Professional Documents

Culture Documents

Saic M 1073

Saic M 1073

Uploaded by

kamvalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic M 1073

Saic M 1073

Uploaded by

kamvalaCopyright:

Available Formats

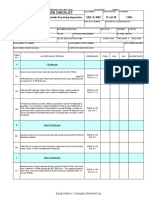

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Structure Installation

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-M-1073

WBS / BI / JO NUMBER

18-May-05

CIVIL-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

General Requirements Connections for secondary structural members (purlins, girts, stair framing, stair treads, stair bracing, toe plate, handrail, ladders, small miscellaneous platforms, stiles, etc.) are bolted with machine bolts conforming to ASTM A307. (PIP STF05520, Para. 4.5) ASTM A307 bolts supplied for secondary structural members are to be limited to sizes 16 mm (5/8 inch) diameter and smaller. (PIP STF05520, Para. 4.5) Bolt holes shall be 1/16" (1 mm) larger than the nominal bolt diameter. For slotted bolt holes, the long direction is perpedicular to the load direction. Enlargement of bolt holes shall be made by reaming or drilling only. Flame cutting, burning, gouging, chipping or drift punching shall not be permitted. (PIP STS05130, Para. 6.7.3) Hardened washers were installed between bolt heads/nuts and the oversized or slotted bolt holes. Galvanized washers and nuts are furnished on galvanized bolts. All bolts, nuts, and washers are properly identified and marked with the material grade and manufacturer's logo. ASTM A307 bolts are tightened to snug-tight condition. (PIP STS05130, Para. 6.5.5) The thickness of gusset and stiffener plates are 10 mm (3/8 inch) minimum. All structural strength welding are continuous with a minimum fillet weld size of 3/16 inch (5 mm).

A1

12-SAMSS-007 Sec. 3.2

A2

12-SAMSS-007 Sec. 3.2 12-SAMSS-007 Para. 6.2.5.11 12-SAMSS-007 Para. 6.2.5.14 12-SAMSS-008 Sec. I 12-SAMSS-007 Para. 6.2.5.15 12-SAMSS-007 Para. 6.2.5.4 12-SAMSS-007 Para. 6.2.5.5 12-SAMSS-008 Sec. I IFC Drawings 12-SAMSS-007 Para. 6.2.6.5 12-SAMSS-007 Para. 6.2.6.9 12-SAMSS-007 Para. 5.1.6.4

A3

A4

A5

A6

A7

A8

A9

A10

A11

The edges of all tightly contacting surfaces of welded structures are A12 completely seal welded with a minimum of 3 mm fillet weld regardless of the base metal thickness. A13 All damaged hot-dip galvanized coating are repaired or touched-up using an organic zinc-rich coating or with SAES-H-101, APCS-26. WALKWAYS and HANDRAILS

B1

Handrails provided on walkways and platforms over 1meter high.

SAES-B-054 Sec. 7 (6.20)

Page 1 of 6

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Structure Installation

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-M-1073

WBS / BI / JO NUMBER

18-May-05

Civil

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Pipe Railing for Walkway and Working Surfaces are 2.4m on center maximum spacing and a maximum of 450mm from corners. (PIP STF05520, Detail Drawing Page 5 of 11) Railings are round structural tubing, cabon steel, Gr B, Std, & 1.9 OD (1.5" NPS). (PIP STF05520, Para. 4.3) Bolts are 5/8" -ASTM A307. (PIP STF05520, Para. 4.5)

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

B2

12-SAMSS-007 Para. 5.4 12-SAMSS-007 Para. 5.4 12-SAMSS-007 Para. 5.4 12-SAMSS-007 Para. 5.4 12-SAMSS-007 Para. 5.4 12-SAMSS-007 Para. 5.4 SAES-B-054 Sec. 7(6.18) SAES-B-054 Sec. 7 12-SAMSS-007 Para. 6.2.1.3 12-SAMSS-007 Para. 6.1.4

B3

B4

B5

All weld joints in top rail are smooth finish. (PIP STF05520, Para. 4.6) Height of top rail is 1050mm from floor line. (PIP STF05520, Detail Drawing Page 5 of 11) Mid-rail installed at 475mm below the top surface of the handrail. (PIP STF05520, Detail Drawing Page 5 of 11) The bending radius of the top handrail shall be 190mm. (Note: Mitered construction is allowed only on removable railing section as shown in PIP STF05520, Detail Drawing Pages 9 & 10 of 11) Rails do not overhang the posts which could pose a projection hazard. Ends of rails are terminated at terminal posts. (ANSI A1264.1, Par. 5.4) Handrails are not connected to fireproofed columns. All open ends of steel pipes or tubing are sealed to prevent internal corrosion. (Note: Vent holes are normally provided for railings that were galvanized and located at the bottom) Exposed corners, edges, burrs or rough spots on handrails, guards, ladders, platforms and stairs, which might cause injury to personnel using the assembled structure, shall be ground or filed smooth. All edges of the walkway are installed so there is no trip hazard.

B6

B7

B8

B9

B10

B11

B12

12-SAMSS-007 Para. 6.1.14 SAES-B-054 Para. 4.6.3 SAES-B-054 Para. 4.6.4 SAES-B-054 Sec. 7 SAES-B-054 Sec. 7 (6.21) SAES-B-054 Sec. 7 (6.22) SAES-B-054 Sec. 7 SAES-B-054 Para. 4.7.1

B13

B14

Dead ends in elevated work areas shall not be over 7.6 m long. Toe boards have minimum height of 3-1/2" (89 mm). (ANSI A1264.1, Para. 5.7) Toe boards are installed on walkways & platforms that are two (2) meter high and over. Toe boards are extended across the first riser at bottom of the stair. Toe boards and mid-rails are seal welded to handrail posts. (ANSI A1264.1, Para. 5.6.1) Minimum clear width of normal walking/surfaces, stairways and stiles shall be 760 mm.

B15

B16

B17

B18

B19

Page 2 of 6

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Structure Installation

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-M-1073

WBS / BI / JO NUMBER

18-May-05

Civil

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

B20

The minimum clear width of walking/surfaces, stairways and stiles shall be 910 mm where working area is needed such as in the front of a manhole for servicing trays, the end of a heat exchanger for servicing the bonnet, channel, and tube bundle, or around rotating equipment. The minimum clear width of aisles shall be 1020 mm. (An aisle is personnel walking space around the equipment at grade level.) The minimum headroom above walking/working surfaces shall be 2030 mm, measured to the lowest point of an overhead obstacle. Non-grating walking surfaces including patterned steel plates shall have a nonskid surface, i.e., anti-skid paint on steel plate (see SAES-H-101, APCS-12). Deck plates and grating around equipment such as pumps, drivers, and compressors shall be removable to allow easy access for maintenance. All removable deck plates and grating shall be held in place with bolts and/or clips Checkered plate flooring with joints perpendicular to the span of the plate flooring shall occur only at supports. The method for fastening grating shall be as specified on the design drawings.

SAES-B-054 Para. 4.7.1(b)

B21

SAES-B-054 Para. 4.7.1(c) SAES-B-054 Para. 4.7.2 SAES-B-054 Para. 4.9.2 SAES-B-054 Para. 4.9.4 SAES-B-054 Para. 4.9.4 12-SAMSS-007 Para. 6.1.18 12-SAMSS-007 Para. 6.1.16

B22

B23

B24

B25

B26

B27

B28

Grating panels are provided with a minimum of 2 fasteners at each support with a minimum of 4 fasteners per panel. 12-SAMSS-007 (Note: Two fasteners, each at approx. 6" from each sides at the ends of Para. 6.1.16 the bearing bar, and one fastener at each intermediate support.--NAAMM MBG 531-00, Page 14) Grating fasteners (Grating clips/hold down bolts) are tight and provide firm anchorage of grating. (NAAMM MBG 531-00, Page 14) Checkered plate have inch (12 mm) diameter drain holes (when specified on contract drawings) provided for each 20 ft (2m) of area, with a minimum of one hole per panel. Grating or checkered plate openings for penetrations dimensioned on the design drawings are cut and banded as shown on the IFC Drawings. Grating material shall be ASTM A1011/A1011M, galvanized per ASTM A123. Grating construction conforms with all of the following a) Rectangular welded type with plain 3/16" x 1-1/4" (5mm x 32mm) bearing bars b) 1-3/16" (30mm) spacing between bearing bars and, c) with cross bars at 4" (100mm) spacing. (Note: When specified, gratings shall conform with the minimum standard sizes specified in NAAMM MBG 531-00, Page 7.) Gratings cut from a standard length are provided with end banding. Grating joints perpendicular to the span of the grating are made only at supports. 12-SAMSS-007 Para. 4.14

B29

B30

12-SAMSS-007 Para. 6.1.19 12-SAMSS-007 Para. 6.1.17 12-SAMSS-007 Para. 4.14

B31

B32

B33

12-SAMSS-007 Para. 4.14

B34

SAES-B-054 Sec. 7, (6.23) 12-SAMSS-007 Para. 6.1.18

B36

Page 3 of 6

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Structure Installation

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-M-1073

WBS / BI / JO NUMBER

18-May-05

Civil

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Bearing surface of grating or grating panels on supports shall be 1" (25mm) minimum for bearing bar depths up to 2-1/4". (NAAMM MBG 531-00, Page 15) Bearing of grating or grating panels on supports shall be 2 " (50mm) for bearing bar depths of 2-1/2" and over. (NAAMM MBG 531-00, Page 15) Grating Span (unsupported distance) does not exceed the span limitations stated in Load Table for Steel Grating of NAAMM MBG 53100. STAIRS Stair treads shall be of steel grating type with an abrasive or checkered plate nosing and galvanized per ASTM A123 and NAAMM MBG 531 & MBG 532. Treads of fixed stairs are installed with a rise of 190 mm and a tread run of 254 mm (Minimum). (Tolerance for Riser: +/-3mm and +/-13mm for bottom step. Refer to Dwg AB-36106 & AC-36198) Height of stair rail is 2'-10" (850 mm) per PIP-STF05520.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

B37

12-SAMSS-007 Para. 4.14 12-SAMSS-007 Para. 4.14 12-SAMSS-007 Para. 4.14

B38

B39

C1

12-SAMSS-007 Para. 4.14

C2

SAES-B-054 Sec. 7 (6.4) SAES-B-054 Sec. 7 (5.5) SAES-B-054 Sec. 7 (6.3) SAES-B-054 Sec. 7 (6.3) SAES-B-054 Sec. 7 (6.9) SAES-B-054 Sec. 7 (6.12) SAES-B-054 Sec. 7 (6.18) AC-36106

C3

C4

Clear width for all stairs except stairs on tanks is 760mm minimum.

C5

Clear width of stairs on tanks is 710mm minimum.

C6

Stairway landing provided every 5m of vertical rise. Vertical clearance above any stair tread to an overhead obstruction shall be at least 2030mm. Bending radius of the top handrail shall be 190mm.

C7

C8

C9

Mid-rail is installed on the handrail and seal welded. Bracing bars (angular 1-1/2" x 1-1/2" x 3/8") installed across bottom of stair stringer at 4'2" spacing per Std. Dwg.AC-36106. Concrete plinth at the bottom of the stair shall have 7-1/2" rise and a leading edge of 12" from the anchor bolt per Detail 2 of Std. Dwg. AC36106. Base of stairs are anchored.

C10

AC-36106

C11

AC-36106

C12

AC-36106

Ladders and Cages A cage, well, or ladder safety system shall be required where the length of climb is more than 6 m or above or below ground level, or above or below a floor or roof with access/egress from ground level, floor, or roof (see Figure 2, ANSI A14.3)."

D1

SAES-B-054 Sec. 8 (4.1.1)

Page 4 of 6

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Structure Installation

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-M-1073

WBS / BI / JO NUMBER

18-May-05

Civil

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Cage or well is installed on ladder where the length of climb is less than 6 meters but the top of the ladder is greater than 6 m above ground level, floor or roof. (ie: ladder is located on elevated platform.) Cage well installed on ladders where the single length of climb is greater than 6 meters but not exceed 15.2m. Safety guard (drop bar) provided on all fixed ladders serving elevations 1.2 meters or more above ground or above existing platform, except on building roof or a loading dock. Detail of Safety guard (Drop Bar) shall ensure that the bar is selfdropping. Ladders shall be of the side-step design, except for ladders on tanks under 3 meter high. Grab bars on ladders are not allowed.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

D2

SAES-B-054 Sec. 8 (4.1.2) SAES-B-054 Sec. 8 (4.1.3) SAES-B-054 Sec. 8 (4.1.7) SAES-B-054 Sec. 8 (4.1.7) SAES-B-054 Sec. 8 (4.1.9) SAES-B-054 Sec. 8 (4.1.11) SAES-B-054 Sec. 8 (5.4.3.4) SAES-B-054 Sec. 8 SAES-B-054 Sec. 8 SAES-B-054 Sec. 8 SAES-B-054 Sec. 8 SAES-B-054 Sec. 8 SAES-B-054 Sec. 8 SAES-B-054 Sec. 8 SAES-B-054 Sec. 8 SAES-B-054 Sec. 8 SAES-B-054 Sec. 8 SAES-B-054 Sec. 8

D3

D4

D5

D6

D7

D8

Side rails and rungs of ladders shall not be used for hangers or supports. Vertical spacing of steps and rungs shall not exceed 12" on centers and shall be uniform in the same length of climb. (ANSI A14.3, Para. 5.1.1) The minimum inside clear width of step surfaces for steps and rungs shall be 16". (ANSI A14.3, Para. 5.1.2) Ladders are welded construction and welds are continuous, smooth and sealed. (PIP STF05501, Para. 3.3) Ladder rungs are 20mm diameter. (ANSI A14.3, Para. 5.1.3.1(3)) Ladder bolts are 5/8" diameter, ASTM A307 bolts. (PIP STF05501, Para. 3.4) Top of rung adjacent to the floor line of the upper platform shall be level with the floor line. (PIP STF05501, Detail Dwg. Page 4 of 9) Side step ladder is extended by at least 4 feet above the upper platform floor line . (PIP STF05501, Detail Dwg. Page 4 of 9) Intermediate supports of ladders shall be provided and not to exceed 10 feet. (PIP STF05501, Detail Dwg. Page 4 of 9) Intermediate platform/rest platform shall be provided at 50ft. maximum per ANSI A14.3, Fig. 5. Intermediate platform/rest platform shall have a minimum space of 30" from the centerline of the ladder on the climbing side and width of not less than 30". (ANSI A14.3, Para. 6.3.2) First bottom rung shall be 1ft above the walking surface. (PIP STF05501, Detail Dwg. Page 4 of 9) Minimum clear space at the back side of ladders is 7" measured from the centerline of rung, or 1-1/2" min. measured from the edge of the side rail for unavoidable obstructions, ie; columns or insulated structures. (PIP STF05501, Detail Dwg. Page 7 and ANSI A14.3, Para. 5.4.2.1)

D9

D10

D11

D12

D13

D14

D15

D16

D17

D18

D19

D20

SAES-B-054 Sec. 8

Page 5 of 6

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Inspection of Structure Installation

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-M-1073

WBS / BI / JO NUMBER

18-May-05

Civil

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Minimum clear space on the sides of ladders is 1'-3" from center line of ladder to each sides. (PIP STF05501, Detail Dwg. Page 7) c) Front : 2'-6" , or 2'-3" if ladder is facing a smooth wall. (PIP STF05501, Detail Dwg. Page 7 and ANSI A14.3, Para. 5.4.3.1) Minimum clear space in front of ladders is 2'-6", or 2'-3" if ladder is facing a smooth wall. (PIP STF05501, Detail Dwg. Page 7 and ANSI A14.3, Para. 5.4.1.1) Ladder rungs shall be drilled through the side rail (stringer), plug welded on the outer side of bar rails, or seal welded on the outer side of channel rails. (PIP STF05501, Detail Dwg. Page 7) Ladder rungs of ladders in high humidity and offshore areas are seal welded on the inner side of the side rails (either bar or channel rails). (Refer to seal welding requirements of SAES-M-001, Para. 7.1.9.3) All structural material for ladders shall be ASTM A36 Steel. (PIP STF05501, Para. 3.2) Vertical bars of the bottom section of ladder cage are extended and bolted to the top of handrails for ladders installed on top of platforms. (PIP STF05501, Detail Drawing Page 6) Centerline of side-step ladder shall be within 1'-3" to 1'-9" from the edge of the platform. This is the step-across distance of the ladder. (PIP STF05501, Detail Drawing Page 7 and ANSI A14.3, Para. 5.4.3.2) Bottom of ladder stringers are anchored. (PIP STF05501, Page 8 of 9)

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

D21

SAES-B-054 Sec. 8

D22

SAES-B-054 Sec. 8

D23

12-SAMSS-007 Par. 5.3

D24

12-SAMSS-007 Par. 5.3 SAES-B-054 Sec. 8 SAES-B-054 Sec. 8

D25

D26

D27

SAES-B-054 Sec. 8 SAES-B-054 Sec. 8

D28

REMARKS:

REFERENCE DOCUMENTS: 1- SAES-M-001 -- Structural Design Criteria for Non-Building Structures, 30 June 2004 2- SAES-B-054 -- Access, Egress, and Materials Handling for Plant Facilities, 31 March 2001 3- 12-SAMSS-007 -- Fabrication of Structural and Miscellaneous Steel, 28 April, 2004 4- 12-SAMSS-008 -- Erection of Structural and Miscellaneous Steel, 28 January 2004 5- SAES-H-001 -- Selection Requirements for Industrial Coatings, 30 October 2002 6- SAES-H-101 -- Approved Protective Coating Systems, 31 August 2003

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 6 of 6

You might also like

- Home Automation SystemDocument18 pagesHome Automation SystemChandrika Dalakoti77% (13)

- Saic A 1004Document2 pagesSaic A 1004Hussain Nasser Al- Nowiesser0% (1)

- Saic Q 1002Document1 pageSaic Q 1002Hussain Nasser Al- NowiesserNo ratings yet

- SAIC-L-2035 Rev 6Document2 pagesSAIC-L-2035 Rev 6biplabpal2009No ratings yet

- Saic Q 1002Document1 pageSaic Q 1002Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 2004Document6 pagesSaic M 2004Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1032Document3 pagesSaic M 1032Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1034Document3 pagesSaic M 1034Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1033Document4 pagesSaic M 1033Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saic M 1072Document5 pagesSaic M 1072Hussain Nasser Al- Nowiesser100% (2)

- Saic M 1025Document4 pagesSaic M 1025Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1060Document1 pageSaic M 1060Hussain Nasser Al- NowiesserNo ratings yet

- Saic o 1001Document1 pageSaic o 1001Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1001Document2 pagesSaic A 1001Vinayak Vaghe100% (1)

- Saic L 1004Document2 pagesSaic L 1004Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Hussain Nasser Al- Nowiesser0% (1)

- Saic Q 1001Document2 pagesSaic Q 1001Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1008Document1 pageSaic M 1008Hussain Nasser Al- NowiesserNo ratings yet

- Saic Q 1006Document2 pagesSaic Q 1006Hussain Nasser Al- Nowiesser100% (1)

- SATIP Q 010 01 Cement Based Non Shrink GroutingDocument2 pagesSATIP Q 010 01 Cement Based Non Shrink GroutingAhmed GamalNo ratings yet

- Saic M 1062Document1 pageSaic M 1062Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1012Document2 pagesSaic M 1012Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1003Document2 pagesSaic A 1003Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1017Document1 pageSaic A 1017jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechmominNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002Sajid ShaikhNo ratings yet

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saic M 1070Document1 pageSaic M 1070Hussain Nasser Al- NowiesserNo ratings yet

- Saic Q 1016Document2 pagesSaic Q 1016Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1053Document1 pageSaic M 1053Hussain Nasser Al- NowiesserNo ratings yet

- Satip Q 001 03Document10 pagesSatip Q 001 03munnaNo ratings yet

- Saic-M-1012 Rev 7 (Final)Document3 pagesSaic-M-1012 Rev 7 (Final)Satheesh Rama SamyNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocument1 pageSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387No ratings yet

- Saic Q 1008Document2 pagesSaic Q 1008Mo'tasem SerdanehNo ratings yet

- Saic Q 1007Document2 pagesSaic Q 1007Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002ansar aliNo ratings yet

- Saic M 1052Document1 pageSaic M 1052Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1004Document2 pagesSaic M 1004Hussain Nasser Al- NowiesserNo ratings yet

- Saic L 1002Document2 pagesSaic L 1002Hussain Nasser Al- NowiesserNo ratings yet

- QMIS LBE Rev Mech Final OldDocument683 pagesQMIS LBE Rev Mech Final OldprabakaranNo ratings yet

- SATIP-Q-001-04 Structural Precast Prestressed ConcreteDocument2 pagesSATIP-Q-001-04 Structural Precast Prestressed ConcreteAbdul HannanNo ratings yet

- Saic B 1002Document3 pagesSaic B 1002jerinNo ratings yet

- Saic M 1047Document1 pageSaic M 1047Hussain Nasser Al- NowiesserNo ratings yet

- SATIP-Q-001-04rev4 (Structural Precast-Prestressed Conc.) PDFDocument2 pagesSATIP-Q-001-04rev4 (Structural Precast-Prestressed Conc.) PDFRamziAhmedNo ratings yet

- Saic Q 1017Document1 pageSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Saic M 2010Document17 pagesSaic M 2010jerinNo ratings yet

- Saic M 1030Document3 pagesSaic M 1030Hussain Nasser Al- NowiesserNo ratings yet

- SAIC-D-2004 Rev 8Document3 pagesSAIC-D-2004 Rev 8Syed ImranNo ratings yet

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechDocument2 pagesSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechAnonymous S9qBDVkyNo ratings yet

- Saic D 2004Document1 pageSaic D 2004Shahzad HussainNo ratings yet

- Saic D 2004Document1 pageSaic D 2004Muhammad Ikram QurashiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistWaleed MedhatNo ratings yet

- Saic-M-1071 Rev 7 (Final)Document2 pagesSaic-M-1071 Rev 7 (Final)ryann mananquilNo ratings yet

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 Mechkarthi51289No ratings yet

- Civil ITPs ChecklistsDocument183 pagesCivil ITPs ChecklistsmunirNo ratings yet

- Saudi Aramco Inspection ChecklistDocument14 pagesSaudi Aramco Inspection Checklistpookkoya thangalNo ratings yet

- Saic M 1069Document2 pagesSaic M 1069Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1032Document2 pagesSaic M 1032noor mohamedazeezNo ratings yet

- Saic M 1002Document2 pagesSaic M 1002Hussain Nasser Al- NowiesserNo ratings yet

- Saic Q 1016Document2 pagesSaic Q 1016Hussain Nasser Al- NowiesserNo ratings yet

- Saic Q 1017Document1 pageSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Saic Q 1008Document2 pagesSaic Q 1008Mo'tasem SerdanehNo ratings yet

- Saic Q 1015Document2 pagesSaic Q 1015Hussain Nasser Al- Nowiesser100% (1)

- Saic Q 1013Document5 pagesSaic Q 1013Hussain Nasser Al- NowiesserNo ratings yet

- Saic Q 1014Document2 pagesSaic Q 1014Hussain Nasser Al- NowiesserNo ratings yet

- Saic Q 1011Document2 pagesSaic Q 1011Hussain Nasser Al- Nowiesser100% (1)

- Saic Q 1017Document1 pageSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Saic Q 1012Document2 pagesSaic Q 1012Hussain Nasser Al- Nowiesser100% (2)

- Saic Q 1017Document1 pageSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Saic Q 1006Document2 pagesSaic Q 1006Hussain Nasser Al- Nowiesser100% (1)

- Saic Q 1017Document1 pageSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Saic Q 1007Document2 pagesSaic Q 1007Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1062Document1 pageSaic M 1062Hussain Nasser Al- NowiesserNo ratings yet

- Saic Q 1017Document1 pageSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Saic o 1004Document1 pageSaic o 1004Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1072Document5 pagesSaic M 1072Hussain Nasser Al- Nowiesser100% (2)

- Saic Q 1004Document2 pagesSaic Q 1004Hussain Nasser Al- Nowiesser100% (1)

- Saic o 1004Document1 pageSaic o 1004Hussain Nasser Al- NowiesserNo ratings yet

- Saic o 1001Document1 pageSaic o 1001Hussain Nasser Al- NowiesserNo ratings yet

- Saic Q 1001Document2 pagesSaic Q 1001Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1069Document2 pagesSaic M 1069Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1067Document2 pagesSaic M 1067Hussain Nasser Al- Nowiesser100% (2)

- Saic M 1070Document1 pageSaic M 1070Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 2021Document6 pagesSaic M 2021Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1065Document2 pagesSaic M 1065Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 2004Document6 pagesSaic M 2004Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1064Document3 pagesSaic M 1064Hussain Nasser Al- NowiesserNo ratings yet

- Saic Q 1017Document1 pageSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- FINAL CONCEPT PAPER Edit 8 PDFDocument10 pagesFINAL CONCEPT PAPER Edit 8 PDFJABUNAN, JOHNREX M.No ratings yet

- Crippled America PDFDocument40 pagesCrippled America PDFGerardo Rogelio Alvarez100% (1)

- Work and IdenityDocument9 pagesWork and IdenityJason A MeteNo ratings yet

- Part 1: Back in The . Century, Kenya Was A More . Society Compared To Today. MenDocument3 pagesPart 1: Back in The . Century, Kenya Was A More . Society Compared To Today. MenthaonguyenwindNo ratings yet

- Report - SharifDocument58 pagesReport - SharifNabilNo ratings yet

- Seiko SLH-2B Instructions ManualDocument4 pagesSeiko SLH-2B Instructions Manualsimpen84No ratings yet

- Tefal Kitchen Machine Users ManualDocument18 pagesTefal Kitchen Machine Users ManualMartinaNo ratings yet

- RCCBDocument3 pagesRCCBsusanth_sukumaranNo ratings yet

- Portable Fire ExtinguisherDocument44 pagesPortable Fire ExtinguisherjohainaNo ratings yet

- Arroyo AdministrationDocument13 pagesArroyo AdministrationAngely Mae MontecalvoNo ratings yet

- Piping SystemsDocument137 pagesPiping SystemsSwapnil KoshtiNo ratings yet

- Old Age Pension VeteranDocument2 pagesOld Age Pension VeteranLADY LYN SANTOSNo ratings yet

- Subjective Tests vs. Objective Tests: Multiple-Choice TestDocument19 pagesSubjective Tests vs. Objective Tests: Multiple-Choice TestMuhammad Hidayatul RifqiNo ratings yet

- PregnylDocument4 pagesPregnylAdina DraghiciNo ratings yet

- OPRKM ETEEAP Data Request As of January 24 2022Document11 pagesOPRKM ETEEAP Data Request As of January 24 2022redNo ratings yet

- ZOOMLION 40T QY40V Tech Specs PDFDocument30 pagesZOOMLION 40T QY40V Tech Specs PDFvikrantathavaleNo ratings yet

- Final Case Based Essay MustafaDocument4 pagesFinal Case Based Essay MustafaMustafa AtakNo ratings yet

- The 7 Levels of Wealth ManualDocument215 pagesThe 7 Levels of Wealth Manualawakejoy89% (18)

- Acquistion of Jaguar Land Rover by Tata MotorsDocument9 pagesAcquistion of Jaguar Land Rover by Tata Motorsajinkya8400No ratings yet

- Final Project Year Phase-2 Report - FormatDocument11 pagesFinal Project Year Phase-2 Report - FormatNikhilGuptaNo ratings yet

- MBM019-1407 Launching of 60Hz Chilled Water Ceiling Cassette MCKE-EW (H) SeriesDocument9 pagesMBM019-1407 Launching of 60Hz Chilled Water Ceiling Cassette MCKE-EW (H) SeriesLeonardo Martinho DobrianskyjNo ratings yet

- Math 3FM3 Fall 2012 Course OutlineDocument2 pagesMath 3FM3 Fall 2012 Course OutlineAngela DaqustNo ratings yet

- Adobe Scan Dec 04, 2021Document9 pagesAdobe Scan Dec 04, 2021AbhjeetNo ratings yet

- Financial Market TextBook (Dragged) 2Document1 pageFinancial Market TextBook (Dragged) 2Nick OoiNo ratings yet

- Measurement of Steam ConsumptionDocument5 pagesMeasurement of Steam ConsumptionkingkakingNo ratings yet

- Control Systems Project ReportDocument18 pagesControl Systems Project Reportayesha amjad100% (2)

- BTBS Tính T + TR NG TDocument12 pagesBTBS Tính T + TR NG Thoangdieulinh0305No ratings yet

- Revit Architecture - FCP Questions & AnswersDocument14 pagesRevit Architecture - FCP Questions & AnswersMohan Kumar100% (1)

- Prototype TutorialDocument451 pagesPrototype TutorialMariela DemarkNo ratings yet