Professional Documents

Culture Documents

Taper Grinding

Taper Grinding

Uploaded by

sujai1981Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Taper Grinding

Taper Grinding

Uploaded by

sujai1981Copyright:

Available Formats

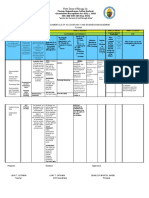

COMBER DETACHING ROLLER COTS TAPER BUFFING

1. First decide how much taper grinding is need for the given diameter of cot. 2. Secondly decide what should be the taper length for given length of cot. 3. The above two factors must be based on model of comber , top arm loading and clearance measured after loading the straight buffed cot on bottom roller . Top loading

Cots buffed without taper buffing

Bowing effect & clearance created

Taper buffed cot l l

FOD

Bowing effect is compensated by taper effect of cot

In the above figure, l is the length of cot to be taper buffed. Normally it would be equal to 1/3rd of the cots total length. Magnitude of Taper grinding (Diameter measured at the centre of cot - Diameter measured at the extreme edge of cot) = 0.10 mm to 0.20 mm. This again depends on model of comber, cots F.O.D & taper grinding length. B.Sujai Sr.Manager - Application Technology & Exports INARCO LTD, 658, Central Studio Compound, TrichyRoad, Singanallur Coimbatore 641005 Office: 0422-2316942, 3 Telefax: 2316954. E mail: products@inarco.com Mobile: +919442633546

You might also like

- Belt Conveyor Pulley Design - Why The FailuresDocument9 pagesBelt Conveyor Pulley Design - Why The FailuresWaris La Joi WakatobiNo ratings yet

- Acute Coronary Syndrome NCP 01Document5 pagesAcute Coronary Syndrome NCP 01AgronaSlaughter0% (1)

- Minimum Pulley Diameters - Fenner DunlopDocument6 pagesMinimum Pulley Diameters - Fenner Dunlopluis martinezNo ratings yet

- Ring Spinning NTPELDocument92 pagesRing Spinning NTPELCraig Martin67% (3)

- RTOS Based Embedded System DesignDocument16 pagesRTOS Based Embedded System DesignSagar DhapkeNo ratings yet

- Spinpact Fine Tuning HandbookDocument10 pagesSpinpact Fine Tuning Handbookselvakumar100% (1)

- Metrology & Instrumentation Course File1Document112 pagesMetrology & Instrumentation Course File1harshith pondeNo ratings yet

- Design and Fabrication of Groundnut Shelling MachineDocument17 pagesDesign and Fabrication of Groundnut Shelling Machinesasi100% (1)

- LRTDocument5 pagesLRTAnish akNo ratings yet

- Tutorial1 Introduction LimitSystemsDocument3 pagesTutorial1 Introduction LimitSystemsSanthosh AmaraNo ratings yet

- Design of Machine Members - I NotesDocument495 pagesDesign of Machine Members - I NotesKrishna MurthyNo ratings yet

- Disclosure To Promote The Right To InformationDocument21 pagesDisclosure To Promote The Right To InformationBrijeshNo ratings yet

- SEKN5047 - Introduction of Ultrasonic Measurement ToolDocument3 pagesSEKN5047 - Introduction of Ultrasonic Measurement ToolMrAlbert2009No ratings yet

- Fundamentals of Machine DesignDocument495 pagesFundamentals of Machine DesignBill MurrayNo ratings yet

- FALLSEM2019-20 MEE2001 ELA VL2019201005431 Reference Material II 12-Jul-2019 Conventional TolerancingDocument22 pagesFALLSEM2019-20 MEE2001 ELA VL2019201005431 Reference Material II 12-Jul-2019 Conventional TolerancingNikhil VermaNo ratings yet

- Design of Machine Elements Sample QuestionsDocument9 pagesDesign of Machine Elements Sample Questionsblogger100% (1)

- Exercise No. 3: Drain Hole Drilling, Rev. 1, 25.10.04Document3 pagesExercise No. 3: Drain Hole Drilling, Rev. 1, 25.10.04SrWilson Z AriasNo ratings yet

- Lecture11 Limit, Fit & Tolerance BETP2503 Sem1 2015-2016 PDFDocument46 pagesLecture11 Limit, Fit & Tolerance BETP2503 Sem1 2015-2016 PDFArecap CoolNo ratings yet

- 5 SegmentDesign WTC2016Document12 pages5 SegmentDesign WTC2016José Luis Rodríguez SánchezNo ratings yet

- Mechanical Measurements Metrology Module 2 3Document171 pagesMechanical Measurements Metrology Module 2 3RanendraRoyNo ratings yet

- Machine DesignDocument495 pagesMachine DesignWalter Zert100% (2)

- Performance Assessment of SFDocument5 pagesPerformance Assessment of SFShital PatilNo ratings yet

- Calculation For Checking The MechanicalDocument6 pagesCalculation For Checking The MechanicalAura RNo ratings yet

- CN Maintenance Practices IIDocument10 pagesCN Maintenance Practices IIavijayakumar_1964No ratings yet

- PE 313 Lab - 1 Wellbore SchematicsDocument5 pagesPE 313 Lab - 1 Wellbore Schematicsjaknpong sangwanpathNo ratings yet

- Design of A Gauge MetrologyDocument8 pagesDesign of A Gauge MetrologyQuality HosurNo ratings yet

- Simplexenhanced 150401131931 Conversion Gate01Document46 pagesSimplexenhanced 150401131931 Conversion Gate01د. م. فادي نقرشNo ratings yet

- Know The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?Document16 pagesKnow The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?ashad100% (1)

- PE 4210 Lab #1 Wellbore SchematicsDocument5 pagesPE 4210 Lab #1 Wellbore SchematicsRichard OwusuNo ratings yet

- Fixtures PDFDocument20 pagesFixtures PDFAbhishek GorkarNo ratings yet

- ITTC - Recommended Procedures: Ship ModelsDocument6 pagesITTC - Recommended Procedures: Ship ModelsKathleen ValdezNo ratings yet

- Information Sheet No10Document15 pagesInformation Sheet No10Kher Bee A. PingolNo ratings yet

- PSC Pole Technical SpecDocument6 pagesPSC Pole Technical Specsakar shresthaNo ratings yet

- Tutorials Printed VersionDocument22 pagesTutorials Printed VersionNjabulo NgobeseNo ratings yet

- Process Parameters in SimplexDocument3 pagesProcess Parameters in SimplexTanvir Alam100% (5)

- Beam Design ThumbruleDocument5 pagesBeam Design ThumbrulehipreyashNo ratings yet

- Estimating Templates ManualDocument43 pagesEstimating Templates ManualAlan MilanNo ratings yet

- Hairiness in YarnDocument8 pagesHairiness in YarnRajesh Dwivedi100% (1)

- CoorsTek StdCapDocument36 pagesCoorsTek StdCapStefan XerriNo ratings yet

- MD Tut PDFDocument6 pagesMD Tut PDFNelsan PatelNo ratings yet

- Design of Machine Members - I NotesDocument495 pagesDesign of Machine Members - I NotesNaveen SuryaNo ratings yet

- PE 4210 Lab #1 Wellbore Schematics MSTDocument5 pagesPE 4210 Lab #1 Wellbore Schematics MSTDilayne SantosNo ratings yet

- Tapers and ScrewDocument7 pagesTapers and Screwstolen mechieducNo ratings yet

- Multiple-Ply Conveyor Belt Splicing Manual - EngDocument24 pagesMultiple-Ply Conveyor Belt Splicing Manual - EngShiena CaparrosNo ratings yet

- K-Factor - SheetMetal PDFDocument2 pagesK-Factor - SheetMetal PDFsunilbholNo ratings yet

- Idler DesignDocument6 pagesIdler DesignVaibhav GuptaNo ratings yet

- Mechanical Engineering Design ProjectDocument20 pagesMechanical Engineering Design ProjectGaming zone and sportsNo ratings yet

- Polybeam Length Calculation in TeklaStructuresDocument6 pagesPolybeam Length Calculation in TeklaStructuresCraciun Paul100% (2)

- Types of Fits: Engineering TolerancingDocument2 pagesTypes of Fits: Engineering TolerancingRandima GajanayakaNo ratings yet

- Wireline Pipe Recovery Considerations in Stuck Drill Pipe SituationsDocument6 pagesWireline Pipe Recovery Considerations in Stuck Drill Pipe Situationsreborn2No ratings yet

- How To Develop A Paste Print Print Process. M03015 - M0201Document20 pagesHow To Develop A Paste Print Print Process. M03015 - M0201jose rodeaNo ratings yet

- Chapter 2Document17 pagesChapter 2Gaurav AgarwalNo ratings yet

- Hot Strip Mill, Slab Sizing Press, Pair Cross Mill, Mill Stabilizing Device, Down CoilerDocument10 pagesHot Strip Mill, Slab Sizing Press, Pair Cross Mill, Mill Stabilizing Device, Down CoilerJJNo ratings yet

- Pile Cap DesignDocument8 pagesPile Cap DesignMuhannad M. Abu AbdoNo ratings yet

- A Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsFrom EverandA Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsRating: 3 out of 5 stars3/5 (1)

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Complete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterFrom EverandComplete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterRating: 3 out of 5 stars3/5 (2)

- Time ManagementDocument19 pagesTime Managementsujai1981No ratings yet

- Itmf Vol 36 2013Document2 pagesItmf Vol 36 2013sujai1981No ratings yet

- List of Brand Names and Compostion of Banned DrugsDocument28 pagesList of Brand Names and Compostion of Banned Drugssujai1981No ratings yet

- Tamil Nadu-Textile PolicyDocument9 pagesTamil Nadu-Textile Policysujai1981No ratings yet

- High Speed Drafting of Textile Material With High Draft Ratio and Its Impact On Cots and Aprons at Ring Spinning MachinesDocument5 pagesHigh Speed Drafting of Textile Material With High Draft Ratio and Its Impact On Cots and Aprons at Ring Spinning Machinessujai1981No ratings yet

- Build An Electronic ElectroscopeDocument2 pagesBuild An Electronic Electroscopesujai1981No ratings yet

- B. Sujai Manager - Application Technology Inarco LTD Email:: AbstractDocument7 pagesB. Sujai Manager - Application Technology Inarco LTD Email:: Abstractsujai1981No ratings yet

- Critical Analysis of Inter Fiber Friction, Role of Top & Bottom Aprons & Drafting ForceDocument6 pagesCritical Analysis of Inter Fiber Friction, Role of Top & Bottom Aprons & Drafting Forcesujai1981No ratings yet

- Table 14: State-Wise Production of Spun Yarn by Textile Mills (Metric Ton Kilogram) States / Union TerritoriesDocument2 pagesTable 14: State-Wise Production of Spun Yarn by Textile Mills (Metric Ton Kilogram) States / Union Territoriessujai1981No ratings yet

- Bhrigu SutramDocument115 pagesBhrigu Sutramsujai1981100% (1)

- Stickness of Cotton and Its Effects On Ring Spinning Process and Quality of YarnDocument12 pagesStickness of Cotton and Its Effects On Ring Spinning Process and Quality of Yarnsujai1981100% (2)

- Tamil Nadu-Textile PolicyDocument9 pagesTamil Nadu-Textile Policysujai1981No ratings yet

- Conductivity of Rubber CotsDocument4 pagesConductivity of Rubber Cotssujai1981No ratings yet

- Money Laundering, Terrorism Financing in NigeriaDocument7 pagesMoney Laundering, Terrorism Financing in NigeriaThe Law Brigade (Journals) PublishersNo ratings yet

- Wordlist Unit 3 PDFDocument3 pagesWordlist Unit 3 PDFYea boyNo ratings yet

- Advanced Baking 1Document61 pagesAdvanced Baking 1Judelmae SisonNo ratings yet

- Circular Motion: American Journal of Physics July 2000Document8 pagesCircular Motion: American Journal of Physics July 2000GurjotNo ratings yet

- ABLRFD v1403 Summary RevisionsDocument2 pagesABLRFD v1403 Summary RevisionsMiguel AngelNo ratings yet

- Top 5 Strumming Patterns OK PDFDocument6 pagesTop 5 Strumming Patterns OK PDFjumpin_around100% (1)

- Notre Dame of Masiag, Inc.: What Formativ e Question S Shall Lead To The Completi On of Efaa? ToDocument2 pagesNotre Dame of Masiag, Inc.: What Formativ e Question S Shall Lead To The Completi On of Efaa? ToLANY T. CATAMINNo ratings yet

- Chapter 10: Virtual Memory: Silberschatz, Galvin and Gagne ©2018 Operating System Concepts - 10 EditionDocument85 pagesChapter 10: Virtual Memory: Silberschatz, Galvin and Gagne ©2018 Operating System Concepts - 10 EditionSuhaib masalhaNo ratings yet

- Class - 8 Chapter - 3 Synthetic Fibres and PlasticsDocument6 pagesClass - 8 Chapter - 3 Synthetic Fibres and Plastics7A04Aditya MayankNo ratings yet

- The Pre-Production Process EvaluationDocument8 pagesThe Pre-Production Process EvaluationMC_Onnell100% (1)

- Group 3 - Strategies For Classroom ManagementDocument25 pagesGroup 3 - Strategies For Classroom ManagementSiti AisyahNo ratings yet

- Iphone DissertationDocument7 pagesIphone DissertationPapersWritingServiceCanada100% (1)

- Nature of Bivariate DataDocument39 pagesNature of Bivariate DataRossel Jane CampilloNo ratings yet

- Coconut: Donesian Export Pro IleDocument39 pagesCoconut: Donesian Export Pro Ile764fqbbnf2No ratings yet

- 322 Dynamic Demographic Characteristic Slum Population in Nashik City With Special Reference From 2011Document6 pages322 Dynamic Demographic Characteristic Slum Population in Nashik City With Special Reference From 2011B-15 Keyur BhanushaliNo ratings yet

- PSS5000-USGU LicenseKey Installation 80558701Document10 pagesPSS5000-USGU LicenseKey Installation 80558701LongNo ratings yet

- About - LUTs Conversion by IWLTBAPDocument5 pagesAbout - LUTs Conversion by IWLTBAPmhkNo ratings yet

- 2021 YISS - INTRODUCTION TO COMPUTER GRAPHICS - Hyunjung KimDocument3 pages2021 YISS - INTRODUCTION TO COMPUTER GRAPHICS - Hyunjung KimFung AlexNo ratings yet

- TFG Miguel SanchezDocument77 pagesTFG Miguel SanchezMazin MursiNo ratings yet

- Tassilipdf PDFDocument33 pagesTassilipdf PDFJustin LoucksNo ratings yet

- Sunil Panda Commerce Classes: Before Exam Practice Questions For Term 2 Boards Accounts-Not For Profit OrganisationDocument3 pagesSunil Panda Commerce Classes: Before Exam Practice Questions For Term 2 Boards Accounts-Not For Profit OrganisationHigi SNo ratings yet

- Pa2200-Series ManualDocument178 pagesPa2200-Series ManualtatfutureNo ratings yet

- Wawa Evolution of Business Process Design PDFDocument35 pagesWawa Evolution of Business Process Design PDFotchmarzNo ratings yet

- JLTR, 02Document8 pagesJLTR, 02Junalyn Villegas FerbesNo ratings yet

- Methods-Time Measurement: MODAPTS Technique. This Technique Was Introduced in 1966 byDocument2 pagesMethods-Time Measurement: MODAPTS Technique. This Technique Was Introduced in 1966 byChisom IkengwuNo ratings yet

- REPORT Multiple DisabilitiesDocument8 pagesREPORT Multiple DisabilitiesIrene FriasNo ratings yet

- 19 8 English+Manual+Rt 3Document249 pages19 8 English+Manual+Rt 3aleba1975No ratings yet

- GMP Checklist Sanitary Facilities and ControlsDocument1 pageGMP Checklist Sanitary Facilities and ControlsATSEDENo ratings yet