Professional Documents

Culture Documents

Planning Calendar Scheduling Forward Scheduling Backward Scheduling

Planning Calendar Scheduling Forward Scheduling Backward Scheduling

Uploaded by

riyadh al kamalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Planning Calendar Scheduling Forward Scheduling Backward Scheduling

Planning Calendar Scheduling Forward Scheduling Backward Scheduling

Uploaded by

riyadh al kamalCopyright:

Available Formats

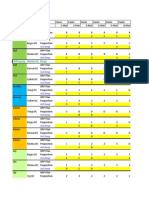

Specific to Plants Scheduling In House Production

SD

Planning Calendar

Scheduling External Procurement

Scheduling

Forward Scheduling BackWard Scheduling

Demand Management

Material Master Plant level Storage Location Level Safety Stock Stock in Transfer Blocked Stock Restricted Use Stock Subcontracted Stock Inspection Stock Purchase Orders Purchase Requisitions Dependent Requirements Reservations Sales Orders Delivery Notes Shipping Notifications Dependent Reservations Call Requirements Production Orders Planned Orders Checking Rule Checking Group Receipt or Issue Elements Determining the Valid BOM Determining the Valid BOM Items Calculating the Dependent Requirements Date Total Requirements Shortage Location Determination in BOM Explosion Subcontracting Direct Production Direct Procurement Storage Location MRP Plant MRP Area MRP Area MRP Areas for Storage Locations MRP Areas for Subcontractors Multi-Plant Site Planning Stock Transfer From Plant to Plant Stocks BOM In House Production Work Centers Routings

Depends Upon

May Need SD

Demand Management

MRP

Planning Levels Can be Excluded Availability Check Procurement Proposal

Plant Level MRP Area Level Determining Source of Supply Quota Arrangement Make to Order Production

Scope of Check

Planning Run

Special Planning Process

Requirements Grouping for Individual Project Plans

You might also like

- Cast Iron BL 1Document3 pagesCast Iron BL 1riyadh al kamal100% (1)

- Manufacturing ERP Requirements TemplateDocument7 pagesManufacturing ERP Requirements TemplateAlaNo ratings yet

- Written Test: Unit Code: - SITXINV002 Unit Name: - Maintain The Quality of Perishable ItemsDocument18 pagesWritten Test: Unit Code: - SITXINV002 Unit Name: - Maintain The Quality of Perishable Itemssandeep kesarNo ratings yet

- Manufacturing ERP Requirements TemplateDocument7 pagesManufacturing ERP Requirements TemplateAlaNo ratings yet

- Done Set 5Document35 pagesDone Set 5Vaibhav SarateNo ratings yet

- Industry Report - E-Commerce in Mexico 2020Document89 pagesIndustry Report - E-Commerce in Mexico 2020Anita GomezNo ratings yet

- Technical StrategiesDocument11 pagesTechnical StrategiesJAVED PATELNo ratings yet

- Sap Production PlanningDocument100 pagesSap Production PlanningHuy Nguyen83% (6)

- SAP MRP - Materials Requirements PlanningDocument58 pagesSAP MRP - Materials Requirements Planningterrific104100% (2)

- Factory CalendarDocument4 pagesFactory Calendarsandeep prajapatiNo ratings yet

- SAP Overview: Sap PP (Production Planning) Course ContentsDocument4 pagesSAP Overview: Sap PP (Production Planning) Course ContentsShahilSinghNo ratings yet

- PP Configuration Steps: Area ActivityDocument4 pagesPP Configuration Steps: Area ActivityBhattahcarjee RupakNo ratings yet

- Sap PPDocument155 pagesSap PPSridhar Allenki100% (1)

- Roadmap For SAP Production PlanningDocument4 pagesRoadmap For SAP Production PlanningJePee GroupNo ratings yet

- Material Management Presentation (New 1)Document73 pagesMaterial Management Presentation (New 1)Prabhu RavindranNo ratings yet

- MM Module: - IntroductionDocument10 pagesMM Module: - IntroductionSachin DewanganNo ratings yet

- Classification: Characteristics Freely DefinableDocument6 pagesClassification: Characteristics Freely Definablemayur_lanjewarNo ratings yet

- My Preparation TopicsDocument10 pagesMy Preparation TopicsGokulNo ratings yet

- Master Task SCM FusionDocument30 pagesMaster Task SCM Fusionazw3adfuNo ratings yet

- Submitted To: Submitted By:: Sachin Kumar Vishal Kumar & RajdeepDocument33 pagesSubmitted To: Submitted By:: Sachin Kumar Vishal Kumar & Rajdeepvishakh kumar srivastavaNo ratings yet

- SAP MM Overview & Course ContentDocument5 pagesSAP MM Overview & Course ContentVasavi AcuteSoftNo ratings yet

- 12 MRPDocument26 pages12 MRPOscar Jimenez CarazoNo ratings yet

- Spare Parts Management With SAPDocument47 pagesSpare Parts Management With SAPamerican7404No ratings yet

- Slide Title: Item Master/Branch PlantDocument14 pagesSlide Title: Item Master/Branch PlantTechno HealthNo ratings yet

- SAP Production Planning: A Workshop That Provides An Overview of The SAP R/3 Production Planning (PP) ModuleDocument177 pagesSAP Production Planning: A Workshop That Provides An Overview of The SAP R/3 Production Planning (PP) ModuleShaffiullahNo ratings yet

- Introduction To Sap MMDocument4 pagesIntroduction To Sap MMRamaKrishna ErrojuNo ratings yet

- Material Requirment Planning: An Operation Management TechniqueDocument24 pagesMaterial Requirment Planning: An Operation Management TechniqueUsman BhattiNo ratings yet

- MRP & ErpDocument7 pagesMRP & ErpAbdAllah KhodaryNo ratings yet

- MRP & ErpDocument7 pagesMRP & ErpAbdAllah KhodaryNo ratings yet

- SAP PP ContentDocument7 pagesSAP PP Contentsrinivas raoNo ratings yet

- Chapter 12: Learning Objectives You Should Be Able ToDocument12 pagesChapter 12: Learning Objectives You Should Be Able ToGeejopNo ratings yet

- Sap PP SyllabusDocument4 pagesSap PP SyllabusZaheer AhamedNo ratings yet

- ECO - 01 - Planning, Execution, and Control OverviewDocument5 pagesECO - 01 - Planning, Execution, and Control Overviewscribd1904No ratings yet

- Routing Is A Sequence of Operations Necessary To Be Performed inDocument2 pagesRouting Is A Sequence of Operations Necessary To Be Performed inSiva Sankar MohapatraNo ratings yet

- Group 9 PPT - Material Requirements Planning (MRP) - CompressedDocument62 pagesGroup 9 PPT - Material Requirements Planning (MRP) - Compressed32MJI Made Angga Dwipaguna MudithaNo ratings yet

- Material Requirements Planning (MRP)Document11 pagesMaterial Requirements Planning (MRP)ajeng.saraswatiNo ratings yet

- Key Audit Areas in Manufacturing CompanyDocument6 pagesKey Audit Areas in Manufacturing CompanyRanjan KhandelwalNo ratings yet

- Sap PP PDFDocument130 pagesSap PP PDFzramuk3No ratings yet

- SapppDocument13 pagesSapppMadhushika WijesekaraNo ratings yet

- Actual Consumption: Get The Basics Right - Industrial PerformanceDocument10 pagesActual Consumption: Get The Basics Right - Industrial PerformanceFernando AFNo ratings yet

- Sap MM SyllabusDocument2 pagesSap MM Syllabussambitk11No ratings yet

- Procurement OperationDocument38 pagesProcurement OperationMuhammad HasnainNo ratings yet

- MM Course Content ConsultantDocument3 pagesMM Course Content ConsultantSupriyo DuttaNo ratings yet

- E2E STO Knowledge Share 11-19-2007Document118 pagesE2E STO Knowledge Share 11-19-2007isabshireenNo ratings yet

- MRP PPDocument28 pagesMRP PPbalu4indiansNo ratings yet

- Discrete Manufacturing - The Made To Order Cycle and Make TO Stock CycleDocument3 pagesDiscrete Manufacturing - The Made To Order Cycle and Make TO Stock Cyclealbertoca990No ratings yet

- Sap PP BADIDocument2 pagesSap PP BADIKRISHNANo ratings yet

- Apttsoft: Delivering Quality SolutionDocument5 pagesApttsoft: Delivering Quality SolutionkalurfrndNo ratings yet

- SevenMentor SAP MM SyllabusDocument4 pagesSevenMentor SAP MM SyllabusSenthil kumar TNo ratings yet

- Sap PP Tutorials - GuruDocument97 pagesSap PP Tutorials - GuruKishor Kolhe100% (1)

- Supply Chain Management Fastforward Flows: Don Klaiss Mark IsraelsenDocument40 pagesSupply Chain Management Fastforward Flows: Don Klaiss Mark IsraelsensjfdhdshsNo ratings yet

- FI Configuration Check ResponsibleDocument6 pagesFI Configuration Check ResponsibleBhuvaneswaran KannaiyanNo ratings yet

- Material Requirement Planning (MRP)Document21 pagesMaterial Requirement Planning (MRP)naveenNo ratings yet

- SAP PP - IntroductionDocument8 pagesSAP PP - IntroductionKoustubha KhareNo ratings yet

- Customer-Anchored Supply Chains: An Executive’S Guide to Building Competitive Advantage in the Oil PatchFrom EverandCustomer-Anchored Supply Chains: An Executive’S Guide to Building Competitive Advantage in the Oil PatchNo ratings yet

- Book 6Document1 pageBook 6riyadh al kamalNo ratings yet

- Barisal Total 8% Chittagong Total 29% Dhaka Total 33% Mymensing 2% Khulna Total 13% Rajshahi Total 8% Rangpur 4% Sylhet Total 3%Document1 pageBarisal Total 8% Chittagong Total 29% Dhaka Total 33% Mymensing 2% Khulna Total 13% Rajshahi Total 8% Rangpur 4% Sylhet Total 3%riyadh al kamalNo ratings yet

- SL No. Division Year 1 Year 2 Market Sales RatioDocument4 pagesSL No. Division Year 1 Year 2 Market Sales Ratioriyadh al kamalNo ratings yet

- Findings - Gas FortuneDocument4 pagesFindings - Gas Fortuneriyadh al kamalNo ratings yet

- Job ProfileDocument2 pagesJob Profileriyadh al kamalNo ratings yet

- ADL TR CostDocument1 pageADL TR Costriyadh al kamalNo ratings yet

- Information About The PropertyDocument8 pagesInformation About The Propertyriyadh al kamalNo ratings yet

- Technical Data Sheet Precipited Calcium Carbonate: (PCC) Product Code CMT-P 300Document1 pageTechnical Data Sheet Precipited Calcium Carbonate: (PCC) Product Code CMT-P 300riyadh al kamalNo ratings yet

- Specification: Standard Mode of DeliveryDocument1 pageSpecification: Standard Mode of Deliveryriyadh al kamalNo ratings yet

- Category Volume at KG Value at Taka: Total 25,979,353 1,655,212,476Document5 pagesCategory Volume at KG Value at Taka: Total 25,979,353 1,655,212,476riyadh al kamalNo ratings yet

- Registration Form For Electronic Trader Order Management SystemDocument1 pageRegistration Form For Electronic Trader Order Management Systemriyadh al kamalNo ratings yet

- Plan Vs Despatch-210313.xlsxbbbbbbbbbbbbbbbbbbbbDocument6 pagesPlan Vs Despatch-210313.xlsxbbbbbbbbbbbbbbbbbbbbriyadh al kamalNo ratings yet

- VsaDocument3 pagesVsariyadh al kamalNo ratings yet

- Pob NotesDocument122 pagesPob NotesFarel ThompsonNo ratings yet

- Pipe SupportsDocument1 pagePipe SupportsChancedaniels EmunaNo ratings yet

- SOSC 3040 ExamDocument3 pagesSOSC 3040 Examshak najakNo ratings yet

- PRICE CHART PATTERN TRADING Trading With Flag, Pennant, Wedge, Double Top, Triangle, Symmetrical Channel, Spike, Gap, Tower,... (Salvon, Derek)Document68 pagesPRICE CHART PATTERN TRADING Trading With Flag, Pennant, Wedge, Double Top, Triangle, Symmetrical Channel, Spike, Gap, Tower,... (Salvon, Derek)HotakoNo ratings yet

- An Introduction To CCAR: Comprehensive Capital Analysis & Review (CCAR)Document10 pagesAn Introduction To CCAR: Comprehensive Capital Analysis & Review (CCAR)Chun Kit ChanNo ratings yet

- The GIC Weekly: Waitin' On The FedDocument14 pagesThe GIC Weekly: Waitin' On The FedIgor MartinsNo ratings yet

- Time Value of MoneyDocument28 pagesTime Value of MoneyJanzel SantillanNo ratings yet

- 4th Periodical Exam WorksheetDocument12 pages4th Periodical Exam WorksheetMc Clent CervantesNo ratings yet

- Monica Kochert Connections Overview Fy22 q2Document5 pagesMonica Kochert Connections Overview Fy22 q2api-592035144No ratings yet

- Introduction MicroDocument10 pagesIntroduction MicroRhea BhatiaNo ratings yet

- Evaluation of Farm Machinery Management System in Guneid Sugar R06 Scheme (Sudan) R06Document143 pagesEvaluation of Farm Machinery Management System in Guneid Sugar R06 Scheme (Sudan) R06Bishaw100% (1)

- Bangladesh Tax ManagementDocument8 pagesBangladesh Tax ManagementRasel AshrafulNo ratings yet

- ArticlesDocument1 pageArticlesBayrem AmriNo ratings yet

- Byculla Urban StudyDocument21 pagesByculla Urban Study2002 ANAS ANSARINo ratings yet

- Shree Bhaskar Industrial Park PDFDocument3 pagesShree Bhaskar Industrial Park PDFjaydeep daveNo ratings yet

- Vocabulary 2 UrbanizationDocument4 pagesVocabulary 2 UrbanizationPhuong AnhNo ratings yet

- India's Geopolitical and Cultural ConcernsDocument5 pagesIndia's Geopolitical and Cultural ConcernsS SAI BALAJI IYERNo ratings yet

- ACC6050 Module 3 AssignmentDocument9 pagesACC6050 Module 3 AssignmentFavourNo ratings yet

- MO Weekly Tesla May 25 Updated - ASICDocument2 pagesMO Weekly Tesla May 25 Updated - ASICBrent CartyNo ratings yet

- Structural Adjustment Program: Nadim PrinceDocument14 pagesStructural Adjustment Program: Nadim PrinceGlorious PrinceNo ratings yet

- CFIN Cheat Sheet - FullDocument2 pagesCFIN Cheat Sheet - FullJoyal ThomasNo ratings yet

- Agriculture in Ghana Facts and Figures 2012Document64 pagesAgriculture in Ghana Facts and Figures 2012Sunil Kumar CheluvaihgalNo ratings yet

- Collectorate, KoraputDocument17 pagesCollectorate, KoraputMihir Ranjan RoutNo ratings yet

- Prasad Lab-2Document1 pagePrasad Lab-2Madhu SudhanNo ratings yet

- BOPDocument15 pagesBOPmrunNo ratings yet

- L5-Evaluating A Single Project - FullDocument59 pagesL5-Evaluating A Single Project - FullHarsh ShahNo ratings yet