Professional Documents

Culture Documents

Characterization of Rheological Behaviors of Polypropylene Carbon Nanotubes

Characterization of Rheological Behaviors of Polypropylene Carbon Nanotubes

Uploaded by

shafaathtCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Characterization of Rheological Behaviors of Polypropylene Carbon Nanotubes

Characterization of Rheological Behaviors of Polypropylene Carbon Nanotubes

Uploaded by

shafaathtCopyright:

Available Formats

Characterization of rheological behaviors of polypropylene/carbon nanotubes

composites and modeling their ow in a twin-screw mixer

F. Thibaud

a,

*

, J.C. Gelin

b

a

Laboratoire dEnergtique et de Mcanique Thorique et Applique, ESSTIN-UHP, 2 rue Jean Lamour, 54500 Vandoeuvre ls Nancy, France

b

Institut Femto ST/Dpartment de Mcanique Applique, ENSMM, 24 rue de lEpitaphe, 25000 Besanon, France

a r t i c l e i n f o

Article history:

Received 3 April 2009

Received in revised form 22 December 2009

Accepted 23 December 2009

Available online 4 January 2010

Keywords:

A. Carbon nanotubes

A. Polymermatrix composites (PMCs)

C. Modeling mixing

C. Finite element analysis (FEA)

D. Rheological behavior

a b s t r a c t

This paper focuses on the numerical simulation of the polypropylene/multi-walled carbon nanotubes (PP/

MWCNT) ow into a twin-screw mixer, during the mixing phase. The PP/MWCNT behavior obeys an

innovating Carreau law enriched temperature built on the rheological properties carried out previously.

The polypropylene was mixed with different MWCNTs contents (1, 2, 4 and 8 wt.% of MWCNT content)

and the rheological tests were performed at shear rate ranges from 10

1

to 2 10

4

s

1

at four tempera-

tures (180, 200, 220 and 240 C). Thus the effects of the temperature and the MWCNTs content on the

rheological properties of the PP/MWCNT composites were investigated. The nite element (FEM) analysis

of the PP/MWCNT ow allows to compute the velocity, the shear rate and the temperature during the

mixing phase period. A good agreement between the experimental measured torque on the screw and

the calculated one is shown. Therefore, one can consider that the physical ow is generally well

described, awaiting a numerical simulation of the PP/MWCNT mixing phase.

2009 Elsevier Ltd. All rights reserved.

1. Introduction

Since carbon nanotubes (CNT) ofcial discovery in 1991 by Iij-

ima [1], their interests have grown in the eld of science and engi-

neering: their mechanical and physical properties make CNT as

attractive candidates for composite materials (polymer/CNT) and

applications. These mechanical performances strongly depend on

the composite melt process. Many studies have been carried out

by several authors and referenced by Coleman et al. [2] and Breuer

and Sundaraj [3].

One of the most important parameters during the elaboration

polymers/CNT composites is the nanotubes dispersion in the poly-

mer matrix. Indeed It is critical for reinforcing the efciency be-

cause the relative ease of nanotubes to nanotubes sliding when

they are assembled in ropes signicantly affects the mechanical

properties of the resulting material. Many investigations on the

nanotubes dispersion in the polymer matrix have been carried

out and a part of them are cited in this paper. Shear mixing by melt

processing is one of the most current methods [4]. Nevertheless,

most of studies are experimental ones.

In the present paper, one proposes an investigation about a poly-

propylene/multi-walled carbon nanotubes (PP/MWCNT) composite

ow into a twin-screw mixer through a nite element based

simulation.

In the rst part, PP/MWCNT composites were built with 1, 2, 4

and 8 wt.% of MWCNT. During the preparation of PP/MWCNT

composites, one has to ensure a proper dispersion of the nano-

tubes in the PP matrix. Generally, two methods are investigated:

the rst one consists in mixing the nanotubes and the polymer in

a suitable solvent before evaporating it to form a composite lm.

It facilitates nanotubes debinding through the polymer and their

dispersion. Jin et al. [6], Shaffer et al. [7], or Qian et al. [8] were

the rst to investigate such a process by using the related

method.

Nevertheless, this method is unsuitable for many polymers that

can not be debinded. Melt processing is a common alternative that

is particularly useful in the case of thermoplastic polymers and

particularly polypropylene type. In general, melt processing in-

volves the melting of polymer pellets to form a viscous liquid. Car-

bon nanotubes are mixed into the melt by shear mixing. Then, bulk

samples can then be realized using different process such as com-

pression molding, injection molding or extrusion. An early study

on the melt mixing of polymer and nanotubes was carried out by

Jin et al. [9]. Andrews et al. [10] showed that commercial polymers

like polypropylene could be melt with carbon nanotubes to form

composites. In addition, very good nanotubes dispersion was ob-

served by Ptschke et al. [11] after blended batches of MWCNT

in polycarbonate (PC) using a microcompounder at 260 C. The

authors clearly show that melt mixing is a powerful method to dis-

perse nanotubes into polymers, and to load polymers, particularly

polypropylene.

0266-3538/$ - see front matter 2009 Elsevier Ltd. All rights reserved.

doi:10.1016/j.compscitech.2009.12.020

* Corresponding author. Tel.: +333 83 68 51 41; fax: +333 83 68 51 01.

E-mail address: frederic.thiebaud@esstin.uhp-nancy.fr (F. Thibaud).

URLs: http://www.lemta.fr (F. Thibaud), http://www.femto-st.fr (J.C. Gelin).

Composites Science and Technology 70 (2010) 647656

Contents lists available at ScienceDirect

Composites Science and Technology

j our nal homepage: www. el sevi er. com/ l ocat e/ compsci t ech

Thus, the rheological behavior of the neat PP and the PP/

MWCNT composites are investigated by using a capillary rheome-

ter. This investigation allows us to identify the rheological behavior

for each PP/MWCNT composite and the neat PP by using a modied

Carreau law enriched temperature. A few studies are reported on

the rheological properties of polymer/nanotubes composites pre-

pared by melt mixing process. Teng et al. [12] investigated the ef-

fect of MWCNTs content on the rheological properties of

polypropylene at high shear rates (10

2

10

4

s

1

) and a temperature

around 200 C. Thus, the authors proposed a power law as a consti-

tutive model to characterize the rheological behavior of the com-

posite. A similar study led by Seo and Park [13] focus on the

rheological behavior of PP/MWCNT composite at low shear rates

(10

1

10

2

s

1

) at a temperature about 170 C. These investigations

clearly show a dependence of the shear viscosity versus the shear

rate at xed temperature (200 C and 170 C respectively).

In the second part, this Carreau temperature law enriched is

used to analyze the ow behavior of the composite into a twin-

screw mixer. The Comsol

software has been chosen because of

its ease to for solving multiphysic coupled problems. The velocity,

the shear rate and the temperature elds were also investigated.

Finally, a comparison between the experimental and the calculated

resulting torques on one screw has been carried out. A good agree-

ment between the experimental measured torque on the screw

and the calculated one shows that a good description of the PP/

MWCNT physics ow is obtained with the uses of this original Car-

reau law enriched temperature. This FEM analysis appears as a rst

step for a next simulation of the mixing phase of PP/MWCNT

composites.

2. Preparation of the PP/MWCNT composites

2.1. Materials characterization

Multi-walled Carbon Nanotubes (MWCNTs) were produced by

Chemical Vapor Deposition (CVD) process and were supplied by

NANOCYL S.A., (Sambreville, Belgium). The purity of MWCNTs

is more than 95%. In order to disperse MWCNTs, an experimental

protocol developed by Ruan et al. [5] was used. MWCNTs powder

was dispersed by using Sodium Dodecyl Sulfate (SDS) stands for

surfactant and ultrasonic process. Thus, it was possible to observe

MWCNTs through SEM images (60,0005 kV) as shown in Fig. 1.

Nevertheless, it remains difcult to evaluate the dimensions of

these MWCNTs. On considers that the diameter of MWCNTs is

around 1020 nm and the length is around 125 lm, their density

is evaluated as q

c

= 1.30 g/cm

3

, according to the specications of

the provider.

Polypropylene is one of the most commonly used thermoplastic

polymers which has been used in automobiles, appliances, con-

struction, housewares, etc. Polypropylene is usually mixed with

reinforcement or ller to improve its properties. The polypropyl-

ene in pellets form was a PP1120 type that corresponds to a homo-

polymer with a Melt Flow Indices (MFI) around 15 g/10 min

(230 C, 2.16 kg). This PP grade is dedicated to injection molding

and its density is evaluated as q

p

= 0.90 g/cm

3

.

2.2. Manufacturing phase

In our work, the mixing experiments were realized with a Brab-

ender

mixer (Plastograph EC W50EHT, Figs. 2 and 3), that allows

to realize batch mixtures up to 40 cm

3

. The temperature in the

mixing cavities and the rotation speed of the screws are regulated.

As it is shown in Fig. 3, the uid is contained in the cavity enclosed

by the frame and the two screws. The left screw rotates in the

clockwise while the right one rotates in the counter clockwise.

The torques and the temperature have been measured using sen-

sors and the associated software provided with the equipment.

Polypropylene was mixed with various MWCNT mass fraction f:

(f = 1, 2, 4 and 8 wt.%) by drawing ones inspiration from the pro-

tocol described by Ptschke et al. [11]. Typically, the temperature

in the mixing cavities and the rotation speed of the screw are reg-

ulated around 200 C and 60 rpm respectively, the process time is

15 min. Thus, bulk samples are collected and crushed into small

particles in a grinder.

Fig. 1. As-received MWCNTs SEM microphotography.

Fig. 2. The Brabender

mixer EC W50EHT .

Fig. 3. Mixing cavities and twin-screw mixer.

648 F. Thibaud, J.C. Gelin/ Composites Science and Technology 70 (2010) 647656

The measured mixing torque versus time is shown in Fig. 4. One

notices that the mixing torque increases with MWCNT content ex-

cept for the batch corresponding to 1 wt.%. As a general tendency,

the mixing torque decreases with time to a limit torque. It can be

related to the temperature of the PP/MWCNT composite increases

until the imposed temperature, resulting in a decrease of the poly-

propylene shear viscosity. Due to the solid state-of-the PP/MWCNT

composite when it is introduced into the mixer, very high values of

the mixing torque are measured (increase of 300% compared to the

torque measured after 10 min for each MWCNT content) until

3 min. Thus, because of heating into the cavity, the PP is softened,

resulting in a rapid decrease of the mixing torque. It takes around

5 min to introduce PP/MWCNT composite at solid state into the

mixer. It explains the fact that the beginning of effective mixing

phase starts after 6 min.

3. Rheological properties of MWCNT/PP composites: results and

discussion

3.1. Rheological measurements

In order to build a consistent law for the rheological behavior of

the PP/MWCNT composites versus shear rate and temperature, the

shear viscosity is measured on a very large shear rate range: (10

1

2 10

4

s

1

) at four temperatures (180, 200, 220 and 240 C). A RO-

SAND

RH2000 capillary rheometer with two dies was used for

these measurements. The rst die (1 mm) was used in the shear

range form 10

1

to 20 s

1

shear rate while the second die (

2 mm) was used in the shear rate range 202 10

4

s

1

. For exam-

ple, the shear viscosity versus the shear rate for the neat PP and the

fourth PP/MWCNT composites at 200 C, are reputed in Fig. 5. Sim-

ilarly, the test temperature inuence on the shear viscosity is

shown in the Fig. 6 for the 4 wt.% PP/MWCNT composite. One

can notice that the same pattern of results is identiable to the

other temperatures and the other composites (neat PP and 1, 2

and 8 wt.% PP/MWCNT composites). Finally, the shear viscosity

versus the temperature for the neat PP and the fourth PP/MWCNT

composites at xed shear rate (

_

c = 200 s

1

) are reputed in Fig. 7.

This xed value of the shear rate corresponds to an average shear

rate of the mixing phase.

At xed temperature, the shear viscosity of the neat PP and PP/

MWCNT composites decreases with the increase of the shear rate.

These viscosity curves clearly indicate the signicant effect of the

MWCNTs content. When the shear rate is in the range 10

1

10

2

s

1

, the PP/MWCNT composite exhibit a shear thinning effect

whereas the neat PP exhibits only small shear rate dependence,

revealing a Newtonian plateau. However, from 1 wt.% MWCNT

content, the viscosity curves present a much steeper slope at low

shear rate, and there is no Newtonian plateau within the shear rate

range studied. Also, from 4 wt.% MWCNT, the viscosity curves ap-

pear nearly power law over this range of shear rate. This phenom-

enon is related to the fact that, the MWCNTsMWCNTs

interactions begin to dominate as the MWCNTs content increases,

eventually leading to a percolation and a formation of intercon-

nected MWCNT structures. One can mention Girish et al. [14]

and Gu et al. [15] who have reported that the shear viscosity of

the conned polymer melts is greater than that of bulk chains. Fur-

thermore, at high MWCNTs content, MWCNTs will entangle

together to form interconnected structures. Hence, it results that

the ow of the PP/MWCNT composite decreases as it was also re-

ported by Lee and Mackley [16]. However, when the shear rate is

0

5

10

15

20

25

30

35

0 5 10 15 20

time (min)

t

o

r

q

u

e

(

N

m

)

neat PP

1wt% CNT

2wt% CNT

4wt% CNT

8wt% CNT

beginning of the

mixing phase

introduction of

PP/MWCNT solid state

Fig. 4. Mixing torque versus time for the neat PP and the composites (PP/MWCNT 1,

2, 4 and 8 wt.%).

T=200C

1

10

100

1000

10000

100000

1000000

0.1 1 10 100 1000 10000 100000

shear rate (/s)

s

h

e

a

r

v

i

s

c

o

s

i

t

y

(

P

a

.

s

)

neat PP

1wt% CNT

2wt% CNT

4wt% CNT

8wt% CNT

Fig. 5. Shear viscosity versus shear rate at 200 C for the neat PP and the loaded

composites.

PP 4wt% CNT

1

10

100

1000

10000

100000

0.1 1 10 100 1000 10000 100000

shear rate (/s)

s

h

e

a

r

v

i

s

c

o

s

i

t

y

(

P

a

.

s

)

T=180C

T=200C

T=220C

T=240C

Fig. 6. Shear viscosity versus shear rate at 180, 200, 220 and 240 C for the 4 wt.%

PP/MWCNT composite.

shear rate : 200 /s

0

100

200

300

400

500

600

700

800

900

170 180 190 200 210 220 230 240 250

temperature (C)

s

h

e

a

r

v

i

s

c

o

s

i

t

y

(

P

a

.

s

)

neat PP

1 wt% CNT

2 wt% CNT

4 wt% CNT

8 wt% CNT

Fig. 7. Shear viscosity versus temperature for the neat PP and the loaded

composites (xed shear rate).

F. Thibaud, J.C. Gelin/ Composites Science and Technology 70 (2010) 647656 649

in the range 10

2

2 10

4

s

1

, the shear viscosity of the PP/MWCNT

composite of the same order than the neat PP: the effect of the

MWCNT content is less important than at low shear rates. When

shear rate is increasing, the shear thinning effect is enhanced and

the wall slip phenomena occurring between PP/MWCNT and the

wall of the rheometer is predominant, as it is supposed by Lee

et al. [17] and Lam et al. [18].

Finally for one PP/MWCNT composite shade, the viscosity

curves indicate a decrease of the shear viscosity with the increase

of the temperature. This is due to the fact that the shear viscosity of

the polypropylene decreases when heating.

3.2. Characterization of the shear viscosity for PP/MWCNT composites

The previous investigations on the rheological behavior of the

neat PP and the fourth PP/MWCNT composites clearly show an

high dependence of the shear viscosity on the shear rate and the

temperature. Thus, the constitutive model must be able to predict

the ow of composites under various processing conditions and

particularly the shear rate and the temperature. Most of the mate-

rial ow models that take into account the shear rate and the tem-

perature effects are summarized in Carreau et al. [19]. One can

mention the power law model, but it does not model the Newto-

nian plateau at low shear rates. A more convenient model pro-

posed by Cross [20] allows switching from the Newtonian

plateau at low shear rates to a straight line at high shear rates.

However, this transition leads to a slope break that the model does

not adjust. Carreau [4] proposed a model to modify the slope break

by changing the Cross law without adding additional parameters.

This Carreau law expression is:

l

_

c; T l

0

T1 k

_

c

2

n1

2

1

where l

_

c; T is the shear viscosity, T the temperature and

_

c the

equivalent shear rate dened by:

_

2

3

dev

_

e : dev

_

e

_

2

with

_

e, dened as the shear rate tensor versus the velocity eld

~

V:

_

e

1

2

grad

~

V grad

t

~

V: 3

and dev_ e, the deviatoric part of the shear rate tensor:

dev

_

e

_

e

1

3

Tr

_

eI 4

where I is the second order identity tensor. The index n is typically

called the shear thinning index. The term l

0

(T) is identied as the

material consistency and it is a characteristic relaxation time of

the material.

In this case, the following expression for the material consis-

tency is proposed:

l

0

T l

0

e

bT

5

where b is another characteristic time of the material. With this

suggested constitutive model, thermal effects are accounted and

the transition from the power law to the Newtonian plateau is more

suitable.

The rheological parameters (l

0

, b, k and n) are summarized in

Table 1 for the neat PP and each PP/MWCNT composite. One can

notice that the parameter l

0

increases with MWCNTs content

while the shear thinning index n substantially decreases. For the

PP/MWCNT composites with 4 and 8 wt.% MWCNTs content, the

parameter l

0

is higher than for other contents. In these conditions,

the constitutive model identied for the Carreau law enriched tem-

perature is almost equivalent to the power law model. Comparison

between the experimental datas and the identied Carreau law for

the neat PP and each PP/MWCNT composite is related in Fig. 8. One

can notice a good correlation between experimental and continu-

ous datas.

4. Numerical simulation of the PP/MWCNT ow in the twin-

screw mixer

4.1. Problem formulation

This work aims as predicting the material (the neat PP and PP/

MWCNT composites) ow into the Brabender

mixer during the

mixing phase. Many assumptions must be considered to lead these

numerical simulations. First of all, a two dimensional (2D) problem

is considered as an approximation of the section screw. In addition,

one considers a laminar and incompressible ow without volumic

loads and the material behavior follows the constitutive Carreau

law proposed in the previous section.

In order to account the rotating motion of both screws, the

material domain X is divided into three sub-domains described

in Fig. 9 as:

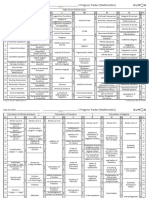

Table 1

Rheological parameters for the neat PP and each PP/MWCNT composite.

MWCNT content 0 wt.% 1 wt.% 2 wt.% 4 wt.% 8 wt.%

l

0

(Pa s

n

) 20,778 34,214 172,783 2 10

6

2 10

7

b (C

1

) 0.0155 0.0116 0.0148 0.0206 0.0242

k (s

1

) 0.207 0.514 0.942 2.645 2.733

n 0.4 0.34 0.29 0.27 0.25

1

10

100

1000

10000

100000

0.1 1 10 100 1000 10000 100000

shear rate (/s)

s

h

e

a

r

v

i

s

c

o

s

i

t

y

(

P

a

.

s

)

neat PP (experimental data)

Neat PP (Carreau law)

1 wt% CNT (experimental data)

1 wt% CNT (Carreau law)

2 wt% CNT (experimental data)

2 wt% CNT (Careau law)

4% wt CNT (experimental data)

4 wt% CNT (Carreau law)

8 wt% CNT (experimental data)

8 wt% CNT (Carreau law)

Fig. 8. Shear viscosity as a function of the shear rate at 180, 200, 220 and 240 C for

the 4 wt.% PP/MWCNT composite: experimental datas and Carreau law enriched

temperature tting curves.

1

2

y

2

x

2

0

1

2

3

4

n

3

y

3

x 3

0

1

y

1

x

1

0

3

12 13

3 2 1

, , z z z

Fig. 9. Moving and xed frame, sub-domains and boundaries denition.

650 F. Thibaud, J.C. Gelin/ Composites Science and Technology 70 (2010) 647656

X

1

, with xed frame R

1

: ~x

1

;~y

1

;~z

1

,

X

2

, around the left screw with clockwise moving mesh, R

2

:

~x

2

;~y

2

;~z

2

,

X

3

, around the right screw with counterclockwise moving mesh,

R

3

: ~x

3

;~y

3

;~z

3

.

Thus, an Arbitrary LagrangianEulerian (ALE) method with

moving mesh on both X

2

and X

3

sub-domains is used to formulate

the problem.

By considering the above geometrical denitions, the resolution

of the coupled uid owthermal problem allows us to calculate:

the velocity eld:

~

Vx; y; t V

x

x; y; t~x

1

V

y

x; y; t~y

1

,

the pressure eld: p(x, y, t),

the temperature eld: T(x, y, t).

The velocity eld and the pressure are governed by the follow-

ing NavierStockes equations:

6

where

~

D is the laplacian operator.

The temperature evolution is governed by the heat equation, gi-

ven by the Eq. (8):

qC

p

@T

@t

grad

!

T

~

V

_ _

div

~

q 2l

_

c; T

_

e :

_

e into X

1

[ X

2

[ X

3

8

where C

p

is the specic heat coefcient. The Fouriers law gives the

relation between the heat ow ~q and the temperature T:

~

q K grad

!

T 9

where K is the thermal conduction coefcient. Assuming this rela-

tion, the heat equation becomes:

qC

p

@T

@t

grad

!

T

~

V

_ _

KDT 2l

_

c; T

_

e

:

_

e into X

1

[ X

2

[ X

3

10

The density q is given by the well-known mixture rule:

q

f

q

c

1 f

q

p

_ _

1

11

The modeling of the thermal conduction into polypropylene/nano-

tubes composite is not obvious, due to the thermal anisotropy of

nanotubes and their random orientation into the polypropylene.

The orientation of the nanotubes is sensitive to the processing

method. Typically, the measured thermal conduction coefcient

in the axes of the nanotubes is higher than that measured in

the transverse direction. In this study, the model issued from

Hamilton and Crosser [21] is used to evaluate the conduction

coefcient:

K K

p

a n 1 n 11 af

v

a n 1 1 af

v

12

where K

p

is the polymer conduction coefcient (n % 6 for cylindrical

particles), f

v

the volume fraction of nanotubes and a an undimen-

sional coefcient dened by:

a

K

c

K

p

13

where K

c

is the nanotubes conduction coefcient. A similar relation

can be written for the composite specic heat C

p

:

C

p

C

PP

a n 1 n 11 bf

v

a n 1 1 bf

v

14

where C

PP

is the polymer specic heat and b an undimensional coef-

cient dened as:

b

C

pc

C

PP

15

where C

pc

is the nanotubes specic heat. Average measured values

of the conduction coefcient and the specic heat for the nanotubes

provided by Fuji et al. [22] are used here and an assessment of the

different coefcients is given in the Table 2 in addition to these gi-

ven in the Table 1.

Moreover, boundary conditions must be considered for the sim-

ulations. For our problem, one can nd these following conditions

for both uid and thermal problem:

frame and screws walls adhesion:

~

V

=Ri

~

0 on o

1

X[ o

2

X[ o

3

X

into the local frame,

open boundary condition at the mixer inlet: r 0 on @

4

X,

imposed temperature on the screws and the frame: T = 473 K on

o

1

X[ o

2

X[ o

3

X,

external heat transfer at the mixer inlet: Kgrad

!

T

hT T

ext

~n on @

4

X,where r is the stress tensor dened versus

the pressure p, the shear viscosity l

_

c; T and the shear rate tensor

_

e:

r pI 2l

_

c; T

_

e 16

T

ext

is the external temperature xed at 293 K, ~n stands for

the outgoing normal vector and h the effective convection

coefcient.

Furthermore, continuity equations must be considered at the

moved/xed frames boundaries o

12

X and o

13

X. These equations

can be written as:

r

1

r

2

0 on @

12

X 17

r

1

r

3

0 on @

13

X 18

for the uid problem, and:

~

q

1

~

q

2

~n

12

0 on @

12

X 19

~

q

1

~

q

3

~n

13

0 on @

13

X 20

for the thermal problem.

Due to the time dependent problem statement, the following

initial conditions are accounted:

~

Vt 0

~

0 21

pt 0 0 22

Tt 0 T

0

23

where T

0

is xed to 423 K, not far from the polypropylene melting

temperature.

In order to complete this problem formulation, moving frames

equations are given below. Let us consider M

2

and M

3

, two points

of X

2

and X

3

, respectively. Moving frames equations impose the

following relations:

Table 2

Thermal parameters for the neat PP and each PP/MWCNT composite.

MWCNT content 0 wt.% 1 wt.% 2 wt.% 4 wt.% 8 wt.%

q (g cm

3

) 0.900 0.903 0.906 0.911 0.923

C

p

(J kg

1

) 1800 1837 1874 1949 2096

K (W m

1

kg

1

) 0.200 0.204 0.208 0.217 0.233

F. Thibaud, J.C. Gelin/ Composites Science and Technology 70 (2010) 647656 651

O

2

M

2

!

t r cos

pN

30

t

_ _

~ x

2

r sin

pN

30

t

_ _

~ y

2

into X

2

24

O

3

M

3

!

t r cos

pN

30

t

_ _

~ x

3

r sin

pN

30

t

_ _

~ y

3

into X

3

25

where r is the effective distance between O

i

and M

i

and N the rota-

tion speed xed to 60 rpm.

4.2. Material and process numerical implementation

Comsol

is a modeling package for the simulation of any phys-

ical process and can be described with partial differential equa-

tions (PDEs). It proposes state-of-the art solvers that address

quickly and accurately complex problems, while its intuitive struc-

ture is designed to provide exibility and easy way to use. The con-

stitutive uidthermal model has been implemented and can be

assimilated to a multiphysic coupled problem between the uid

ow module (for the uid problem), the heat transfer module

(for the thermal problem) and the ALE moving mesh module

(for the moving meshes).

The use of en automatic mesher, allows to discretized the sub-

domains X

1

, X

2

and X

3

with 1066 quadratic TRI6 elements, result-

ing in a total of 9336 degrees of freedom (DOF) (Fig. 10). An explicit

time stepping scheme is used for the time dependant solver algo-

rithm with an automatic time step adjustment. A convergence test,

which is not detailed here validates this mesh choice. The diagram

related in Fig. 11 shows the interaction between the three mod-

ules. The solution is given on the actual frames at each time step

until t = t

f

, where t

f

designed the simulation time. One considers

here that t

f

= 3 s.

5. Results

Many simulations were leaded for the neat PP and the fourth

PP/MWCNT composites considering the rheological and the ther-

mal parameters related in Tables 1 and 2 respectively.

The following results are related to the PP/MWCNT composite

with 8 wt.% MWCNTs content. The same results tendencies are ob-

tained for the other PP/MWCNT contents and the neat PP.

Fig. 12af relates the velocity eld at different time steps. One

can notice that the maximum value for the velocity eld is located

at the middle of the frame (x = 0.02 m, y = 0) and near the screws

extremity. Further, the wall adherence condition on the frame

~

V

~

0 is clearly respected.

The shear rate is represented in Fig. 13ad, at t = 1 s and t = 3 s.

These gures reveal that the shear rate is approximately constant

in the cavity except near the screws extremity where the shear rate

is nearly fty times higher than in the cavity. One can afrm that

the mixing phase is effective near the screw extremity (at high

shear rate). Furthermore, the shear rate eld is practically constant

in time.

Fig. 11. Interactions diagram between material ow, heat transfer and moving mesh module.

Fig. 10. Mesh denition related to the two screws mixer FE model (9336 DOF).

652 F. Thibaud, J.C. Gelin/ Composites Science and Technology 70 (2010) 647656

The temperature evolution is shown in Fig. 14af. At the begin-

ning of the simulation, the PP/MWCNT composite temperature is

globally equal to 423 K except on the frame and screws walls,

where the temperature is imposed (T = 473 K). During the simula-

tion, the temperature in the cavity increases to a limit value equal

to 473 K, corresponding to the imposed mixing temperature on

Fig. 12. Velocity elds (in mm/s) at several time steps for the 8 wt.% PP/MWCNT composite.

F. Thibaud, J.C. Gelin/ Composites Science and Technology 70 (2010) 647656 653

the frame and screws walls. This simulation clearly indicates that

the mixing temperature is quickly reached, which guarantees opti-

mal mixing conditions. The heat transfer inuence at the mixer in-

let is shown in these gures. This shows that a signicant variation

of the temperature in the middle of the cavity, where the temper-

ature is practically equal to the PP melting temperature.

From the FEM analysis results, the resulting torque on both

screws can be calculated for each PP/MWCNT composite and neat

PP ow simulation. For example, let us consider the left screw mix-

ing torque

~

C expression is given by the following equations:

~

C

_

S

O

2

P

2

!

^r~ndS 26

where P

2

stands for a geometrical point of the screw boundary, ~n

represents the outpointing normal vector at the screw/uid bound-

ary and S the lateral surface screw. Due to the 2D assumption, one

can write the mixing torque per unit length

~

C

l

as:

~

C

l

L

_

l

O

2

P

2

!

^r~ndl 27

where l is screw section perimeter, dl its curvilinear abscissa and L

the screw length in the 0

2

;~z

2

axis direction. Assuming the deni-

tion of the stress tensor related in Eq. (16), one can get explicitly the

stress tensor components:

r

r

11

r

12

0

r

12

r

22

0

0 0 r

33

_

_

_

_ 28

where:

r

11

p 2l

_

c; T

@V

x

@x

29

r

22

p 2l

_

c; T

@V

y

@y

30

r

12

l

_

c; T

@V

x

@y

@V

y

@x

_ _

31

r

33

p 32

Assuming the following denitions for 0

2

P

2

!

and the outgoing ~n

vectors:

O

2

P

2

!

x ~x

2

y ~y

2

33

~n n

x

~x

2

n

y

~y

2

34

The resulting mixing torque expression is given by:

Fig. 13. Shear rate (in /s) at t = 1 s and t = 3 s for the PP/MWCNT composite with 8 wt.% in MWCNT.

654 F. Thibaud, J.C. Gelin/ Composites Science and Technology 70 (2010) 647656

Fig. 14. Temperature eld (in K) at several time step for the PP/MWCNT composite with 8 wt.% in MWCNT.

F. Thibaud, J.C. Gelin/ Composites Science and Technology 70 (2010) 647656 655

~

C L

_

l

xn

x

r

12

n

y

r

22

yn

x

r

11

n

y

r

22

dl

~

z

2

35

Thus, a numerical integration of the Eq. (35) is performed on the

section screw perimeter, at each time step for each PP/MWCNT

composite and the neat PP. Assuming that the screw length in

about 47 mm, the mixing torque

~

C can be calculated and thus rep-

resented in Fig. 15.

Fig. 15 shows that the torque increases with the MWCNT con-

tent. One can explain it due to the increase of the shear viscosity

of the PP/MWCNT composite with the MWCNT content. Neverthe-

less, there is a more important gap between the 4 wt.% and 8 wt.%

MWCNT content curves than the other ones.

Due to the temperature increase in the cavity, the shear viscos-

ity decreases. Consequently, it results a decrease of the mixing tor-

que versus time when for each PP/MWCNT composite. However,

this decrease phenomenon is more signicant when the MWCNT

content increases. Finally, even if many assumptions are done,

these numerical results are in good agreement with the experi-

mental torque values, reported in Fig. 4.

6. Conclusion

The physical modeling and numerical simulations of PP/

MWCNT composite ow in a twin-screw mixer at high shear rates

has been investigated in this paper, based on properly identied

material behavior and an appropriate nite element modeling of

the composite ow in a twin-screw mixer.

The rst part of the paper relates the experiments carried out

for the determination of the rheological properties of PP/MWCNT

with various MWCNT contents estimated in the temperature range

from 180 to 240 C. The rheological properties have been in the

range 10

1

2 10

4

s

1

using capillary rheometry. The signicant

effects of the MWCNT content have been proved, as the increase

of shear viscosity versus MWCNT volumic fraction associated to

shear rate increase. These rheological characterizations have been

used to set up and to build a constitutive model for the ow of PP/

MWCNT based on the extension of the well-known Carreau law

coupled with a thermal factor. The resulting parameters have been

identied for the neat PP and the PP/MWCNT composites.

Then, physical and mechanical analyses have been proposed for

the ows in a twin-screw mixer, resulting in a nite element mod-

eling of the mixing process; accounting the very high values of

shear rate between the screw and the frame, as well as tempera-

ture contours. The compromise between experimental mixing

torques and the ones obtained through the nite element simula-

tions attests about the validity of the rheological ow model as

well as the nite element results. The reported nite element sim-

ulations permit to account the temperature effects and provide a

well founded basis for the simulations of the PP/MWCNT compos-

ite in the mixer according a multiphase model developed at the

microscale.

References

[1] Iijima S. Helical microtubes of graphitic carbon. Nature 1991;354(6348):

568.

[2] Coleman N, Kahn U, Blau WJ, Gunko YK. Small but strong: a review of the

mechanical properties of carbon nanotubepolymer composites. Carbon

2006;44:164452.

[3] Breuer O, Sundaraj U. Big returns from small bers: a review of polymer/

carbon nanotube composites. Polym Compos 2004;25:63045.

[4] Carreau PJ. Rheological equations from molecular network theories. Trans Soc

Rheol 1972;16:99127.

[5] Ruan SL, Gao P, Yang XG, Yu TX. Thoughening high performance ultrahigh

molecular weight polyethylene using multiwalled carbon nanotubes. Polymer

2003;44(19):564354.

[6] Jin L, Bower C, Zhou O. Alignment of carbon nanotubes in a polymer matrix by

mechanical stretching. Appl Phys Lett 1998;73(9):11979.

[7] Shaffer MSP, Windle AH. Fabrication and characterization of carbon nanotube/

poly(vinyl alcohol) composites. Adv Mater 1999;11(11):93741.

[8] Qian D, Dickey EC, Andrews R, Rantell T. Load transfer and deformation

mechanisms in carbon nanotubepolystyrene composites. Appl Phys Lett

2000;76(20):286870.

[9] Jin Z, Pramoda K, Xu G, Goh SH. Dynamic mechanical behavior of melt-

processed multi-walled carbon nanotube/poly(methyl methacrylate)

composites. Chem Phys Lett 2001;337(1-3):437.

[10] Andrews R, Jacques D, Qian DL, Rantell T. Multiwall carbon nanotubes:

synthesis and application. Acc Chem Res 2002;35(12):100817.

[11] Ptschke P, Bhattacharyya AR, Janke A, Goering H. Melt mixing of

polycarbonate/multi-wall carbon nanotube composites. Compos Interf

2003;10(4-5):389404.

[12] Teng CC, Ma CCM, Huang YW, Yuen SM, Weng CC, Chen CH, Su SF. Effect of

MWCNT content on rheological and dynamic mechanical properties of

multiwalled carbon nanotube/polypropylene composites. Compos Part A:

Appl Sci Manuf 2008;39:186975.

[13] Seo MK, Park SJ. Electrical resistivity and rheological behaviors of carbon

nanotubes-lled polypropylene composites. Chem Phys Lett

2004;395:448.

[14] Girish G, Ramesh C, Lele A. A rheological study on the kinetics of hybrid

formation in polypropylene nanocomposites. Macromolecules 2001;34:8528.

[15] Gu SY, Ren J, Wang QF. Rheology of poly(propylene)/clay nanocomposites. J

Appl Polym Sci 2004;91:242734.

[16] Lee K, Mackley MR. The signicance of slip in matching polyethylene

processing data with numerical simulation. J Non-Newton Fluid

2000;94:15977.

[17] Lee SH, Kim MW, Kim SH, Youn JR. Rheological and electrical properties of

polypropylene/MWCNT composites prepared with MWCNT masterbatch

chips. Eur Polym J 2008;44:162030.

[18] Lam YC, Wang ZY, Joshi SC. Wall slip of concentrated suspension in capillary

ows. Powder Technol 2007;177:1629.

[19] Carreau PJ, De Kee DCR, Chhabra ORP. Rheology of polymeric systems:

principles and applications. Munich: Hanser; 1997.

[20] Cross MM. Rheology of non-Newtonian uids: a new ow equation for

pseudoplastic systems. J Colloid Sci 1965;20:41737.

[21] Hamilton RL, Crosser OK. Thermal conductivity of heterogeneous two-

component systems. Ind et Engin Chem Fund 1962:1187.

[22] Fujii M, Zhang X, Xie H, Ago H, Takahashi K, Ikuta T, Abe H, Shimizu T.

Measuring the thermal conductivity of a single carbon nanotube. Phys Rev Lett

2005;95:065502.

0

5

10

15

20

25

30

0 0.5 1 1.5 2 2.5 3

simulation time (s)

m

i

x

i

n

g

t

o

r

q

u

e

(

N

.

m

)

neat PP

1wt% CNT

2wt% CNT

4wt% CNT

8wt% CNT

Fig. 15. Mixing torque on the left screw for the neat PP and the fourth PP/MWCNT

composites.

656 F. Thibaud, J.C. Gelin/ Composites Science and Technology 70 (2010) 647656

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Accp 2021 P 1Document584 pagesAccp 2021 P 1Sarra HassanNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Composites Part A: SciencedirectDocument11 pagesComposites Part A: SciencedirectshafaathtNo ratings yet

- Conference Brochure EDMMT 2020Document2 pagesConference Brochure EDMMT 2020shafaathtNo ratings yet

- Finite Element Analysis and Modeling of Water AbsorptionDocument8 pagesFinite Element Analysis and Modeling of Water AbsorptionshafaathtNo ratings yet

- Coatings of Polymers and Plastics - Rose RyntzDocument371 pagesCoatings of Polymers and Plastics - Rose Ryntzakhand12724No ratings yet

- O Level Physics 2023-2025 ATP TipsDocument7 pagesO Level Physics 2023-2025 ATP TipsAmy WolmesNo ratings yet

- 3 Ijrerd-A128 PDFDocument6 pages3 Ijrerd-A128 PDFRathod NileshNo ratings yet

- The Midas Touch byDocument12 pagesThe Midas Touch byymmarga18No ratings yet

- Daltotherm TSW 38-00 SDS (2013.11.11)Document10 pagesDaltotherm TSW 38-00 SDS (2013.11.11)shane.scbservicesNo ratings yet

- Apollo-Soyuz Test ProjectDocument120 pagesApollo-Soyuz Test ProjectAviation/Space History LibraryNo ratings yet

- Mini ProjectDocument12 pagesMini ProjectHima Bindu PambalaNo ratings yet

- Proceedings 10th Mountain Cheese DefDocument95 pagesProceedings 10th Mountain Cheese DefLazline BrownNo ratings yet

- MNU-1651-51 (x51121 - E)Document264 pagesMNU-1651-51 (x51121 - E)HoppeHNo ratings yet

- Final Wind LoadDocument23 pagesFinal Wind LoadjohnrendeltumaronNo ratings yet

- CASE STUDY - Smart Stores Reinvent The Retail SpaceDocument1 pageCASE STUDY - Smart Stores Reinvent The Retail Spacetranthihien29604No ratings yet

- RP 2002E ManualDocument172 pagesRP 2002E ManualTu Pham Minh75% (16)

- Rohith R Fouress Report 1Document22 pagesRohith R Fouress Report 1Nithish ChandrashekarNo ratings yet

- Assignment: Embedded SystemsDocument6 pagesAssignment: Embedded SystemsSudarshanNo ratings yet

- Sabrine Lure of The Expanse ExpansionDocument9 pagesSabrine Lure of The Expanse Expansionmalador99991% (11)

- National Biogas Manure Management Programme (NBMMP) 12thplanDocument7 pagesNational Biogas Manure Management Programme (NBMMP) 12thplanRG SegaranNo ratings yet

- Hierapolis of Phrygia The Drawn Out DemiDocument33 pagesHierapolis of Phrygia The Drawn Out Demivladan stojiljkovicNo ratings yet

- Arni DivisionDocument42 pagesArni DivisionAO VandavasiNo ratings yet

- CRICKET SKILLS INJURY (PPT For Assignment) LnipeDocument59 pagesCRICKET SKILLS INJURY (PPT For Assignment) LnipeVinod Baitha (Vinod Sir)No ratings yet

- Francisco - JM - Ahu Equipment Selection FinalDocument30 pagesFrancisco - JM - Ahu Equipment Selection FinalJoe ManipolNo ratings yet

- BCA Semester 5 2019Document48 pagesBCA Semester 5 2019vaje rohanNo ratings yet

- ფიზიკა 7 - მოსწავლის წიგნიDocument219 pagesფიზიკა 7 - მოსწავლის წიგნიBeso ChargeishviliNo ratings yet

- LCI 80 Standard Line Control DisplayDocument2 pagesLCI 80 Standard Line Control DisplayMeasurementTechNo ratings yet

- Analysis and Modelling of CFT Members Moment Curvature AnalysisDocument10 pagesAnalysis and Modelling of CFT Members Moment Curvature AnalysisMahdi ValaeeNo ratings yet

- Kumon Mathematics Progress Tracker Levels C To O PDFDocument2 pagesKumon Mathematics Progress Tracker Levels C To O PDFcharmradeekNo ratings yet

- Lecture 1 Surface and Interfacial PhenomenaDocument26 pagesLecture 1 Surface and Interfacial Phenomenabattal eduNo ratings yet

- Fatima 121 ThesisDocument144 pagesFatima 121 ThesisNecesario BanaagNo ratings yet

- Insulin TherapyDocument14 pagesInsulin TherapyElimar Alejandra David GilNo ratings yet

- Periodic Waveform Generation in FPGADocument7 pagesPeriodic Waveform Generation in FPGAnm2007kNo ratings yet

- The Pentagon Bio-Weapons - Dilyana - BGDocument34 pagesThe Pentagon Bio-Weapons - Dilyana - BGOn The PathNo ratings yet