Professional Documents

Culture Documents

Run Out

Run Out

Uploaded by

Mohamed BorhamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Run Out

Run Out

Uploaded by

Mohamed BorhamCopyright:

Available Formats

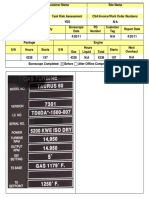

Shaft Radial-Run-Out, Flange Coaxial Run and Plan-Parallelism Tolerances for rotating electrical machinery (Electric Motors)

According ISO, DIN 42 955

Shaft Radial-Run-Out Measurement

The Radial-Run-Out shall be measured at shaft mid point The shaft shall be rotated slowly a full rotation. The dial indicator shall not exceed the specified value see chart below

To ensure a long trouble free Motor / Gearbox operation NUGART USA recommends the Tolerances R !

Shaft Diameter d (mm) 0 to 10 10 to 18 18 to 30 30 to 50 50 to80 80 to 120 120 to 180 180 to 250

Radial Run-Out Tolerances (mm) N-Normal R- Reduced 0.03 0.015 0.035 0.018 0.04 0.021 0.05 0.025 0.06. 0.03 0.07 0.035 0.08 0.04 0.09 0.045

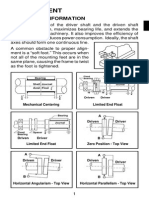

Flange Coaxial Run and Plan-Parallelism

The measuring Dial indicator shall be attached abbot 10 mm from the Flange surface. The shaft shall be rotated slowly a full rotation. The dial indicator shall not exceed the specified value see chart below

To ensure a long trouble free Motor / Gearbox operation NUGART USA recommends the Tolerances R !

Centering (Pilot) Coaxial-Run Measurement

Flange Plan-Parallel-Run Measurement

Flange Centering (Pilot) Diameter B (mm) 0 to 22 22 to 40 40 to 100 100 to 230 230 to 450 450 to 800 800 to 1400

Coax- and Plan Parallel-Run Tolerances (mm) N-Normal R- Reduced 0.05 0.025 0.06 0.03 0.08 0.04 0.1 0.05 0.125 0.063 0.16 0.08 0.2 0.1

You might also like

- Boroscopeo Turbina PDFDocument9 pagesBoroscopeo Turbina PDFegr00No ratings yet

- Rolls Royce Gas Engine of 5.255 MWDocument1 pageRolls Royce Gas Engine of 5.255 MWRashid Mahmood0% (1)

- JCB Generator - Spec 100 KvaDocument3 pagesJCB Generator - Spec 100 KvaDheeraj Yadav0% (1)

- R S O TestDocument5 pagesR S O TestSchubert D'SouzaNo ratings yet

- Windrock 6320 Brochure 2013Document4 pagesWindrock 6320 Brochure 2013Amaury André100% (1)

- Leroy Somer 3 PhaseDocument4 pagesLeroy Somer 3 PhaseAkhmad Ri RifaiNo ratings yet

- Tsi Sap FormatDocument6 pagesTsi Sap FormatmaheshNo ratings yet

- PTC Thermistors Temperature Sensors For Motor Protection and ElectronicsDocument4 pagesPTC Thermistors Temperature Sensors For Motor Protection and ElectronicsPradeep_VashistNo ratings yet

- GT2009 59268Document9 pagesGT2009 59268Mohammad BahreiniNo ratings yet

- 3GAA091002 ASE Ac Motor M2aa90l 2 2kwDocument3 pages3GAA091002 ASE Ac Motor M2aa90l 2 2kwedgarNo ratings yet

- Astm 531Document5 pagesAstm 531JOSEPH REFUERZONo ratings yet

- SM AtexDocument12 pagesSM AtexnelsonacuaNo ratings yet

- Cukurova Power BrochureDocument6 pagesCukurova Power Brochuremay100% (1)

- TTR100 1 DS Us V01Document6 pagesTTR100 1 DS Us V01andyNo ratings yet

- 04 - Appendix A - Scope Service - EMS - Offshore - R2Document26 pages04 - Appendix A - Scope Service - EMS - Offshore - R2Jephthah BalogunNo ratings yet

- Motor SpecsDocument132 pagesMotor SpecsgrezmosNo ratings yet

- Motores Siemens PDFDocument237 pagesMotores Siemens PDFare_reeNo ratings yet

- SR5 Generation Rewind Data - General InformationDocument4 pagesSR5 Generation Rewind Data - General InformationHalit yalçınkayaNo ratings yet

- Flameproof MotorsDocument16 pagesFlameproof MotorsKiran KumarNo ratings yet

- Unsteady Flow Visualisation T Akes The Heat Out of Hot SpotsDocument2 pagesUnsteady Flow Visualisation T Akes The Heat Out of Hot SpotsDeepak Chachra100% (1)

- Spare Bushing Work FilesDocument16 pagesSpare Bushing Work FilesBarry79xNo ratings yet

- Champion - Sparkplugs - en - Toadas RN79G PDFDocument36 pagesChampion - Sparkplugs - en - Toadas RN79G PDFPilar TorquemadaNo ratings yet

- Fact Sheet Til 1292Document2 pagesFact Sheet Til 1292PervimNo ratings yet

- API Standard 612 - Special Purpose Steam Turbines For Petroleum, Chemical, and Gas Industry ServicesDocument1 pageAPI Standard 612 - Special Purpose Steam Turbines For Petroleum, Chemical, and Gas Industry ServicesHamed HamedNo ratings yet

- Asme B133.12-1981Document10 pagesAsme B133.12-1981vijay pawarNo ratings yet

- 3516B Generator Set: Prime Power Caterpillar Engine SpecificationsDocument4 pages3516B Generator Set: Prime Power Caterpillar Engine Specificationsbambang ismailNo ratings yet

- QSK60 G6 PDFDocument2 pagesQSK60 G6 PDFShahzad Ali100% (2)

- 1 Motor 2 eDocument42 pages1 Motor 2 eUsman NasrullahNo ratings yet

- Cat d-81-1 2012 enDocument501 pagesCat d-81-1 2012 enRichard SatNo ratings yet

- Catalog Megger Ttr1000Document6 pagesCatalog Megger Ttr1000leha_pc3No ratings yet

- Standards For Electrical Rotating Machines - DOC2014.02.26.01ENDocument4 pagesStandards For Electrical Rotating Machines - DOC2014.02.26.01ENSaravana KumaranNo ratings yet

- PillerDocument12 pagesPillerEnrique RiberoNo ratings yet

- D81 1 N - 1009 enDocument68 pagesD81 1 N - 1009 enbotondh77No ratings yet

- Catalogo Resina IngleseDocument9 pagesCatalogo Resina IngleseLevi Franco CarvalhoNo ratings yet

- SGT-A20 (Industrial Avon) : Gas TurbineDocument2 pagesSGT-A20 (Industrial Avon) : Gas TurbineEduleofNo ratings yet

- Enclosed Genset Noise Summary - Renatl Product 60Hz: 2000/14/EC 6 Point Data Tests. 1)Document1 pageEnclosed Genset Noise Summary - Renatl Product 60Hz: 2000/14/EC 6 Point Data Tests. 1)Paulo De Tarso PiccininiNo ratings yet

- Iecex Certificate of ConformityDocument6 pagesIecex Certificate of ConformityFrancesco_CNo ratings yet

- As BhelDocument45 pagesAs Bhelshubham agrawalNo ratings yet

- As 4307.1-1995 Rotating Electrical Machines - Repair and Overhaul Low Voltage MachinesDocument8 pagesAs 4307.1-1995 Rotating Electrical Machines - Repair and Overhaul Low Voltage MachinesSAI Global - APACNo ratings yet

- Install Bevel Gears PDFDocument3 pagesInstall Bevel Gears PDFjemanuelvNo ratings yet

- Sgen-3000W Water-Cooled Generator Series: For Gas and Steam Power Applications From 540-1,300 MvaDocument4 pagesSgen-3000W Water-Cooled Generator Series: For Gas and Steam Power Applications From 540-1,300 Mvaasdop1567100% (1)

- Brochure Gas Turbine SGT-300 For Power GenerationDocument4 pagesBrochure Gas Turbine SGT-300 For Power GenerationIvo SilvaNo ratings yet

- Training Session 5: Gas Turbine Repair: by Scott Hastie / Liburdi Turbine ServicesDocument42 pagesTraining Session 5: Gas Turbine Repair: by Scott Hastie / Liburdi Turbine Serviceskp pkNo ratings yet

- SGP750PR PDFDocument4 pagesSGP750PR PDFDipesh100% (1)

- API Rotor BalancingDocument8 pagesAPI Rotor BalancingdevdownNo ratings yet

- Solar Centaur 40 DSDocument2 pagesSolar Centaur 40 DSabuahnfNo ratings yet

- Steam Turbines - TurbotechDocument29 pagesSteam Turbines - TurbotechArjun PatelNo ratings yet

- Figure 1 - Typical FFT Showing Gear MisalignmentDocument4 pagesFigure 1 - Typical FFT Showing Gear MisalignmentDario SesarNo ratings yet

- Chapter 3. Alternator: 1. DescriptionDocument21 pagesChapter 3. Alternator: 1. DescriptionGabriel QuijadaNo ratings yet

- Catalogue Mitsubishi S4K DT65SAGDocument25 pagesCatalogue Mitsubishi S4K DT65SAGhafizan razakNo ratings yet

- Cutler-Hammer Instructions For The Installation, Operation, and Maintenance of TRITON SL 160/200/320/400 Medium Voltage Vacuum Contactors, Model ADocument16 pagesCutler-Hammer Instructions For The Installation, Operation, and Maintenance of TRITON SL 160/200/320/400 Medium Voltage Vacuum Contactors, Model ADiego Lobos100% (1)

- Electric Motors Generators WebDocument8 pagesElectric Motors Generators WebYisus Torres MNo ratings yet

- U18 AA EN 001 N-R 601d 0515 PDFDocument134 pagesU18 AA EN 001 N-R 601d 0515 PDFhaydarNo ratings yet

- 3.1 - Electrical System, Instruments (OCR)Document138 pages3.1 - Electrical System, Instruments (OCR)mnbvqwert100% (1)

- MH pgs0700Document15 pagesMH pgs0700Hamza Nouman100% (1)

- Yamaha Ax-470Document23 pagesYamaha Ax-470faroltekNo ratings yet

- Dial IndicatorDocument27 pagesDial IndicatorAntay KorakotNo ratings yet

- Oriental MotorDocument23 pagesOriental MotorSameer SangvikarNo ratings yet