Professional Documents

Culture Documents

SS 410

SS 410

Uploaded by

saikarthik103212Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SS 410

SS 410

Uploaded by

saikarthik103212Copyright:

Available Formats

Hamilton Precision Metals 1780 Rohrerstown Road, Lancaster, PA 17602 Phone: (717) 569-7061 Fax: (717) 569-7642

TECHNICAL DATA SHEET

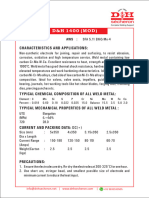

SS 410 SS 410 is a heat treatable martensitic chromium stainless steel. Melt practice is controlled to develop a surface nearly free from defects. It provides the best combination of wear resistance and corrosion resistance, and is used in demanding medical accessories.

NOMINAL COMPOSITION: Chromium Manganese Silicon 11.8% .40% .30% Nickel Carbon Iron .20% .14% Balance

TYPICAL MECHANICAL PROPERTIES:1 ANNEALED COLD ROLLED HEAT TREATED Ultimate Tensile Strength Yield Strength (.2% Offset) Elongation in 2 * Hardness (DPH 1000 Grams) Modulus of Elasticity (Tension) Poissons Ratio 75,000 PSI 45,000 PSI 25% 200 29 X 106 PSI 0.24 110,000 PSI 80,000 PSI 10% 200 220,000 PSI 170,000 PSI 5% 450

*The measured elongation will be less as thicknesses decreases to .002 and less.

These values may be adjusted by control of process variables consult HPM for desired values.

Rev. 1 03/13/95

-1-

SS 410 PHYSICAL PROPERTIES:2 Density Melting Point (Approx.) Electrical Resistivity @ R.T. Thermal Expansion Coefficient (0 to 100 C) Thermal Conductivity @ 100 C Magnetic Attraction -

7750 KG/m3 1460C 57 Microhm cm 9.9 x 10-6/C 25.0 W/m K Yes

GENERAL INFORMATION: The alloy can be cold formed from the annealed temper. Welding should be accomplished by pre and post heating. Pre-heating at 450 F and post-heated at 1300F will prevent cracking. The corrosion resistance is optimized in the heat-treated temper and assured by passiviation. It is resistant to water and organic materials. Oxidation resistance remains favorable in most applications up through 1200F.

AVAILABILITY: SS 410 is available from Hamilton Precision Metals as strip product from .001 to .060 in widths up to 12.0 The material conforms to UNS S41000.

Typical values to guide alloy selection but are not a guarantee of minimum or maximum.

-2-

You might also like

- X65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Document2 pagesX65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Jim SmithNo ratings yet

- SS430Document2 pagesSS430RavinJohnNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data Sheetpradeep4545No ratings yet

- SS 6mo - 1.4547Document1 pageSS 6mo - 1.4547f_riseNo ratings yet

- MP35N LTiDocument2 pagesMP35N LTiAnonymous AlhzFE9EVNNo ratings yet

- SS 1.4122Document2 pagesSS 1.4122Bipin Sadasivan100% (2)

- SS 302Document2 pagesSS 302XXXWEBGNo ratings yet

- Specification Sheet: Alloy 310/310S/310H: (UNS S31000, S31008, S31009) W. Nr. 1.4845Document2 pagesSpecification Sheet: Alloy 310/310S/310H: (UNS S31000, S31008, S31009) W. Nr. 1.4845Manoj PaneriNo ratings yet

- Uns s32760Document3 pagesUns s32760NitinNo ratings yet

- 1.4006 en PDFDocument2 pages1.4006 en PDFdiego.peinado8856No ratings yet

- Stainless Steel Bar 431 Atlas 431: Colour Code: Signal RedDocument3 pagesStainless Steel Bar 431 Atlas 431: Colour Code: Signal RedNitin AggarwalNo ratings yet

- Macsteel VRN: Stainless Steel Plate, Sheet & Coil SX316/316LDocument4 pagesMacsteel VRN: Stainless Steel Plate, Sheet & Coil SX316/316LNirav PatelNo ratings yet

- 1 4021 PDFDocument2 pages1 4021 PDFSarah FitzgeraldNo ratings yet

- Utp 63Document1 pageUtp 63Eileen TylerNo ratings yet

- Aluminium Bronze Data Sheet - C630Document1 pageAluminium Bronze Data Sheet - C630jr_satishNo ratings yet

- DH 1232NSDocument1 pageDH 1232NSGopiNathNo ratings yet

- Chemical CompositionDocument6 pagesChemical CompositionAkbar DarmawansyahNo ratings yet

- 1.4462 PropertiesDocument1 page1.4462 PropertiesutreshwarmiskinNo ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperMADDI MADHAV.No ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperPradeep KumarNo ratings yet

- 410 Spec SheetDocument2 pages410 Spec SheetThomasJolyNo ratings yet

- Amari Aerospace LTD Stainless Steel 14542 Bar 100Document5 pagesAmari Aerospace LTD Stainless Steel 14542 Bar 100Ria MustikaNo ratings yet

- Datenblatt 4105 UKDocument2 pagesDatenblatt 4105 UKVahid SarfarazNo ratings yet

- OK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWDocument1 pageOK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWGokul RajanNo ratings yet

- DH 1400modDocument1 pageDH 1400modGopiNathNo ratings yet

- 1.4742 enDocument2 pages1.4742 enGoran ErakovicNo ratings yet

- SX 316 / 316L Technical DataDocument3 pagesSX 316 / 316L Technical DatavkmsNo ratings yet

- SUPRATHERME NiSPLH4RDocument1 pageSUPRATHERME NiSPLH4RJagan TnNo ratings yet

- Wavemax® 5000 - Wave Solder PalletsDocument2 pagesWavemax® 5000 - Wave Solder PalletsornotNo ratings yet

- SS 304Document5 pagesSS 304Nirav PatelNo ratings yet

- .Au-Aluminium Alloy 3003Document5 pages.Au-Aluminium Alloy 3003ali alhamilNo ratings yet

- Alloy321 SpecSheetDocument2 pagesAlloy321 SpecSheetVinod tiwariNo ratings yet

- Stabilized Ferritic Stainless Steel: General CharacteristicsDocument37 pagesStabilized Ferritic Stainless Steel: General CharacteristicsBina Niaga MultiusahaNo ratings yet

- 400 SeriesDocument37 pages400 SeriesShashank SaxenaNo ratings yet

- 17 4 PHDocument2 pages17 4 PHzaranrajputNo ratings yet

- Manganese Steel 3401Document1 pageManganese Steel 3401kazdoelahNo ratings yet

- Cor-Ten - Weather & Corrosion Resistant SteelDocument5 pagesCor-Ten - Weather & Corrosion Resistant SteelAnjan DeyNo ratings yet

- High Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®Document2 pagesHigh Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®ivanoliveira3261No ratings yet

- PART 92 Cu-Ni Welding - Part 1 Cu-Ni Material PropertiesDocument16 pagesPART 92 Cu-Ni Welding - Part 1 Cu-Ni Material Propertiesravindra_jivaniNo ratings yet

- Alloy 410S Spec SheetDocument2 pagesAlloy 410S Spec SheetPrakash SundharamNo ratings yet

- 1.4313 enDocument2 pages1.4313 envesselNo ratings yet

- SS 1.4313Document2 pagesSS 1.4313mechkashanNo ratings yet

- Alloy SteelDocument7 pagesAlloy SteelRavinJohnNo ratings yet

- 13-8 MoDocument2 pages13-8 MofedaquiNo ratings yet

- RefrectarioDocument2 pagesRefrectarioCristian Mena HidalgoNo ratings yet

- PK2SPDocument3 pagesPK2SPEmanuelValenciaHenaoNo ratings yet

- Zeron 100 PDFDocument5 pagesZeron 100 PDFNAVANEETHNo ratings yet

- Properties of Ss410Document5 pagesProperties of Ss410gregkilatonNo ratings yet

- Datasheet Sandvik 12c27 enDocument4 pagesDatasheet Sandvik 12c27 enRizqi D. KurniantoNo ratings yet

- Specification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Document2 pagesSpecification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Felipe A. Gutiérrez M.No ratings yet

- 1.4313 en PDFDocument2 pages1.4313 en PDFZeljko68No ratings yet

- Implant: Stainless SteelDocument2 pagesImplant: Stainless SteelSachin GhalmeNo ratings yet

- Pressure Trasducers ArkerDocument26 pagesPressure Trasducers ArkerVictor Hugo Benitez Paez100% (1)

- Conarc85 EngDocument2 pagesConarc85 Engdeepak2803No ratings yet

- Din 1.4003Document2 pagesDin 1.4003Dhaniel100% (1)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet