust remover). The fuse bodies and brass primer units are firmly corroded in place. These rounds are not as hopeless as

22PMA

they sound. The bodies and tail sections are in good shape and one would be hard pressed to COPY' them for the price of $6. The fuse and base assemblies could be either.drilled a~d threaded to accept repair sectlons or drll1ed and chiseled out entirely) to be replaced with new units.Even if you intend to produce all of your own rounds from scratch, I suggest you obtain a couple of these practice bombs for reference. I doubt if they will be available for long, and they are the only examples I've seen for sale at less than collector's prices of $20 or more.

PR 8 Departsrnant Defense

avo de Tervueren 168 - B 1150 Bruxelles

~ Belgium

• 60 mm mortar and ammunition

The 60mm mortar round consists of three main sections. 1) An aluminum plunger housing wi plunger and firing pin that screws into the main fuse body, also of aluminum .. 2) A forged steel body threaded at the front to accept the plunger/fuse assembly and at the rear for attachment of the tail assembly. 3) A tail assembly consisting of a machined tube, closed and threaded at the front to fit the body, and threaded at the rear for the brass primer unit. The tube is hollow and carries the launching charge. The bomb is stabilized in flight by four sets of stamped steel fins that are spot welded to the outside of the tube. A stamped steel ring with spring clips is fitted around the front of the tail. These clips are intended to hold secondary sheets or bags of propellant for increasing the range of the round.

The following dimensions will allow you to copy all components of the 60mm bomb de-

.

51gn.

Ta i 1

AMMUNmON ...-- LOT HUMee:A

Reprinted from Army FM 23-85

GENERAL. The 60-mm mortar fires complete, semifixed rounds of ammunition. The rounds are "complete" since each round comes packed in an individual container; complete with its fuze and propellent charge. The rounds arc "sernifixed" since part of the propellent charge may be removed to vary the range.

All rounds are provided with stabilizing fins which make the round stable in flight and cause it to strike fuze end first, even though it is fired from a smoothbon: weapon.

Each round (except the training projectile) has a propelling charge consisting of an ignition cartridge in the base of the fin assembly and four propellent increments (bundles of sheet powder) which are fitted between the blades of the fin. Each increment is called a charge. To prepare a round for firing with a certain charge, those increments not needed are removed from the shell.

Ammunition allowances for training are found in T / A 23-100.

DESCRIPTION AND CHARACTERISTICS. Description and characteristics

of the principal classes of 60·mm mortar ammunition are:

High Explosive (HE)) }.tf49A2 (fig. 8). Weight-3.00 pounds.

Color-Olive drab with yellow markings. Filler-TNT bursting charge.

Fuze-M52 super-quick fuze. Range-2,OOO yards.

Used for fragmentation and casualty effect against personnel.

PIG'U RE 8. SH Ell. HIGH EXPLOSIVE M49A2

/. 5 (/

Clip/Collar ASSemblY~

..

'"

- ... II< .. -

Ta i 1 Body Tube

'3'"

I.,,·tt l

l.'-t II v f

I

r ~ /.1'1

~ Fin Pattern (make 4)

PMll ? ~

M52 FUZE. General, This standard fuze, (fig .. 12), a super-quick type, is l\J identified by PDF (point detonating fuze) M52 stamped on the body. This fuze ~ is designed to function before any penetration occurs, permitting the maximum ~ surface effect of fragmentation of the shell. For use in the field, it is issued

assembled to the shell as a part of the complete round. To prepare for firing it is only necessa ry to remove: the sa fety wire.

Safety features. This fuze is classifiedas bore-safe. It is equipped with safety devices that keep the bursting charge from exploding while the shell is in the barrel-s-even should the primer or detonator malfunction.

A safety wire passes through the body of the fuze and the set-back pin, thereby locking all movable parts in their original safe position. Pull the safety wire just before firing (fig. 12). If a round is fired without pulling the safety wire, it may or may not explode upon impact. The safety wire is designed to lock the set-back pin in place only during normal handling of {he round before firing.

The set-back pin, held in place by the safety wire, in turn locks "the safety pin in position. The set-back pin is supported by a spring and is positioned in a recess of the safety pin. Until the set-back pin moves out of this recess the safety pin is locked in the body of the fuze.

The safety pin, held in place by the set-back pin, is the main locking device of the fuze. It holds the slider (which contains the primer and detonator) in its retracted position and prevents premature alinernent of the various elements of the powder train.

Functioning. The fuze is not armed until the primer and slider detonator are alincd with the firing pin and booster lead. The first step in the arming of the fuze i! the removal of the safety wire just before firing. The shell, when inserted in the barrel, slides down until the primer of the ignition cartridge strikes the firing pin of the mortar. The combined forces of the shell striking the breech of the mortar and the blow delivered to the shell by the propelling charge gases cause the inertia of the set-back pin to overcome the resistance: of the setback pin spring. This permits the set-back pin to move toward the base of the fuze (fig. 12). This movement withdraws the shank of the setback pin from the recess of the safety pin. The safety pin, now being released by the set-back pin, is thrown outward by the action of the safety pin spring, but is prevented from leaving the fuze by striking and bearing against the bore of the mortar. At this time, the safety pin has not movc:d far enough to disengage the slider, and the slider remains locked in its unarmed position.

When the shell leaves the muzzle and the safety pin no longer rides against the bore, the pin and spring By out of the fuze, thereby releasing the slider. Under the action of the slider spring, the slider is forced to the opposite end of its chamber. The slider locking pin, pressed upward by its spring and guided by a groove in the lower surface of the slider, is lined up with a recess in the slider. The spring forces it into the recess, locking the slider in position and completing the alinement of the powder train. At this time, the fuze is completely armed.

FfR~NG 1I.._4--\----- PIN

L...\----- SL.IDER SPRING L~~:::\:=== PRIMER

:c: SLIDER DETONATOR

J/ .. IIM---+---SAFETY PIN SPRING

BOOSTER

ETONATOR (INCLUDING PRIMER)

SLIDER lOCKING PIN

SLiDER LOCKING PIN SPRING

BACK PIN SETBACK 'L...------P'N SPRlNG

-.-

SETBACK L-----PIN PLUG

SUDER LOCKING-~S:::

PIN PLUG

TETRYL LEAD CHARGE

FIGURE 12. WORKINS PARTS OF M52 FUZE

When the shell hits the ground, the striker is compressed and drives the firing pin into the primer of the slider detonator. The Hash from the primer ignites the detonator, which in turn explodes the booster lead and the booster .. The explosion of the booster detonates the TNT filler in the body of the shell.

60mm Mo rta r She 11 (Fu 11 Size) 1------------ Cant i nued Next Issue ------------------t PMA 25

Top View

----- J. '1 jl __;.

--- / Ya.'f. It TP)

60mm Mortar Shell Body Forged Steel

FUSE

COLLAR

CLIP

FLASH HOLE

60mmMortar

part 2 BY CLYDE BARROW

NOTE: Please make 'the following corrections on pp.23 and 25 of Vol.2/Issuel.

PP. 23- Clip collar assembly ID is .95" (not .095").

- The third row of ve~t holes in

the tail body tube is 1.1" from the base (not 1.0").

PP. 25 - Diameter of shell mouth is 1.4"ID - Inside threads on the mouth of the shell are l~"x12 threads per inch

(not l!.Jxll TPI).

- Body OD at the base is .95" (not shown) •

- Inside radius of the Bourre1et section is .9" (not 1.0"). Wall thickness in this section should be held to .23"

mi n . / . 28" rna x .

The info presented in part one of this article (Vol II, No.1) was based on measurements taken from a 60 mrn practice round. I have since obtained copies of government machinist drawings for the 60 mm round. This material was de-classified after WW II, so PMA ;s free to reprint it The set of copies was both incomplete and illegible in several spots. live drawn

Notes on Filler and Booster Charge:

TNT (Trinitrotoluene) is produced from toluene,sulfuric acid, and nitric acid. It is a powerful high explosive with a velocity of detonation of about 21,000 feet per second. It is well suited for steel cutting, concrete breaching, and general demolition.

TNT is relatively insensitive to shock. It will not detonate on the strike of a single rifle bullet, but may do so under sustained rnachl nequn or rifle fire.

TNT may vary in color from a pale yellow

to an orange. Its color is influenced by time and by the purity of the explosive. TNT is crystalline and is issued in

pres sed form. I t can be 5 team me 1 ted. It burns at 2660 F. Small quantities (up to 1 pound) of it may be burned in open areas without fear of detonation.

the missing pieces with estimated dimensions. Included are several notes to clarify unreadable items.

Readers familiar with working from blueprints should have no trouble.If your needs are for a more s imp'l t fi ed set of dimensions' the chart on page seven of issue one can be used. Round off the four place decimal numbers to simple fraction~

Example: The plans specify the fuze body length as 1.77"-.02" long. The engineer has allowed the finished length to vary from 1.77"{max)to 1.75"(min). You may find it appropriate to simply list

the finished length as 1. 75" or even 1-3/4."

live devoted a great deal of space to this material because the information can be applied to a variety of other weapons projects.

Example: Compare the specs for the rough shell castings and forging (pg.58) with the dimensions of the finished shell

(pg.59). Note that the dimensions for the shell interior must be correct after ceetiing or forging, as no further machine

work is done inside the shell. On the other hand, all exterior surfaces are cast or forged oversized ro allow for final shaping on a lathe. The relationsip of the rough and finished measurements can be used as a guideline when designing

too Ids , cores and forging tools for similar projects.

TNT is toxic; TNT dust should not be inhaled in quantity o~ allowed to contact the skin excessively. The gases produced by an explosion of TNT are poisonous. Tetry1

Tetry1 (trinitrophenylmethylnitramine) is a fine, yellow crystal1 ine which is

more powerful than TNT. Pure tetryl is too shocksensitive to be used as a demo 1 i t i on ex p 1 os i ve ; h owev e r , wh ens ma 1 1 quantities are compressed into pellet form it is perfectly safe. Tetryl booster pellets are commonly used in bursting projectiles to assure the detonation

of a less sensitive filler explosive. Tetryl is also compounded with TNT to form the demolition explosive tetryol.

Tetry1 is practically nonhygroscopic and is insoluable.Tetryl will detonate if exposed to a temperature of 5000 F.

56 PMA

AA - Casting Shell Bodies

Most small shops will not be able to produce steel castings, and will have to use gray iron, brass or an aluminum allo~ Iron is prefered, but most home foundries are set to pour brass and aluminum only. One furnace capable of melting iron is featured on pg.73 of this issue. Use of alternate shell body materials will re-

quire slight adjustments in dimensions In lieu of taps/dies, all thread cut-

to maintain proper weight, shell capaci- ting,(except in the three small holes in

ty and wall strength. the fuze body) can be done on a thread

BB - Forging Shell Bodies cutting lathe.

The above furnace (pg.73)will also be

sufficient to allow hot forging. Refer to FF - Machining

Vol II, No.1 for info on shell forging in Almost all remaining machine work, inthe small shop. The 60mm shell is similar eluding all small parts, can be done on a

to the 81 mm shell shown. metal cutting lathe. All holes c~n be

CC - Dieforming Shell Bodies drilled with a drill press. A rotary in-

The info for dieforming shell bodies dexing table for the drill press is not

was not included in set of drawings. In essential, but it simplifies locating the

general, body halves are pressed from various holes in the fuze body in proper

flat pieces of sheet steel. The completed relation to each other. (900 and 40° from

halves are joined by welding as outlined reference lines).

on page 59. As with the other types of -Tne only flat machining required is

shell production, all interior dimensions slotting and milling a flat on the slider

should be correct after pressing. After assembly. This can also be done w/a file

welding the outside is machined to the or hand grinder or by clamping the piece

specs on page 59. in a horizontal feed unit on a drill

UD - Shell Body 00 - CRITICA6 press. The work is fed into a grinding

The mortar barrel is constructed from stone mounted in the drill's chuck.

2.75 OD-2.375 IO steel seamless mechani- Note that various parts can be made

cal tubing. Manufacturing tolerances re- from aluminum, zinc, brass or steel, de-

quire tubing 10 to be honed to .0051~.OlO" ~p=en~d~i~n~g~up~o~n~a~v~a~il~a=b~i~l~i~ty~~~~~~~~~

oversized (2.380"+.005"). It is there- Spring making is a complex process.

fore critical that finished shell bodies Appropriate springs should be obtained

(including painting and marking) are able readymade to insure rel tabi l t tv ..

to slip through a 2.364" max IO ring GG - Ole Forming/Die Casting

gage. Max 00 of completed tail assembly Punch and die info for stamping out

is 2.375"-.005". and fanning the striker and booster cup

EE - Thread Cuttins will be covered in Vol II, No.3 & 4.These

The following S1zes of taps and dies parts can also be machined from solid

are needed to complete the 60mm mortar stock or from tube and flat stock a~shown.

round. Items marked NF (National Fine)are btl;/'. ~ E ~~\"\"'I~~I~II~"'i'\)

avai lable from most auto supply or hard- TVfiE. D WEl.ooR ::-tIl V , -fL- + --;--

ware s to res . Those marked NS (non- s tand- ~r~ . ~~tR w~ ~ ~d

ard)are special sizes that must be ob-Production of die casting molds for

tained from tool suppliers like B-Square the fuze body and head assemblies are be-

Co. (see Vol II,No.l, pg.13) or Field yond the scope of the small shop_ These

Tool Supply Co., 2350 N.Seeley Ave., pieces can be produced as oversized sand

Chicago, ILLINOIS 60647. castings machined to finished size.

SHELL BODIES - STEEL GRADES

Type A- Forgi ng-WD 55-1 carbon 0.18-.028% Type B-Ro 11 ed Pl ate - WD 1020 Steel

Type D-Casting-Cast Steel

Type F-Stamped and Drawn Plate Type G-Stamping-WD 1010 Steel

If you are limited to the use of standard NF taps and dies, convert the NS Slzes to their NF equivilant as shown in the chart.

locally

II

Standard Taps/Dies: 1-1/2x12 NF -available

5/16 x24 NF - II

1/4 x28 NF _ It

u

Special Tap/Dies: 1-1/8x20 (NS) or use

9/16 x 24 (NS) II II

3/4 x 18 ( NS ) II 11

1-1/ax12 NF 9/16 xI8 NF 3/4 xI6 NF

PMA 57

._---------.rfI.S'4 r..f>iI. --------- ........ ~------------~A~~~er~~~·~~----------~

~----------~--------------~

~----------------------I.~I----------

-{

SEE M)TE A8 -PAGES7

!VorES:-

A-MAX/MVM P£"MI177!'1) E«ENrlrlClry 4en""'~4"N OIV/rY q,.. SHEJ.t. AND OVrJI"~ .s(/A'~AC'£ AT ;tI1t/)" PfO/NT. .t14~" I'WN£N M49'SVIl/N6 EC&4"NrNIClrY 4Y M£tAA/-S

"" A DIAt. INI)ICAr(M rH~ Tt1TAL. ~£At>IN6 t:>N TN/: P/A£ IS nv/CE THE ECCENrHlt:'lry.) II-Cll/SrINu 7?:J WlrNSTANJ) AN /Hr£~NAL AI' PNS'SVA'4' TfSr OP" 4S0 i.4S. .I"F~ S,,~ IN. 1:- oor ,4NP I)AS'# L.IN4"S INO/CArE '/N/SNEP .sN1!'.u.. ..

~"I/NP~i./NFD mM£NShJNS A~d FINISNF.IJ SIZ~S AN/J W/i." NOT BE M;t&'HIN£D .. I'·CAV/rY MUS; ~ ;trA'EF ..... ~ SCAJ.ES'. r'lr~ S'lAM.s;-LAMlNAT/QNS. ~CK..s;

6J.fJW HtnI"S~ Nt:'K~TS .. s:ANI1. ",If IJnvEH IM~4'CT/ONS'. TN' 'I#ISN OF THE CA~/ry Sv,wrACE Mvsr 8.F TNF rqVAI.. fA" A "HIPI' 4t:M'r~ CAYI,..".,,.

",. CAPAC/rY (JIll' CAVITY AS CAS'- .,S'HA4.1. JIll 8.8S' Cv. lAi: A~~

G - "HNtI/I"':IJCnNtER IN' CASTIIIi; I:J ALXI MANUPAC1VItCItOl'TIfE .5H£LL; 0I1"11!N!!JJON$ OF CAsrlNG HAY IJC VAKf£'O 'R) GIVE """o~ ~ MACHINING A5 R£QU/~D BY HIM.

CASrlNG FOR ..sHE~L ..

ram §f!zt51ftisz~ [75120 )&]

.)

-------4.$,.-.04----

.,.__ -----04 .• '14 +.o~o-· -----...-e1

,J·ur

PHYSICAl- PRQPERT,IE:S

Y/£LO :JTRENGTH NOT l..£.S5 THAN 3tJ.OOOLlS5.PCH.3Q.IN.

ELONGATION IN Z INCHf;S NOT LCs:5 THI4N 1.5~ .

R£lVCTIONOF Nr£.A. Nor L£5.S TH/ItN 30",

rr"

t!

i

...:..

L.___;:::~D

SE ~ NOTE BB-PA6E 57

------------05.51'------------

F"OlfGlt:I£..5H£LL J'S-20-lJ5A I 8«1-

MAX. WEIGHTOF' RXGlNt;- .3. 33 L~.:s.

FORGING FOff SHELL H. E.

~~:J;_5QA2

1751 ZOl85 I

58 PMA

1 Wt:l\)l~C; "'-'IJ S TYPe.,,\· S"

IP-,lJl ;(4;S·C.~~ FCIC~,w ~_'-

. r-·u'";.CJ ~ ..

~

)'

.

_': Mft7.J'f !II.lt.flattf~ll'!IfIt).~ .'4Ii.tJ ,.(1' ;'or,,",Ru'i'iJAflJ v 6'.m.~.u; '£HCMfiJ'~ Xlt!:U~4r.

.117

---/.1 -~I>t

(I"f:JTE~ tttJY, ,J'j;£ u .. , lYP.!' .$ ..

Jf~l:l. ;Fr,M~~r

.'IX #I" ':l'U' .iV"tf.i'QxW.ill ,':J.'1;r1?&A •

~1tJ· PEW1 tYIlRllC/EJ IN $(J(JRRILlT

SlAKIN6 NOT~ 0 ~TIoNAL.

.«1!l:'a-tf1TKI, .9AJnJli"$PIIJ/;',:: p~.,a.ytY';-;.;;r,..c • .!.,:.?y. '~,)f'll Y J,..",.

N NI/UIIf,T,f{,;"II.I,wrs iiY ~~~m.¥-,. /?J s.tlr Jf,I!Il/,r.tt:/ZWo u,~~£~y arrn'/S ~ nJ,;/'; #AiJ!iI~ ro t'1'1. .'''''~?;'C.I., ~~r.'::.:ff ;;1'.7 il»~ tZW/1t:1.#' .fiji" iItX'(;JI In}';;:,, .1'jff.1 sa: n:; ....

"

.~;t_':) -18 NF ... ,

.;etJM· .NA' 6# ,PJIr#- ..1'Y.1 If.o:/I(J$" JIi.1Clf' •. g<IQ '1:«1/'1

sa: JQtl TH¥XA'(.iJ Jw.t. , :,.$/' utEVI'A:J.lT AtfAXI'Tg IZJ ~.",1,3 •

¥JI.t T&rIK$1 WIJ i:»'.!! (LJS WI JJ),Ir

.J.fl'i'rWr",7tr.f JIl'/;;N./Z'IiT/:V.IN &, ~'asJ .w

1.lJYh.iK ChiJ.t ;;n.JrVAJI lYil'.!f'IJ,(£lRl1Illt'( . "-In:atc: m:JarlitUIIU SiIII.l. IlJI'LKIU .44:1

• S.JIT---------------------;----------~

~----------~--- ~~~--------------------------------~~

,lU./c" - ~.f:t» - Itl.¥. .4'TCH - I <6;fn .,s,X7~ ;I(/tkM'-1. 4pge ~(J(J:J(J

~ENOIE Cc.-PAr£$7

SEE NOTE DD-PAGES7

n?rA;~ AmIf·~.

I?'N '§:'IJIfINKEJ711' ~ SI"I"aILlY MJ..!JJ 1£I/:r.IN Ifl1.AW iMd/ll)/.f',uv. 1'!'J:V."#'_ ~o~ sari. GIST!.«

rYPr·;r :'~JJ sr ,TrA¥I";MI.tNMJIR I1DII JT( a "-'IT;£.

n:"'L;''_ ~l'llInliltfl,l,,_""'Mlnmw.nr.u Nrr. "';/. KtJI'/f1.IJI'~ 1J(f£/'WI "<f.U /JbfUJ) IN I'fACE(SC£ GlfI!4IJJ).

Ae.T.tY-·

~ -.lttUN 1fX!.tW Y ,~~HU1IhM1 ' (f ?t'1f~ .JH.olQf' .. I· ~ ::Ni'J'~f vu~,. ~,.Ii# 1f.f.¥IiITS.

('- "::L{('~.+'t'r U'(,,(?At'rT't'II1ItIhD'Y .w,U4+"l:r M' .P.~~.

4' ¥£"1f7' .f'1;1.U'1P"r.::£ Mr~~ur IVA:JU.l'.I<+'W !lJtJ'..rMt:ZS~ ~ 11ltr,..w:o fttJIIf/.W SIU.:.J .I.1:J 1'" .44t~ :J/lJSIIIIIr ~t.

r- S).MU'$~1 /TN''',.~ JiIIIH:tlH.utiJ ,IN $9'l-.t' .r.u MfT.v M/Ild'1:IIiUY .MIIt:8.

..,. Nlt:1.L.¥.Wr if! Ch¥~G1rT.(J''!'' i1.:Jl';~tS ~'~$ Mc.t'l¥lW'>-~'I flY Dttf'AU F.f .. rJ:.fl.t'a:JIf:'Qfl',lf(In£¥ IV' ('II/~4: .f.,.',f'.f".(/'A ~ /f%4$3::J,f .IIJr,;KVtf Ir;.'t:""'£·-:-/T/LS iY~/r"" .J6'11/"A.&'rJ rIR.J: N ~'TU, {JlIII:N JlUft,lf.'~'Il !:,z"r..itJ:Y,71"',tiC.iU iJI""I:¥fA (ro:R(/,f' nr 11ni«~ v l¥ IVl JJ l111(£ o« aU"7'1(1m

-,. At rrzr» i).; II¥! ~..HJ, 1'.'.JUr l;~t1I.7S "*" .JtITSJI!' J:'7ZJlYOJOK".f1 ~,.(t'l'J J ,.fill'.

(WNt'N 7A.U1V ~~N IJO(.IAIUU 1'; wnw NCH'71fIil'£f40$ ~ 6AU "~t#,

mJ. UANC,c ~:J CVT c.Y ~~IICSS 0/11' 1"1«:1".)

.. -PRIOR TO p.q'N~CLEAN SHEL L SI.IRRfJ(:..E.'S IN If/ICt:ORDIfNC/i wlrH IliRHbI JI,!lItEr ..,..C-4 g(t

N·r.,'llT 111'.1,4;)1 ~Mfil rrctsr rlfN£AClJ ;t','K AO/}-P,fW¥ 1t.-4(,K A4,WT, rrsr r ()# IT.

If'- iSG U'J'.Wi £r~:tpr £IIIIIrIa J)I'J,..f~ I., :.{ i'U!' ,w!JI AIIW> ~ ~ t.«~ I/IMHtIIII. GW ~. ()t..H'E /JfII!.rU1.

;. ""'.1~ rrs: .,. /lIIIi'!!Ir JMIChl'£S N £1..,'" M ~.!!Ika; IfIIt':C'T nw AfJlCJ'..I1. AI' IUAtiff /UrN; .MII'h.IRW T.IfIr cw~.r :)II' J!iIU. If'" Ai'" .p..»tr JM .. J. .It/IW. Drr:r::Ff.1.f N /.£JS r4:t't'.1»

It.. sn. f'U MAr, j'1oq- oIiPIW IY$ £JI(lt.liI'f'.i "tfllS. L IXAUlE ..."Z,/Mf /lLAT n ~t;1IJIr SJl'£ClFIED 60(/ANft w J~JMArf.NS, ..,INIItffII'f IUlQIf/II/IML "t/AI'{rlrr (),t SJ(JIEA socoe« Wt.el

TD is[ »rs KIN. A'A..I U /..()NG,/'tUfi ro 4( MAt.E/J ~ IlfACHAVIN'; OF"'~ CAwrr lIND £r7U~ "':!WEU.. 3-MIU'IHV-'f Al.t.Clif.ItllifU flJliltPlIV ~£A$UkJN6 tXIT o;r ~fiS$ q,t' ~~l(tJ AUS wnl( !SHEll. NO$£' MCE

JII#£N bET.'/tfiINi.J) N~'" tv:1>NANt.V &ifl5E~..oo,

T-4«J11t.llJ!L6T "F77'A I'1rIrJtFT/N~ Iiitl$T f"Jf:U,of f!..I,I&4MAX.JJlAM£TIhP..t!rAIIJ Wtrfi.l!.

x'~rr ,.. --- _

ry~& '-'EC(_If,l~K Ti',£ PI£~CAU"

"if . y·,t·L"A II .,- 7S-I'~48' 10

~. '!S·./-UII 10

-,,. lJ'!L4L4,,, 10

~,I' • 1.JY.,M4" 10 .IU IIRZ K ..r

JllTAi. IJIlfrS JHlI'I'fNQ ..ISJ'UBi. Y "'..,.NlL to

.." UJtU IY" tw I'JfW l'fJR JJ/fC,/TU ~.J/II8Mf'If DIf ty .:vrhAt.l ~ ()f ,A,lJlJIlfl,t'

IIIffMiJ .:w $YM'IIa/. ,. .MItWIrHrwr, lIN -tm ...... N I:IIJY,.ISI' tN.H IWr.t1WIY SACK !':IN.

A1lrJ--

.#-l»#r OT/N U~.st!W"..«r.ua"r ~ !'Ji'N4n.IJIJ SUr..." 1'£11 avd~ .. M'7!1t' AAr 11M' ~tWIU IMMLI. IN' ""M~".lltr.IM " ~'r"P¥l tt:Wr;llhU MJr" ill' IW,,.,rr4. (MJ

~~laUT'It'.t!Y NfWlLk ~ L.fh"·. PNt ar h# ""'17£$",., hJ"CN IIU.. 4Y 6t/S·IIM'"·L rlifRAt)J IYI1:'. ?,.I-JU& •• IM; /.i .AN. Il'llteil'lM

6.4II1M 4"..IV: TAU,tI.fa ~J N/r-,.·~kUllV INA'''''''' .JiUTtH $MIiI/.Ktf1J r·Ut:tArllt'ln" lC"r.cJI.'tTrN PM tII".U·jlkJ·L IJtl£fb.lllJ1'l1TH 4U. K

.I.H·M""·~ rMN.I.:J ,.. .If:.Nf. H'J/·IMt: •• 4R1KD.~/," A 1fJYi. 4IAt. t.tfI,I(;tl'l1# '~nlW' N.MI1 • D.CDR7 GUITY.fNJI 7J.IP£4a" WI", Ct.£HR LK&t/£P EN~,,*l N' /'*N£At:U ~""Pt!'N~« ~IIV YAM"NA'N: TIWC~NE$$ or COII7JN8 ON 1HIi'£A:;JS IIMIsr NOr E XCECD .OQ:JS 1*1\1

(NOTE: REFER To PAGE ~.,- VOL.1WO I#ON~ I

• #'UIntfll ~ ~ IY &dl7lNr t:Ut17IlNUAIC 1r4ftllfC11» ~tI~Y.IIK iT.nra ildJ I/!'Jr

• """""TAt.'W ,. /; ~ M'N.IiIlII' a I'J!#IITr£P 1'fItIr.t Mil'S MIle MJr N~N .tn'A/k MWL.4Ul

/I.~

£rs:u,...,.", NTJiI'UN 11t'C -1<1-.111l1li. NKAU ..I1f/7 tltlt'H .1M. IY . TJ'..",d"l /III£,IIJ. AJSMU~A"liIt tWl/ClIiM" &IIIINIIY ..,

MJq1~J(AI

»a» .. n - J(/~ i..tI /'¥'.i" # I~ MIN &JAItII1'ifW ~ /"", AWN.

AU, M .II ~ IIIIr

CARTRIDGE C.O~TA.\t\lER.

AND FIN ASsf:MBL 'f

175 I Z 1285]

PH YlIC!1. /'ff'Ini7!($

NrUl ~r • <f- i.N.IrIJW1.~ J.u:Wt,iFNW· q $IIIIN..

/Ul'Wf.fJ • IS MI f,IIJalb.J. ."

I'll/ £}£Y£i.iJPK£Nr

(4) /DI.UWAr~J ~Hi.It'.4IJ.r t» ~ AMP tJIU

60 PMA

-,r .03 ,,-, 0 I '>-r--------------------.

$B CM'TH/~/GiVITlOlVHSA~FM· G(}_MfJItTAR ~M"IUN/RON,

~ A.sSCM8LY ANO acTAli.:!

. ..L...-

PIle, CL08JNC 14'-;'-74H3 rmelDAA It t;4MMtRCAAL

~ DIK AN() TIJM: r.

WMIIII1f .I/n TN OJ.. U~.

./ I

- I -

_I

J

-.oj ~

IIS'-,(#- -" .... 71J1(

S4C'1Ht~ WITH 1I1.1C

L-iS#-sIJl-- ...

BODY A55€.MlJV 1S.J9-7«'+ .tJDY '"'.£ "'!tOE ,,'DM STAIfDIlIfD COMMEIrCIAL ~A'MFF'INED CMrltlDtl£ 1"IfI"1!If, oVT'IIDE ,"YEif (OLDIIED.'"D AND Y£l.t(JW,

AIIV'$OllY L~It~TH 0' OUT1!'1f TV •• , UNC"Jr,,...,,,£q r..,"'-,Ol

WAt1HER,ruae,ASS"""", y 7S;'13-"JtJJI:»

Ef$

-.DDZ":.DOI

; COliER n-II-7~1f3

;: 9rf/(lNSIfIN '.lfPs."

• Af.;I.jI£ TEA JM/t~ k.t141f

~-fJ $Mr~DU r_MAil~ e

-l ~-.t>lE +'4C'Z~.Odt

IF SMALlGRAnJS OF SMOkELESS POWDEQ ~Rc USf:t:»F1 f...lD 11 COMf;USTAelE GLUE OR.. BINDER To Fo~H THEM, NTO S\-tt:~TS AS S HOW~ }N SPEcS.

INCR£Mf~PROpeLLe.NT, MJAJ FOR 00 MM.

MiJRTAR A UN/TION. ASSE.MBLY AND DeTAIL.

,K'llAV8:tt

A\.LOIM'Lt ICCI.'ITifClTV &ETWUN C.UUJU ~ ntt16. fUI6 '-MfTY AID HOU5"" CAVITY ",OOK; "LL.OW.AIIU. E.CCEJl11hCJTY ItTW(!tIG6MUI 0' trlR1HG P'U.ki CAfrn OQ ~ UNfTY AID PtTCH OWIE. Tf,. tI.OOS

PlOW .0." AIOY£ To..ot. 8II.J)rw sc.'A(,lCW teUD.

Yl.AJI LOAD.I)

r+ ""-t-a. -- ... ~~r-~o 'pte'S Fofit "'TlH~ :LT_~ t4 ~& ,... LA-R.4 E

f>ISTOL "tt.I~£R.

:x;.:;UtCf. DIsc. TO HEAD WIn. Cl,...£AR LA~"' •• COl .. IIJU.w.,.. 0" VA ... 1"" StUI.\.AC. TYP'E rr, air4)£. ..

• OQILL.

JM()Io.J4' OR,U., .o.u ~OO5 0f.U

PR'ME~ PEJ2CUSStON. M.32. ASSEMBLY AND DE.TAlLS

49

BOOSTER AND DETONATOR..

ASSi;MBlY AND DEI AJLS 73---1 !73-;L.

TETRYL WElGHTS ARE 61 SPECS REMA1NJNG SPECS ARE. EST[MATES ONLY

L-, rot

C'( -

'" ~

0 0

r

1

'"

In • g 1,a!S ON

.. ~

« .. ~o

-

.

-

. \ R. Jl

.. ;tS'" ~TER l~ C.UP 73-J-/6lfX &IL.D)N& ~ETAL...

f.1S1F& PELkfI 73-J-J"~2..

;;J.S .0 ti-lt4tkS Te:,.-rt.-t L..

Pk.~-S ..t" .. Tb BooST£!: Ie. C()' f'>

BOOS,ER Cu.'" 13-}-ICP'tf AL\t"')lJ\t~ t&,..SE. /'rI,.Lo,/ CA ~ T/AJ G-

SUDEA. 7.3-t-t .. C"

C:OMueRC'AL. &RAS~. QOOa~IDOH"a-.1=W.F HARP ,2;V ALI. 01(" aCE". A3 HOTED.

:* S ET13PL:.\s t> IN PLU G- .

B AA5!> R.<>o

NOTE:ALLITEMS WITH~ ARE ESTIMATES Ot\JLY- NOT GI SPECS

.375

./~S ·Ob1t.OtO

"SAFETY PJN

"* SLJ D~R S Pral tJ & ,3-{ -/~3H

st~~ ( \..h't....e...

* SLIDER PLUG- 73-J-/'3F t3RASS

. 5''' ~ S" )< ). 4 -r PIN oN - f$, A~:'

_L

WNJJNN ~

J. .Cf -1T

M«,.-t c-. \ I

oS k,\o\\d. E'"",o.,Q...

. 'tt40~ Ioe,\ow -----..f 5 ff{.:t7 ~ r " k ~ o.d.

. " SAfETY PI~ Se~tJ{l 13-1 ~JC.3G- ~ st.(-e.\wtttc..

RtU~ o-\-f 't.V\d oi P\~

1lr'O'f37 ~

~

-

5E.T8fC.K ?J~ :* 13-J-I<"3-8

s+e e.l \,o.vt..

(~+ s c.n ew ~ eo.d 51 dt -+Q~ 0. h, V\ 'M e \.\T ,?..f kfll e. ~ Ht ~ t"" S t o.ll \\0\ 1 ,v(

+U 2:,e.. 10 Dd Y

~ t=;\ltit (Q' \ $. ~v.\ d ~1J\' Q ,e._ ~ }t4()v-f_ I" S(t b~C:" 'P\~

Wi clJl.. d"f ~ 02 .-fo~ .fu.\l ('OWi.f~IO"'-

SETBAC~ PIN SPf(UVGr '* ~-+-ee.' \.u\~Q... -73-1-/(..)0

73-1-/~3 htt BI<AS!>

. SEE' 1 TEM *'1" PAGE' ~~

WORKING PARTS FOR M 52 FUZE

PMA h?

.2S-28NF-(NON-ST/J)" 42MIIV

~;'l: gfj :~~~~ !'~'b05t?J' .I80f, OIS

AI/NOR "fA . Z I / j .,J.. O()~O .12 Alb\! EF,r THO.! .

D/?ILL PO/NT.tJ.S bfAA' O£EP 8Y .. 2 MAX PIA PERhI'lTTELl

/.

.,_________,..,....._. 980 1-. OIS ~___.,.._.. 29 MIN EFE£CTIV4' r as ~O.?TNK£Aas

.05-1:02

.22 M/NEF":-ECTIVE TNREAIJS_"""~"" ........ -.1.1IJfAA' . 475 of.(}/S--1~--+---

· 7().]il7l4 ~--- -/. 77-.02 --- ..... ~

~

t·

~

•

I./Z5-20NS-/ ~ MAJOR L)/A L 1250 MIN PITCH £J/A I.CJ9ZS'f-; 0074 MINOR OIA /,07tJ.9r-. ()OS4-

/. S -/~Nr-tWON"STP)

MAvtJR LJIA /'497~-(OJ8(J). PITCH 0,,4 I. 44.1S -(. 0/00)'" MINOR [)/A i 3954 MAX

64 PMA

.!TAKE OR PRICK I"UNCK "-...

)I.O ..... CllLlLlllDJJill:Jlll.U~'U.

1'3-I·lv'2P OIl 13~H"2.F

HEAO ASSEMBLY (~TIVE METHOO)

.... eAQ ASSEMBLY (ALT.) T3-H"'1Pta F'OI:! OtHER INf'ORIW\ATlOIi,Sn: T!!·':"~6t.'

HEAD ASSE.MBLY n-I-lt02FIO

HEAD (~) 75- .... \61. Gt I

CQlIotMS,Q.Cl Pol.. BRASS. RO~,~~POS_ITIOM .. e· , I-lALf- HARD rI N 1;1-1 ALL OYER fZy'

~EAO 7.3-I-I~Z Ell

~~..:...~}"1,OYI DI~ ~Ac:.TINC1. COMpo AO~ a ,OICHFtOMSlJ" FILM MI NIMUM WEI~HT. 111.5 G>RAII'f$

1'!-l-I''2ft

c .........

1S-\-It.2D ONL."1' ~~~~---,<,

FlQING PIN

~ I"f~TM; OR $P'I~

FUctNG PlN ASStM&'V ~ 7l-I-lw;M4

"" ~ .. --- ---+:8+.

--

R.JZES, POiNT ~AllNG,.

MS2At,MS2AIBI AND MB2 DETAILS

You might also like

- Winchester Model 37 ShotgunDocument3 pagesWinchester Model 37 Shotgunblowmeasshole1911No ratings yet

- FM 23-41: User Manual For M3 Grease GunDocument83 pagesFM 23-41: User Manual For M3 Grease GunGasMaskBob100% (1)

- Post 4 23085 M6 Scout InfoDocument32 pagesPost 4 23085 M6 Scout InfoMike Nichlos100% (2)

- Heckler & Kock HK MP7A1 Submachine Gun (Germany) 8Document2 pagesHeckler & Kock HK MP7A1 Submachine Gun (Germany) 8blowmeasshole1911100% (2)

- Federal Arms Fa 91 ReceiverDocument15 pagesFederal Arms Fa 91 ReceiverArmando Pescador100% (3)

- How To Formulate Parkerizing SolutionDocument3 pagesHow To Formulate Parkerizing SolutionOtter1zNo ratings yet

- AR 7 Henry AR7 Survival ManualDocument11 pagesAR 7 Henry AR7 Survival ManualBruce JollyNo ratings yet

- Armas Pistol Revolver and AmmunitionDocument233 pagesArmas Pistol Revolver and AmmunitionMarius BaraNo ratings yet

- Sten Mkii: Complete Machine PlansDocument24 pagesSten Mkii: Complete Machine Planszafnequin100% (1)

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsFrom EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- The Gun Digest Book of Firearms Assembly/Disassembly Part IV - Centerfire RiflesFrom EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part IV - Centerfire RiflesNo ratings yet

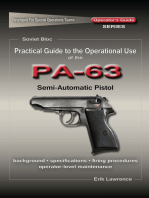

- Practical Guide to the Operational Use of the PA-63 PistolFrom EverandPractical Guide to the Operational Use of the PA-63 PistolRating: 5 out of 5 stars5/5 (1)

- The Book of the Springfield: A Textbook Covering all the Various Military and Sporting Rifles Chambered for the Caliber .30 Model 1906 Cartridge; Their Metallic and Telescopic Sights and the Ammunition Suited to ThemFrom EverandThe Book of the Springfield: A Textbook Covering all the Various Military and Sporting Rifles Chambered for the Caliber .30 Model 1906 Cartridge; Their Metallic and Telescopic Sights and the Ammunition Suited to ThemRating: 2 out of 5 stars2/5 (1)

- D585D Gustloff Volkssturmgewehr VG 1 5 Rifle GermanyDocument2 pagesD585D Gustloff Volkssturmgewehr VG 1 5 Rifle GermanyKurt100% (1)

- A MAC History LessonDocument11 pagesA MAC History Lessonlopezm93No ratings yet

- W mp40Document7 pagesW mp40Антон ЗахаровNo ratings yet

- US20080086926A1Document19 pagesUS20080086926A1ProfessorNo ratings yet

- Armalite AR10 Super SassDocument48 pagesArmalite AR10 Super SassJustinNo ratings yet

- Tel - Escope Mounting FDR Guns.: N0. 69 - , 248. V ' Patented Lan. I4, - 902Document4 pagesTel - Escope Mounting FDR Guns.: N0. 69 - , 248. V ' Patented Lan. I4, - 902Radim KadlecNo ratings yet

- Stemple SuomiDocument5 pagesStemple SuomiIvano Boss0% (1)

- Navigation Search: Jump ToDocument9 pagesNavigation Search: Jump ToMăry CrețaNo ratings yet

- The TZ-45 - Italy's Late-War SMG With A Special Safety - Forgotten WeaponsDocument5 pagesThe TZ-45 - Italy's Late-War SMG With A Special Safety - Forgotten Weaponstyrant88100% (1)

- MAS-38 Submachine Gun (France)Document4 pagesMAS-38 Submachine Gun (France)blowmeasshole1911No ratings yet

- GG2 Operator's ManualDocument30 pagesGG2 Operator's ManualWerner Patric WengNo ratings yet

- MAX11kManual Rev A PDFDocument12 pagesMAX11kManual Rev A PDFJorge Mercado NajeraNo ratings yet

- ARCCB TR 95011 Rifling Twist DesignDocument38 pagesARCCB TR 95011 Rifling Twist DesignRick Gaines100% (3)

- P226 TACOPS SellDocument2 pagesP226 TACOPS SellLarry C Sandt100% (1)

- АК туториалDocument63 pagesАК туториалLucas Gabriel100% (2)

- Silenced GunDocument2 pagesSilenced GunThomas SjölingNo ratings yet

- SHRIKE 5.56 MANUAL Ver1.1Document50 pagesSHRIKE 5.56 MANUAL Ver1.1Arkane1988100% (2)

- m1903 SpringfieldDocument10 pagesm1903 Springfieldpcojedi67% (3)

- OP 1157 3.5 and 5 in Aircraft Rockets 3.25 Motor 1945Document17 pagesOP 1157 3.5 and 5 in Aircraft Rockets 3.25 Motor 1945FrancescoNo ratings yet

- Makarov DDRDocument77 pagesMakarov DDRp317No ratings yet

- Hebrew Cased / U Zi/ Open-Bolt Blowback Submachine Guns Machine Pistols Telescoping Bolt MagazineDocument1 pageHebrew Cased / U Zi/ Open-Bolt Blowback Submachine Guns Machine Pistols Telescoping Bolt MagazinePranjul SinghNo ratings yet

- The Ballard RifleDocument4 pagesThe Ballard Rifleblowmeasshole1911No ratings yet

- World Intellectual Property Organization International Publication NumberDocument30 pagesWorld Intellectual Property Organization International Publication NumberAcc1337No ratings yet

- Bev Fitchett's Guns: Open Bolt Trigger MechanismDocument3 pagesBev Fitchett's Guns: Open Bolt Trigger MechanismValdez RulioNo ratings yet

- 1 Army Gun ListDocument2 pages1 Army Gun ListCletus GodwinNo ratings yet

- The 10mm Automatic - by Chuck HawksDocument2 pagesThe 10mm Automatic - by Chuck Hawksblowmeasshole1911No ratings yet

- Mosin Nagant Parts InterchangeabilityDocument13 pagesMosin Nagant Parts Interchangeabilitygreaternorthroad8820100% (2)

- StempleSuomi PDFDocument5 pagesStempleSuomi PDFAndrew GatesNo ratings yet

- Remington 700 Rebuild: .243 Dec 2007 - Jan 2008Document23 pagesRemington 700 Rebuild: .243 Dec 2007 - Jan 2008john smith100% (2)

- Hugo Schmeisser (Germany)Document4 pagesHugo Schmeisser (Germany)blowmeasshole1911No ratings yet

- Sighting in A PU SniperDocument7 pagesSighting in A PU Snipera90470No ratings yet

- VZ 58 Military Manual PDFDocument42 pagesVZ 58 Military Manual PDFcasaka100% (1)

- SA VZ 58 High Cap Rifle Instructions Manual PDFDocument43 pagesSA VZ 58 High Cap Rifle Instructions Manual PDFMonteiro Antonio100% (1)

- Lancaster PistolDocument5 pagesLancaster Pistolblowmeasshole1911No ratings yet

- RPD Build - Red Neck EngineerDocument6 pagesRPD Build - Red Neck EngineerDale Wade67% (3)

- ST GW ManualDocument23 pagesST GW ManualBen FloodNo ratings yet

- Multiple Barrel FirearmsDocument6 pagesMultiple Barrel FirearmsYorgos KordoniasNo ratings yet

- Notes On The Proof On Shotguns Other Small ArmsDocument17 pagesNotes On The Proof On Shotguns Other Small ArmsThomas James AttreeNo ratings yet

- The M14 Conversion To The M1 Garand: Version OneDocument13 pagesThe M14 Conversion To The M1 Garand: Version Oneleleva13No ratings yet

- Making Your Own Rivets - The AK Files ForumsDocument7 pagesMaking Your Own Rivets - The AK Files Forumsscout50No ratings yet

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet