Professional Documents

Culture Documents

AzLM - ELDYNE - MSDAC

AzLM - ELDYNE - MSDAC

Uploaded by

Bhavna Kaushik BajpaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AzLM - ELDYNE - MSDAC

AzLM - ELDYNE - MSDAC

Uploaded by

Bhavna Kaushik BajpaiCopyright:

Available Formats

Az LM

Installation Guideline

All information contained in or disclosed by this document is confidential and proprietary to

Eldyne Electro Systems Pvt. Ltd. By accepting this material the recipient agrees that this

material and the information contained therein will be held in confidence and will not be

reproduced, disclosed, or used in whole or in part except for purposes of this document.

All rights reserved. This publication and its contents are proprietary to Eldyne Electro

Systems Pvt. Ltd. No part of this publication may be reproduced in any form or by any

means without the written permission of Eldyne Electro Systems Pvt. Ltd.

Please contact for detail information

Eldyne Electro Systems Pvt. Ltd., P-21 Old Ballygunge Road, Kolkata – 700 019, India.

Phone - +91 33 2281 5454, 5425, 5426 Fax - +91 33 2281 5757

e-mail : eldyne@vsnl.com

Rev. Date Author Reviewed

A September 20, 2004 S. Misra S. Chatterjee

B December 30, 2005 P. Nandi S.Chatterjee

C August 10, 2006 P. Nandi S.Chatterjee

Revision & Change:

Rev. Date Author Reason For Changes

A September 20,2004 S. Misra First Edition

B December 30, 2005 P. Nandi Incorporation of changes for

V5.1.2

C August 10, 2006 P. Nandi Incorporation of Toolkit details

AzLM – Installation Guideline REV. C 1/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

Contents :

Topic Page

1. Introduction 3

2. Installation Of Rail Contacts (SK30H) 4

3. Installation of Track-Side Electronic Unit (EAK) 8

4. Checking Of Power Supply 10

5. Earthing of the Equipment 10

6. Terminations 10

7. Communication Link 11

8. Adjustment of Rail Contact 12

9. Address Setting 15

10. LED Indications Of EAK 16

11. Axle Counter Central Evaluator (ACE) 18

12. Connection of ACE 19

13. Connection of PDCU 23

14. LED Indication on ACE 24

15. Connection Diagram of EAK, PDCU, Serial Card and 27

Parallel Card in a 2 DP – Single Section Configuration

16. Arrangement of Serial and Parallel Cards in ACE 28

17. System Diagnosis By Computer 29

18. Connection of Reset Box 38

19. Calculation of Current Consumption 41

20. Do‘s and Dont‘s 42

21. Log Sheet 43

22. ETU001 Specification and Ordering Code 44

23. Wiring Diagram of ACE Cabinet and Reset Panel 45

24. Pre-commissioning Check List Annexure - A

AzLM – Installation Guideline REV. C 2/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

1 INTRODUCTION

1.1 Overview

This document provides the specific guidelines along with Do’s and Don’ts practices for installation,

commissioning and adjustment of Multi Section Digital Axle Counter of AzLM system. This document is more

of a ready reference hand book for installer and maintainer for the system.

1.2 Recommended Tools

• Drilling jig from Alcatel / Chembre

• Tool Kit ETU001

1.3 Reference Count Direction (RCD)

REFERENCE COUNT DIRECTION (RCD)

RAIL RAIL

CONTACT1 SECTION1 CONTACT2

SK1 SK2 SK1 SK2

Figure 1: Reference Count Direction (RCD)

The reference count direction (RCD) must be defined for the track layout independent of the direction of

travel. The use of RCD ensures that the correct order of counting into and out of a section is maintained

throughout a series of detection points. Without the RCD the system cannot be correctly configured.

According to figure 1, axles are counted in the section when a train passes Rail Contact1 in the direction of

the arrow or a train passes Rail Contact2 in the opposite direction of the arrow. Axles are counted out of the

section when a train passes Rail Contact1 in the opposite direction of the arrow or a train passes Rail

Contact2 in the direction of the arrow.

AzLM – Installation Guideline REV. C 3/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

2 INSTALLATION OF RAIL CONTACTS (SK30H)

Figure 2: Fitting of Rail Contacts on Rail Web

2.1 Selection of Installation Point on Rail

• When choosing the new location for installing Rail Contact, all signalling aspects like overlap, shunting

limits etc. have to be considered.

• The rail contact is mounted on the rail as shown in Fig. 2 between two sleepers.

• Any embossments on the rail web must be removed else another location for the rail contact has to be

selected.

• On double-track lines the rail contact should be mounted preferably on the outside rail.

• Recommended spacing

≥ 1 m Distance to a rail joint (fishplated or welded or insulating joint)

If the condition of the track is poor, the rail contact should have a distance of approximately 2 m to the

next welded rail joint. This is recommended for reducing strain on rail contacts due to vibration.

• Mandatory spacing

≥ 2 m Distance to the rail contact of same type (Sk30, Sk30H) of a neighbouring detection

point. This is recommended for avoiding influence of flux between each other.

• The operator must ensure that other equipment used or installed at the track does not influence the

correct functioning of the detection points of Zp30H (AzLM) (e.g. detection points of other

manufacturers).

AzLM – Installation Guideline REV. C 4/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

2.2 Rail Mounting Holes

It is extremely important that the mounting holes are drilled in the correct position to ensure accurate

adjustment of the Rail Contacts and therefore reliable working of the system.

The following approximation formula can be used for calculating the height of the holes on the rail web. It is

to be noted that all the heights are to be measured from the foot of the rail.

Approximation formula a = (0.409 * h)

It is important to note that, this formula is only a general one for an intial guideline. Experience from a pilot

installation is more indicative for actual height. Same applies for old rails or rail with other profile.

Figure 3: Drilling Position for installation of Rail Contacts

a1, a2, a3 must not differ from

a= a calculated ± 1.5 mm

each other by more than 1 mm.

b= 13 mm ± 0.2 mm

c= 148 mm ±0.2 mm

As seen in Fig. 3, position "a" of the mounting holes depends mainly upon the height of the rail “h”.

Indicative examples for various rail profiles with a rail height between 140 mm and 180 mm and a rail

width between 125 mm and 150 mm are indicated in the following table. They refer to "Flat Bottom" rail

profiles as shown in Figure 3. Suitability of other rail profiles such as "Bullhead" or rails with a width less

than 125 mm or larger than 150 mm must be individually established.

Rail Profile 90 lb 52 Kg 60 Kg

a [mm] 56 mm 63 mm 68 mm

With the calculated dimension "a", the maximum adjustment of the Tx heads should be possible without

infringing on the clearance profile or touching the rail.

AzLM – Installation Guideline REV. C 5/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

2.3 Drilling

The final three holes of diameter 13mm are to be made on the rail web. A pilot drill of 6mm or 8mm

diameter can be made for convinience.

2.4 Use of Drilling Jig (Recommended)

The drilling jig consists of:

• Drilling template

• Mounting device for the drilling machine

• Templates for the standard rail profiles

• Fastening device

• The drilling machine

Optionally, drilling machine may be made available from Eldyne.

2.5 Mounting of Rail Contact

• The rail contact must be mounted on the rail so that the Tx heads are on the outside and the Rx heads

on the inside of the rail. The heads may get damaged if left loose on the rail.

The three M12 bolts must be tightened to 45 Nm by means of an adjustable torque wrench supplied

only with the Tool Kit ETU001.

• Each Tx head is mounted on an aluminium casting with two M8 bolts. It is important that the teeth and

grooves of the aluminium casting and the Tx head are correctly lined-up.

The four M8 bolts must be tightened to 25 Nm by means of an adjustable torque wrench supplied only

with the Tool Kit ETU001.

Washer

Nut M12 Bolt

Nylon Bush

Insulating Plate

Figure 4: Mounting of Rail Contact

AzLM – Installation Guideline REV. C 6/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

Note:

• After tightening the nuts, the bolts should protrude a minimum of 2mm. If it is less than 2mm the

transmitter head and the aluminium casting must be re-checked for correct fitting.

• The transmitter head must not touch the rail-head.

• The brackets for the protective hose must be insulated from the rail. For this purpose nylon bushes are

inserted into the holes of the bracket.

• The rail contact cables are protected electrically and physically by means of protective hose.

• Mark the rail contact integral cables, before putting them inside the protective hose, as Sk1 / Sk2

according to reference count direction so that after taking out from the other end of the protective hose,

those cables can be identified easily.

• The protective hose must be cut to the correct length before the cable is inserted. The hose must be

made watertight with a rubber seal on the rail contact side and the hose clamp on the side of the EAK.

• The length of the protecting hose must be adequate to ensure that the necessary support for the cable at

the heads is provided and that the hose clamp at the EAK can be correctly installed.

• Exposed integral cables of rail contact at the Tx & Rx side should have adequate radius of curvature so

as to avoid stress on the cable. Measure should be taken that, this exposed part of the cable does not

touch the sharp edge of the ballast.

• The integral cables of rail contacts must be laid avoiding loops (i.e. going directly away from the track

and then at a right angle into the electronic unit). The integral cables of the rail contact are available

with three different lengths 4m, 5.5m and 8m. Choosing right length of integral cable is very important

before installation.

• The rail contacts are now ready to get connected to the electronic unit. The cable should not be

shortened.

• Deflector plates to be installed as shown in figure 5, to protect the rail contacts from hanging metal

objects from passing train.

Deflector Plates

Figure 5: Installation of Deflector Plates

AzLM – Installation Guideline REV. C 7/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

3. Installation of Track-Side Electronic Unit (EAK)

3.1. Housing Of the Equipment

It is strongly recommended to house the EAK in the Mushroom Cover, if installed, out side the location box.

EPC 001 – CI Lockable Mushroom Cover with SS stand is optionally available from Eldyne.

If EAK is placed inside the location box it is recommended to house the EAK with a dust cover also available

optionally from Eldyne.

3.2 Connections

To obtain the correct direction of counting, an axle counter reference direction has been defined. This would

normally be the direction of increasing mileage.

The rail contact that is first crossed by an axle in the axle counter reference direction is defined as rail

contact 1 (Rx1/Tx1) and the other rail contact as rail contact 2 (Rx2/Tx2).

The contacts are connected according to this definition to the terminals of the electronic unit. (see table

below).

Rail contact and wire colour Terminal on Zp30H

Rx 1(black) Sk1 / E1

Rx 1 (transparent) Sk1 / E2

Rx 1 (blue) Sk1 / E3

Tx 1 (transparent) Sk1 / S2

Tx 1 (black) Sk1 / S1

Tx 2 (black) Sk2 / S1

Tx 2 (transparent) Sk2 / S2

Rx 2 (blue) Sk2 / E3

Rx 2 (transparent) Sk2 / E2

Rx 2 (black) Sk2 / E1

The screen of the rail contact cables is connected to the earthing bar:

• Remove the cable insulation for a length of approximately 45mm.

• Fasten the screen to the earthing bar by means of a cable tie and connect the screen to the earthing bar

using the clip supplied.

AzLM – Installation Guideline REV. C 8/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

The pairs of wire have to be twisted properly as shown in Figure 6.

Twisting of conductors

Exposing the screen

Earthing Clip

Fig. 6: Fixing of Rail Contact Integral Cable at EAK Side

The connection for Power Supply / Communication to the EAK is furnished in the following table.

Connections Terminals

Superimposed Power (+) & Data Line 3

Superimposed Power (-) & Data Line 13

It is mandetory to provide a shorting link between terminal 2 & 1 and 12 & 11 if the same pair of

conductors is used for superimposed data & power supply to the EAK.

Note:

If separate power supply is used for installation, the communication line has to be connected

between terminals 3 & 13 and the 60V power supply has to be connected to terminals 1 &

11.

AzLM – Installation Guideline REV. C 9/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

4. Checking Of Power Supply

Recommended power supply for track-side electronic unit (EAK) for AzLM is

• 54 VDC to 72 VDC. The power consumption per EAK is 9W (appoximately).

• The ripple content of the power supply is recommended to be lower than 24mV peak to peak.

• Extreme care should be taken to see that the power source does not have any change over time from

mains to battery during mains failure.

• Care should also be taken to see that power supply does not have any kick beyond upper tolarence

value (72VDC) during startup or charging after power failure.

• Care should also be taken that power supply source is not under / over loaded beyond it’s specification.

Before installation the available voltages are to be checked at the power supply connectors 1 & 11. This

must be ensured that in all the conditions the available power supply voltages should be in the above

tolerance limit (54VDC to 72VDC).

As there is a SMPS based DC-DC converter in the analog card, it takes much higher current during startup.

Therefore care should be taken considering cable resistance and available voltage at the EAK so that the

system can start up in a normal way.

5. Earthing of the Equipment

The EAK has to be connected to the earth with a copper cable of minimum 25mm2 or an iron cable of

minimum 50mm2. Other cross-sections may be necessary due to national regulations.

The housing has to be earthed to a suitable low inductance (approximately L<40µH) and low

resistance (approximately R<4 Ω) earth.

The earthing rules of the railway must be adhered to.

6. Terminations

All service wires of EAK (viz. Power, Communication, are recommended to be properly terminated

preferably with cage-clamp type of terminals of proper matching of cable cross sections.

AzLM – Installation Guideline REV. C 10/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

7. Communication Link

For communication with the axle counter central evaluator, a physical communication link must be needed.

The system uses two wire ANSI T1.601communication protocol with ISDN modulation. The maximum

transmission distance is 13KM with a good quality communication cable having maximum resistance of

56ohm/KM and capacitance of 45nF/KM. Though the transmission level of the system is 0dBm, yet a

maximum attenuation in the communication link is 24dB.

For better reliability the correct pair of star quad cable should be used with proper terminations.

QUAD 4

QUAD 1

QUAD 3

QUAD 2

Cable Dia: 0.9 mm

Specification: IRS TC 30/96.

QUAD 1: QUAD 2:

1st Pair: Blue - White 5th Pair: Brown - White

& &

2nd Pair: Red - Grey. 6th Pair Red - Grey.

QUAD 3: QUAD 4:

3rd Pair: Green - White 7th Pair Orange - White

& &

4th Pair: Red - Grey. 8th Pair Red - Grey.

Figure 7: Matched Pair of 4 Quad Cable

AzLM – Installation Guideline REV. C 11/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

8. ADJUSTMENT OF RAIL CONTACT

8.1 Positioning of Dummy Wheel

A dummy wheel is required for the adjustment of the rail contact. On main lines the device is normally set to

40mm. During adjustments the dummy wheel must be kept vertically at the centre of Rx heads.

40

Figure 8: Positioning of Dummy wheel

8.2 Adjustment with Tool Kit ETU001

For adjustments, tool kit ETU001 (for detailed specification refer Chapter 22) has to be used only with its

dummy wheel, true RMS multimeter and adjusteble torque wrench.

Dummy wheel-simulates wheel

presence

True RMS multi-meter

Integral cable with connector. The

connector fits to matching connector on EAK

Fig. 8: Tool Kit ETU001 Multi function selector switch

Adjustable Torque Wrench

Figure 9: Tool Kit ETU001

AzLM – Installation Guideline REV. C 12/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

For adjustment, the test equipment must be connected to the diagnostic port of EAK and the Tx heads are

moved upward or downward along the serration, if necessary.

• The selector switch position 1 shows the value of the output of 1st internal DC-DC Converter (Channel1)

in Analog card. This should be within the range of 22VDC to 35VDC.

• The selector switch position 2 shows the value of output voltage of 2nd internal DC-DC Converter

(Channel2) in Analog card. This should also be within the range of 22VDC to 35VDC.

• The selector switch position 4 shows the rectified Rx voltage (MESSAB1) for SK1. This should be positive

without dummy wheel. After placing the dummy wheel on Rx1 vertically on the center, the MESSAB1

voltage should be negative. In ideal condition and for proper adjustment of rail contact, MESSAB1

voltage without dummy wheel should be equal to the MESSAB1 voltage with dummy wheel but having

an opposite polarity. The value of MESSAB1 should be within 80mV to 1000mV depending upon the

drill position and rail profile.

Steps to adjust the rectified voltage:

• Turning the potentiometer (R2) on analog board, the rectified voltage without dummy wheel must be set

to positive maximum.

• The rectified voltage has to be checked with dummy wheel. If there is a big difference between the

positive value and the negative value, the Transmitter head should be taken pulled up or pushed down.

Taking the transmitter head upwards increases the negative voltage and decreases the positive voltage

and vice versa.

• After getting the positive and negative voltages within the specified limit the transmitter head has to be

tightened properly with the torque wrench set at 25 Nm. For proper adjustment the positive voltage

should be greater than negative voltage by a value not less than 30mV for achieving suppression of

spoke trolley wheels (As shown in Figure 10) so that the rectified Rx voltage does not go to negative

(Figure 11) with the specified trolley wheel. It is recommended that the adjustment should be done using

a spoked trolley wheel that is normally used in the section. For fine adjustment the potentiometer R2

may be used.

• The selector switch position 5 shows the value of reference voltage for SK1 (PEGUE1). This can be

adjusted by the potentiometer R1 on the Analog board and is made equal (or ±2%) to the value of

MESSAB1 as measured without the dummy wheel.

• Keeping the selector switch at position 7, the SK2 is adjusted by measuring rectified Rx voltage for SK2

(MESSAB2) following the same way as mentioned above. For fine adjustment the potentiometer R4 on

the Analog board should be used.

• The selector switch position 8 shows the reference voltage for SK2 (PEGUE2) and can be adjusted

following the same way as mentioned above using potentiometer R3 on the analog board.

AzLM – Installation Guideline REV. C 13/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

• The voltage and frequency of the transmitter heads are to be measured by the true RMS multi meter

only. For this purpose additional probe set is provided with ETU001. These readings are available at the

connectors of Tx cable for both SK1 and SK2.

Figure 10: Spoked Trolley Wheel which will not be detected by

Axle Counter after adjustment

W h e e l D is t a n c e v s S K 1 R e c t if ie d V o lt

200

180

SK1-Rectified Volt (mV)

160

140

120

100

80

60

40

20

0

-2 5 0 -2 0 0 -1 5 0 -1 0 0 -5 0 0 50 100 150 200 250

D is t a n c e f r o m C e n t r e ( m m )

Figure 11: Voltage Pattern with a trolley wheel after adjsutment

The power supply voltage fed to the track side electronic unit is also to be measured with the meter and the

probe set directly to the power supply connector.

The adjustment details carried out during installation or periodic maintenance for the detection point should

be noted in the logsheet for future reference.

AzLM – Installation Guideline REV. C 14/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

9. Address Setting

Each EAK connected to the same ACE for a particular installation, must have an unique address. This

address setting can be done by setting the DIP switches provided on the mother board as shown in Figure

12.

S4 S3 S2 S1

16 9 8 1 16 9 8 1

1 1

0

0

Address Setting For EAK With HEX Address 0001

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 on both set of

S4 S3 S2 S1

16 9 8 1 16 9 8 1

1 1

0 0

Address Setting For EAK With HEX Address 0002

0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 on both set of

Figure 12: Setting of Address

The system will not work without proper address as defined in site specific software. The set of addresses

assigned to the EAKs in the site specific software must be maintained during installation.

Ensure that the switches are firmly set to the correct position. Only insulated long needle like materials to be

used.

• To set a ´1´ press switch to the end that is marked “1”.

• To set a ´0´ press switch to the other end.

Labeling: 1 ONE SET 1

ZERO SET 0 0

AzLM – Installation Guideline REV. C 15/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

10. LED Indications of EAK

LEDs are provided on the Analog and Evaluator / Digital cards to indicate different status of the system as

shown in the Figure 13.

Analog Card

IDSN Card (Digital Card)

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

Figure 13 : LED Indication for EAK of AzLM

AzLM – Installation Guideline REV. C 16/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

Different LED indications are shown in the following table for Analog card.

LED Colour Indication Flashing

H1-1 red on: wheel on rail contact 1

off: no wheel on rail contact 1

H1-2 green off: wheel approaching sensor voltages (MESSAB1) within tolerance,

no wheel approaching

H2-1 red on: wheel on rail contact 2

off: no wheel on rail contact 2

H2-2 green off: wheel approaching sensor voltages (MESSAB2) within tolerance,

no wheel approaching

H3-1 red on: voltage H24V out of tolerance

off: voltage H24V within tolerance

H3-2 green on: voltage H5V o.k.

off: voltage H5V not o.k.

Different LED indications are shown in the following table for Evaluator / Digital card during system

operation.

LED Colour Indication Normal operation

H1-1 green Transmitting data Flashing

H1-2 green CPU1 indicates a fault during self- OFF

test of Analog part

H2-1 green Transmitting data Flashing

H2-2 green CPU2 indicates a fault during self- OFF

test of Analog part

AzLM – Installation Guideline REV. C 17/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

11. Axle Counter Central Evaluator (ACE)

Axle Counter Central Evaluator is the decision making unit for multi section digital axle counter. It has the

following sub components.

CPU Card acts as the brain of AzLM. Two CPU Cards are required for 2oo2 system. These CPU Cards

have diagnostic interfaces and an alphanumeric display. For a specific application, the CPU Cards used

must be loaded with the site specific software. Diagnostic interfaces are available on CPU Card to connect it

to a PC and check the system status, health messages etc. with the help of a diagnostic software.

Power Supply Card has DC-DC converters. It works on 24VDC and generates 5VDC and 12VDC

required for the electronic circuitry. Two Power Supply Cards are required for 2oo2 system.

Serial Card receives information from detection points through ISDN communication link and provides this

information to CPU Cards. One Serial Card can monitor maximum two detection points.

Parallel Card is responsible for providing section information. This card takes instruction from CPU Cards

and gives section clear/occupied output through potential free contact of relays in it. The reset of a section is

commanded through the Parallel Card. A Parallel Card has two non-vital outputs which are also

configurable through site specific software for getting different signals, for example, indication of

acceptance of reset by the system or a technical defect in a section etc.

All the cards are housed in a SUBRACK. The nomenclature indicates the number of Power Supply and CPU

Cards and the number of I/O slots present in the subrack. Different possible configurations are

• ACE-2-10 is a 2oo2 system with 10 I/O slots.

• ACE-2-26 is a 2oo2 system with 26 I/O slots.

• ACE-2-42 is a 2oo2 system with 42 I/O slots.

AzLM – Installation Guideline REV. C 18/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

12. Connection of ACE

The following connections are to be made during installation of ACE.

• Power Supply to ACE.

• Connection to the detection point.

• Connection of relays.

Figure 14 : Backplane of Axle Counter Central Evaluator ACE-2-10

U1 & U2 are the connectors for 24VDC Supply to ACE. Polarity of the supply should be checked before

connection.

The slots S01 to S10 are used for I/O cards, either Serial or Parallel depending upon the site specific

software.

If the second subrack is used to convert an ACE-2-10 to an ACE-2-26, a flat cable with FRC connector of 10

pins is to be connected from C1 connector of the first subrack to the C1 connector of the second subrack as

shown in figure 16 (page 21).

Each I/O slot has 12-pin WAGO strip connectors numbered from X01 to X12 on the backplane of the

subrack.

If a Serial Card is plugged into an I/O slot, say slot 1, connectors X01/9 & X01/10 are used for

communicating (ISDN) with a detection point. Connections from X01/9 & X01/10 go to Pin14 & Pin15

respectively of the PDCU that is connection with the concerned detection point. Connectors X01/11 &

X01/12 of the same I/O slot are used for communicating with another detection point. Connections from

X01/11 & X01/12 go to Pin14 & Pin15 respectively of another PDCU that is in connection with the

concerned detection point. Connectors X01/5 & X01/6, and X01/7 & X01/8 should be made short with a

small looping wire to avoid cross talk between two ISDN communication signal coming from two detection

points connected with the same Serial I/O Card.

AzLM – Installation Guideline REV. C 19/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

The pin assignments for a Parallel Card plugged in, say, slot 10, are given below.

• Connectors X10/1 & X10/2 are used for providing Vital Input No 1 (viz. Preparatory reset).

• Connectors X10/3 & X10/4 are used for providing Vital Input No. 2 (viz. Hard Reset).

• Connectors X10/5 & X10/6 are used for providing non-vital output no. 1 (viz. Reset Acceptance).

• Connectors X10/7 & X10/8 are used for providing non-vital output no. 2 (viz. Technical defect).

Both the non-vital outputs give 4-second pulse through opto-coupler for the conditions defined in site

specific software. Pull up voltages are required to use these outputs in electronic circuits.

• Connectors X10/9, X10/10, X10/11 & X10/12 give the vital relay output through the potential free

contact of two relays provided on the Parallel Card. The detail of connections is shown in figure 15. In

2oo2 system two different relays are controlled by two different CPUs and both are supervised by each

other. When both relays are picked up only then the vital relay connected externally to the Parallel Card

is picked up.

A free wheeling diode (1N 4007) should be connected across the vital relay coil as shown in the figure

15. This will help to protect the Parallel Card from higher voltage generated across the relay coil during

the change of position of relay.

The contacts of the external vital relay QN1 (8F-8B) can be connected to interlocking as per

requirement.

24 V DC

CONNECTOR X10/9

FUSE

500mA

CONNECTOR X10/10

VITAL

CONNECTOR X10/11 RELAY

COIL

CONNECTOR X10/12

24 V COMMON

Figure 15 : Connection of Vital Realy with Parallel Card

AzLM – Installation Guideline REV. C 20/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

Figure 16 : Backplane of Axle Counter Central Evaluator ACE-2-26

AzLM – Installation Guideline REV. C 21/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

Fig. 17 : Backplane of Axle Counter Central Evaluator ACE-2-42

AzLM – Installation Guideline REV. C 22/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

13. Connection of PDCU

PDCU is the interface between outdoor equipment (Detection Point) and indoor equipment (ACE). It has a

superimposing circuit for using same conductor for power and data. One PDCU is used for one detection

point only.

There is a 315mA fuse inside the PDCU. The power to the EAK goes through this fuse and if it is blown then

there will be no power at detection point and a red LED within the PDCU will glow.

To EAK (PIN 3 & 13 RESPECTIVELY)

- -

60 V 60 V

+ +

1 2 3 4 5 6 7 8

FUSE 315MA

FUSE BLOWN

INDICATOR

11 12 13 14 15 16 17 18

TO SERIAL I/O CARD

CONNECTOR 9 & 10 RESPECTIVELY

OR

CONNECTOR 11 & 12 RESPECTIVELY

Fig. 18 : Connection of Power Data Coupling Unit ( PDCU )

PDCUs are to be installed on 35mm DIN rail.

In some applications (where local power supply is used to feed the EAK) the superimposed power and data

is not used. In that case, the PDCU should be used for isolation of communication line and only connector

no. 4, 5 and 14,15 are used.

AzLM – Installation Guideline REV. C 23/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

14. LED Indication on ACE

All the cards in ACE have their own LED indications.

14.1 Power Supply Card

There are three LEDs on power Supply Card.

LED Meaning

LED 1 LED 2 LED 3

LED 1

ON ON ON Normal operation

ON OFF ON Over load, under voltage at output 1

ON ON OFF Over load, under voltage at output 2

ON OFF OFF Input voltage too low, input voltage too high

LED 2 OFF ON ON Not applicable

LED 3 OFF ON OFF Not applicable

OFF ON ON Not applicable

OFF OFF OFF No input voltage

Figure 19. LED Indication of Power Supply Card

14.2 CPU Card

Fig. 20 : Front Panel of CPU Card

The alphanumeric display on the CPU Card shows the following indications:

Start up:

Initially the display is illuminated for a short while, then the screen goes blank for a short period. After that a

’_’ sign appers and stays for approximately 2.5 minutes. Then the normal operation begins.

AzLM – Installation Guideline REV. C 24/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

Normal operation:

Rotating bar

Faults:

Axle counter application stopped, diagnostic still available:

Alternating x and X

Axle counter application and diagnostic stopped:

Standing bar in any orientation

LED1 The flashing LED shows the communication on the Ethernet interface.

LED 2 and 3 The flashing LEDs show the communication between the processors. In normal

operation both LEDs flash.

LED 4 Not used.

The serial interface is used to download diagnostic data by means of serial (RS232) interface cable. The

data download through serial interface is only possible with CPU Card 1. (Facing the Axle Counter Central

Evaluator, The CPU Card installed in the left slot is mentioned as CPU Card 1 and the CPU Card installed

in the right slot is mentioned as CPU Card 2 (Ref. Figure 24). Both CPU Cards are interchangeable.)

The Ethernet port is used to download diagnostic data using Ethernet interface. The data download

through Ethernet interface is only possible with CPU Card 2.

14.3 Serial Card

The I/O Interface consists of two independent ISDN transmission paths. e.g. in a 2oo2 CPU system they are

used for two detection points.

The LED goes on, if the ISDN link to the associated detection point is operational.

The LED flashes, if a valid ISDN telegram was received from the associated detection point.

Fig. 21 : LED Indication Of Serial Card

AzLM – Installation Guideline REV. C 25/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

14.4 Parallel Card

LED Channel 1

LED Channel 2

1

2

3

4

5

6

Fig. 22 : LED Indication of Parallel Card

LED Channel Colour Function

Row

1 1+2 green External input 1 activated

2 1+2 green External input 2 activated

3 1+2 green Relay picked up (voltage on relay)

4 1 yellow Non-vital output 1 activated

4 2 yellow Non-vital output 2 activated

5 1+2 yellow Polling

6 1+2 green Don’t Care

AzLM – Installation Guideline REV. C 26/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

15. Connection Diagram of EAK, PDCU, Serial Card and Parallel Card in a 2 DP – Single

Section Configuration

External Input 1 (+) [Connector 1 of Parallel I/O] : From ‘RST+’ connector of Reset Box

External Input 1 (-) [Connector 2 parallel I/O] : 24V (-) Common from Power Supply

External Input 2 (+) [Connector 3 of Parallel I/O] : From ‘RST+’ connector of Reset Box

External Input 2 (-) [Connector 4 parallel I/O] : 24V (-) Common from Power Supply

Non-vital Output 1 (+) [Connector 5 parallel I/O]: To ‘RA’ connector of Reset Box

Non-vital Output 1 (-) [Connector 6 parallel I/O] : 24V (-) Common from Power Supply

Either External Input 1 or External Input 2 to be used.

Fig. 23 : Connection Diagram for 2 DP – Single Section Configuration

AzLM – Installation Guideline REV. C 27/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

16. Arrangement of Serial and Parallel Cards in ACE

Fig. 24 : Arrangement of Power Supply Unit (PSU), CPU, Serial and Parallel

Cards in ACE in a 8 DP – 6 Section Configuration

AzLM – Installation Guideline REV. C 28/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

17. System Diagnosis By Computer

For AzLM, the main diagnostic tool is the PC, loaded with a diagnostic software. The diagnostic PC must be

a Pentium PC having a serial interface RS-232 (19200 bps) port with Windows operating system. The serial

interface has to be connected to the serial interface port on the CPUCard 1 of ACE by a Nullmodem cable.

This cable must have female DB9 connector at both ends.

After running the diagnostic software, the system data (viz. Elements current data and Historical data) can

be downloaded and analysed on the PC. The historical data may be used to reconstruct the sequential

occurance of events happened in the AzLM system. The elements data includes status of section, detection

point, interfaces, versions etc.

The status of elements are displayed on the PC screen in a coded message format with date & time of

occurance. The diagnostic messages are explained in the following chapter.

Note:

The nullmodem cable should always be kept connected at the CPU card end as well at the diagnostic PC

end. In case the nullmodem cable needs to get disconnected, it should be disconnected from both ends. It is

not recommended at all to disconnect the nullmodem cable from diagnostic PC end but keep it connected

at the CPU card end.

AzLM – Installation Guideline REV. C 29/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

17.1 Important Diagnostic Messages

The following format of diagnostic messages is used in the history files and element data files generated by the diagnostic tool.

RNr CPU number from where the diagnostic messages are read out.

Replica 0 Æ Message from all running CPUs

1 Æ Message from CPU1 (that is, CPU Card on left side of ACE subrack)

2 Æ Message from CPU2 (that is, CPU Card on right side of ACE subrack)

3 Æ Message from CPU1 and CPU2

Date/Time Date and time of occurrence of diagnostic event.

Element Type There are several element types, e.g., section,detection point, parallel I/O card, serial I/O card etc.

Element Number Each element has its own number (e.g., n=1, 2, …) which is specified in the site specific data. These element numbers are listed in

the element window of the diagnostic tool together with the names which are used in the layout plan.

Diagnostic Event There are five types of diagnostic events, namely, operational name, site specific data, state, version and axles.

Parameter Information about different events.

RNr Replica Date/ Element Type Element Diagnostic Event Parameter Explanation

Time Number

1 3 yy:mm:dd Detection Point n DP information VERSATZ x (y) Counting fault of x axles in DP n.

The new difference between the CPUs is y axles.

hh:mm:ss:sss

Information:

CPU 1 and 2 are sending a different number of

counted axles. This may be caused by a miscount

in one CPU due to non-standard small wheels.

1 3 yy:mm:dd Detection Point n DP information ST A w x D y z Self Test of Analogue part and Digital part

hh:mm:ss:sss Parameter format:

w: result of Analogue Self Test of CPU1

x: result of Analogue Self Test of CPU2

y: result of Digital Self Test of CPU1

z: result of Digital Self Test of CPU2

AzLM – Installation Guideline REV. C 30/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

RNr Replica Date/ Element Type Element Diagnostic Event Parameter Explanation

Time Number

w/x/y/z = 1 : o.k.

w/x/y/z = 0 : test failed

1 3 yy:mm:dd Detection Point n DP information DRW sz Drift Warning from DP n:

hh:mm:ss:sss Information:

A drift warning is activated if the analogue

voltage “MESSAB“ is out of tolerance.

sz=0: no drift warning in the last 5 minutes

sz=1: drift warning

1 3 yy:mm:dd Detection Point n DP information DRW sz (a b c d; w x y z) Summary of Drift Warnings from DP n every 5

minutes:

hh:mm:ss:sss

Information:

A drift warning is activated if the analogue

voltage “MESSAB“ is out of tolerance.

Parameter format:

sz=0: actual no drift warning

sz=1: actual drift warning

a: Actual message from CPU 1 about rail contact

1

b: Actual message from CPU 2 about rail contact

1

c: Actual message from CPU 1 about rail contact

2

d: Actual message from CPU 2 about rail contact

2

w: number of DRW seen from CPU 1 at rail

contact 1

x: number of DRW seen from CPU 2 at rail

contact 1

y: number of DRW seen from CPU 1 at rail

contact 2

z: number of DRW seen from CPU 2 at rail

AzLM – Installation Guideline REV. C 31/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

RNr Replica Date/ Element Type Element Diagnostic Event Parameter Explanation

Time Number

contact 2

1 3 yy:mm:dd Detection Point n DP information DFW sz Defect Warning from DP n.

hh:mm:ss:sss Information:

The wheel pulse generation part of the detection

point may be defective. This message may also be

due to vehicle movements with non-standard

small wheels or due to shunting movements over

the rail contact.

sz=0: no defect warning in the last 5 minutes

sz=1: defect warning

1 3 yy:mm:dd Detection Point n DP information DFW sz (a b; y z) Summary of Defect Warnings from Dp n every 5

minutes.

hh:mm:ss:sss

Information:

The wheel pulse generation part of the detection

point may be defect. This message may also be

due to vehicle movements with non-standard

small wheels or due to shunting movements over

the rail contact.

Parameter Format:

sz=0: actual no defect warning

sz=1: actual defect warning

a: Actual message from CPU 1

b: Actual message from CPU 2

y: number of DFW from CPU 1

z: number of DFW from CPU 2

1 3 yy:mm:dd Detection Point n DP information DFM a b Defect message from DP n .

hh:mm:ss:sss Information:

The wheel pulse generation part of the detection

point may be defect.

AzLM – Installation Guideline REV. C 32/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

RNr Replica Date/ Element Type Element Diagnostic Event Parameter Explanation

Time Number

Parameter format:

a: Actual message from CPU 1

b: Actual message from CPU 2

a/b = 1 : defect found

a/b = 0 : no defect found

1 3 yy:mm:dd Detection Point n DP information AR a b Restart of the detection point n.

hh:mm:ss:sss Information:

Might be caused by a temporary power loss at the

detection point.

Parameter format:

a: Actual message from CPU 1

b: Actual message from CPU 2

a/b = 1 : restart

a/b = 0 : no restart

1 3 yy:mm:dd Detection Point n DP information AKT a b Detection point n has a communication time out.

hh:mm:ss:sss Parameter format:

a: Actual message from CPU 1

b: Actual message from CPU 2

a/b = 1 : normal operation

a/b = 0 : communication time out

1 3 yy:mm:dd Detection Point n DP information WPoZ sz Wheel pulse without counting

hh:mm:ss:sss sz=0: no WPoZ in last 5 minutes

sz=1: WPoZ

1 3 yy:mm:dd Detection Point n DP information WPoZ a b c d Summary of WPoZ from DP n in every 5 minutes

hh:mm:ss:sss a: Number of WPoZ from CPU1 at rail contact1

b: Number of WPoZ from CPU2 at rail contact1

c: Number of WPoZ from CPU1 at rail contact2

d: Number of WPoZ from CPU2 at rail contact2

AzLM – Installation Guideline REV. C 33/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

RNr Replica Date/ Element Type Element Diagnostic Event Parameter Explanation

Time Number

1 3 yy:mm:dd Detection Point n DP transmission REIH (1) NN p … r The ACE did not receive the detection point

telegram with the telegram number between p

hh:mm:ss:sss and r.

1 3 yy:mm:dd Detection Point n DP transmission TO CAN STP xy

hh:mm:ss:sss No telegram received from the detection point

within the predefined timeout;

x: CPU1 of the detection point

y: CPU2 of the detection point

x/y = 1: timeout occurred

x/y = 0: no timeout occurred

1 3 yy:mm:dd Detection Point n State OK dfw The status of DP n is “ok“, but a defect warning

was sent.

hh:mm:ss:sss

1 3 yy:mm:dd Detection Point n State OK da The status of DP n is “ok“, but one of the rail

contacts indicates a permanent wheel pulse. If no

hh:mm:ss:sss train is present, this indicates a faulty rail contact

or analogue board.

1 3 yy:mm:dd Detection Point n State OK The status of DP n is “ok“.

hh:mm:ss:sss

1 3 yy:mm:dd Detection Point n State DEF st The status of DP n is “defect“ due to an

unsuccessful self test.

hh:mm:ss:sss

1 3 yy:mm:dd Detection Point n State DEF komm The status of DP n is “defect“ due to a loss of

communication.

hh:mm:ss:sss

1 3 yy:mm:dd Detection Point n State DEF dfm The status of DP n is “defect“ due to a defect

message (dfm).

hh:mm:ss:sss

1 3 yy:mm:dd Extern_parallel_I/O n EA fault STP xx - FK_ParEA_GF_Error Output relay “track clear“ dropped due to a fault

(a) - on the parallel IO board n with the address xx.

hh:mm:ss:sss a = number of faults

1 3 yy:mm:dd Extern_parallel_I/O n EA_command_refusal STP xx,Eingabe m abgewiesen The two channels of input m have not been

- activated at the same time on the parallel IO

hh:mm:ss:sss FK_ParEA_SchalterTasteProblem board n with the address xx.

(a) - a = number of faults

1 3 yy:mm:dd Extern_parallel_I/O n EA_command_refusal STP xx,Eingabe m abgewiesen Reset command via parallel I/O card n with the

- FK_ParEA_EingabeZuLang (a) address xx is not accepted due to the input m

hh:mm:ss:sss - being activated for a too long a time.

AzLM – Installation Guideline REV. C 34/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

RNr Replica Date/ Element Type Element Diagnostic Event Parameter Explanation

Time Number

a = number of faults

1 3 yy:mm:dd Extern_parallel_I/O n EA_command_refusal STP xx,Eingabe m abgewiesen Reset command via parallel I/O card n with the

- FK_ParEA_EingabeZuKurz (a) address xx is not accepted due to the input m

hh:mm:ss:sss - being activated for too short a time.

a = number of faults

1 3 yy:mm:dd Extern_parallel_I/O n RSTWA_command_refusal Eingabe m zu lang Reset command via parallel I/O card n not

accepted due to input m being activated for a too

hh:mm:ss:sss long time.

1 3 yy:mm:dd Extern_parallel_I/O n RSTWA_command_refusal Eingabe m zu kurz Reset command via parallel I/O card n not

accepted due to input m being activated for a too

hh:mm:ss:sss short time.

1 3 yy:mm:dd Extern_parallel_I/O n State KS (a b c d) Inputs and outputs of parallel IO board n

inhibited due to a detected fault on the board.

hh:mm:ss:sss

a = KS: output at channel1 inhibited

b = KS: output at channel2 inhibited

c = ES: input at channel1 inhibited

d = ES: input at channel2 inhibited

a/b/c/d = IO: input/output not inhibited

1 3 yy:mm:dd Extern_parallel_I/O n State IO (IO IO IO IO) Parallel IO board n is ok.

hh:mm:ss:sss

1 3 yy:mm:dd Extern_parallel_I/O n State ES (IO IO c d)) Inputs of parallel IO board n inhibited due to a

detected fault on the board

hh:mm:ss:sss

c = ES : input at channel 1 inhibited

d = ES : input at channel 2 inhibited

c/d = IO: input not inhibited

1 3 yy:mm:dd 0x1090000 n State OK Selftests on CPU board are ongoing.

hh:mm:ss:sss

1 3 yy:mm:dd 0x1090000 n State DEF - Selftests on CPU board are not executed.

hh:mm:ss:sss

1 3 yy:mm:dd 0x1090000 n State DEF 0 Selftests on CPU board are not executed (there is

no error counter available).

hh:mm:ss:sss

1 3 yy:mm:dd 0x1090000 n State DEF 33 Selftests on CPU board are not executed (there

are more than 32 error counters).

AzLM – Installation Guideline REV. C 35/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

RNr Replica Date/ Element Type Element Diagnostic Event Parameter Explanation

Time Number

hh:mm:ss:sss

1 3 yy:mm:dd 0x1090000 n State DEF Tst: 5:72 One of the selftests has been executed in time.

The concerned CPU board is halted.

hh:mm:ss:sss

1 3 yy:mm:dd 0x1090000 n State DEF Anz 5 - > 6 The number of error counters has increased from

5 to 6.

hh:mm:ss:sss

1 3 yy:mm:dd Section n Command Kdo abgew AZEGR_ANFORD Reset for section n cannot be carried out due to a

Grund TECHNISCH technical defect.

hh:mm:ss:sss

1 3 yy:mm:dd Section n Command Kdo abgew AZEGR_ANFORD Conditional reset not carried out for section n

Grund Einschr = Einzaehlen bei because the last count was a count into the

hh:mm:ss:sss BELEGT section (section occupied).

1 3 yy:mm:dd Section n Command Kdo abgew AZEGR_ANFORD Reset not carried out for section n because

Grund BETRIEBLICH section n is already clear.

hh:mm:ss:sss

1 3 yy:mm:dd Section n Command Kdo empf AZGR_ANFORD id Unconditional reset commanded for section n.

Achszahl x

hh:mm:ss:sss id = 01070000 : Parallel interface

x = number of axles in the section

1 3 yy:mm:dd Section n Command Kdo empf AZEGR_ANFORD id Conditional reset commanded for section n.

Achszahl x

hh:mm:ss:sss id = 01030000 : SSI

id = 01070000 : Parallel interface

x = number of axles in the section

1 3 yy:mm:dd Section n Command Kdo empf Deactivation commanded for an inhibited

AZEGR_EINSCHRÄNK- conditional reset.

hh:mm:ss:sss UNGSAUFHEBEUNG id

Achszahl x id = 01070000 : Parallel interface

x = number of axles in the section

1 3 yy:mm:dd Section n Command Kdo empf AZVGR_ANFORD id Preparatory reset commanded for section n.

Achszahl x

hh:mm:ss:sss id = 01030000 : SSI

id = 01070000 : Parallel interface

x = number of axles in the section

1 3 yy:mm:dd Section n Command Kdo empf AZVGRQ_ANFORD Preparatory reset with acknowledgement

id Achszahl x commanded for section n.

hh:mm:ss:sss

AzLM – Installation Guideline REV. C 36/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

RNr Replica Date/ Element Type Element Diagnostic Event Parameter Explanation

Time Number

id = 01030000 : SSI

id = 01070000 : Parallel interface

x = number of axles in the section

1 3 yy:mm:dd Section n Command Kdo empf AZVGR_Quittung id Acknowledgement for preparatory reset

Achszahl x commanded for section n.

hh:mm:ss:sss

id = 01030000 : SSI

id = 01070000 : Parallel interface

x = number of axles in the section

1 3 yy:mm:dd Section n State OK fre Section n clear.

hh:mm:ss:sss

1 3 yy:mm:dd Section n State OK bel Section n occupied.

hh:mm:ss:sss

1 3 yy:mm:dd Section n State DEF ges AZ: x Section n disturbed.

A reset is possible.

hh:mm:ss:sss x = number of axles in the section

1 3 yy:mm:dd Section n State DEF def AZ: x Section n disturbed due to a defect.

A reset is not be possible.

hh:mm:ss:sss x = number of axles in the section

1 3 yy:mm:dd Section n State DEF gru WAZ Section n is waiting for a train movement after a

preparatory reset was commanded.

hh:mm:ss:sss

1 3 yy:mm:dd Section n State DEF gru WAQ Section n is waiting for acknowledgement of the

train movement after the preparatory reset.

hh:mm:ss:sss

1 3 yy:mm:dd Section n Axles X x = number of axles in the section

hh:mm:ss:sss

1 3 yy:mm:dd Serial I/O n DP fault STP xx - Lebenssignal FEHLT Serial IO board n with the subrack address xx

sends no life signal due to a defect.

hh:mm:ss:sss

1 3 yy:mm:dd Serial I/O n DP information STP xx - Lebenssignal IO Serial IO board n with the subrack address xx

sends a valid life signal again.

hh:mm:ss:sss

1 3 yy:mm:dd RSTWA n RSTWA information Veraltete SW-Version The software in the Parallel I/O board is not able

to handle non-vital outputs

hh:mm:ss:sss

AzLM – Installation Guideline REV. C 37/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

18. Connection of Reset Box

Reset Preparatory Line Section Section Reset Counter

Push Button Reset Verification Clear Occupied

Fig. 25: Front Panel of Reset Box (ERBM-02)

ERBM-02 is the reset box for Alcatel’s Multi Section Digital Axle Counters AzLM. it provides the basic

resetting pulse (24VDC) for 3 seconds (approximately) to ACE to reset a particular section.

The front panel of the terminal consists of:

1. PUSH SWITCH

2. RESET COUNTER

3. PREPARATORY RESET INDICATION – GREEN LED

4. LINE VERIFICATION INDICATION – YELLOW LED

5. SECTION CLEAR / UNOCCUPIED INDICATION - GREEN LED

6. SECTION CLOSED / OCCUPIED INDICATION - RED LED

SM’s Key

Power On

Fig. 26: SM’s Key Module

The SM‘s Key module for multisection reset panel consists of:

1. Reset Key

2. Power On LED Indication (Yellow LED)

This Reset Key acrs as the common key for all the reset boxses used in a particular installation.

Additionally a buzzer is provided to give audio indication that the 3-second reset pulse is on.

AzLM – Installation Guideline REV. C 38/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

Following steps are to be followed to initiate a reset.

1. The authorized person inserts the KEY, turns it clockwise and then pushes. (If optional Cooperative

reset key is provided this has also to be turned simultaneously by another authorized person. For this

H & R are to shorted at selection jumper J1 on PCB. If the cooperation / line verification is not

required then P & R are to be shorted).

2. While KEY is in turned position the RESET PUSH BUTTON for a specific section is pressed

momentarily.

3. BUZZER sounds for 3 seconds and then stops.

4. The KEY is then turned back anti-clockwise and taken out.

A reset operation is only possible when section is occupied or disturbed.

When reset is initiated for a straight line section, that is assigned for preparatory reset in the site specific

software, and the system accepts the reset, ERBM-02 front panel indicates that the system is under “Reset

State” by means of the PREPARATORY RESET (Green) LED. The SECTION OCCUPIED (RED) LED also glows

indicating that the system is waiting for a train movement through the section. With the passage of a train

through the section with equal count in and out of (>1) axles, the system commands the vital relay to pick

up. Contacts of this vital relay change the status of the OCCUPIED (red) LED to OFF and CLEAR (green) LED

to ON indicating that the section is now CLEAR. The RESET ON LED also goes OFF indicating reset is

successfully completed.

If the section is a point zone, that is assigned for hard reset in the site specific software, the vital relay picks

up immediately after commanding the reset provided there is no technical defect in the system.

Each reset is registered in the sealed reset COUNTER unit. The count increases by one after each reset

commanded by the operator.

Each train, now moving into the section, is indicated by the OCCUPIED (RED) LED. A complete passage of a

train out of the section is indicated by the CLEAR (GREEN) LED.

ERBM-02 is very compact yet extremely rugged. It is simple to install and operate. The unit is housed in

heavy sheet metal with scratchproof powder coated finish. Wedged mounting base gives the front panel

comfortable view and ease of operation for the operator. The detachable top cover is locked at the rear and

makes ERBM-02 tamper proof, yet accessible only to authorized service personnel if required. The field

cables have their entry from the back through cable gland and are terminated at cage clamp type Wago

terminals.

Only serviceable parts inside ERBM-02 two 500mA slow blow glass cartridge fuses.

AzLM – Installation Guideline REV. C 39/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

24V(+) 1 24VDC(+) (21.6V TO 28.8V)

24V(+) 2

24V(+) 3

24V(-) 4 24V(- ) (COMMON)

24V(-) 5

24V(-)

6

LV(-) 7

LV(+) 8 +24V FROM LINE VERIFICATION BOX

VR 9 +24V FROM VITAL RELAY PICK UP CONTACT

RV(+) 10

RV(-) 11

RST(+) 12 +24V TO RESET RELAY COIL (R1)

RST(-) 13

RA 14 +24V FROM PARALLEL CARD AS RESET ACCEPTANCE INPUT

SMK 15 +24V FROM ‘SMK’ TERMINAL OF COMMON SM‘s KEY

BZ 16 +24V TO COMMON BUZZER

Fig. 27: ERBM-02 Reset Box Terminal Connection Details

AzLM – Installation Guideline REV. C 40/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

19 Calculation of Current Consumption

This table will help to calculate the fuse rating of the 24VDC and 60VDC mains power supplies.

Item No. of item Current Total current

consumption per consumption

unit

ACE-2-10 2.30A

ACE-2-26 3.95A

ACE-2-42 5.70A

Vital relay 0.12A

Reset box (with line 0.3A

verification box)

EAK 0.17A

19.1 Indoor Equipment (Example)

In AzLM system, the indoor equipments, that is, ACE, vital relay and reset box, work on 24VDC. Based on

the above table, an AzLM system having 8 detection points, 6 sections with one ACE-2-10 central evaluator

will consume a maximum current of 4.82A. Therefore the indoor fuse for 24VDC main power supply should

be of 5A.

19.2 Outdoor Equipment (Example)

In AzLM system, the outdoor equipment, that is, EAK, work on 60VDC. Based on the above table, the

outdoor equipment, i.e. the EAKs of an AzLM system having 8 detection points will consume a maximum

current of 1.36A. Therefore the indoor fuse for 60VDC mains power supply should be of 2A.

AzLM – Installation Guideline REV. C 41/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

20. Do‘s and Dont’s

This should also be followed with Precommissioning Check list for AzLM V5.1.2

Sl. No. Item Do’s Dont’s

1 Documentation Always refer correct Never practice any self

documentation. made guideline not

recommended in manual.

2 Tools Always use recommended Tools other than those

tools. recommended in the

manual can cause damage

to the system and hence is

not recommended.

3 Installation of Rail Contact Selection of installation point Never bypass mandatory

on rail to be strictly followed recommendation as stated

as per manual. in the manual.

4 Installation of EAK EAK, whether installed inside Recommendation if not

location box or outside, followed can damage the

recommendations to be sensitive electronics.

stricktly followed as per the

manual.

5 Power supply Being most important part of Never use infirior /

the installation, all requisite unreliable power source.

recommendations should be

stricktly followed as per the

manual.

6 Earthing To be followed as per

Railway practice.

7 Termination All point to point run

through terminations to be

checked.

8 Communication Matched pairs of cables to Never use unmatched cable

be used. pair. Do not make wires

parallel for communication.

9 Adjustments & To be stricktly done with tool Never Use any other tools

measurements kit ETU001 only. for adjustments and

measurements.

10 Trolley Supression Applicable only for light Never over adjust beyond

spoked trolleys. Procedures recommendation as per

to be followed as per manual.

manual.

11 Address setting To be strickltly followed as in Never use same address for

the site specific software. different detection points.

12 Reset Box Connection To be stricktly followed as

per manual.

13 Log Sheet To be regularly updated and

kept as future reference.

AzLM – Installation Guideline REV. C 42/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

21. LOG SHEET

This should also be followed with Precommissioning Check list for AzLM V5.1.2

Station Name :

Log item AzLM Tolerance range DP: DP: DP:

Rail Profile

Switch S1 & S2 address for CPU1 Bit 16…….1

Switch s3 & S4 address for CPU2 Bit 16 ……1

Selector position Input power supply

54 V to 72 VDC

in test unit ETU001 (terminal 3 & 13 of EAK)

1 a)Power supply Channel 1 22…35 VDC

2 b)Power supply Channel 2 22…35 VDC

c) MESSAB1 ( Rx1 voltage

+80..+1000mVDC

w/o dummy wheel )

4

d) With dummy wheel set

-80….-1000mVDC

on 40 mm

e) Reference voltage

5 Adjust (per 4c)

PEGUE1

f) MESSAB2 ( Rx2 voltage

+80..+1000mVDC

w/o dummy wheel )

7

g) With dummy wheel set

-80…..-1000mVDC

on 40 mm

h) Reference voltage

8 Adjust (per 7f)

PEGUE2

Transmitter

30.0….. 31.25KHz

frequency SK1

Terminal SK1/S1 & SK1/S2

Transmitter

40……85 VAC

voltage SK1

Transmitter

27.4…..28.6KHz

frequency SK2

Terminal SK2/S1 & SK2/S2

Transmitter

40……85 VAC

voltage SK2

AzLM – Installation Guideline REV. C 43/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

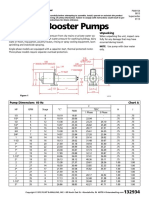

22. Test Unit (Tool Kit) ETU001

Dimensions:

c

a = 435 mm approx

b = 320 mm approx

b c = 95 mm approx

Ordering Code no: 20000201

Content of Test Equipment:

1) True RMS digital multimeter with probe set (Type Fluke-177)– 1 no.

2) Extended wired Socket to interface with diagnostic plug – 1 no.

3) Selector Switch on panel-base – 1 no.

4) Adjustable reversible torque wrench (Type Norbar –6013011)- 1 no.

5) Deep Socket inserts with (13 mm & 19 mm) – I set.

6) 19 mm combined double ended spanner – 1 no.

7) Dummy wheel – 1 no.

8) Screw driver individual (Type Wago-210119) – 1 no.

9) Screw driver set (Type Taparia 812) – 1 set.

10) Screw driver individual (Taparia-932) – 1 no.

Purpose of Test Equipment.

1) Signal voltage level and frequency measurement.

2) AC & DC Current /Voltage measurement.

During : Installation, Testing, Commissioning, Diagnosing and Calibrating the Outdoor Unit of

AzLS & AzLM, Alcatel Axle Counter.

FOR FURTHER DETAILS / ORDERING PLEASE CONTACT

Eldyne Electro Systems Pvt. Ltd.

P21 Old Ballygunge Road,

Kolkata- 700019. INDIA.

Tel: 91-33-2281 5454/5425

Fax: 91-33-2281 5757

Email: eldyne@vsnl.com

Visit us at www.eldynegroup.com

AzLM – Installation Guideline REV. C 44/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

23. Wiring Diagram of ACE Cabinet and Reset Panel

Following pages illustrate the wiring diagram of a typical Axle Counter Central Evaluator Cabinet and a

Reset Panel.

AzLM – Installation Guideline REV. C 45/54

Eldyne Electro Systems Pvt. Ltd.

Railway Signalling Automation Product & Systems

In Association with Alcatel SEL AG, Germany

You might also like

- Ufsbi SLDocument51 pagesUfsbi SLkrispr4u100% (9)

- S29-Signalling Installation & Quality Hand BookDocument284 pagesS29-Signalling Installation & Quality Hand BookArvind Kumar Singh83% (6)

- User Manual: HGM6100U Series Automatic Control ControllersDocument39 pagesUser Manual: HGM6100U Series Automatic Control ControllersMohamed R KhamissNo ratings yet

- UFSBI Manual PDFDocument81 pagesUFSBI Manual PDFawnishNo ratings yet

- S26Document139 pagesS26Pawan Shyamsundar Gadewad100% (2)

- Bpac Ufsbi User's Manual (DL)Document76 pagesBpac Ufsbi User's Manual (DL)Krishna Prasad100% (3)

- 6-SSDAC-G36 2DP1S Installation ManualDocument128 pages6-SSDAC-G36 2DP1S Installation ManualNavin Singh67% (6)

- IPS With LED Signal Load Calculation 8 Hrs BackupDocument12 pagesIPS With LED Signal Load Calculation 8 Hrs BackupVikas Srivastav100% (5)

- Eldyne Msdac PDFDocument80 pagesEldyne Msdac PDFsubhajitNo ratings yet

- RDSO Spec For Data Logger For Indian RailwaysDocument24 pagesRDSO Spec For Data Logger For Indian RailwaysVikas Srivastav100% (4)

- Frequently Asked Questions On Integrated Power Systems For Railway SignalingDocument3 pagesFrequently Asked Questions On Integrated Power Systems For Railway SignalingVikas Srivastav100% (3)

- Fuses Used For Signaling Circuits On Indian RailwaysDocument20 pagesFuses Used For Signaling Circuits On Indian RailwaysVikas Srivastav100% (4)

- Presentation On CEL SSDAC PDFDocument506 pagesPresentation On CEL SSDAC PDFPrince Shah83% (6)

- Electrical Key Transmitter (Rotary Type) : CAMTECH/S/2001/EKT (R) /1.0 1Document15 pagesElectrical Key Transmitter (Rotary Type) : CAMTECH/S/2001/EKT (R) /1.0 1Rohit Kumar100% (1)

- Electric Operated Gate For L-Xing For RailwayDocument10 pagesElectric Operated Gate For L-Xing For RailwayVikas Srivastav83% (6)

- Irs Point MachineDocument60 pagesIrs Point MachineNaga Raju100% (2)

- Installation Manual MSDAC DACF-730P V2.6Document128 pagesInstallation Manual MSDAC DACF-730P V2.6Jeet DattaNo ratings yet

- Notes On Token Instrument and Double Line Sge Block Instrument (Iriset)Document78 pagesNotes On Token Instrument and Double Line Sge Block Instrument (Iriset)Vikas Srivastav100% (4)

- Ufsbi General PresentationDocument61 pagesUfsbi General PresentationAvinash Kumar Singh100% (2)

- Notes On LED Signal Used in Indian RailwaysDocument8 pagesNotes On LED Signal Used in Indian RailwaysVikas Srivastav93% (15)

- Block Proving With Axle CounterDocument21 pagesBlock Proving With Axle CounterVikas Srivastav100% (4)

- Error Code List & Recommended Actions For Block Working With UFSBI & DAC in Case of Faults/ErrorsDocument7 pagesError Code List & Recommended Actions For Block Working With UFSBI & DAC in Case of Faults/ErrorsSHARAT SINGH0% (1)

- Notes On Solid State InterlockingDocument58 pagesNotes On Solid State InterlockingVikas Srivastav78% (9)

- Notes On SGE Block InstrumentDocument22 pagesNotes On SGE Block InstrumentVikas Srivastav92% (12)

- Signaling Data HandbookDocument118 pagesSignaling Data HandbookVikas Srivastav97% (30)

- Bpac NoteDocument17 pagesBpac NoteSampreeth Nambisan Perigini100% (1)

- Relay Interlocking Siemense Type NotesDocument79 pagesRelay Interlocking Siemense Type NotesVikas Srivastav96% (23)

- K L R (KLCR) : Key Lock Relay (KLCR) Is Used at Level Crossing Gates. in KLCRDocument1 pageK L R (KLCR) : Key Lock Relay (KLCR) Is Used at Level Crossing Gates. in KLCRVishal UpadhyayNo ratings yet

- Instalation Practice For Axle Counter On Indian RailwaysDocument36 pagesInstalation Practice For Axle Counter On Indian RailwaysVikas Srivastav100% (1)

- S&T DisconnectionDocument2 pagesS&T DisconnectionVikraman100% (3)

- Installation Manual For Single Section Digital Axle Counterdacf710p (CEL Make)Document137 pagesInstallation Manual For Single Section Digital Axle Counterdacf710p (CEL Make)Vikas Srivastav100% (7)

- IRS S 36-87 - Relay Interlocking SystemDocument34 pagesIRS S 36-87 - Relay Interlocking SystemVikas Srivastav100% (9)

- Question Bank-Signal & Telecom-01Document27 pagesQuestion Bank-Signal & Telecom-01anon-97627388% (16)

- S18Document98 pagesS18Harshit Jain0% (1)

- Safety in SignallingDocument91 pagesSafety in SignallingVikas Srivastav100% (3)

- Sge Block InstrumentDocument20 pagesSge Block InstrumentVikas Srivastav90% (10)

- Notes On Automatic SignalingDocument38 pagesNotes On Automatic SignalingVikas Srivastav100% (5)

- Neals Token InstrumentDocument39 pagesNeals Token InstrumentVikas Srivastav100% (2)

- TWS Installation DrawingDocument2 pagesTWS Installation DrawingMadhav PrasadNo ratings yet

- Question Bank For Signal EngineerDocument20 pagesQuestion Bank For Signal EngineerVikas Srivastav81% (21)

- Relays FOR RAILWAY SIGNALINGDocument26 pagesRelays FOR RAILWAY SIGNALINGVikas Srivastav98% (51)

- Earth 2Document25 pagesEarth 2Vikas Srivastav75% (4)

- Signal 1Document107 pagesSignal 1Vikas Srivastav100% (3)

- Essential of Interlocking For Signaling in RailwaysDocument73 pagesEssential of Interlocking For Signaling in RailwaysVikas Srivastav100% (11)

- Notes On Relay Interlocking (IRISET)Document64 pagesNotes On Relay Interlocking (IRISET)Vikas Srivastav100% (49)

- Signaling in RE AreaDocument30 pagesSignaling in RE AreaVikas Srivastav93% (15)

- S29 PDFDocument284 pagesS29 PDFPawan Shyamsundar GadewadNo ratings yet

- Manual - D03Document82 pagesManual - D03Ranjeet SinghNo ratings yet

- Panasonic tc-26lx60c tc-32lx60c LCD TV SMDocument53 pagesPanasonic tc-26lx60c tc-32lx60c LCD TV SMov1338946No ratings yet

- KX Tga270lxsDocument64 pagesKX Tga270lxsAnonymous Lfgk6vygNo ratings yet

- Chapter Four: Construction, Testing and ResultsDocument6 pagesChapter Four: Construction, Testing and ResultsNathaniel AdegheNo ratings yet

- S3 Radio-Remote-Control Scanreco 20120503Document14 pagesS3 Radio-Remote-Control Scanreco 20120503tsdcn100% (1)

- MSDACDocument40 pagesMSDACSonu Alam100% (1)

- DRAFT OHE Layout and Plan - 05082020 - UploadingDocument68 pagesDRAFT OHE Layout and Plan - 05082020 - UploadingAQIBNo ratings yet

- AN 1229SimpleSwitcherPCBLayoutGuidelinesDocument15 pagesAN 1229SimpleSwitcherPCBLayoutGuidelinesRodrigo Aguilar VillasecaNo ratings yet

- Kertas Penerangan 6Document10 pagesKertas Penerangan 6neddylalolaNo ratings yet

- ADE Lab EXPERIMENTS - MergedDocument73 pagesADE Lab EXPERIMENTS - Mergedjainhassan4848No ratings yet

- El 01 33 03 enDocument12 pagesEl 01 33 03 enJar Za ArNo ratings yet

- New Site Aop 2020 - CJDocument50 pagesNew Site Aop 2020 - CJHendro WibowoNo ratings yet

- PCW Series PC Wiring SystemDocument40 pagesPCW Series PC Wiring SystemsunhuynhNo ratings yet

- Uln 2803 CDocument22 pagesUln 2803 CJesin KimNo ratings yet

- Instruction Manual: Voice Alarm SystemDocument37 pagesInstruction Manual: Voice Alarm Systempancudan1966No ratings yet

- RL-Series Manual (N00-811-00)Document137 pagesRL-Series Manual (N00-811-00)Deri Vulko AnandaNo ratings yet

- AECMSGuideRevision 20091120Document104 pagesAECMSGuideRevision 20091120kmattaiNo ratings yet

- SAFTRONICSDF8PLUS AA1152 ManualDocument20 pagesSAFTRONICSDF8PLUS AA1152 ManualMarcelo CabriNo ratings yet

- Danfoss Quick Reference Guide PDFDocument2 pagesDanfoss Quick Reference Guide PDFNas Pedro De LumbanNo ratings yet

- BC8001A Manual-UL-200702Document54 pagesBC8001A Manual-UL-200702rvc004No ratings yet

- Carestream DRX 1 SystemDocument36 pagesCarestream DRX 1 SystemHexxeN1No ratings yet

- SMD-24B-2020-00 Driver: Basic Installation InstructionsDocument3 pagesSMD-24B-2020-00 Driver: Basic Installation InstructionsKien Nguyen TrungNo ratings yet

- CMK Series: Operating ManualDocument48 pagesCMK Series: Operating ManualTrien DoNo ratings yet

- SilverCrest Aspirator de Mana 279206 - RO - 21Document73 pagesSilverCrest Aspirator de Mana 279206 - RO - 21Nicoleta PopescuNo ratings yet

- DVD Philips-550Document52 pagesDVD Philips-550Valeriu DuraNo ratings yet

- FWPB Booster Pumps InstructionsDocument15 pagesFWPB Booster Pumps InstructionsRamadanNo ratings yet

- QUICK-APLUS - enDocument3 pagesQUICK-APLUS - enmanual imbNo ratings yet

- AKUS Panel & Control Panel Cabling Diagram (Three-Phase Automatic Door)Document1 pageAKUS Panel & Control Panel Cabling Diagram (Three-Phase Automatic Door)sulthan1975No ratings yet

- CX4-120 Site PreparationDocument3 pagesCX4-120 Site PreparationrajenderdhingraNo ratings yet

- UIT EMC StandardsDocument139 pagesUIT EMC StandardsAmity2009No ratings yet

- Distributor: & EngineeringDocument18 pagesDistributor: & EngineeringLUATNo ratings yet

- Catalogue Khởi Động Mềm LSDocument32 pagesCatalogue Khởi Động Mềm LShuy taNo ratings yet

- Eaton 048893 Dilet70 A en GBDocument9 pagesEaton 048893 Dilet70 A en GBEdgar Poma MedinaNo ratings yet

- 220V AC Powered White Led LampDocument16 pages220V AC Powered White Led LampOpalis BkdNo ratings yet

- Vacon 20 PFC User Manual DPD01436B UK PDFDocument124 pagesVacon 20 PFC User Manual DPD01436B UK PDFMohamed AdelNo ratings yet

- Ultravac 250: Vacuum Chamber Packaging MachineDocument68 pagesUltravac 250: Vacuum Chamber Packaging Machinejose luisNo ratings yet

- Ps 202Document4 pagesPs 202AgnewNo ratings yet

- STD.22 Parameters DetailsDocument1 pageSTD.22 Parameters DetailsJay SanchaniyaNo ratings yet

- Guide To Iec 62353 UsDocument48 pagesGuide To Iec 62353 UsJoão Francisco MontanhaniNo ratings yet

- Prose Data Center Infrastructure Solution-20230102Document41 pagesProse Data Center Infrastructure Solution-20230102Syed ArsalanNo ratings yet

- Installaton Manual For FPRADocument157 pagesInstallaton Manual For FPRAShahin Matraku67% (3)

- 10508Document44 pages10508Swaroop Kumar0% (1)

- Generator Set Data Sheet HFW 75 t5 Soundproof EnglishDocument7 pagesGenerator Set Data Sheet HFW 75 t5 Soundproof EnglishMyatmin htetwaiNo ratings yet