Professional Documents

Culture Documents

Design Guide & Part Selection: Sparging/Gas-Liquid Contacting

Design Guide & Part Selection: Sparging/Gas-Liquid Contacting

Uploaded by

chetanudctOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Guide & Part Selection: Sparging/Gas-Liquid Contacting

Design Guide & Part Selection: Sparging/Gas-Liquid Contacting

Uploaded by

chetanudctCopyright:

Available Formats

Sparging/Gas-Liquid Contacting

Design Guide & Part Selection

mott corporation

84 Spring Lane, Farmington, CT 06032-3159 860-747-6333, Fax 860-747-6739 www.mottcorp.com

SURFACE AREA The Critical Variable Sparging The Process

High surface area means fast, efficient mass transfer. The key to high-efficiency sparging is fine bubble propagation which provides maximum surface area for effective "mass transfer." Mott precision porous metal creates fine bubbles* over a broad range of application requirements. Mott spargers, both static and dynamic, far exceed the performance of drilled pipe and other conventional spargers. With thousands of pores over the surface, large volumes of gas can be passed with very high specific area. For example, with equal volumes of gas, 1mm bubbles would have 6.35 times more gas-liquid contact surface area than 6.35mm (1/4) bubbles. Sparging, the introduction of gas into a liquid is accomplished in many different process variations. In-tank applications, with the sparging elements located in the tank, can be batch or continuous flow, with or without agitation. Continuous pipe line sparging can be inline with a non-intrusive Mott GasSaver, or using intrusive pipe line mounted sparger elements. This guide will show you how to size and design cost-effective sparger systems for each of the process variations.

Industries Served

Beverage Chemical Fish Farming Food Industrial Minerals Mining Paper Petrochemical Pharmaceutical Power Waste Treatment And Many Others

Precision Porous Metal Media

The high performance of Mott spargers comes from the superior characteristics of Mott precision porous media. Its controlled porosity is a result of Mott proprietary manufacturing methods and dedication to quality.

Materials of Construction

Standard porous media for spargers is 316L stainless steel, which provides good corrosion resistance and high temperature capability, up to 750F. Standard sparger hardware is 316 stainless steel. Other materials are available on special order, including 304L SS, 347 SS, 430 SS, Inconel 600, Monel 400, Nickel 200; Hastelloy C276, C22 and X; and Alloy 20.

Common Gases

Gas Air Ammonia Argon Carbon Dioxide Chlorine Hydrogen Nitrogen Oxygen Ozone Symbol Air NH3 Ar CO2 Cl2 H2 N2 O2 O3 Density #/Ft3 @ STP 0.076 0.045 0.105 0.116 0.189 0.005 0.073 0.084 0.126

Sparging Media Grades

For most gas sparging applications, Mott Media Grade 2* is recommended. For steam sparging, Media Grade 10 is recommended. Media grade 40 is used for agitation. Other grades are available consult factory.

* - Actual diameter of bubbles will vary depending on liquid media and application conditions. Mott makes no claim as to actual size of bubbles. Tests conducted at Mott indicate that our Media Grade 2 provides fine bubbles over a broad range of application requirements.

Sparger Sizing DESIGN GUIDE

IN-TANK / STATIC SPARGER

Gas Exit Velocity Chart

In-Tank, Not Agitated: 5 10 FPM Design 25 FPM Maximum In-Tank, Agitated:

Sparger sizing is based on the superficial gas exit velocity from the porous sparger surface, expressed in feet per minute (FPM), calculated from actual cubic feet per minute per square foot of sparger surface area (ACFM/Ft.2). ACFM is calculated at the liquid pressure and temperature at the sparger,it is not based on gas pressure. Sizing Procedure for In-Tank Spargers 1. 2. 2.1 Determine gas flow required in standard cubic feet per minute (SCFM). Determine liquid pressure at the sparger, in PSIG (P). For open or vented tanks, liquid head in feet x 0.433 x specific gravity = PSIG. (Specific Gravity of water = 1.0) For closed tanks or vessels with a pressurized head space, add head space pressure to the liquid head pressure to obtain (P) Determine liquid temperature F, (T). Determine ACFM, from SCFM using standard gas formula. ACFM = SCFM x 14.7 x (460 + T) (14.7 + P) 520 5. 6. Select Gas Exit Velocity, FPM. See Gas Exit Velocity Chart. Calculate sparger area required Ft (A). A = ACFM FPM 7. Select appropriate Mott sparger element or elements, and determine best in-tank arrangement based on process requirements. Refer to Mott Sparging Literature (Ref: PMSPARG) or Mott Sparger Selection Key. In agitated tanks, use reinforced elements or provide support as required.

2

If

1 5 FPS*

Then

25 FPM Design 50 FPM Maximum 25 FPM Design 100 FPM Maximum 50 FPM Design 150 FPM Maximum

5 10 FPS*

>10 FPS*

2.2

*Calculate agitator tip speed: Agitator Diameter (in) x RPM = FPS 229

3. 4.

Lower exit velocities will produce smaller bubbles. Exit velocities may be less than the design values given. In some instances, actual application must be tested/proven. Reinforced or supported elements should be used in agitated vessels.

INTRUSIVE PIPELINE SPARGER DESIGN GUIDE

Intrusive Pipe Line Sparger Sizing

Intrusive pipe line sparger sizing, where the sparger element is located inside of the pipe line, is based on the superficial Gas Exit Velocity from the sparger element in relation to the liquid velocity in the annulus between the inside of the pipe line and the sparger element. Exit velocity is expressed in feet per minute (FPM), calculated from actual cubic feet per minute per square foot of sparger surface area (ACFM/Ft2). ACFM is calculated at the liquid pressure and temperature in the pipe line, (not gas pressure).

Gas Exit Velocity Chart

If 1 - 5 FPS** 5 - 10 FPS** > 10 FPS** Then 25 FPM design 50 FPM maximum 25 FPM design 100 FPM maximum 50 FPM design 150 FPM maximum

Element Diameter Guide

Pipe Size 1/2 3/4 1 1-1/2 2 3 4 Sparger 3/8 1/2 3/4 1 1 1-1/2 2 2-1/2 2-1/2 Flow @ 10 FPS* 6 GPM 10.5 GPM 13.1 GPM 39 GPM 80 GPM 175 GPM 299 GPM 747 GPM Calculate**

Intrusive Pipe Line Sparger Sizing Procedure

1. 2. 3. 4. Determine gas flow required in standard cubic feet per minute (SCFM). Determine liquid pressure in the pipe line in PSIG (P). Determine liquid temperature F, (T). Determine ACFM using standard gas formula ACFM = SCFM x 14.7 x (460 + T) (14.7 + P) 520 5. 6. 7. 8. Determine liquid flow in gallons per minute (GPM). Determine pipe line size. Assume a sparger diameter. Calculate liquid linear velocity in the annulus between the pipe line ID and the sparger element ID.** Select Gas Exit Velocity FPM. Calculate sparger area required Ft2 (A). A = ACFM FPM 11. Select the appropriate Mott sparger element. A reinforced element, or an element with a centering spider for support within the pipe line, is recommended for pipe line spargers.

6 >6

*Based on schedule 40 pipe. **Liquid linear velocity in annulus between the pipe and sparger element FPS. FPS = GPM [(pipe ID)2 - (sparger OD)2] x 2.448

9. 10.

Lower gas exit velocities produce finer bubbles. Exit velocities can be <5 FPM with good performance. In some instances, actual application must be tested/proven. Reinforced elements are recommended, or elements with a centering spider for support within the pipe line. See Mott Sparging Literature (Ref: PMSPARG) or Mott Sparger Selector Key.

INLINE DYNAMIC SPARGER DESIGN GUIDE

Non-Intrusive Inline Dynamic Sparger Sizing

Sizing is based on liquid flow. Nominal flow rate is based on 10 FPS linear velocity through the ID of the Dynamic Sparger. These spargers can operate effectively from less than 5 FPS up to 20 FPS. Select the Dynamic Sparger Model 8501 or GasSaver for a given application, then determine the gas flow in ACFM and check gas exit velocity through the porous media to be sure it is within maximum design limits. Should the exit velocity be too high, go to the next size larger model or order a special GasSaver with a 12" long porous section for double the area.

Gas Exit Velocity Chart

Liquid Linear Velocity* 1 - 5 FPS 5 - 10 FPS >10 FPS Gas Exit Velocity 25 FPM design 50 FPM maximum 25 FPM design 100 FPM maximum 50 FPM design 200 FPM maximum

*Liquid linear velocity FPS. FPS = GPM (Porous ID2 x 2.448)

Sizing Method

1. Determine liquid flow rate in gallons per minute (GPM). Select Inline Dynamic Sparger model. Determine liquid line pressure, PSIG (P). Determine gas flow in standard cubic feet per minute (SCFM). Determine liquid temperature F (T). Calculate actual cubic feet per minute (ACFM) using standard gas formula: ACFM = SCFM x 14.7 x (460+T) (14.7+P) 520 7. 8. Record GasSaver area, Ft2 (A). Calculate gas exit velocity, FPM FPM=ACFM A 9. Check to be sure that the exit velocity is within the maximum range, based on the operating conditions.

Lower gas exit velocities produce finer bubbles. In some instances, actual application must be tested/proven. GasSavers provide a very broad range of effective operation, with both liquid and gas flows. See Dynamic Sparger Selection in Mott Literature (Ref: PMSPARG) or Mott Sparger Selector Key.

2. 3. 4.

5. 6.

MOTT SPARGER SELECTOR KEY

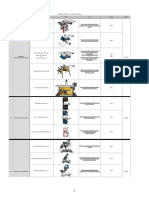

In-tank and/or Intrusive Precision Sparger Elements

Mott porous metal sparger elements are available in many configurations to suite specific process requirements. Standard materials are 316L stainless steel porous media, and 316 stainless steel hardware. Other materials and sizes available on special order.

NOTES: XX Specify Media Grade in the Product Description. Media Grade 2 recommended for gas sparging / Media Grade 10 recommended for steam sparging / Media Grade 40 recommended for tank agitation.

(* G can be any length specify)

Seamless Sparger Elements

Description

2306-A04-06-A00-XX-AB -12-18-24-362308-A04-06-A00-XX-AB -12-18-24-362312-A04-06-A00-XX-AB -12-18-24-362316-A08-06-A00-XX-AB -12-18-24-36-

Seamless Sparger Elements

A NPT Area Ft2

1/4 0.05 0.10 0.15 0.20 0.29 0.06 0.13 0.20 0.26 0.39 0.10 0.20 0.29 0.39 0.59 0.13 0.26 0.39 0.52 0.78

D Dia L

0.375 6 12 18 24 36 0.5 6 12 18 24 36 0.75 6 12 18 24 36 1.0 6 12 18 24 36

Description

2306-G06-06-A00-XX-AB -12-18-24-362308-G08-06-A00-XX-AB -12-18-24-362312-G12-06-A00-XX-AB -12-18-24-362316-G16-06-A00-XX-AB -12-18-24-36-

D Dia L

0.375 6 12 18 24 36 0.5 6 12 18 24 36 0.75 6 12 18 24 36 1.0 6 12 18 24 36

G*

1

Area Ft2

0.05 0.10 0.15 0.20 0.29 0.06 0.13 0.20 0.26 0.39 0.10 0.20 0.29 0.39 0.59 0.13 0.26 0.39 0.52 0.78

1/4

1/4

1/2

Rolled and Welded Elements

Description

2224-A04-10-A00-XX-AB -20-30-402232-A08-10-A00-XX-AB -20-30-402240-A16-10-A00-XX-AB -20-30-40-

Rolled and Welded Elements

A NPT Area Ft2

1/4 0.33 0.65 0.98 1.31 0.44 0.87 1.31 1.75 0.54 1.09 1.64 2.18

D Dia L

1.5 10 20 30 40 10 20 30 40 10 20 30 40

Description

2224-G24-10-A00-XX-AB -20-30-402232-G32-10-A00-XX-AB -20-30-402240-G40-10-A00-XX-AB -20-30-40-

D Dia L

1.5 10 20 30 40 10 20 30 40 10 20 30 40

G*

1

Area Ft2

0.33 0.65 0.98 1.31 0.44 0.87 1.31 1.75 0.54 1.09 1.64 2.18

2.0

1/2

2.0

2.5

2.5

MOTT SPARGER SELECTOR KEY

Inline Dynamic Sparger 8501 Series

Mott 8501 Series Tee-Mounted Sparger Assemblies offer simple mounting in process piping systems. Gas is introduced into the element which mounts within the pipe housing. Gas passes from inside to the outside of the element. Liquid enters the side inlet to the tee and passes through the annulus between the pipe and the element and shears the bubbles from the element for fine-bubble performance. Upon reaching the end of the element, there is a sudden expansion in area that creates turbulence and good mixing of the gas and liquid. Standard materials are 316L stainless steel hardware. Other materials are available on special order.

Sparger 850 Series

Product Description

850-1/2-06-XX -12-18-24-36850-3/4-06-XX -12-18-24-36850-1-06-XX -12-18-24-36850-1 1/2-06-XX -12-18-24-36-

D

0.375

A NPT B NPT L

1/2 1/8 6 12 18 24 36 6 12 18 24 36 6 12 18 24 36 6 12 18 24 36

PL

4 10 16 22 34 3.75 9.75 15.75 21.75 33.75 3.5 9.5 15.5 21.5 33.5 2.5 8.5 14.5 20.5 32.5

Porous AreaFt2

0.03 0.08 0.13 0.18 0.28 0.04 0.10 0.17 0.24 0.37 0.06 0.15 0.25 0.35 0.55 0.05 0.18 0.32 0.45 0.71

0.5

3/4

1/4

Sparger Element 8501 Series

0.75

1/2

1.0

1 1/2

3/4

Nominal Product Liquid Description Flow

6 gpm 8501-1/2-06-XX -12-18-24-368501-3/4-06-XX -12-18-24-368501-1-06-XX -12-18-24-36-

A NPT B NPT L

1/2 1/8

PL

Porous AreaFt2

0.03 0.08 0.13 0.18 0.28 0.04 0.10 0.17 0.24 0.37 0.06 0.15 0.25 0.35 0.55 0.05 0.18 0.32 0.45 0.71

Sparger Element 850 Series

6 0.375 4 12 10 18 16 24 22 36 34 6 0.5 12 18 24 36 3.75 9.75 15.75 21.75 33.75

10 gpm

3/4

1/4

13 gpm

1/2

6 0.75 3.5 12 9.5 18 15.5 24 21.5 36 33.5 6 1.0 12 18 24 36 2.5 8.5 14.5 20.5 32.5

NOTES: XX Specify Media Grade in the Product Description. Media Grade 2 is recommended for gas sparging / Media Grade 10 is recommended for steam sparging. Nominal flow rates are given based on 10 FPS liquid velocity through the annulus. The 8501 will operate effectively over a wide range, from less than 5 FPS up to 20 FPS. 10 FPS is a good design basis.

39 gpm

8501-1 1/2-06-XX 1 1/2 -12-18-24-36-

3/4

MOTT SPARGER ELEMENT SELECTOR KEY

Reinforced Sparger Elements

NOTES: XX Specify Media Grade in the Product Description. Media Grade 2 recommended for gas sparging / Media Grade 10 recommended for steam sparging / Media Grade 40 recommended for tank agitation.

Type 6400 Sparger Elements

Product Description

D Dia L

T A NPT C Dia Area Ft2 0 1/2 0.840 0.32 6 0.32 12 0.32 0 6 12 0 6 12 0.65 0.65 0.65 0.98 0.98 0.98

Product Description

D Dia

A NPT 1/4

B NPT 1/8

L 6 12 18 24 36 6 12 18 24 36 6 12 18 24 36 6 12 18 24 36 6 12 18 24 36 6 12 18 24 36

Area Ft2 0.05 0.10 0.15 0.20 0.29 0.05 0.10 0.15 0.20 0.29 0.06 0.13 0.20 0.26 0.39 0.06 0.13 0.20 0.26 0.39 0.10 0.20 0.29 0.39 0.59 0.10 0.20 0.29 0.39 0.59

2224-CD08-10-AD00-XX-AB 1.5 10 -10/6-AD00-XX-AB 10 -10/12-AD00-XX-AB 10 2224-CD08-20-AD00-XX-AB -20/6-AD00-XX-AB -20/12-AD00-XX-AB 2224-CD08-30-AD00-XX-AB -30/6-AD00-XX-AB -30/12-AD00-XX-AB 2232-CD12-10-AD00-XX-AB 2 -10/6-AD00-XX-AB -10/12-AD00-XX-AB 2232-CD12-20-AD00-XX-AB -20/6-AD00-XX-AB -20/12-AD00-XX-AB 2232-CD12-30-AD00-XX-AB -30/6-AD00-XX-AB -30/12-AD00-XX-AB 20 20 20 30 30 30 10 10 10 20 20 20 30 30 30

6400-3/8-1/4-1/8-06-XX 0.375 -12-18-24-366400-3/8-1/2-1/8-06-XX 0.375 -12-18-24-366400-1/2-1/2-1/4-06-XX 0.500 -12-18-24-366400-1/2-3/4-1/4-06-XX 0.500 -12-18-24-366400-3/4-3/4-1/2-06-XX 0.075 -12-18-24-366400-3/4-1-1/2-06-XX -12-18-24-360.750

1/2

1/8

0 3/4 1.050 0.43 6 0.43 12 0.43 0 6 12 0 6 12 0 1 6 12 0 6 12 0 6 12 0.87 0.87 0.87 1.30 1.30 1.30 1.315 0.54 0.54 0.54 1.09 1.09 1.09 1.63 1.63 1.63

1/2

1/4

3/4

1/4

2240-CD16-10-AD00-XX-AB 2.5 10 -10/6-AD00-XX-AB 10 -10/12-AD00-XX-AB 10 2240-CD16-20-AD00-XX-AB -20/6-AD00-XX-AB -20/12-AD00-XX-AB 2240-CD16-30-AD00-XX-AB -30/6-AD00-XX-AB -30/12-AD00-XX-AB 20 20 20 30 30 30

3/4

1/2

1/2

MOTT SPARGER SELECTOR KEY

Inline Non-Intrusive Dynamic Spargers

Mott GasSaver Series provides a new dimension in sparger and gas/liquid contacting performance. Gas is introduced into the annulus around the porous metal from outside to inside. The liquid passing through the inside of the porous element shears the bubbles from the media before they can fully propagate, resulting in very fine bubbles and the ultimate in performance. Standard materials are 316L stainless steel porous media, 316 stainless steel hardware and housings, and non-asbestos gasket. Other materials are available on special order. NOTES: XX Specify Media Grade in the Product Description. Media Grade 2 is recommended for gas sparging / Media Grade 10 is recommended for steam sparging. Nominal flow rates are given based on 10 FPS liquid velocity through GasSavers. GasSavers will operate effectively over a wide range, from 5 FPS up to 20 FPS. 10 FPS is a good design point. Exit velocities can be <5 FPS with good performance in some applications actual application must be tested.

Mott Sanitary GasSavers

Nominal Product Liquid Description Flow

3.5 gpm 6 gpm 6 gpm 10 gpm 15 gpm 30 gpm 50 gpm 50 gpm 75 gpm 75 gpm 100 gpm 140 gpm 100 gpm 150 gpm 200 gpm

A Dia

ID

Porous AreaFt2

24 24 0.05 0.06 0.06 0.08 0.10 0.15 0.18 0.18 0.23 0.23 0.28 0.31 0.28 0.33 0.38

S71B24B65-B06FXXAB-65 1 S71B24B65-B08FXXAB-65 1

0.375 1 0.5 1

S71C24B65-C08FXXAB-65 1 1/2 0.5

1 1/2 24

S71C24B65-C10FXXAB-65 1 1/2 0.625 1 1/2 24 S71C24B65-C12FXXAB-65 1 1/2 0.75 1 1/2 24 S71D24B65-D18FXXAB-65 2 S71D24B65-D22FXXAB-65 2 1.125 1 1/2 24 1.375 1 1/2 24 24 24 24 24 24 24 24 24

S71V24B65-V22FXXAB-65 2 1/2 1.375 2 S71V24B65-V28FXXAB-65 2 1/2 1.75 2 S71E24B65-E28FXXAB-65 3 S71E24B65-E34FXXAB-65 3 S71E24B65-E38FXXAB-65 3 S71F24B65-F34FXXAB-65 S71F24B65-F40FXXAB-65 S71F24B65-F46FXXAB-65 4 4 4 1.75 2 2.125 2 2.375 4 2.125 4 2.5 4 2.875 4

Mott Industrial GasSavers

Nominal Product Liquid Description Flow

10 gpm 15 gpm 40 gpm 50 gpm 100 gpm 150 gpm 200 gpm 300 gpm 400 gpm 600 gpm 800 gpm 71B24B78-B10FXXAB-65 71C24B78-C12FXXAB-65 71D24B78-D20FXXAB-65 71D24B78-D22FXXAB-65 71E24B78-E34FXXAB-65 71E24B78-E40FXXAB-65 71F24B78-F46FXXAB-65 71G24B78-G56FXXAB-65 71G24B78-G66FXXAB-65 71G24B78-G80FXXAB-65 71H24B78-H92FXXAB-65

A Dia

1 2 2 3 3 4 6 6 6 8

ID

Porous AreaFt2

0.08 0.10 0.16 0.18 0.28 0.33 0.38 0.46 0.54 0.65 0.75

0.625 3/4 24 24 24 24 24 24 24 24 24 24 24 1.25 1 1.375 1 2.125 1 2.5 3.5 5.0 1 2 2 2.875 1 4.125 2 5.75 2

1 1/2 0.75 1

Sanitary GasSaver Shown Above

Mott Laboratory GasSavers All-Welded Construction

Nominal Liquid Flow Product Description Tubing Conn Porous Overall Dia ID Lg Porous AreaFt2

1.5 gpm 6.0 gpm

7610-1/4-6-XX-AB 7610-1/2-6-XX-AB

0.50 0.75

0.25 10 0.50 10

0.03 0.06

Industrial GasSaver Shown Below

MOTT SPARGER SELECTOR KEY

Inline Non-Intrusive Sanitary S71 Series

Motts sanitary tee-mounted sparger offers state-ofthe-art sparging performance. Mott porous metal media provides fine bubble propagation for an optimal gas/liquid interface and effective mass transfer. Gas/liquid mixing occurs when the gasladened liquid reaches the end of the sparger element. A sudden increase in cross-sectional area results in a zone of turbulence.

Mott gas spargers mean lowers gas consumption with high performance. Mott spargers eliminate steam hammer and reduce steam consumption in direct steam injection applications. Standard construction: Mott precision 316L stainless steel porous media, 316 stainless steel hardware, 3A finish, and polished wells. Simple sanitary flange/clamp assembly allows for ease of installation and removal for cleaning. Permanent porous 316L stainless steel media can easily be cleaned for long service life.

Nominal* Liquid Flow ----------------12 gpm 30 gpm 60 gpm 110 gpm 150 gpm 260 gpm

Sparger Element A Part Desc. Tube Dia ----------------------- ------------S7116-L-XX-AB 1.0 S7124-L-XX-AB S7132-L-XX-AB S7140-L-XX-AB S7148-L-XX-AB S7164-L-XX-AB 1.5 2.0 2.5 3.0 4.0

B Sparger Dia C ----------------- -------0.5 4.0 0.75 1.0 1.0 1.5 2.0 4.5 6.0 6.0 6.5 8.0

6 Area 12Area D Ft2 Tri-Clamp** Ft2 ---------- ------------ -----------------.06 .13 1.5 .10 .13 .13 .19 .26 .20 .26 .26 .39 .52 1.5 2.0 2.5 3.0 4.0

E Tri-Clamp** ------------------1.5 1.5 1.5 1.5 1.5 2.0

L = Length: 6 (6) or 12 (12). Other Lengths Available Consult Factory. XX = Media Grade: Media Grade 2 (2) for most gas applications; Media Grade 10 (10) for steam. Example Product Description: S7132-12-2-AB (2 Tee Mount 1 Diameter Element x 12 Porous Length, Media Grade 2, 316L/316).

*Nominal flow specified at 10 FPS annular liquid velocity. Can operate from 1-20 FPS. **Tri-Clamp sanitary flanges or equivalent.

ISO 9001:2000 CERTIFIED

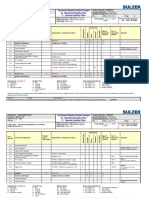

SPARGING APPLICATION DATA SHEET

CUSTOMER ADDRESS CONTACT PHONE E-MAIL FAX DATE

APPLICATION: Please check appropriate box for your application. AERATION AGITATION BULKING CARBONATION CHLORINE BLEACHING COLUMN FLOTATION DEWATERING OIL GAS/LIQUID REACTIONS HYDROGENATION OIL FLOTATION OXYGEN BLEACHING OXYGEN STRIPPING OXYGENATION OZONATION pH CONTROL STEAM INJECTION VOLATILES STRIPPING OTHER

PROCESS DESCRIPTION AND OBJECTIVES: Please complete the following (with details).

LIQUID TYPE SPECIFIC GRAVITY

DENSITY

LB/IN3

TEMPERATURE

DEG F

GAS TYPE PRESSURE

PSIG

SPECIFIC GRAVITY

DENSITY

LB/IN3

IN-TANK: BATCH CONTINUOUS GAS VOLUME SCFM TANK DIMENSIONS FT HEAD SPACE FT VENTED PRESSURIZED PSIG LIQUID VOLUME GAL LIQUID HEAD FT AGITATED NOT AGITATED AGITATOR DIA. FT AGITATOR SPEED RPM MOUNTING REQUIREMENTS: SPECIFY ANSI FLANGE SIZE SANITARY SIZE NPT SIZE

PIPE LINE: LIQUID FLOW RATE LIQUID PRESSURE PIPE SIZE (IPS) GAS FLOW RATE MOUNTING REQUIREMENTS: SPECIFY INLINE ANSI FLANGE SANITARY NPT ELBOW TEE SIZE SIZE SIZE

GPM PSIG IN SCFM

You might also like

- Tank Baffles Design CalcDocument8 pagesTank Baffles Design CalcJorge Alberto Martinez Ortiz100% (1)

- BookofRaziel PDFDocument74 pagesBookofRaziel PDFLoli Darriba Perez100% (1)

- Chlorine SpargerDocument18 pagesChlorine SpargersrshahNo ratings yet

- 325 - Sparger DesignDocument3 pages325 - Sparger DesignInggit Prillasari100% (1)

- Heat Exchanger Design Calculation EOR Condition Design InputsDocument4 pagesHeat Exchanger Design Calculation EOR Condition Design InputsSiva baalanNo ratings yet

- Jet Mixing CalculationDocument3 pagesJet Mixing CalculationRachel FloresNo ratings yet

- WS-CA-PR-024 - Atmospheric & Low Preesure Tank VentingDocument4 pagesWS-CA-PR-024 - Atmospheric & Low Preesure Tank Ventinghhvg100% (1)

- Power Requirement (Agitator and High-Torque Stirrer)Document8 pagesPower Requirement (Agitator and High-Torque Stirrer)DozdiNo ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- Agitator - Xls 0Document2 pagesAgitator - Xls 0Prathmesh Gujarati100% (4)

- Blending and AgitationDocument18 pagesBlending and AgitationSivanand SNo ratings yet

- Calculation AgitatorDocument3 pagesCalculation AgitatorKrishnaAgarwalNo ratings yet

- Storage Tank Heat Loss Calcs - 28.09.2009Document10 pagesStorage Tank Heat Loss Calcs - 28.09.2009Ali MoazamiNo ratings yet

- Limpet Coil On Dish Design As Per PD5500Document1 pageLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNENo ratings yet

- Agitator Power Calculation FormatDocument2 pagesAgitator Power Calculation FormatSandeep GosaviNo ratings yet

- Mixer (So3 Jadi H2so4)Document6 pagesMixer (So3 Jadi H2so4)Evi SiswantoNo ratings yet

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocument2 pagesDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658No ratings yet

- Agitator DesignDocument3 pagesAgitator DesignSmrutiNo ratings yet

- Conventional JacketsDocument4 pagesConventional JacketskayeNo ratings yet

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocument2 pagesE-03.0) General Static-Mixing Customer Specification QuestionnaireimyourscinNo ratings yet

- Stacks: Ammonia Injection: A Route To CleanDocument8 pagesStacks: Ammonia Injection: A Route To CleanZEN MA100% (1)

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BDocument8 pagesSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BAgus MarpaungNo ratings yet

- Agitator Vessel Design CostingDocument20 pagesAgitator Vessel Design CostingneelNo ratings yet

- CN - Heat Tracing Calcualtion: Calculation Note D3-NGD PRO 024 NG-018Document1 pageCN - Heat Tracing Calcualtion: Calculation Note D3-NGD PRO 024 NG-018EmamokeNo ratings yet

- Air N2 Receiver Size EstimationDocument4 pagesAir N2 Receiver Size EstimationParthi DatchinamoorthyNo ratings yet

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetandrew rachmanNo ratings yet

- HP Calculation For 1000kg Cap Screw-R2Document3 pagesHP Calculation For 1000kg Cap Screw-R2Yogin Alavani0% (1)

- Hydrofoil Agitator 1Document8 pagesHydrofoil Agitator 1Production AdvisorNo ratings yet

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationGLENDA CASINONo ratings yet

- Control Valve Sizing - EnggcyclopediaDocument4 pagesControl Valve Sizing - EnggcyclopediaazitaggNo ratings yet

- AgitatorDocument2 pagesAgitatorThiruvilan Arakkonam Mohan100% (1)

- Power CalculationDocument4 pagesPower CalculationGunasekaran100% (1)

- Agitator DesignDocument5 pagesAgitator DesignSaepul RochmanNo ratings yet

- R V C V: API STD 2000-2014, Calculation For Max. Flow Rates For Normal InbreathingDocument10 pagesR V C V: API STD 2000-2014, Calculation For Max. Flow Rates For Normal InbreathingAnonymous a4Jwz14W0% (1)

- Agitator Power Requirement and Mixing Intensity CalculationDocument28 pagesAgitator Power Requirement and Mixing Intensity Calculationcandra100% (3)

- Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Document15 pagesAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)HyungTae JangNo ratings yet

- Mesh & Vane Mist EliminatorsDocument16 pagesMesh & Vane Mist EliminatorsstressesNo ratings yet

- A Guideline For Design Pressure - Part 1Document4 pagesA Guideline For Design Pressure - Part 1Said Ahmed SalemNo ratings yet

- Calculation Vapour Line DiameterDocument2 pagesCalculation Vapour Line DiameterAbdul BasitNo ratings yet

- Plate and Frame Heat ExchangersDocument6 pagesPlate and Frame Heat ExchangersAndrés Ramón Linares100% (1)

- Tank EductorDocument3 pagesTank Eductorkonainglincho001No ratings yet

- Mixing CalculationDocument31 pagesMixing CalculationTubagus100% (2)

- Existing:-Pitch Blade Turbine AgitatorDocument5 pagesExisting:-Pitch Blade Turbine AgitatorPrathmesh Gujarati100% (1)

- "Design and Fabrication of Agitated Thin Film Dryer": Bhushan M. Thengre, Sulas G. BorkarDocument11 pages"Design and Fabrication of Agitated Thin Film Dryer": Bhushan M. Thengre, Sulas G. BorkarshirinNo ratings yet

- Total Length Calcs For Pipes Valves and FittingsDocument6 pagesTotal Length Calcs For Pipes Valves and FittingsImtinan MohsinNo ratings yet

- We Need A Mist Eliminator in That Knockout Drum!: AmacsDocument5 pagesWe Need A Mist Eliminator in That Knockout Drum!: AmacsmanuNo ratings yet

- Agitator Calculation. - SPLDocument2 pagesAgitator Calculation. - SPLAbarajithan RajendranNo ratings yet

- Presure Regulator Calculate PDFDocument5 pagesPresure Regulator Calculate PDFGorast KolevNo ratings yet

- Master Calculation ScrubberDocument14 pagesMaster Calculation ScrubberViqiNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Sparger Design Guide PDFDocument11 pagesSparger Design Guide PDFRyan SyahMemethNo ratings yet

- Detail Engineering Services For Engen Tank X368 RebuildDocument9 pagesDetail Engineering Services For Engen Tank X368 RebuildpavanNo ratings yet

- Standards: (Comment Based On Propane)Document3 pagesStandards: (Comment Based On Propane)zorro21072107No ratings yet

- 15 Foam MakerDocument8 pages15 Foam MakerMatthew BennettNo ratings yet

- Series LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Document8 pagesSeries LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Achraf BoudayaNo ratings yet

- Juntas Flanchadas, Empaques y PernosDocument8 pagesJuntas Flanchadas, Empaques y Pernosjuancparra20No ratings yet

- Coalescers ZM E25Document2 pagesCoalescers ZM E25abaskmNo ratings yet

- Standards Brazed Plate HEDocument5 pagesStandards Brazed Plate HEprad_21adNo ratings yet

- PAC98F4Document2 pagesPAC98F4behtam2407No ratings yet

- FMGCEM40xx Series: Flue Gas AnalyserDocument6 pagesFMGCEM40xx Series: Flue Gas AnalyserMeindert gerssenNo ratings yet

- Biku Module: Front Power Range: 350W 365WDocument2 pagesBiku Module: Front Power Range: 350W 365Wblackslash82No ratings yet

- Data Book de BombaDocument7 pagesData Book de BombaSharon Botiny100% (1)

- Research Report: G Fryer, J Carub, S MclverDocument7 pagesResearch Report: G Fryer, J Carub, S MclverMitchTolontanNo ratings yet

- Ar6017 Urban Housing by A Sivaraman 01 - NoDocument156 pagesAr6017 Urban Housing by A Sivaraman 01 - Nosiva ramanNo ratings yet

- Who Uses The Drug? What Is Powdered Cocaine?Document2 pagesWho Uses The Drug? What Is Powdered Cocaine?api-607022055No ratings yet

- Stolarska Radionica - Procjena Troškova: Vrsta Naziv Slika Link Cijena Total VrstaDocument7 pagesStolarska Radionica - Procjena Troškova: Vrsta Naziv Slika Link Cijena Total VrstaMarko PalicNo ratings yet

- Actual 2005 STPMDocument16 pagesActual 2005 STPMNishan JayramanNo ratings yet

- Ethernet/Ip: Technical ManualDocument68 pagesEthernet/Ip: Technical ManualDiana HerreraNo ratings yet

- Low-Loss Power Splitters - Multi-Band 800 - 2500 MHZ 860 10017, 860 10018, 860 10019Document1 pageLow-Loss Power Splitters - Multi-Band 800 - 2500 MHZ 860 10017, 860 10018, 860 10019Zoheir KacimiNo ratings yet

- Grammar Test CommasDocument2 pagesGrammar Test CommasAbeer Mohammed HamhoumNo ratings yet

- Physical Pharmaceutics - 1Document15 pagesPhysical Pharmaceutics - 1Odin GODNo ratings yet

- Iso 1328-Agma - Parte 1Document35 pagesIso 1328-Agma - Parte 1bernaldoarnaoNo ratings yet

- TP48200A-DX12A1 Telecom Power User ManualDocument68 pagesTP48200A-DX12A1 Telecom Power User ManualDavid TombeNo ratings yet

- E PerioTherapyDocument5 pagesE PerioTherapymaherinoNo ratings yet

- Samri MSc. Thesis FinalDocument125 pagesSamri MSc. Thesis FinalMinilik Tikur SewNo ratings yet

- Vegan Mayonnaise - Simple Vegan Blog PDFDocument2 pagesVegan Mayonnaise - Simple Vegan Blog PDFjkoiluNo ratings yet

- Google - Cloud Digital Leader.v2023 06 22.q106Document50 pagesGoogle - Cloud Digital Leader.v2023 06 22.q106peacegroupngNo ratings yet

- Electrical Engineering Software PDFDocument12 pagesElectrical Engineering Software PDFAkd Deshmukh50% (2)

- BS 7910Document12 pagesBS 7910Mas Arman Tewo50% (2)

- Flight Vehicle LoadsDocument15 pagesFlight Vehicle LoadsSantosh G Pattanad100% (1)

- Manual de Calidad de Cerveza de Barril-2019 PDFDocument122 pagesManual de Calidad de Cerveza de Barril-2019 PDFAndrey Giovanny Riveros MerchanNo ratings yet

- Product Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5Document27 pagesProduct Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5marciocambruzziNo ratings yet

- Disciplines and Ideas in The Social SciencesDocument18 pagesDisciplines and Ideas in The Social SciencesArjane Grace SullanoNo ratings yet

- GRK-CV-17CV741-DESIGN OF BRIDGES - MODULE - 2 (DESIGN OF DECK SLAB) - Deck Slab - 11Document24 pagesGRK-CV-17CV741-DESIGN OF BRIDGES - MODULE - 2 (DESIGN OF DECK SLAB) - Deck Slab - 11monikaNo ratings yet

- What Hetman Do I NeedDocument2 pagesWhat Hetman Do I NeedCem GüngörNo ratings yet

- Professional AbilitiesDocument154 pagesProfessional AbilitiesChunchu AnilNo ratings yet

- Subiect - III - 2019Document4 pagesSubiect - III - 2019Valeriu CondreaNo ratings yet

- Example of Single Node-PairDocument14 pagesExample of Single Node-Pairahmad firdausNo ratings yet

- IW2P1Document3 pagesIW2P1Eong Huat Corporation Sdn BhdNo ratings yet