Professional Documents

Culture Documents

Assignment 9

Assignment 9

Uploaded by

PiNg WanwatanakulOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assignment 9

Assignment 9

Uploaded by

PiNg WanwatanakulCopyright:

Available Formats

Engineering Economy 255330

Assignment 9

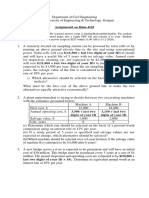

Chapter 11 Replacement and retention decisions. Due Date: 11.7 A machine purchased 1 year ago for $85,000 costs more to operate than anticipated. When purchased, the machine was expected to be used for 10 years with annual maintenance costs of $22,000 and a $10,000 salvage value. However, last year, it cost the company $35,000 to maintain it, and these costs are expected to escalate to $36,500 this year and increase by $1,500 each year thereafter. The salvage value is now estimated to be $85,000-$10,000k, where k is the number of years since the machine was purchased. It is now estimated that this machine will be useful for a maximum of 5 more years. Determine the values of P, AOC, n, and S for a replacement study performed now.. (P= $75,000 , AOC= $36,500 + 1,500k (k=1 to 5) , n=5 years ,S= $25,000) 11.13 A piece of equipment has a first cost of $150,000, a maximum useful life of 7 years, and a salvage value described by S = 120,000 20,000k, where k is the number of years since it was purchased. The salvage value does not go below zero. The AOC series is estimated using AOC = 60,000 + 10,000k. The interest rate is 15% per year. Determine the economic service life (a) by hand solution, using regular AW computations, and (b) by computer, using annual marginal cost estimates. ( ESL = 3 years with AW3 = $-127,489) 11.22 Five years ago, the Nuyork Port Authority purchased several containerized transport vehicles for $350,000 each. Last year a replacement study was performed with the decision to retain the vehicles for 2 more years. However, this year the situation has changed in that each transport vehicle is estimate to have a value of only $8,000 now. If they are kept in service, upgrading at a cost of $50,000 will make them useful for up 2 more years. Operating cost is expected to be $10,000 the first year and $15,000 the second year, with no selvage value at all. Alternatively, the company can purchase a new vehicle with an ESL of 7 years, no salvage value, and an equivalent annual cost of $-55,540 per year. The MARR is 10% per year. If the budget to upgrade the current vehicles is available this year, use these estimates to determine (a) when the company should replace the upgraded vehicles and (b) the minimum future salvage value of a new vehicle necessary to indicate that purchasing now is economically advantageous to upgrading. ((a) The defender ESL is 2 years with AWD = $-45,800; therefore keep the current vehicles for 2 more years. (b) S = -9740/0.10541 = $92,401)

11.28

Three years ago. Mercy Hospital significantly improved its hyperbaric oxygen (HBO) therapy equipment for advanced treatment of problem wounds, chronic bone infections, and radiation injury. The equipment cost $275,000 then and can be used for up to 3 years more. If the HBO system is replaced now, the hospital can realize $20,000. If retained, the market values and operating costs tabulated are estimated. A new system, made of a composite material, is cheaper to purchase initially at $150,000 and cheaper to operate during its initial years. It has a maximum life of 6 years, but market values and AOC change significantly after 3 years of use due to the projected deterioration of the composite material used in construction. Additionally, a recurring cost of $40,000 per year to inspect and rework the composite material is anticipated after 4 years of used. Market values, operating cost, and material rework estimates are tabulated. On the basis of these estimates and i= 15% per year, what are the ESL and AW values for the defender and challenger, and in what year should the current HBO system be replaced? Work this problem by hand.(See Problems 11.29 and 11.31 for more questions using these estimates.) (Keep the defender 1 more year at AWD= $-63,000, then replace for 4 years at AWC=$-66,844)

year 1 2 3 4 5 6 Current HBO System market AOC, $ value, $ 10,000 -50,000 6,000 -60,000 2,000 -70,000 Proposed HBO System Market AOC, $ Material Value, $ Rework, $ 65,000 -10,000 45,000 -14,000 25,000 -18,000 5,000 -22,000 0 -26,000 -40,000 0 -30,000 -40,000

11.35 A machine that was purchased 3 years ago for $140,000 is now to slow to satisfy increased demand. The machine can be upgraded now for $70,000 or sold to a smaller company for $40,000. The current machine will have an annual operating cost of $85,000 per year. If upgraded, the presently owned machine will be kept in service for only 3 more years, then replaced with a machine that will be used in the manufacture of several other product lines. This replacement machine, which will serve the company now and for at least 8 years, will cost $220,000. Its salvage value will be $50,000 for years 1 through 5; $20,000 after 6 years; and $10,000 thereafter. It will have an estimated operating cost of $65,000 per year. The company asks you to perform an economic analysis at 20% per year, using a 5-year time horizon. Should the company replace the presently owned machine now, or do it 3 years from now? What are the AW values? (Replacement the defender with the challenger now.)

You might also like

- Diseño y Fabricación de Hologramas Con MatlabDocument273 pagesDiseño y Fabricación de Hologramas Con MatlabEder Manuel Alfaro Alfaro estNo ratings yet

- Ekotek - Alfiano Fuadi5Document40 pagesEkotek - Alfiano Fuadi5Alfiano Fuadi100% (2)

- Solution - Depreciation and Tax Review ProblemsDocument7 pagesSolution - Depreciation and Tax Review ProblemsNhuNgocHuynh100% (3)

- Home Assignment - 1Document2 pagesHome Assignment - 1Pankaj kumarNo ratings yet

- Seem 2440A/B - Engineering Economics First Term (2011 - 2012)Document3 pagesSeem 2440A/B - Engineering Economics First Term (2011 - 2012)Sun KelvinNo ratings yet

- CFD ExercisesDocument6 pagesCFD ExercisesJohn Paul CristobalNo ratings yet

- Test 14Document7 pagesTest 14Zoloft Zithromax ProzacNo ratings yet

- Runner Design Guide Lines-Issue 5Document15 pagesRunner Design Guide Lines-Issue 5sivanandp100% (1)

- Fortress Square MallDocument5 pagesFortress Square MallUmair Hassan100% (3)

- Week 12 HomeworkDocument2 pagesWeek 12 HomeworkMichael Clark0% (1)

- MEC210 Assignment#4 241Document3 pagesMEC210 Assignment#4 241Mohamed Gamal100% (1)

- Annual Worth, Capitalized, RorDocument11 pagesAnnual Worth, Capitalized, RorNaveen KumarNo ratings yet

- Economics Tutorial-Sheet-2Document3 pagesEconomics Tutorial-Sheet-2Saburo SahibNo ratings yet

- Replacement Analysis: SolutionDocument10 pagesReplacement Analysis: Solutionthawatchai112225120% (1)

- Soal Ekotak Chapter 6 PDFDocument6 pagesSoal Ekotak Chapter 6 PDFSanti MarianaNo ratings yet

- Assignment 4Document4 pagesAssignment 4PrashanthRameshNo ratings yet

- BT Lựa Chọn Dự Án EDocument2 pagesBT Lựa Chọn Dự Án EstormspiritlcNo ratings yet

- 7 Problems On Investment Analysis V 1646203039086Document1 page7 Problems On Investment Analysis V 1646203039086Risshi AgrawalNo ratings yet

- Eceecon Problem Set 2Document8 pagesEceecon Problem Set 2Jervin JamillaNo ratings yet

- 6.1 Present Worth AnalysisDocument26 pages6.1 Present Worth AnalysisNur Aniem0% (2)

- EE Assignments 2016Document8 pagesEE Assignments 2016manojNo ratings yet

- Study Set 5Document8 pagesStudy Set 5slnyzclrNo ratings yet

- Pteroleum Economy Exercise - DepreciationDocument31 pagesPteroleum Economy Exercise - Depreciationshaziera omarNo ratings yet

- En Econ - Replacement and Retention DecisionDocument11 pagesEn Econ - Replacement and Retention DecisionMoshi JungkasemsukNo ratings yet

- Applied Science University: Faculty of Engineering Mechanical and Industrial EngineeringDocument6 pagesApplied Science University: Faculty of Engineering Mechanical and Industrial EngineeringMahmoud AlswaitiNo ratings yet

- Decisions Under CertaintyDocument23 pagesDecisions Under CertaintyJom Ancheta Bautista100% (1)

- Sheet 7Document2 pagesSheet 7Amany SobhyNo ratings yet

- Engineering Economy AssignmentDocument1 pageEngineering Economy Assignmentprateekagrawal812004No ratings yet

- EE Assignment 1-5 PDFDocument6 pagesEE Assignment 1-5 PDFShubhekshaJalanNo ratings yet

- EEM - Assignment 2 During QuaramtineDocument2 pagesEEM - Assignment 2 During Quaramtineshreya mishraNo ratings yet

- Assignment 5Document2 pagesAssignment 5Chalermchai New KawinNo ratings yet

- EM Final Paper Assingment EE GCU S18Document4 pagesEM Final Paper Assingment EE GCU S18KhanNo ratings yet

- Chapter 8Document15 pagesChapter 8GOD100% (1)

- ENGR301 Exam Practice Questions2 Winter 2013Document1 pageENGR301 Exam Practice Questions2 Winter 2013Jonathan RuizNo ratings yet

- Engineering Economy 16th Edition Sullivan Test Bank DownloadDocument13 pagesEngineering Economy 16th Edition Sullivan Test Bank DownloadBrett Falcon100% (15)

- CH #3 NumericalsDocument3 pagesCH #3 NumericalsMs Noor ul AinNo ratings yet

- Engineering Economics and Finacial Management (HUM 3051)Document5 pagesEngineering Economics and Finacial Management (HUM 3051)uday KiranNo ratings yet

- Engineering Economy 16th Edition Sullivan Test Bank instant download all chapterDocument31 pagesEngineering Economy 16th Edition Sullivan Test Bank instant download all chaptertimmiesejjad86100% (7)

- Practice Problems 2Document7 pagesPractice Problems 2Emily Simpson0% (1)

- Tutorial 8 Time Value Money 2021Document8 pagesTutorial 8 Time Value Money 2021Hai Liang OngNo ratings yet

- 2 Prod Assignment 5Document2 pages2 Prod Assignment 5Mohamed GamalNo ratings yet

- Engineering Economy 16th Edition Sullivan Test BankDocument5 pagesEngineering Economy 16th Edition Sullivan Test BankDanielThomasxjfoq100% (15)

- Engineering Economics and Finacial Management (HUM 3051) Jul 2022Document6 pagesEngineering Economics and Finacial Management (HUM 3051) Jul 2022uday KiranNo ratings yet

- Corporate Finance AssignmentDocument2 pagesCorporate Finance AssignmentAsad razaNo ratings yet

- Assignment5 1st MechanicalDocument3 pagesAssignment5 1st Mechanicallapepeng2067No ratings yet

- Chapter 5 - Replacement AnalysisDocument29 pagesChapter 5 - Replacement AnalysisUpendra ReddyNo ratings yet

- Lecture 3Document11 pagesLecture 3Awil MohamedNo ratings yet

- 2nd Assignment 2021Document3 pages2nd Assignment 2021No NameNo ratings yet

- Assignment 5 (Economics Exercises)Document5 pagesAssignment 5 (Economics Exercises)OlyvianurmaharaniNo ratings yet

- Instant Download PDF Engineering Economy 16th Edition Sullivan Test Bank Full ChapterDocument31 pagesInstant Download PDF Engineering Economy 16th Edition Sullivan Test Bank Full Chaptertrkyrawasy100% (9)

- Cash Flows-Capbud PDFDocument2 pagesCash Flows-Capbud PDFErjohn PapaNo ratings yet

- HomeWork Slide 7Document5 pagesHomeWork Slide 7Anisa Fitriani0% (1)

- Assignment1 On Hum-4103: Must Ensure The Scanned Answer Script Is Intelligible/readable/legible. The StudentDocument1 pageAssignment1 On Hum-4103: Must Ensure The Scanned Answer Script Is Intelligible/readable/legible. The StudentMd Mithu MiahNo ratings yet

- Eefm ProblemsDocument4 pagesEefm ProblemsChitrala DhruvNo ratings yet

- Economics For Engineers Model QuestionsDocument16 pagesEconomics For Engineers Model QuestionsNaman KumarNo ratings yet

- Chapter 3 - Replacement Analysis-1Document28 pagesChapter 3 - Replacement Analysis-1VENKATA SAI KRISHNA YAGANTINo ratings yet

- Engineering Economy 16th Edition Sullivan Test BankDocument36 pagesEngineering Economy 16th Edition Sullivan Test Bankfoxysolon8cfh5100% (26)

- Dwnload Full Engineering Economy 16th Edition Sullivan Test Bank PDFDocument36 pagesDwnload Full Engineering Economy 16th Edition Sullivan Test Bank PDFserenafinnodx100% (18)

- Process Economics: Dr. Farrukh JamilDocument35 pagesProcess Economics: Dr. Farrukh JamilHadia SAULATNo ratings yet

- Assignment 2Document2 pagesAssignment 2Parth ShahNo ratings yet

- Test Bank For Engineering Economy 16th Edition by Sullivan Wicks Koelling ISBN 0133439275 9780133439274Document35 pagesTest Bank For Engineering Economy 16th Edition by Sullivan Wicks Koelling ISBN 0133439275 9780133439274AshleyParksegn100% (30)

- Microsoft Excel-Based Tool Kit for Planning Hybrid Energy Systems: A User GuideFrom EverandMicrosoft Excel-Based Tool Kit for Planning Hybrid Energy Systems: A User GuideNo ratings yet

- Energy Storage in Grids with High Penetration of Variable GenerationFrom EverandEnergy Storage in Grids with High Penetration of Variable GenerationNo ratings yet

- Studio 8Document3 pagesStudio 8api-609099270No ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 09P702-0005-F1Document21 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 09P702-0005-F1lyndondrNo ratings yet

- Demand Forecasting and Estimating Methods ProblemsDocument22 pagesDemand Forecasting and Estimating Methods ProblemsNagarjuna ReddyNo ratings yet

- 2021 Book SustainableLandManagementInAEuDocument344 pages2021 Book SustainableLandManagementInAEuEdson Ricardo Amaya SilvaNo ratings yet

- Boulanger and BeatyDocument13 pagesBoulanger and BeatySarah WilliamsNo ratings yet

- Form 0NE PDFDocument3 pagesForm 0NE PDFAlphonsius WongNo ratings yet

- 4 File PDFDocument89 pages4 File PDFGifson MuntheNo ratings yet

- Turboexpander: o o o o oDocument7 pagesTurboexpander: o o o o oYoesuf DecipherNo ratings yet

- NN ST661 (CPH)Document42 pagesNN ST661 (CPH)Patrice PaulNo ratings yet

- Basic Circuit Laws: Georg Ohm Kirchhoff's LawsDocument4 pagesBasic Circuit Laws: Georg Ohm Kirchhoff's LawsrezhabloNo ratings yet

- 5WG1527 1AB41 Siemens PDFDocument2 pages5WG1527 1AB41 Siemens PDFsamim_khNo ratings yet

- VIBu Introduction Bio Counter 06 - 2012Document11 pagesVIBu Introduction Bio Counter 06 - 2012Asuka Q. QinNo ratings yet

- Global Problem AMR-NAP - EATDocument32 pagesGlobal Problem AMR-NAP - EATWolfy D Harold100% (1)

- CSB02 CSE02 CSH02 CDB02 Project Planning R911338962 - 03Document146 pagesCSB02 CSE02 CSH02 CDB02 Project Planning R911338962 - 03DylanNo ratings yet

- IAMSARDocument9 pagesIAMSARDivyanshu SharmaNo ratings yet

- Neural Networks ExamDocument3 pagesNeural Networks Examfruit1991No ratings yet

- Torr and Li 1993 Gravitoelectric-Electric CouplingDocument13 pagesTorr and Li 1993 Gravitoelectric-Electric Couplingjmulder1No ratings yet

- Evs Project & SeminarDocument21 pagesEvs Project & Seminarpratibhaawari01No ratings yet

- Jepson Manual of Vascular Plants PDFDocument31 pagesJepson Manual of Vascular Plants PDFXochilt MoralesNo ratings yet

- Chapter 3 - Cropping SystemsDocument35 pagesChapter 3 - Cropping SystemsAbdi KhadarNo ratings yet

- MG311 TUTORIAL - Statistics - 2016Document1 pageMG311 TUTORIAL - Statistics - 2016TetzNo ratings yet

- Hall - Panikkar Trusting The OtherDocument23 pagesHall - Panikkar Trusting The OtherOscar Emilio Rodríguez CoronadoNo ratings yet

- Foxboro Evo™ Process Automation System: Product SpecificationsDocument12 pagesFoxboro Evo™ Process Automation System: Product SpecificationsSukdeb MaityNo ratings yet

- Diagnostic Testing Strategies To Manage COVID-19 Pandemic: Position PaperDocument4 pagesDiagnostic Testing Strategies To Manage COVID-19 Pandemic: Position PaperMia FernandezNo ratings yet

- Project Completion Report For Eco-Agric UgandaDocument19 pagesProject Completion Report For Eco-Agric UgandajnakakandeNo ratings yet

- MEO Class 2 Orals Function 4 & 6 Q & ADocument8 pagesMEO Class 2 Orals Function 4 & 6 Q & Aneeraj118578% (9)

- Observation Report: Analytical ChemistryDocument8 pagesObservation Report: Analytical ChemistryLindsay BulgerNo ratings yet