Professional Documents

Culture Documents

Ion Exchange or Reverse Osm..

Ion Exchange or Reverse Osm..

Uploaded by

Andri Sanjaya SembiringOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ion Exchange or Reverse Osm..

Ion Exchange or Reverse Osm..

Uploaded by

Andri Sanjaya SembiringCopyright:

Available Formats

Ion Exchange or Reverse Osmosis? http://www.dow.com/liquidseps/design/ix_ro.

htm

search

FILMTEC Membranes Ion Exchange or Reverse Osmosis?

DOWEX Ion

Exchange Resins The decision to install an ion exchange (IX) system or reverse osmosis (RO) system is contingent on

CADIX System several economic factors including capital and operating costs as well as chemical and wastewater

Design Software disposal requirements.

Products

As a manufacturer of both technologies, Dow can provide you with an objective view without bias for

Applications one technology over another.

Ion Exchange Resins

Technical To aid with the decision-making, there are several factors to consider when determining an

Information economic comparison between IX and RO. The economic factors affecting a break-even analysis

Basics of Ion include chemicals, resins, membranes, energy, operating labor, maintenance, and capital related

Exchange items.

Feasibility Testing Occasionally, technical considerations will outweigh the economics in determining the water

and Samples

treatment system. Such technical factors may include the size of the system, the water quality and

Design an Ion flow rate.

Exchange Resin

System Whether the deciding factor boils down to economic or technical considerations, you must determine

Storage and the acceptable number of years for payback.

Handling

Ion Exchange or Reverse Osmosis?

Installation

Start Up and Shut The first question that must be addressed in the design of a new water treatment plant is whether to

Down Procedures install an ion exchange system or reverse osmosis. The principal drivers for such a decision will be

Operating a economic in terms of capital and operating costs, as well as regional requirements for chemical and

DOWEX Ion waste water disposal. In many cases, familiarity with one or other technology is also a factor in the

Exchange System decision process.

Cleaning and

Maintenance Comparison between these two technologies as options for water treatment applications has been

Ion Exchange the subject of a number of studies and continues to generate a high level of interest in the

1

Troubleshooting literature . As technical developments in both product areas continue to be made, such as

Guide counter-flow regeneration packed bed systems, narrow particle sized ion exchange resins and high

DIRECTOR rejection, lower energy membranes, there is a need for monitoring economic performance. In

Services: Ion addition, external factors such as water costs and disposal, power and chemical costs continue to

Exchange Resin change and are different around the world, further affecting the economics.

Sample Analysis

Disposal Economics of Ion Exchange and Reverse Osmosis

Interactive Product

Studies carried out using a cost model which includes capital investment and depreciation,

Selection Guide

chemical, utility and water costs have been made over a range of water salinities and service

ADSORBSIA GTO run-lengths with water analyses based on averaged compositions from a number of locations.

Ultrafiltration (UF)

Electrodeionization Two different types of water treatment systems were used: ion exchange only (IX) and reverse

(EDI) osmosis followed by ion exchange polishing mixed beds (RO-IX). The systems were sized to

continuously produce mixed bed quality water (<1 µS/cm and 10 ppb SiO2 ) at flow rates of 50 and

200 m3 /hour net (220 and 880 gpm). Operating costs include chemicals, power, labor and

maintenance, together with water and waste water, which are an increasing consideration in water

treatment economics 3,4. Surface water was used for both size plants with pretreatment consisting of

flocculation,clarification and sand filtration. Acid and antiscalant were dosed prior to RO and 5

micron filters were used. Water storage facilities and the cost of neutralizing the waste water were

Answer Center also included together with the disposal costs of the waste effluent. Labor costs were not assumed

Contact Us to vary across the options studied and are based on 1.5 man years. Annual maintenance costs were

included but not the cost of land, buildings or taxes.

Current News

1 dari 3 1/4/1980 8:09 AM

Ion Exchange or Reverse Osmosis? http://www.dow.com/liquidseps/design/ix_ro.htm

Download Software The IX plant considered was a packed bed counter-flow regenerated design consisting of 2 x 100%

streams with cation-degasser-layered bed anion-mixed bed polishers containing uniform particle

Literature

sized resins. Regeneration with both H2SO 4 and HCl were evaluated, although it was found that the

Product Selection cost per unit of treated water were similar for both acid regenerants, as the increased chemical

Guide via the Periodic efficiency of HCl and lower resin inventories are off-set by the higher cost of the chemical. Only the

Table economics using H2SO 4 are therefore reported.

Regulatory /

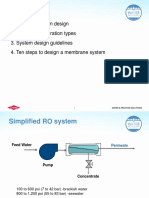

Certifications / MSDS The RO system consists of 1 x 100% line with RO-degasser-mixed bed polisher for 50 m /hour

3

Request Information 3

(220 gpm) and 2 x 50% lines for 200 m /hour (880 gpm). A system recovery of 80% was used. The

Regarding Our Sample

mixed bed design was the same as for the IX system.

Process

Subscribe for Info Results

Training

The results of the calculation indicate that the cost to produce water using only ion exchange

Where to Buy

increases with feed TDS as expected, principally due to regenerant chemical costs. Although the

regenerant costs increase proportionately, the effect of increasing plant size lowers the cost to

produce water, since the capital, raw water, labor and maintenance costs are relatively lower for the

Dow Water Solutions larger plant.

Home

The costs for IX vary between $0.5-0.7/m3 ($1.9-2.6/1000 gal) at 50 m3 /hour (220 gpm) and

3 3

$0.25-0.45/m ($1.0-1.7/1000 gals) at 200 m /hour (880 gpm). At the lower flow rate, operating

costs account for ~70% of the total cost with regenerants, raw water, labor and maintenance making

3

the most significant contributions. At 200 m /hour (880 gpm), operating costs increase to ~80%.

The cost of producing water using RO/IX is also dependent on feed TDS, but much less so than for

the IX system, due to the fact that the main cost contributors (power, water, labor, maintenance and

capital) are relatively constant over a range of water salinities.

RO/IX costs are $0.6 and 0.4/m3 ($2.3 and $1.5/1000 gals) for the 50 m3 /hour (220 gpm) and 200

3

m /hour (880 gpm) plants respectively. Operating costs are 72-80% of the total cost for the two

plant sizes.

3

The salinity break-even point for the two technologies was found to be between 7 and 8 eq/m

(350-400 ppm as CaCO3 ) TDS for the two flow rates. It should be emphasized that these

break-even points are derived from one set of assumptions, so sensitivity studies were also made to

assess the effect of the changes in the cost of power, chemicals and water on the economics.

Sensitivity Studies

Varying power costs over the range of $0.05-0.16/kWh resulted in a change in the cost to produce

water of ±$0.04/m3 ($0.15/1000 gals) for the RO/IX system compared to the base case above,

3

thereby affecting the break-even point with IX by ±1.5 eq/m (± 75 ppm as CaCO3 ).

The sensitivity of caustic regenerant price over the range $200-400/ton on IX economics yields a

3

break-even point change of ± 1.2 eq/m (± 60 ppm as CaCO3 ).

Finally the effect of varying low cost raw water/effluent (e.g. surface water) was considered and this

3

had a marginal influence on the breakeven point of ± 0.6 eq/m (± 30 ppm as CaCO 3 ). If, however,

mains water is taken or the cost of effluent treatment is expensive, the cost of RO/IX vs IX increases

3

and the break-even point is above 10 eq/m (500 ppm as CaCO3 ).

Conclusions

This economic evaluation considers the major factors contributing to the total cost of treated water

by RO/IX and IX. The effect of system size and the latest technology in both resins and membranes

has been included. The main conclusions from this study are summarized below:

The break-even point above which it is more economical to use RO/IX versus IX alone is 7-8

3 1,5,6

eq/m (350-400 ppm as CaCO3 ). This is higher than earlier studies and reflects

developments in packed bed counter-flow regenerated IX systems compared to co-flow systems

and also regional differences in power costs.

Chemical costs for IX and electrical power costs for RO are the most important operating

2 dari 3 1/4/1980 8:09 AM

Ion Exchange or Reverse Osmosis? http://www.dow.com/liquidseps/design/ix_ro.htm

expenses and those that need to be carefully considered in the decision for a new plant.

Although capital has a significant effect on the total cost of water for all options considered,

operating costs represent the major portion at 70-80% of the total.

This study considers mainly surface water and low cost discharge of effluent from the water

treatment plant into a river. More expensive water sources (e.g. mains) will have a higher

impact on RO costs, unless the concentrate from the RO plant can be used elsewhere on site.

References

1. See for example, A.F. Ashoff, UltraPure Water, July/August 1995 p. 39

2. P.A. Newell, S.P.Wrigley, P.Sehn & S.S.Whipple, Proceedings of SCI Conference IEX '96, 15.

July 1996

3. VGB-Kraftwerkstechnik GmbH literature, May 1995

4. K. Grethe and C. Beltle, "Power station make-up water using RO and ion exchange for

demineralisation" Steinmuellertagung 1993

5. S. Beardsley, S. Coker and S. Whipple, Watertech Expo '94, 9. Nov 1994

6. S.S. Whipple, E. Ebach and S. Beardsley, UltraPure Water, October 1987

®™* Trademark of The Dow Chemical Company ("Dow") or an affiliated company of Dow

Dow Water Solutions Home : DOWEX Ion Exchange Resins : Ion Exchange Resins Technical Information

: Design an Ion Exchange Resin System : Ion Exchange or Reverse Osmosis?

Dow Home Privacy Statement Terms of Use Accessibility Statement Site Map

Copyright © The Dow Chemical Company (1995-2009). All Rights Reserved.

3 dari 3 1/4/1980 8:09 AM

You might also like

- E2185 - Offer RENESCO - Rev0Document39 pagesE2185 - Offer RENESCO - Rev0Umut Sinan ÇetinbaşNo ratings yet

- Global Water IntelligenceDocument5 pagesGlobal Water IntelligenceKhyati MistryNo ratings yet

- Uf Toray PresentationDocument54 pagesUf Toray PresentationPrateek VermaNo ratings yet

- Thu06 Pentair MembranefiltrationDocument29 pagesThu06 Pentair MembranefiltrationdagNo ratings yet

- DemineralizationDocument4 pagesDemineralizationJoshuaGideonNo ratings yet

- PhET Plate Tectonics - 2013Document2 pagesPhET Plate Tectonics - 2013CloudKielGuiangNo ratings yet

- "Let Not The Failure and The Pain Turn Aside The WorshippersDocument35 pages"Let Not The Failure and The Pain Turn Aside The Worshipperspdavidthomas100% (1)

- Fix It With Fixed Film - The Details of IFAS - MBBR Design and ConstructionDocument28 pagesFix It With Fixed Film - The Details of IFAS - MBBR Design and ConstructionhtuhnitNo ratings yet

- Siemens Water TechnologiesDocument33 pagesSiemens Water TechnologiesmaheshvbendreNo ratings yet

- Kuliah Ion ExchangeDocument46 pagesKuliah Ion ExchangeNila Fitra AndiniNo ratings yet

- Hydranautics - Nitto Membrane Applications, Case Studies, Lessons LearntDocument37 pagesHydranautics - Nitto Membrane Applications, Case Studies, Lessons Learntkalyan patilNo ratings yet

- TMF Lime SofteningDocument2 pagesTMF Lime SofteningRachel HechanovaNo ratings yet

- Reverse Osmosis Design GuidelinesDocument2 pagesReverse Osmosis Design Guidelineswacsii ccasullaNo ratings yet

- Anion Resin Spec SheetDocument12 pagesAnion Resin Spec SheetarufatoNo ratings yet

- PH and Buffer CapacityDocument7 pagesPH and Buffer CapacityJuan David OrtizNo ratings yet

- Resumen de AgitadoresDocument8 pagesResumen de Agitadoresruben quedo salazarNo ratings yet

- 1 Designing A Reverse Osmosis Plant For Desalination of Agricultural Drainage WaterDocument14 pages1 Designing A Reverse Osmosis Plant For Desalination of Agricultural Drainage Waterabdo magdyNo ratings yet

- Spiral Wound Forward Osmosis Membrane ModuleDocument12 pagesSpiral Wound Forward Osmosis Membrane Modulejigar patelNo ratings yet

- High Efficiency Reverse OsmosisDocument21 pagesHigh Efficiency Reverse OsmosisPranav KumarNo ratings yet

- DM PlantDocument9 pagesDM Plantsohag97No ratings yet

- Application of Electro-Membrane Technologies in Zero Liquid Discharge TechnologyDocument27 pagesApplication of Electro-Membrane Technologies in Zero Liquid Discharge TechnologyYesid Tapiero MartínezNo ratings yet

- Boron Removal From Saline Water A Comprehensive ReviewDocument13 pagesBoron Removal From Saline Water A Comprehensive ReviewDóri Mai TóthNo ratings yet

- GVT-ODIS-SWRO For PBMC PDFDocument35 pagesGVT-ODIS-SWRO For PBMC PDFSwati BhattacharyyaNo ratings yet

- Water Desalination & Wastewater Treatment For Vietnam 18.2Document5 pagesWater Desalination & Wastewater Treatment For Vietnam 18.2Luan NguyenNo ratings yet

- Ion ExchangeDocument24 pagesIon ExchangemarkNo ratings yet

- 04 Manifold HydraulicsDocument29 pages04 Manifold HydraulicsVeena NageshNo ratings yet

- LTE PresentationDocument28 pagesLTE PresentationKapa Kamalakar100% (1)

- Demineralisation of Water: Rahul Agarwal Varun Aggarwal Pinaki GhoshDocument16 pagesDemineralisation of Water: Rahul Agarwal Varun Aggarwal Pinaki GhoshVarun AggarwalNo ratings yet

- 3.de MineralisationDocument56 pages3.de MineralisationYogesh WadhwaNo ratings yet

- Rode Sign BasicsDocument43 pagesRode Sign BasicsAshish GulrandheNo ratings yet

- UPCORE QuestionsDocument12 pagesUPCORE QuestionsIsmael KhalilNo ratings yet

- WWTP Budgeting SaddamDocument11 pagesWWTP Budgeting SaddamAQUAMART INDONESIANo ratings yet

- Food Grade ResinsDocument3 pagesFood Grade ResinsWarme DamianNo ratings yet

- Innovative Catalyst Solutions For (Ultra) Low Sulphur DieselDocument24 pagesInnovative Catalyst Solutions For (Ultra) Low Sulphur DieselArka Pravo BandyopadhyayNo ratings yet

- Prensentation Slides For Industry BriefingDocument40 pagesPrensentation Slides For Industry BriefingkunalkhubaniNo ratings yet

- EDR Technical Training-PublicDocument80 pagesEDR Technical Training-PublicHassan Feki100% (1)

- Berghof Filtration ConceptDocument3 pagesBerghof Filtration Conceptskthen72No ratings yet

- Watertech Mar 04Document4 pagesWatertech Mar 04Junnaid NissarNo ratings yet

- 9 IER Training Make Up Water Nigeria KompatibilitaetsmodusDocument135 pages9 IER Training Make Up Water Nigeria KompatibilitaetsmodusRamon Esteban Martinez AvalosNo ratings yet

- Silica Removal During Lime Softening in Water Treatment PlantDocument10 pagesSilica Removal During Lime Softening in Water Treatment PlantLouay MansourNo ratings yet

- Water Softening IndustryDocument4 pagesWater Softening IndustryArslanAliNo ratings yet

- Applications of Weak Acid Cation Resin in Waste TreatmentDocument9 pagesApplications of Weak Acid Cation Resin in Waste TreatmentSandeep MishraNo ratings yet

- Sismat Externally Fed Drum Screen (DAT) Brochure A4 - SpreadsDocument5 pagesSismat Externally Fed Drum Screen (DAT) Brochure A4 - SpreadsasddNo ratings yet

- 1 IER FundamentalsDocument54 pages1 IER FundamentalsAdam FendrychNo ratings yet

- Astm D 2187 - 94 ResinaDocument19 pagesAstm D 2187 - 94 ResinaIvette LorenaNo ratings yet

- 4-MCran Membrane CleaningDocument41 pages4-MCran Membrane CleaningKhalid AbdelRahimNo ratings yet

- Design ChallengesDocument52 pagesDesign ChallengesDrSurendra Pratap SinghNo ratings yet

- Sajid HussainDocument48 pagesSajid HussainTimothy GarciaNo ratings yet

- Filmtec™ Membranes Flow Factor For Ro System DesignDocument3 pagesFilmtec™ Membranes Flow Factor For Ro System DesignJuan MendozaNo ratings yet

- MB 11 BrochureDocument7 pagesMB 11 BrochurePhliip StaintonNo ratings yet

- Ultrafiltration For Oily Industrial Water: Separation Dynamics Paper SeriesDocument13 pagesUltrafiltration For Oily Industrial Water: Separation Dynamics Paper SeriesböhmitNo ratings yet

- Ionexchange PDFDocument31 pagesIonexchange PDFAnonymous 6Nt20xKNo ratings yet

- Ohio Biosolids Nereda Seminar 2017Document71 pagesOhio Biosolids Nereda Seminar 2017فؤاد مهندسNo ratings yet

- Treatment of High StrengthDocument57 pagesTreatment of High StrengthDarrell MerchantNo ratings yet

- Corporate GEA KestnerDocument8 pagesCorporate GEA KestnerlaurentpalierneNo ratings yet

- AVS Overview Avista Essential User Guide - AVSUS - 2020Document32 pagesAVS Overview Avista Essential User Guide - AVSUS - 2020Yanina Aliaga100% (1)

- KMS Membrane CleaningDocument2 pagesKMS Membrane CleaningmagzigioNo ratings yet

- IX News: Water Demineralisation. Ion Exchange and Reverse Osmosis: Competitors or Associates ?Document8 pagesIX News: Water Demineralisation. Ion Exchange and Reverse Osmosis: Competitors or Associates ?nermeen ahmed100% (1)

- 225 Na Engg DataDocument8 pages225 Na Engg DatadeyprasenNo ratings yet

- Cross ReferenceDocument3 pagesCross ReferenceABDUL MUZAMMILNo ratings yet

- Aventura Iron Removal MediaDocument2 pagesAventura Iron Removal MediaAkshay NarayankarNo ratings yet

- Topic 1: Introduction To Nursing TheoryDocument24 pagesTopic 1: Introduction To Nursing Theoryalmira garciaNo ratings yet

- Sat Sankalp EnglishDocument2 pagesSat Sankalp Englishrohan100% (1)

- VPS Impression MaterialsDocument55 pagesVPS Impression MaterialsalhaleemNo ratings yet

- Chapter 1 Introduction: 1.1 Purpose of The Manual For Micro-Hydro DevelopmentDocument7 pagesChapter 1 Introduction: 1.1 Purpose of The Manual For Micro-Hydro DevelopmentAde Y SaputraNo ratings yet

- Course Syllabus: L&S 126 Strategy Formulation First Semester SY 2012 - 2013 Instructors & ScheduleDocument5 pagesCourse Syllabus: L&S 126 Strategy Formulation First Semester SY 2012 - 2013 Instructors & ScheduleJullie Kaye Frias DiamanteNo ratings yet

- Notification No. 477 (E) Dated 25th July, 1991 of The Department of Industrial Policy and Promotion, Ministry of IndustryDocument39 pagesNotification No. 477 (E) Dated 25th July, 1991 of The Department of Industrial Policy and Promotion, Ministry of IndustryHarish100% (3)

- CCD CMOS WhitePaperDocument28 pagesCCD CMOS WhitePaperVictor CiprianNo ratings yet

- Renal FunctionDocument5 pagesRenal FunctionMunish DograNo ratings yet

- Which Functor Is The Projective Line?Document16 pagesWhich Functor Is The Projective Line?flores3831_814460512No ratings yet

- QMP 15 Identification and TraceabilityDocument6 pagesQMP 15 Identification and Traceabilityom cncNo ratings yet

- Psychological Assessment: IntroductionDocument4 pagesPsychological Assessment: Introductionkainat mumtazNo ratings yet

- Talal AsadDocument30 pagesTalal Asadcarolinasacarva2175No ratings yet

- PT0-101 NetworkArmyDocument84 pagesPT0-101 NetworkArmyMohammad Malek KhataeiNo ratings yet

- Andrea Reaction Paper FinalDocument3 pagesAndrea Reaction Paper FinalIrene SabidNo ratings yet

- Notes of Cost (Microeconomics)Document10 pagesNotes of Cost (Microeconomics)Nishant DoshiNo ratings yet

- Component Identification of GearDocument6 pagesComponent Identification of GearWandiNo ratings yet

- Genetic: Introduction To Genetic AlgorithmsDocument44 pagesGenetic: Introduction To Genetic AlgorithmsMeyer Al-HayaliNo ratings yet

- Part 1 固定常考: Work/StudyDocument31 pagesPart 1 固定常考: Work/Study书签No ratings yet

- Zanskar Expedition Himalaya Com MonkDocument1 pageZanskar Expedition Himalaya Com MonkIvan IvanicNo ratings yet

- Digital Storage Oscilloscopes: TDS210 TDS220 TDS224Document4 pagesDigital Storage Oscilloscopes: TDS210 TDS220 TDS224Jime SiepeNo ratings yet

- Gigabyte Ga-K8ns Rev 1.1 SCHDocument37 pagesGigabyte Ga-K8ns Rev 1.1 SCHMohammad AhamdNo ratings yet

- Pemurnian EnzimDocument54 pagesPemurnian EnzimwulanNo ratings yet

- Zohdy, Eaton & Mabey - Application of Surface Geophysics To Ground-Water Investigations - USGSDocument63 pagesZohdy, Eaton & Mabey - Application of Surface Geophysics To Ground-Water Investigations - USGSSalman AkbarNo ratings yet

- STM Unit-1,2,3 PDFDocument88 pagesSTM Unit-1,2,3 PDFsaranyaNo ratings yet

- Sankalp Final ProjectDocument40 pagesSankalp Final Projectsankalp mohantyNo ratings yet

- Recent Advances in The Synthesis of Pipe Rid Ones and Piperidines PM Weintraub JS Sabol JM Kane DR Borcherding Tetrahedron 59 2953 2989 2003Document37 pagesRecent Advances in The Synthesis of Pipe Rid Ones and Piperidines PM Weintraub JS Sabol JM Kane DR Borcherding Tetrahedron 59 2953 2989 2003KybernetikumNo ratings yet

- Consilium Navigation Sal Broschyr PDFDocument8 pagesConsilium Navigation Sal Broschyr PDFSeamen 777No ratings yet

- Exercises 1Document4 pagesExercises 1Xena Nurraini Anun CakranegaraNo ratings yet