Professional Documents

Culture Documents

Automatic PaperBag Making Machinery

Automatic PaperBag Making Machinery

Uploaded by

Muni NaagCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BS EN12079-1999 (Inspection and Testing of Offshore ContainerDocument32 pagesBS EN12079-1999 (Inspection and Testing of Offshore Containerjohnsonpinto100% (3)

- 1-Romco Sap PM BBP V.1.2Document53 pages1-Romco Sap PM BBP V.1.2Muni NaagNo ratings yet

- SAC Premium ContentDocument23 pagesSAC Premium ContentMuni NaagNo ratings yet

- 8 Years of Experience in Data Warehousing and Business Intelligence Technologies Along With Around 3 Years of Data Visualization Using TableauDocument13 pages8 Years of Experience in Data Warehousing and Business Intelligence Technologies Along With Around 3 Years of Data Visualization Using TableauMuni NaagNo ratings yet

- BW Security ApproachesDocument5 pagesBW Security ApproachesMuni NaagNo ratings yet

- MSDS of Asi-CalphosDocument4 pagesMSDS of Asi-Calphosthiensuty74No ratings yet

- Abstract On Honey PotsDocument18 pagesAbstract On Honey PotsBen Garcia100% (3)

- Vet State Benefits - MO 2019Document10 pagesVet State Benefits - MO 2019DonnieNo ratings yet

- AirportsDocument12 pagesAirportsfairus100% (2)

- Funny Short StoriesDocument43 pagesFunny Short StorieschicankzNo ratings yet

- "A Study On Scope of Airtel Broadband": International Journal of Pure and Applied Mathematics No. 12 2018, 4093-4111Document20 pages"A Study On Scope of Airtel Broadband": International Journal of Pure and Applied Mathematics No. 12 2018, 4093-4111Muskan YadavNo ratings yet

- Akbar2015Document33 pagesAkbar2015DEDY KURNIAWANNo ratings yet

- Winddevil ProductDocument2 pagesWinddevil Productavalladolid05No ratings yet

- Index MC Sept 2018Document21 pagesIndex MC Sept 2018Everson Jumao-as100% (1)

- Combisafe Net BarrierDocument10 pagesCombisafe Net BarrierjoebriffaNo ratings yet

- Credit TransactionsDocument29 pagesCredit TransactionsGabrielle Louise de Peralta0% (1)

- Day Bang by Roosh V by Gene - PDF ArchiveDocument8 pagesDay Bang by Roosh V by Gene - PDF ArchivemohammaderfandardashtiNo ratings yet

- Data Sheet SCLFP48100 3U Rev 2Document2 pagesData Sheet SCLFP48100 3U Rev 2hermantoNo ratings yet

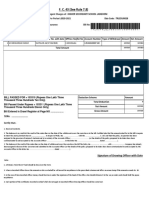

- F. C. 43 (See Rule 7.8) : Signature of Drawing Officer With DateDocument2 pagesF. C. 43 (See Rule 7.8) : Signature of Drawing Officer With Dateazad100% (1)

- M.Sc. Nguyen Thi Thanh Tam International School - DTUDocument25 pagesM.Sc. Nguyen Thi Thanh Tam International School - DTUDũng NguyễnNo ratings yet

- JE Mercer ODIDDocument70 pagesJE Mercer ODIDNabhan -100% (1)

- Chap 6 SolnsDocument2 pagesChap 6 SolnsjoNo ratings yet

- An Epistle From Ed: by Ed Cadwallader, PastorDocument4 pagesAn Epistle From Ed: by Ed Cadwallader, PastorBradford Woods ChurchNo ratings yet

- Changing HRM Practices With Firm Growth: Bernice Kotey and Alison SheridanDocument12 pagesChanging HRM Practices With Firm Growth: Bernice Kotey and Alison SheridanAhmed KhanNo ratings yet

- Emilio Aguinaldo College - Cavite Campus School of Business AdministrationDocument9 pagesEmilio Aguinaldo College - Cavite Campus School of Business AdministrationKarlayaanNo ratings yet

- Smart Sprinkler System Using Basic StampDocument22 pagesSmart Sprinkler System Using Basic StampdiegoNo ratings yet

- Rice Milling SystemDocument151 pagesRice Milling SystemZheejae Lao-aten100% (4)

- Driving SAR ADCsDocument7 pagesDriving SAR ADCsandresmdn22No ratings yet

- LO 2 Apply Java Advanced Class Design and Object Oriented Design PrinciplesDocument24 pagesLO 2 Apply Java Advanced Class Design and Object Oriented Design PrinciplesLJames SacuezaNo ratings yet

- CS Datasheet BiHiKu6 - CS6W MB AG - v2.1 - EN (Canadise)Document2 pagesCS Datasheet BiHiKu6 - CS6W MB AG - v2.1 - EN (Canadise)AlejandraNo ratings yet

- Chapter 1 - Slope Deflection Method For Statically Indeterminate BeamsDocument6 pagesChapter 1 - Slope Deflection Method For Statically Indeterminate BeamsTharshini GobiNo ratings yet

- Foreign: JUCHE 110Document20 pagesForeign: JUCHE 110mike johnNo ratings yet

- Sub Order LabelsDocument4 pagesSub Order LabelsLubhNo ratings yet

- Boyce ODEch 2 S 1 P 32Document1 pageBoyce ODEch 2 S 1 P 32Charbel KaddoumNo ratings yet

Automatic PaperBag Making Machinery

Automatic PaperBag Making Machinery

Uploaded by

Muni NaagCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic PaperBag Making Machinery

Automatic PaperBag Making Machinery

Uploaded by

Muni NaagCopyright:

Available Formats

Automatic Paper Bag Making Machinery

Automatic Machine Produces Hug Bags, Brown Bags without any Box Bottom

There will be Side Guzzettes but not Bottom Gazette

Bottom of the Bags will be like this.. (V Shape Bottom)

But if the Box Bottom is necessary, same bags can be converted into Box Bottom Type through some Methods

After the bags are made, two scoring has to be done in the bottom of the machinery (By using Manual Scoring Machinery)

This is Manual Creasing Machine

There are some calculations to make the scoring, that will be taught to you at the time of procuring the machinery

Then it can be folded like this

Finished Bag

Advantage of Automatic Machinery

1) High Speed (Minimum 74 Bags Per Min) 2) Brown Bags, Hug Bags and Shopping bags can be produced by this. 3) Reel Feeding Online Flexo Printing Unit can be attached 4) Cost of the bags are very competitive 5) Side, bottom pasting are done automatically

Brown Bag Costing

To produce 18 x 24 Cms. Brown Bag With 50 GSM Paper. Reel Width Required 38 cms.

Weight Calculation of Each Bag

Actual Paper Size for Each Bag - 38x26 cms General Formula :38 x 26 x 50 (GSM) / 10000 = 4.94 Weight of each bags = 4.94 Grams

Cost of the Paper for 1000 bags

Weight of 1000 Bags Cost of the Paper Per Kg. 23.00 x 4.94 Rounded Off

= 4.94 Kgs. = Rs. 23.00 = Rs.113.62 = Rs.114.00

Cost of the Labor

Labor Cost Per Kg. 2.25 x 4.94 Rounded Off = Rs.2.25 = Rs. 11.12 = Rs.11.00

Cost of the Adhesive

Adhesive Cost Per Kg. 0.20 x 4.94 Rounded Off = 0.20 Paise = 0.98 Paise = 1.00 Rs.

Power & Transport

Power & Transportation Per Kg. = Rs. 1.80 1.80 x 4.94 Rounded off = Rs.8.89 = Rs.9.00

Total Expenses to Produce 1000 Bags

Cost of the Paper Cost of the Labor Cost of the Adhesive Cost of the Power and Transportation

- 114.00 - 11.00 - 1.00

- 9.00 -----------Total Rs. - Rs.135.00 ------------

Net Profit

Cost Rs. 135.00

Profit Margin @ 25% Rs. 34.00 ----------------Rs. 169.00 -----------------

*******

Auxiliary (Manual) Machineries Provided with the Automatic Machinery

1. Paper Creasing Machine

2. D Shape Handle Cutting (Hydraulic) Machine

3. Eyelet Button Punching Machine 4. Bag Pressing Machine

With the Auxiliary Machineries you can produce following kind of bags (Manually)

All kind of Box bottom bags can be formed (pre-printed bags)

Bags Made out of News Papers, Recycled Papers or any kind of Waste Papers.. These bags are called Tree Free Bags or Eco Bags

These kind of bags are very very cheap in cost and hold the weight of around 1.250 Kgs. because two tags are given inside the handles. Now a days these kind of bags are spreading like anything around the world because it has got its own Economical value, because made out of Waste Papers, hence we dont destroy trees for the paper.

Why Eco Friendly Packaging ?

Plastic Menace

Across the world, animals are dieing consuming plastics every day. Are we concerned?

Photograph showing the dead trees due to, the plastic bags stop water from reaching its roots.

Agriculture land is becoming unusable due to plastic carry bags.

Let us stop using the Plastic Bags & Cups * Switch to Paper Bags, Cups & Cloth Bags *************************

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BS EN12079-1999 (Inspection and Testing of Offshore ContainerDocument32 pagesBS EN12079-1999 (Inspection and Testing of Offshore Containerjohnsonpinto100% (3)

- 1-Romco Sap PM BBP V.1.2Document53 pages1-Romco Sap PM BBP V.1.2Muni NaagNo ratings yet

- SAC Premium ContentDocument23 pagesSAC Premium ContentMuni NaagNo ratings yet

- 8 Years of Experience in Data Warehousing and Business Intelligence Technologies Along With Around 3 Years of Data Visualization Using TableauDocument13 pages8 Years of Experience in Data Warehousing and Business Intelligence Technologies Along With Around 3 Years of Data Visualization Using TableauMuni NaagNo ratings yet

- BW Security ApproachesDocument5 pagesBW Security ApproachesMuni NaagNo ratings yet

- MSDS of Asi-CalphosDocument4 pagesMSDS of Asi-Calphosthiensuty74No ratings yet

- Abstract On Honey PotsDocument18 pagesAbstract On Honey PotsBen Garcia100% (3)

- Vet State Benefits - MO 2019Document10 pagesVet State Benefits - MO 2019DonnieNo ratings yet

- AirportsDocument12 pagesAirportsfairus100% (2)

- Funny Short StoriesDocument43 pagesFunny Short StorieschicankzNo ratings yet

- "A Study On Scope of Airtel Broadband": International Journal of Pure and Applied Mathematics No. 12 2018, 4093-4111Document20 pages"A Study On Scope of Airtel Broadband": International Journal of Pure and Applied Mathematics No. 12 2018, 4093-4111Muskan YadavNo ratings yet

- Akbar2015Document33 pagesAkbar2015DEDY KURNIAWANNo ratings yet

- Winddevil ProductDocument2 pagesWinddevil Productavalladolid05No ratings yet

- Index MC Sept 2018Document21 pagesIndex MC Sept 2018Everson Jumao-as100% (1)

- Combisafe Net BarrierDocument10 pagesCombisafe Net BarrierjoebriffaNo ratings yet

- Credit TransactionsDocument29 pagesCredit TransactionsGabrielle Louise de Peralta0% (1)

- Day Bang by Roosh V by Gene - PDF ArchiveDocument8 pagesDay Bang by Roosh V by Gene - PDF ArchivemohammaderfandardashtiNo ratings yet

- Data Sheet SCLFP48100 3U Rev 2Document2 pagesData Sheet SCLFP48100 3U Rev 2hermantoNo ratings yet

- F. C. 43 (See Rule 7.8) : Signature of Drawing Officer With DateDocument2 pagesF. C. 43 (See Rule 7.8) : Signature of Drawing Officer With Dateazad100% (1)

- M.Sc. Nguyen Thi Thanh Tam International School - DTUDocument25 pagesM.Sc. Nguyen Thi Thanh Tam International School - DTUDũng NguyễnNo ratings yet

- JE Mercer ODIDDocument70 pagesJE Mercer ODIDNabhan -100% (1)

- Chap 6 SolnsDocument2 pagesChap 6 SolnsjoNo ratings yet

- An Epistle From Ed: by Ed Cadwallader, PastorDocument4 pagesAn Epistle From Ed: by Ed Cadwallader, PastorBradford Woods ChurchNo ratings yet

- Changing HRM Practices With Firm Growth: Bernice Kotey and Alison SheridanDocument12 pagesChanging HRM Practices With Firm Growth: Bernice Kotey and Alison SheridanAhmed KhanNo ratings yet

- Emilio Aguinaldo College - Cavite Campus School of Business AdministrationDocument9 pagesEmilio Aguinaldo College - Cavite Campus School of Business AdministrationKarlayaanNo ratings yet

- Smart Sprinkler System Using Basic StampDocument22 pagesSmart Sprinkler System Using Basic StampdiegoNo ratings yet

- Rice Milling SystemDocument151 pagesRice Milling SystemZheejae Lao-aten100% (4)

- Driving SAR ADCsDocument7 pagesDriving SAR ADCsandresmdn22No ratings yet

- LO 2 Apply Java Advanced Class Design and Object Oriented Design PrinciplesDocument24 pagesLO 2 Apply Java Advanced Class Design and Object Oriented Design PrinciplesLJames SacuezaNo ratings yet

- CS Datasheet BiHiKu6 - CS6W MB AG - v2.1 - EN (Canadise)Document2 pagesCS Datasheet BiHiKu6 - CS6W MB AG - v2.1 - EN (Canadise)AlejandraNo ratings yet

- Chapter 1 - Slope Deflection Method For Statically Indeterminate BeamsDocument6 pagesChapter 1 - Slope Deflection Method For Statically Indeterminate BeamsTharshini GobiNo ratings yet

- Foreign: JUCHE 110Document20 pagesForeign: JUCHE 110mike johnNo ratings yet

- Sub Order LabelsDocument4 pagesSub Order LabelsLubhNo ratings yet

- Boyce ODEch 2 S 1 P 32Document1 pageBoyce ODEch 2 S 1 P 32Charbel KaddoumNo ratings yet