Professional Documents

Culture Documents

Bitumen

Bitumen

Uploaded by

Akhilesh Krishna RamkalawonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bitumen

Bitumen

Uploaded by

Akhilesh Krishna RamkalawonCopyright:

Available Formats

Bitumen

-Bitumen education:

There is bitumen everywhere. Chances are, you got to the computer where you are reading this by walking over some bitumen. But where did it come from? How is it made? Read on to find out. Bitumen is a lot older than you think. Although now associated with roads and produced in large, complex, modern refineries belonging to enormous petrochemical companies (such as Shell), natural bitumen was found long before this, among the desert dunes of Arabia. Etymology The Romans called it gwitu-men (pertaining to pitch) or pixtu-men (bubbling pitch), converted, after the barbarian invasions to bitumen. The word passed into French, and then, after the Norman conquest of England in 1066, into English, where it was used interchangeably with tar for over a thousand years (though tar derives from coal, and bitumen from petroleum). Early Uses The earliest recorded use of something like bitumen was by the Sumerians, who ruled from the ancient city of Ur on the Euphrates river (near present-day Kuwait). There is evidence, too, that Babylonian King Nebuchadnezzar used it for waterproofing and even as grouting for stone roads. The use of bitumen spread further West, and the Bible records a bituminous substance (tar, asphalt or bitumen, depending on the translation) was used in building the Tower of Babel. In 1595 Sir Walter Raleigh discovered a thick viscous lake in the jungles of Trinidad. This was to be the largest natural deposit of bitumen ever found and was used extensively until the mid 1970s. In the late nineteenth century, however, bitumen began to be used for the major industrial uses common today, and with those began synthetic production. Shell began major bitumen production in the UK in 1920, after opening the Shell Haven refinery. Today, Shell produces bitumen all over the world, and is at the forefront of research into new applications for this substance people have used since the dawn of civilization.

GasOilEngineering GmbH. Gymnasiumstrasse 52/4, 1090 Vienna, Austria, Telephone: +43 1 890 10 48 0, FAX: +43 1 890 10 48 11, E-mail:office@gasoil-engineering.com

-Bitumen in General

The building material bitumen is a high-tech product whose quality is controlled in continuously advancing test procedures. Bitumen is mostly used in roadworks - 90% of the bitumen used in Austria (500,000 t annually). The remaining 10% are converted into industrial bitumen (oxidation bitumen). Example: bitumen consumption for 1 km of the S1 The demand depends on the width of the carriageway, the thickness of the layers and the type of asphalt. The S1 is an express way and corresponds to a moderately developed motorway. Its total width is 30 m. The total bitumen required for 1 km of the S1 amounts to 524.6 t. Of the 524.6 t of material, 292.6 t are street construction bitumen and 232 t are polymer modified bitumen. Bitumen is a mixture of high and non-boiling crude oil components and is yielded via the distillation of crude oil. It is not chemically changed during this. Not all crude oils are suitable for bitumen production: what is decisive is a sufficient amount of residue from the vacuum distillation with high-boiling components above 500C. Bitumen contains, aside from pure hydrocarbon, non-metallic elements in organically bonded form (oxygen, nitrogen, sulfur), traces of phosphorus and halogens as well as traces of metals (e.g. nickel, iron and vanadium). The distribution of hydrocarbons - alcanes, naphthenes, aromatic compounds, resins, asphaltenes - in bitumen varies depending on the origin of the crude oil. History of Bitumen Long before our time, bitumen was known in its natural form as natural asphalt. Natural asphalt is a relatively hard bitumen that is found in natural deposits; it is solid at 25C and liquid at 175C. A few examples demonstrate its cultural and historical significance: In Mesopotamia (present-day Iraq and Turkey) bitumen was used to seal houses and baskets 6,000 years ago - that's around 1,000 years before Oetzi the Iceman lived. In the ziggurats in Mesopotamia between 3,000 and 2,000 B.C., bitumen was used as a binding agent 10% of the time. For an average-sized temple (surface area: 60 x 45 m, height: 90m), the Sumerians, Arcadians or Babylonians used around 50,000 m3 of bitumen, corresponding to a month's worth of production of the Schwechat refinery. The word mummy, which derives from the Phoenician "mumia", means bitumen. Bitumen was only used rarely to embalm the dead in ancient Egypt; for the most part, plant oil was used. The Phoenician word "mumia" does mean bitumen, but it was actually plant oils were mostly used to embalm the dead in ancient Egypt. (Source: Corbis)

GasOilEngineering GmbH. Gymnasiumstrasse 52/4, 1090 Vienna, Austria, Telephone: +43 1 890 10 48 0, FAX: +43 1 890 10 48 11, E-mail:office@gasoil-engineering.com

In a royal gravesite in Ur, the Sumerian capital (in present-day Iraq) around 2600 B.C., a board game was found in which bitumen was used as a bonding agent for the inlays and the black coloring. In early antiquity, the main deposits of naturally occurring petroleum and/or bitumen were by the Black Sea. The export of these products brought a certain level of wealth to the people living in the area.

Bitumen & Road Construction In the road construction industry, bitumen with varying consistency is used. Depending on the requirements at hand, harder bitumen can provide increased sturdiness, while softer bitumen can provide higher flexibility. Harder bitumen can be processed at higher temperatures, but is more sensitive to environmental influences. Softer bitumen provides better resistance against environmental influences, but is also less sturdy when exposed to greater stress. The situation in Austria's alpine regions, where street paving is exposed to extreme fluctuations in temperature, places great demands on the quality of the bitumen. Conventional distillation bitumen was mainly used as a binding agent in road construction. The residue after the distillation contains enough high-molecular asphaltenes. Ideal crude oils for exclusive bitumen production come from Central America, for example. They contain up to 60% bitumen and are viscous. Austria imports bitumen crude oils from Saudi Arabia, Iran, Iraq and Russia. Bitumen & Polymers Polymer-modified bitumen is bitumen to which certain plastics and polymers (macromolecules: chemical combinations of a multitude of smaller molecules) have been added. This special kind of bitumen is used for road construction in areas where heavy traffic and great stress on the paving is anticipated (e.g. motorway). Polymer-modified bitumen is more resistant to deformation and makes asphalt covers extremely durable. Bitumen is yielded during the distillation of crude oil. It is used mainly in road construction. The modification with plastics influences the properties of conventional bitumen. To improve its elastic behavior, the softening point (around 70C) is raised, the plasticity span increased and the elasticity thus improved (less deformation). The following polymers are added to bitumen:

GasOilEngineering GmbH. Gymnasiumstrasse 52/4, 1090 Vienna, Austria, Telephone: +43 1 890 10 48 0, FAX: +43 1 890 10 48 11, E-mail:office@gasoil-engineering.com

Thermoplastics (plastomers) consist of linear polymers with little branching. They are softened when warmed and hardened when cooled (even repeatedly). This addition raises the viscosity and stiffness of the bitumen, but not its elasticity. Elastomers consist of long, sometimes balled-up polymer chains that are linked with a wide mesh. They are rubbery elastic at low temperatures all the way to decomposition temperatures, but cannot be re-melted after being processed once. Their addition increases the viscosity of the bitumen while only marginally increasing elasticity. Thermo-elastic plastics turn soft (not liquid) like a thermoplastic at temperatures above their service temperature and can then be shaped. They combine properties of rubber and thermoplastics.

Oxidation Bitumen Oxidation bitumen is used in industrial applications, e.g. to manufacture roof and sealing sheets, or for coatings and joint sealing compounds. Oxidation bitumen is produced by having oxygen (controlled injection) act on bitumen at 230C to 270C. By attachment of oxygen, the proportion of resins and asphaltenes rises, which leads to higher viscosity and a clear hardening of the binding agent. OMV uses a specially developed procedure (Biturox procedure) for the oxidation technology and uses high-performance air injection reactors that inject and distribute air and water across large surfaces. Test Procedures The properties of bitumen that are used in Austria and Europe are primarily evaluated by means of empirical test procedures. Among other things, these describe their elasticity and viscosity, their adhesion behavior, their solubility, their hardening stability, their flash point, their paraffin content and their shelf life. Recently, examinations of bitumen have focused on the rheological properties of bitumen. Rheology is the science of flowing substances and describes, using physical characteristics, the deformation of a substance when subjected to loading by external forces. This can be described by physical parameters such as shear modulus, phase difference or tensile stiffness. Bitumen is a visco-elastic substance, i.e. its behavior can be described using an elastic and a viscous component. This behavior can be presented with the aid of the Maxwell model. The rheometer measures the properties of bitumen especially in the upper temperature rang

GasOilEngineering GmbH. Gymnasiumstrasse 52/4, 1090 Vienna, Austria, Telephone: +43 1 890 10 48 0, FAX: +43 1 890 10 48 11, E-mail:office@gasoil-engineering.com

-Solutions for Bitumenpacking

Today there is only limited solutions for Bitumen packing in the market. The only widespread transport tool established are so far bitumen drums , containing many disadvantages. Gasoili engineering has new solutions to offer for Bitumen packing, containing various logistical and financial advantages compared to drums. Please contact us for further information.

GasOilEngineering GmbH. Gymnasiumstrasse 52/4, 1090 Vienna, Austria, Telephone: +43 1 890 10 48 0, FAX: +43 1 890 10 48 11, E-mail:office@gasoil-engineering.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Fundamentals of Concrete ADocument174 pagesFundamentals of Concrete AV Venkata Narayana100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Venkat Master Semi-Log Curves For Metal GradationDocument28 pagesVenkat Master Semi-Log Curves For Metal GradationV Venkata Narayana100% (1)

- Venkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersDocument68 pagesVenkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersV Venkata Narayana96% (28)

- Bituminous Mixtures in Roads - 1Document586 pagesBituminous Mixtures in Roads - 1V Venkata Narayana100% (2)

- PJ - 2 - 5 - Bougainvillea Glabra.....Document4 pagesPJ - 2 - 5 - Bougainvillea Glabra.....irishjamile dulosNo ratings yet

- RTS Chemistry SPM Question Bank Chapter 5Document10 pagesRTS Chemistry SPM Question Bank Chapter 5ryder1man64330% (1)

- Venkat Rigid Pavement Tables of Joints and Steel PDFDocument2 pagesVenkat Rigid Pavement Tables of Joints and Steel PDFV Venkata NarayanaNo ratings yet

- Venkat Rigid Pavement Tables of Joints and SteelDocument2 pagesVenkat Rigid Pavement Tables of Joints and SteelV Venkata NarayanaNo ratings yet

- VenkatBox Cell Structuresa at Glance GraphicDocument3 pagesVenkatBox Cell Structuresa at Glance GraphicV Venkata NarayanaNo ratings yet

- Road Safety Measures On Stretches of National Highways - RegardingDocument4 pagesRoad Safety Measures On Stretches of National Highways - RegardingDhiren PatelNo ratings yet

- VenkatBox Cell Structuresa at Glance GraphicDocument3 pagesVenkatBox Cell Structuresa at Glance GraphicV Venkata NarayanaNo ratings yet

- అందమైన గ్రామీణ జీవితం Beautiful village life PDFDocument53 pagesఅందమైన గ్రామీణ జీవితం Beautiful village life PDFV Venkata NarayanaNo ratings yet

- 60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesDocument1 page60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesV Venkata Narayana100% (3)

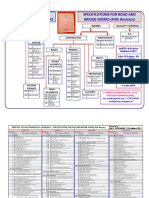

- Venkats Interpretation On Configuration of MORTHDocument29 pagesVenkats Interpretation On Configuration of MORTHV Venkata Narayana100% (3)

- 60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesDocument1 page60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesV Venkata Narayana100% (3)

- 57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintDocument4 pages57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintV Venkata Narayana100% (2)

- 56 - Venkat - MoRTH 5th Revision Essential Tables For Highway Field Engineers PrintDocument34 pages56 - Venkat - MoRTH 5th Revision Essential Tables For Highway Field Engineers PrintV Venkata Narayana100% (4)

- 57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintDocument4 pages57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintV Venkata Narayana100% (2)

- IRC 85 1983 Part2 PDFDocument11 pagesIRC 85 1983 Part2 PDFV Venkata NarayanaNo ratings yet

- Venkat Master SemiLog CurvesPlainDocument28 pagesVenkat Master SemiLog CurvesPlainV Venkata NarayanaNo ratings yet

- Venkat Master SemiLog CurvesPlainDocument28 pagesVenkat Master SemiLog CurvesPlainV Venkata NarayanaNo ratings yet

- VenkatBox Box Culverts AbstractDocument1 pageVenkatBox Box Culverts AbstractV Venkata Narayana0% (1)

- APPROACH SLABS Venkata NarayanaDocument9 pagesAPPROACH SLABS Venkata NarayanaV Venkata Narayana100% (1)

- Morth400 Sub-Bases and Bases Tables of Gradation Tests LimitsDocument5 pagesMorth400 Sub-Bases and Bases Tables of Gradation Tests LimitsV Venkata Narayana100% (2)

- Membership Form A-1Document2 pagesMembership Form A-1V Venkata NarayanaNo ratings yet

- Approach Slabs - For BRIDGES VenkatDocument3 pagesApproach Slabs - For BRIDGES VenkatV Venkata Narayana0% (1)

- The Modern Asphalt Pavement 1904 PDFDocument617 pagesThe Modern Asphalt Pavement 1904 PDFV Venkata NarayanaNo ratings yet

- Standard Data Book (Roads & Bridges)Document353 pagesStandard Data Book (Roads & Bridges)shariqabideen81% (63)

- 1904Document24 pages1904Palani KumarNo ratings yet

- d36 Softening Point Test Ring and BallDocument5 pagesd36 Softening Point Test Ring and BallNurul RizalNo ratings yet

- Lab-Synthesis and Analysis of AlumDocument2 pagesLab-Synthesis and Analysis of Alumhels245No ratings yet

- Determination of Total Phenolic Content and Antioxidant Activity in Methanolic Extract of Robusta and Arabica Coffee LeavesDocument4 pagesDetermination of Total Phenolic Content and Antioxidant Activity in Methanolic Extract of Robusta and Arabica Coffee LeavesRameRed LiNo ratings yet

- Nomenclature Practice ProblemsDocument4 pagesNomenclature Practice ProblemsMax DavidsonNo ratings yet

- HiTEC 2607 PDSDocument2 pagesHiTEC 2607 PDSMehmet PetronolNo ratings yet

- Material Science and Metallurgy Question BankDocument3 pagesMaterial Science and Metallurgy Question BankVinay KorekarNo ratings yet

- Ozone and Global WarmingDocument8 pagesOzone and Global WarmingCamilleKingNo ratings yet

- Methanol From Biomass: What Is Methanol? The ResourceDocument4 pagesMethanol From Biomass: What Is Methanol? The ResourceMuhammad BurhanNo ratings yet

- VanDeventer Provis DuxsonBrice WasteBiomassValorization Vol1no1 2010 pp145-155Document12 pagesVanDeventer Provis DuxsonBrice WasteBiomassValorization Vol1no1 2010 pp145-155زھرة ٱلبيلسآنNo ratings yet

- ANGELESDIOSA - PAMAN - DETAILED LESSON PLAN - SHS Applicant481Document16 pagesANGELESDIOSA - PAMAN - DETAILED LESSON PLAN - SHS Applicant481Diane PamanNo ratings yet

- The Role of Fat in The Stabilisation of Gas Cells in Bread DoughDocument12 pagesThe Role of Fat in The Stabilisation of Gas Cells in Bread DoughEmil Emmanuel Estilo100% (1)

- Name - Class - : Q: No1. Choose The Correct Answer. 10Document2 pagesName - Class - : Q: No1. Choose The Correct Answer. 10Syed Salman SaeedNo ratings yet

- DPP HaloAlkanes Physical PropertiesDocument1 pageDPP HaloAlkanes Physical PropertiesHimadri BhardwajNo ratings yet

- Sphere FitupDocument103 pagesSphere FitupAnonymous wxLjBEzNo ratings yet

- Standard Specification For: Designation: B166 11Document9 pagesStandard Specification For: Designation: B166 11mahfuzNo ratings yet

- 2423 e 3Document21 pages2423 e 3Abdel Rahman MohamedNo ratings yet

- CSEC Study Paper - Chemistry (Atomic Structure)Document16 pagesCSEC Study Paper - Chemistry (Atomic Structure)Samuel Jamal WilliamsNo ratings yet

- Nitrogen and Sulfur AS LevelDocument5 pagesNitrogen and Sulfur AS LevelThapelo SebolaiNo ratings yet

- Adhesive Contaminants and Methods For RemovalDocument11 pagesAdhesive Contaminants and Methods For RemovalAkash GadekarNo ratings yet

- Sinopec-Engine Coolant-Environmentally Friendly-YF-2ADocument3 pagesSinopec-Engine Coolant-Environmentally Friendly-YF-2ApedriscoNo ratings yet

- NROchre: MSDS - UmberDocument4 pagesNROchre: MSDS - UmberNew Riverside Ochre Company, Inc.No ratings yet

- In The Styrenic Value Chain: Product ScopeDocument1 pageIn The Styrenic Value Chain: Product ScopetotpityiNo ratings yet

- Us 3087787Document6 pagesUs 3087787ndsdarknessNo ratings yet

- Firefighting Foam NFPA 409Document3 pagesFirefighting Foam NFPA 409Ahmad Riaz Qureshi100% (1)

- Bioethanol Production From Durian (Duriozibethinus) and Mangosteen (Garcinia Mangostana) PeelsDocument18 pagesBioethanol Production From Durian (Duriozibethinus) and Mangosteen (Garcinia Mangostana) PeelsDonetha Grace MerkaNo ratings yet

- 10 11648 J Ogce 20210906 13Document13 pages10 11648 J Ogce 20210906 13altamirano21No ratings yet

- Calculation of K From E: at Equilibrium G 0, E 0Document9 pagesCalculation of K From E: at Equilibrium G 0, E 0Ghadeer M HassanNo ratings yet

- SZS Bi Nghien Su Ceramic Zs Czs HelicoDocument2 pagesSZS Bi Nghien Su Ceramic Zs Czs HelicoAnonymous Ske1XzNo ratings yet

- Stoichiometry PowerPointDocument23 pagesStoichiometry PowerPointAngelaWillson100% (1)