Professional Documents

Culture Documents

Bore Pile Dev Elopement

Bore Pile Dev Elopement

Uploaded by

Kamol AmornfaCopyright:

Available Formats

You might also like

- กฎหมายออกแบบบ้านพักอาศัยDocument5 pagesกฎหมายออกแบบบ้านพักอาศัยSantawut NacawirotNo ratings yet

- ควบคุมงานก่อสร้าง PDFDocument202 pagesควบคุมงานก่อสร้าง PDFSivarak Vangbooncong0% (1)

- Sheet PileDocument38 pagesSheet PileTanawat NuchNo ratings yet

- คู่มือเสริมเหล็กต้านแผ่นดินไหว สกว.Document97 pagesคู่มือเสริมเหล็กต้านแผ่นดินไหว สกว.wutce GmailNo ratings yet

- C2 Design MethodDocument17 pagesC2 Design MethodMongkol JirawacharadetNo ratings yet

- รวมเล่ม คู่มือการออกแบบปตร.OKDocument139 pagesรวมเล่ม คู่มือการออกแบบปตร.OKJay AcousticNo ratings yet

- การก่อสร้างอาคารสูง (พิเศษ)Document10 pagesการก่อสร้างอาคารสูง (พิเศษ)Feaw KoshiNo ratings yet

- Civil 1Document30 pagesCivil 1ธเนศ นาระคลNo ratings yet

- การใช้ท่อเหล็กในโครงการก่อสร้างขนาดใหญ่Document16 pagesการใช้ท่อเหล็กในโครงการก่อสร้างขนาดใหญ่apirakqNo ratings yet

- การออกแบบระบบประปาภูเขา กรมชลประทาน PDFDocument46 pagesการออกแบบระบบประปาภูเขา กรมชลประทาน PDFPatipol GunhomepooNo ratings yet

- การออกแบบโครงข้อแข็งDocument94 pagesการออกแบบโครงข้อแข็งFeaw KoshiNo ratings yet

- เอกสารบรรยาย เคล็ดลับสำคัญ การบริหารโครงการก่อสร้างอย่างมีประสิทธิภาพDocument114 pagesเอกสารบรรยาย เคล็ดลับสำคัญ การบริหารโครงการก่อสร้างอย่างมีประสิทธิภาพWeerapong SaengseasonNo ratings yet

- Qc5V0W2ZT3qqnBfmrlwC Money Pre-PrintDocument224 pagesQc5V0W2ZT3qqnBfmrlwC Money Pre-PrintAmir SanNo ratings yet

- Digital Business InnovationDocument27 pagesDigital Business Innovationclicks2net.comNo ratings yet

- คู่มือ การออกแบบอาคารระบายน้ำDocument414 pagesคู่มือ การออกแบบอาคารระบายน้ำนเดช มีนาNo ratings yet

- ตารางส่วนผสมคอนกรีตDocument1 pageตารางส่วนผสมคอนกรีตpuwarin najaNo ratings yet

- กำแพงกันดินB6235505Document23 pagesกำแพงกันดินB6235505Kongsak AkkharawongwhatthanaNo ratings yet

- การก่อสร้างอาคารคอนกรีตระบบสำเร็จรูปDocument19 pagesการก่อสร้างอาคารคอนกรีตระบบสำเร็จรูปAum AmphunNo ratings yet

- คู่มือการเสริมเหล็ก rev03 chapter01Document6 pagesคู่มือการเสริมเหล็ก rev03 chapter01ศิวาเวช อบมาNo ratings yet

- Found กำแพงกันดิน 2BWDocument48 pagesFound กำแพงกันดิน 2BWPong Hongsuwan100% (6)

- คอนกรีตเทคโนโลยีDocument86 pagesคอนกรีตเทคโนโลยีeakbkk100% (1)

- Channarong 1Document205 pagesChannarong 1Sanchai_SaNo ratings yet

- คู่มือการซ่อมแซมและบำรุงรักษาสะพานDocument151 pagesคู่มือการซ่อมแซมและบำรุงรักษาสะพานSOMYOTNo ratings yet

- เล่ม ชลศาสตร์ ฝายห้วยแม่สลิดDocument35 pagesเล่ม ชลศาสตร์ ฝายห้วยแม่สลิดJay AcousticNo ratings yet

- ค่า kDocument39 pagesค่า kkovo 053No ratings yet

- การสึกร่อนของคอนกรีตและการทดสอบDocument9 pagesการสึกร่อนของคอนกรีตและการทดสอบklairoongNo ratings yet

- f1c42d76-d6c6-4007-a7e8-e84dbe3e4b30Document24 pagesf1c42d76-d6c6-4007-a7e8-e84dbe3e4b30อัชวิน เจริญสินNo ratings yet

- SteelPlateGirder Gnem RVCDocument9 pagesSteelPlateGirder Gnem RVCCe WinNo ratings yet

- 1 Axial July18-07Document43 pages1 Axial July18-07nauew erfweewNo ratings yet

- การใช้งานโปรแกรม NEO RC DESIGN V5Document173 pagesการใช้งานโปรแกรม NEO RC DESIGN V5Life of TharatepNo ratings yet

- การเก็บตัวอย่างลูกปูนDocument11 pagesการเก็บตัวอย่างลูกปูนสันต์ โยธาภูธรNo ratings yet

- หลักเกณฑ์การคำนวณราคากลางงานก่อสร้างDocument65 pagesหลักเกณฑ์การคำนวณราคากลางงานก่อสร้างTOANo ratings yet

- CH 02Document29 pagesCH 02lavyNo ratings yet

- พฤติกรรมทางกลของผนังคอนกรีตบล็อกเสริมเหล็กDocument149 pagesพฤติกรรมทางกลของผนังคอนกรีตบล็อกเสริมเหล็กWinNo ratings yet

- RCSDM 01 IntroductionDocument33 pagesRCSDM 01 IntroductionNattapat Wongnurak /SiteConREG3No ratings yet

- คอนกรีตกำลังสูง วัสดุที่ใช้และปัจจัยที่ควรพิจารณาDocument9 pagesคอนกรีตกำลังสูง วัสดุที่ใช้และปัจจัยที่ควรพิจารณาklairoongNo ratings yet

- Foundation Engineering by DR - Jirayut Suebsuk 04-011-310Document328 pagesFoundation Engineering by DR - Jirayut Suebsuk 04-011-310Jirachai LaohaNo ratings yet

- 01 WeldingDocument128 pages01 WeldingBenjamin RattharojthakunNo ratings yet

- ประสบการณ์และเทคนิคในการก่อสร้างDocument61 pagesประสบการณ์และเทคนิคในการก่อสร้างWatatwork AtworkNo ratings yet

- A05 TorsionDocument11 pagesA05 Torsionthanakit wiwitboonyakornNo ratings yet

- รายการประมาณราคา 2555Document68 pagesรายการประมาณราคา 2555ชยกร แก้วผดุงNo ratings yet

- ผลงานเด่นลำดับที่ 1Document193 pagesผลงานเด่นลำดับที่ 1Suthiwat PromraksaNo ratings yet

- MRT03 - มาตรฐานการตรวจสอบโครงสร้างคอนกรีตเสริมเหล็ก มยผ. 1501-1507 - 51Document86 pagesMRT03 - มาตรฐานการตรวจสอบโครงสร้างคอนกรีตเสริมเหล็ก มยผ. 1501-1507 - 51Watatwork AtworkNo ratings yet

- Circular Stair CalDocument9 pagesCircular Stair Calmongkol_1001No ratings yet

- Ncce 23gteid117Document11 pagesNcce 23gteid117noppadol.ch100% (1)

- guide collar จมบ่อDocument7 pagesguide collar จมบ่อTanako KomoNo ratings yet

- 2439 บทความฉบับสมบูรณ์ 33359 1 10 20230709Document7 pages2439 บทความฉบับสมบูรณ์ 33359 1 10 20230709นพดล ชูคงNo ratings yet

- Thaweesak GTE027 NCCE16 2554Document12 pagesThaweesak GTE027 NCCE16 2554Lamthong LvkNo ratings yet

- Lessons From The CollapseDocument9 pagesLessons From The Collapsemote34No ratings yet

- เล่มออกแบบฝายDocument86 pagesเล่มออกแบบฝายJay AcousticNo ratings yet

- Chomphunut 64120520 Con3Document15 pagesChomphunut 64120520 Con3cpnNo ratings yet

- VCM TechnologyDocument47 pagesVCM TechnologyChatchai ChaninNo ratings yet

- CE7Document231 pagesCE7อัชวิน เจริญสินNo ratings yet

- Influence of Tunnelling Effect On Existing Pile Foundation in Bangkok Subsoil by Finite Element ModelDocument8 pagesInfluence of Tunnelling Effect On Existing Pile Foundation in Bangkok Subsoil by Finite Element ModelBarames VardhanabhutiNo ratings yet

- 09 - ท่อฝังกลบ ท่อลอด ทางลอด และอุโมงค์Document24 pages09 - ท่อฝังกลบ ท่อลอด ทางลอด และอุโมงค์Putthipong HaleerattanawattanaNo ratings yet

- เทคนิคการก่อสร้างฐานรากคอนกรีตขนาดใหญ่ ในงานอาคารสูงDocument16 pagesเทคนิคการก่อสร้างฐานรากคอนกรีตขนาดใหญ่ ในงานอาคารสูงapirakqNo ratings yet

- TSEA Template-01Document29 pagesTSEA Template-01abudabeejajaNo ratings yet

- รายงานการทางDocument18 pagesรายงานการทางweerachai.mNo ratings yet

- PC Joint Beams PaperDocument7 pagesPC Joint Beams PaperdongngoNo ratings yet

Bore Pile Dev Elopement

Bore Pile Dev Elopement

Uploaded by

Kamol AmornfaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bore Pile Dev Elopement

Bore Pile Dev Elopement

Uploaded by

Kamol AmornfaCopyright:

Available Formats

.

DESIGN AND CONSTRUCTION DEVELOPMENT OF WET PROCESS BORED

PILES IN THAILAND

(Narong Thasnanipan)

E-mail : narong@seafco.co.th

(Kamol Singtokaw)

E-mail : kamolsing@seafco.co.th

(Chanchai Submaneewong)

E-mail : seafco@seafco.co.th

: (Wet Process Large Diameter Bored Piles)

30

ABSTRACT : Wet process large diameter bored piles have been introduced to use as the foundation piles in Bangkok subsoil for

approximately 30 years ago. At the early stage of using this pile type, the design engineers and the piling contractors were new to this

piling system. So the design engineers have designed the safe working load based on the conservative limit and the contractors also

had not much experience to install the high load capacity piles. But at present the design engineers and the piling contractors all have

better experience in the design and installation technology of bored piles than the past and also there are many research about the

behavior of wet process bored piles. As a result the wet process bored piles are nowadays designed and installed with the capacity far

higher than those of the past. This paper presents the design and construction development of wet process bored pile in Thailand

since the past to present.

KEYWORDS: BORED PILE, FRICTION FACTOR, BEARING CAPACITY

1.

-

-

-

-

-

-

2.

.. 2514 -2525

(Rotary drilling under bentonite slurry)

(Reverse circulation method: RC)

(Auger and Bucket method: A&B)

45 .. 2514

45 . 2520

49 .. 2525

(Auger and bucket)

( )

33

32 2522 2523

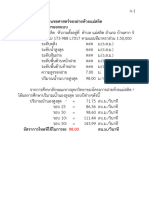

1

[5]

. .

.

() ()

(.)

RC 1.50x45.

410

820

5.00

RC 1.50x45. 500

1200

7.76

RC 1.50x49. 550

1100

8.15

A&B 1.00x33. 320

750*

24.6

A&B 1.50x32. 800

1600

100.8

1.00x32. 300

1125*

118.3

* Ultimate load of the pile

3.

.. 2526 2540

50

.. 2526

45 75

Ng

Kim Cheng [5] [2] Pimpasugdi [6]

Friction Factor ( & -Value) Bearing Factor

(Nc & Nq)

2

Auger and Bucket

Barrette

Barrette 5,290

61.24

1 2

2

. 2526-2540

(.)

()

(.)

800 . 300

3-4

750

10 - 12

1000 . 450

3-4

11250

12 - 18

1200 . 600

3-5

1500

16 - 20

1500 . 950

3-6

2250

18 - 25

1 Barrette 6,000

(Barrette)

.. 2528

International Trade Center

Barrette

2 Static Load Test Barrette

BECM Tower

L O AD (T o n s )

0

2000

4000

6000

0 .0

SET T LEM ENT (mm)

2 0 .0

4 0 .0

6 0 .0

B a r r e tte (1 .5 x 3 .0 m )

B o r e d P ile (d ia . 1 .5 0 m )

8 0 .0

.. 2528

9 2.00 .

35 .[4] [1]

Friction factor (-Value) Mobilized

Nq-Value 3 4

0.60

Bored Pile using Bentonite

Base Grouted Pile

0.40

0.20

Bored Pile using Polymer

Polymer

0.4

0.2

Bentonite

Normal Pile

0.00

0.0

30.0

28.0

30.0

32.0

34.0

36.0

Effective Angle of Internal Friction ( ', degree)

6.0

5.0

Base Grouted Bored Pile

4.0

Base Grouted Pile (Tip in Sand)

Normal Pile (Tip in Sand)

Barrette Pile

2.0

1.0

32.0

30.0

32.0

34.0

36.0

38.0

Effective Angle of Internal Friction (', degree)

34.0

35.0

36.0

Angle of Internal Friction, '

1.80 . 60.0 1600

300 %

4800 ( 6)

Base Grouted Barrette Pile

0.0

33.0

5 Friction Coefficient of Bangkok Sand () [7]

Normal Bored Pile

3.0

31.0

38.0

3 -value [1]

Mobilized Nq

0.6

Base Grouted Pile (Tip in Sand)

Normal Pile (Tip in Sand)

Normal Pile (Tip in Clay)

= (Ks.tan )

Friction Factor , KStan

0.80

Load (tons)

40.0

. 2541

[7]

5

Littlechild [3]

Thasnanipan [8]

2000

3000

4000

5000

6000

0

Settlement (mm.)

4 Mobilized Nq-value [1]

4.

1000

20

40

60

80

6 1.80

60.0 .

7 3

Load (KN)

0

10000

20000

30000

40000

Pile Head Movement (mm)

0

10

20

30

Dia. 1.5m x 60.0m (Bentonite)

40

50

Dia. 1.5m x 63.7m (Bentonite)

Dia. 1.5m x 55m (Polymer)

Dia. 1.5m x 54m (Polymer)

60

()

0.80 X 49

0.80 X 50

1.20 X 51

1.80 X 62

1.50 X 54

1.00 X 51

1.00 X 30

0.80 X 41

0.80 X 43

0.60 X 26

0.60 X24

()

330

330

720

1100

1200

450

260

330

330

100

80

(.) (.)

()

990

3.90

14.95

990

5.20

21.05

1800

4.61

19.76

3300

4.00

12.96

3200

8.60

23.03

1125

2.49

9.15

650

1.67

5.38

990

2.75

11.60

660

4.52

11.20

250

1.61

4.55

200

1.09

4.22

Load (tons)

0

500

1000

1500

2000

2500

0

10

20

30

40

50

8 1.35

56.0 .

5.

Load (tons)

0

Settlement (mm.)

5.1

0.60 0.80 1.00 1.20 1.50 1.80

2.00 .

2

58.0 . 1.50 .

1100 1.80 . 1400

1250

1.80 .

1.35 1.65 .

8 9

1.35 .

56.0 1.65 .

58.0 .

Settlement (mm)

500

1000

1500

2000

2500

3000

3500

0

5

10

15

20

25

30

9 1.65

58.0 .

5.2

(Stress Bulb)

( 10)

30 50 -100%

20 30 %

[1] ,

,

, 2542.

[2] ,

,

, 2531.

[3] Littlechild, B. and Plumbridge, G., Effect of Construction Technique

on the Behavior of Plain Bored Cast In Situ Piles Constructed under

Bentonite Slurry. 7th Intl. Conf. and Exhibition on Piling and Deep

Foundation. Vienna Pp. 1.6.1-1.6.8 ,1998.

[4] Morison, I.M. Bored piled foundation for Chao Phya river crossing at

Wat Sai, Bangkok. 9th South East Asian Geotechnical Society

Conference, Bangkok. 6-207 to 6-218, 1987.

[5] Ng, K.C., The Construction Problems and Performance of Large

Bored Piles in Second Sand Layer. Masters Thesis, GT-82-26 Asian

Institute of Technology, Bangkok, 1983.

[6] Pimpasugdi, S., Performance of Bored, Driven and Auger Press Piles

in Bangkok Subsoil. Masters Thesis, GT-88-12, AIT, Bangkok, 1989

[7] Teparaksa, W. and Boonyarak, T., Performance and Behavior of

Polymer Slurry in Wet Process Bored Pile in Bangkok Subsoils. 14th

KKNN Seminar on Civil Engineering Kyoto, Japan, 2001.

[8] Thasnanipan, N., Baskaran, G. and Anwar, M.A. Effect of

.

10 1.50 55.0 .

Construction Time and Bentonite Viscosity on Shaft Capacity of

Bored Piles. 3rd Intl. Seminar Deep Foundation on Bored and Auger

Piles., Ghent, Belgium. Pp 171-177. 1998.

You might also like

- กฎหมายออกแบบบ้านพักอาศัยDocument5 pagesกฎหมายออกแบบบ้านพักอาศัยSantawut NacawirotNo ratings yet

- ควบคุมงานก่อสร้าง PDFDocument202 pagesควบคุมงานก่อสร้าง PDFSivarak Vangbooncong0% (1)

- Sheet PileDocument38 pagesSheet PileTanawat NuchNo ratings yet

- คู่มือเสริมเหล็กต้านแผ่นดินไหว สกว.Document97 pagesคู่มือเสริมเหล็กต้านแผ่นดินไหว สกว.wutce GmailNo ratings yet

- C2 Design MethodDocument17 pagesC2 Design MethodMongkol JirawacharadetNo ratings yet

- รวมเล่ม คู่มือการออกแบบปตร.OKDocument139 pagesรวมเล่ม คู่มือการออกแบบปตร.OKJay AcousticNo ratings yet

- การก่อสร้างอาคารสูง (พิเศษ)Document10 pagesการก่อสร้างอาคารสูง (พิเศษ)Feaw KoshiNo ratings yet

- Civil 1Document30 pagesCivil 1ธเนศ นาระคลNo ratings yet

- การใช้ท่อเหล็กในโครงการก่อสร้างขนาดใหญ่Document16 pagesการใช้ท่อเหล็กในโครงการก่อสร้างขนาดใหญ่apirakqNo ratings yet

- การออกแบบระบบประปาภูเขา กรมชลประทาน PDFDocument46 pagesการออกแบบระบบประปาภูเขา กรมชลประทาน PDFPatipol GunhomepooNo ratings yet

- การออกแบบโครงข้อแข็งDocument94 pagesการออกแบบโครงข้อแข็งFeaw KoshiNo ratings yet

- เอกสารบรรยาย เคล็ดลับสำคัญ การบริหารโครงการก่อสร้างอย่างมีประสิทธิภาพDocument114 pagesเอกสารบรรยาย เคล็ดลับสำคัญ การบริหารโครงการก่อสร้างอย่างมีประสิทธิภาพWeerapong SaengseasonNo ratings yet

- Qc5V0W2ZT3qqnBfmrlwC Money Pre-PrintDocument224 pagesQc5V0W2ZT3qqnBfmrlwC Money Pre-PrintAmir SanNo ratings yet

- Digital Business InnovationDocument27 pagesDigital Business Innovationclicks2net.comNo ratings yet

- คู่มือ การออกแบบอาคารระบายน้ำDocument414 pagesคู่มือ การออกแบบอาคารระบายน้ำนเดช มีนาNo ratings yet

- ตารางส่วนผสมคอนกรีตDocument1 pageตารางส่วนผสมคอนกรีตpuwarin najaNo ratings yet

- กำแพงกันดินB6235505Document23 pagesกำแพงกันดินB6235505Kongsak AkkharawongwhatthanaNo ratings yet

- การก่อสร้างอาคารคอนกรีตระบบสำเร็จรูปDocument19 pagesการก่อสร้างอาคารคอนกรีตระบบสำเร็จรูปAum AmphunNo ratings yet

- คู่มือการเสริมเหล็ก rev03 chapter01Document6 pagesคู่มือการเสริมเหล็ก rev03 chapter01ศิวาเวช อบมาNo ratings yet

- Found กำแพงกันดิน 2BWDocument48 pagesFound กำแพงกันดิน 2BWPong Hongsuwan100% (6)

- คอนกรีตเทคโนโลยีDocument86 pagesคอนกรีตเทคโนโลยีeakbkk100% (1)

- Channarong 1Document205 pagesChannarong 1Sanchai_SaNo ratings yet

- คู่มือการซ่อมแซมและบำรุงรักษาสะพานDocument151 pagesคู่มือการซ่อมแซมและบำรุงรักษาสะพานSOMYOTNo ratings yet

- เล่ม ชลศาสตร์ ฝายห้วยแม่สลิดDocument35 pagesเล่ม ชลศาสตร์ ฝายห้วยแม่สลิดJay AcousticNo ratings yet

- ค่า kDocument39 pagesค่า kkovo 053No ratings yet

- การสึกร่อนของคอนกรีตและการทดสอบDocument9 pagesการสึกร่อนของคอนกรีตและการทดสอบklairoongNo ratings yet

- f1c42d76-d6c6-4007-a7e8-e84dbe3e4b30Document24 pagesf1c42d76-d6c6-4007-a7e8-e84dbe3e4b30อัชวิน เจริญสินNo ratings yet

- SteelPlateGirder Gnem RVCDocument9 pagesSteelPlateGirder Gnem RVCCe WinNo ratings yet

- 1 Axial July18-07Document43 pages1 Axial July18-07nauew erfweewNo ratings yet

- การใช้งานโปรแกรม NEO RC DESIGN V5Document173 pagesการใช้งานโปรแกรม NEO RC DESIGN V5Life of TharatepNo ratings yet

- การเก็บตัวอย่างลูกปูนDocument11 pagesการเก็บตัวอย่างลูกปูนสันต์ โยธาภูธรNo ratings yet

- หลักเกณฑ์การคำนวณราคากลางงานก่อสร้างDocument65 pagesหลักเกณฑ์การคำนวณราคากลางงานก่อสร้างTOANo ratings yet

- CH 02Document29 pagesCH 02lavyNo ratings yet

- พฤติกรรมทางกลของผนังคอนกรีตบล็อกเสริมเหล็กDocument149 pagesพฤติกรรมทางกลของผนังคอนกรีตบล็อกเสริมเหล็กWinNo ratings yet

- RCSDM 01 IntroductionDocument33 pagesRCSDM 01 IntroductionNattapat Wongnurak /SiteConREG3No ratings yet

- คอนกรีตกำลังสูง วัสดุที่ใช้และปัจจัยที่ควรพิจารณาDocument9 pagesคอนกรีตกำลังสูง วัสดุที่ใช้และปัจจัยที่ควรพิจารณาklairoongNo ratings yet

- Foundation Engineering by DR - Jirayut Suebsuk 04-011-310Document328 pagesFoundation Engineering by DR - Jirayut Suebsuk 04-011-310Jirachai LaohaNo ratings yet

- 01 WeldingDocument128 pages01 WeldingBenjamin RattharojthakunNo ratings yet

- ประสบการณ์และเทคนิคในการก่อสร้างDocument61 pagesประสบการณ์และเทคนิคในการก่อสร้างWatatwork AtworkNo ratings yet

- A05 TorsionDocument11 pagesA05 Torsionthanakit wiwitboonyakornNo ratings yet

- รายการประมาณราคา 2555Document68 pagesรายการประมาณราคา 2555ชยกร แก้วผดุงNo ratings yet

- ผลงานเด่นลำดับที่ 1Document193 pagesผลงานเด่นลำดับที่ 1Suthiwat PromraksaNo ratings yet

- MRT03 - มาตรฐานการตรวจสอบโครงสร้างคอนกรีตเสริมเหล็ก มยผ. 1501-1507 - 51Document86 pagesMRT03 - มาตรฐานการตรวจสอบโครงสร้างคอนกรีตเสริมเหล็ก มยผ. 1501-1507 - 51Watatwork AtworkNo ratings yet

- Circular Stair CalDocument9 pagesCircular Stair Calmongkol_1001No ratings yet

- Ncce 23gteid117Document11 pagesNcce 23gteid117noppadol.ch100% (1)

- guide collar จมบ่อDocument7 pagesguide collar จมบ่อTanako KomoNo ratings yet

- 2439 บทความฉบับสมบูรณ์ 33359 1 10 20230709Document7 pages2439 บทความฉบับสมบูรณ์ 33359 1 10 20230709นพดล ชูคงNo ratings yet

- Thaweesak GTE027 NCCE16 2554Document12 pagesThaweesak GTE027 NCCE16 2554Lamthong LvkNo ratings yet

- Lessons From The CollapseDocument9 pagesLessons From The Collapsemote34No ratings yet

- เล่มออกแบบฝายDocument86 pagesเล่มออกแบบฝายJay AcousticNo ratings yet

- Chomphunut 64120520 Con3Document15 pagesChomphunut 64120520 Con3cpnNo ratings yet

- VCM TechnologyDocument47 pagesVCM TechnologyChatchai ChaninNo ratings yet

- CE7Document231 pagesCE7อัชวิน เจริญสินNo ratings yet

- Influence of Tunnelling Effect On Existing Pile Foundation in Bangkok Subsoil by Finite Element ModelDocument8 pagesInfluence of Tunnelling Effect On Existing Pile Foundation in Bangkok Subsoil by Finite Element ModelBarames VardhanabhutiNo ratings yet

- 09 - ท่อฝังกลบ ท่อลอด ทางลอด และอุโมงค์Document24 pages09 - ท่อฝังกลบ ท่อลอด ทางลอด และอุโมงค์Putthipong HaleerattanawattanaNo ratings yet

- เทคนิคการก่อสร้างฐานรากคอนกรีตขนาดใหญ่ ในงานอาคารสูงDocument16 pagesเทคนิคการก่อสร้างฐานรากคอนกรีตขนาดใหญ่ ในงานอาคารสูงapirakqNo ratings yet

- TSEA Template-01Document29 pagesTSEA Template-01abudabeejajaNo ratings yet

- รายงานการทางDocument18 pagesรายงานการทางweerachai.mNo ratings yet

- PC Joint Beams PaperDocument7 pagesPC Joint Beams PaperdongngoNo ratings yet