Professional Documents

Culture Documents

Arc Blow

Arc Blow

Uploaded by

rmjiranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arc Blow

Arc Blow

Uploaded by

rmjiranCopyright:

Available Formats

Prevent Arc Blow When Welding

Arc blow can cause a number of welding problems including excessive spatter, incomplete fusion and porosity. What is arc blow and how can it be prevented?

rc blow, also called arc wander, occurs in DC arc welding when the arc stream does not follow the shortest path between the electrode and the workpiece and deflects forward or backward from the direction of travel or, less frequently, to one side. Back blow occurs when welding toward the workpiece connection, the end of a joint or into a corner. Forward blow occurs when welding away from the workpiece connection, or at the starting end of the joint. It is especially troublesome when shielded-metal-arc (SMA) welding with electrodes that tend to produce large slag coverings. In these cases, forward blow drags the slag or the crater forward and under the arc, disrupting the weld. The direction of arc blow can be observed during open-arc welding, but not during submerged-arc welding. In this case, direction is determined by the type of weld defect produced. Back blow is indicated by spatter; undercut, either continuous or intermittent; a narrow, high bead, usually with undercut; an increase in penetration; or surface porosity at the finish end of welds on sheetmetal. Forward blow is indicated by a wide bead, irregular in width; a wavy bead; undercut, usually intermittent; or a decrease in penetration.

42

Electrode Travel

Forward blow

Back blow

Fig. 2Flux concentration behind the welding arc at the start of joint forces the arc forward while flux concentration ahead of the arc at the end of the joint forces the arc backward. Arc Direction of arc blow

rection to relieve squeezing and restore the magnetic-field balance, veering away from the side of flux concentration. This veering is observed as arc blow.

Work

Fig. 3Here, arc blow is caused by the welding current returning to the workpiece connection. The resulting magnetic flux combines with the flux around the electrode, causing a high-flux concentration at (x) that blows the arc away from the workpiece connection.

Arc-Blow Direction and Joint Location

Fig. 2 illustrates flux squeezing and distortion at the start and finish of a weld joint. At the start, flux lines concentrate behind the electrode. The arc tries to compensate for this imbalance by moving forward, creating forward arc blow. As the electrode approaches the end of the joint, the lines squeeze ahead of the arc. Again, the arc moves in a direction to relieve squeezing, in this case backward and observed as back blow. At the middle of a joint in two plates of the same width, the magnetic field is symmetrical, so no arc blow occurs. But, if one plate is wider than the other, side blow could occur at the midpoint of the weld due to flux squeezing. Another squeezing phenomenon results from the welding current returning back toward the workpiece connection within the workpiece. As shown in Fig. 3, electrical current passing through the workpiece to the workpiece lead may create a flux. The heavy line represents the path of the welding current while the light lines represent the flux created by the current. As the current changes direction or turns the corner from the arc to the work, a flux concentrates at x, causing arc blow away from the workpiece connection.

www.metalforming.com

Arc blow can be one of two types: magnetic or thermal.

Magnetic Arc Blow

Magnetic arc blow, responsible for more welding problems than thermal arc blow, results from an unbalanced condition in the magnetic field surrounding the arc. This unbalanced condition usually occurs because the arc is located farther from one end of the weld joint than the other end and at varying distances from the workpiece connection. Imbalance also exists due to the change in direction of weld current as it flows through the arc and into and through the workpiece.

www.metalforming.com

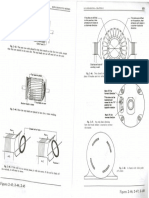

Fig. 1 shows a DC current passing through a conductoreiDirection ther the welding of flux electrode or the plasma stream between an electrode and a weld Direction joint. A magnetic of current field surrounds the conductor; Fig. 1Current its lines of mag- passing through a netic force, or conductor sets up a flux, are repre- magnetic field, repsented by con- resented by planes centric circles at of concentric circles right angles to known as flux lines.

MetalForming/May 2001

the direction of the current. These lines of force diminish in intensity in direct proportion to their distances from the electrical conductor. The lines of force remain circular in a medium large enough to contain them until they diminish to essentially nothing. But if the medium changes, from steel plate to air, for example, the circular lines become distorted and tend to concentrate in the steel where they encounter less resistance. At a boundary between the edges of a steel plate and air, the lines squeeze and deform. This results in a heavy flux concentration behind or ahead of the welding arc. The arc then tends to move in a diMay 2001/MetalForming

Arc movement due to this effect combines with movement resulting from the flux concentration previously described to give the observed arc blow. The effect of the returning current may diminish or increase the arc blow caused by the arc flux. In fact, controlling the direction of returning current is one way to control arc blow. In Fig. 4a, the workpiece cable connects to the starting end of the joint, and the flux created by the returning welding current in the work forms behind the arc. The resulting arc movement is forward. Near the end of the joint, however, forward arc movement diminishes the total arc blow by canceling some back blow created by flux concentration from the arc at the end of the workpiece (Fig. 5a). In Fig. 4b, the work cable connects to the finish end of the seam, resulting in back blow, increasing in intensity at the finish of the weld. Fig. 5b illustrates the combination of squeezed fluxes. A workpiece connection at the finish of the weld, however, may be needed to reduce excessive forward blow at the start of the weld. But workpiece-connection positioning is only moderately effective in controlling arc blow. Other measures should be used to reduce arc blow when welding.

43

Prevent Arc Blow When Welding

Fixtures Contribute to Arc Blow

(a)

Travel

(b)

e aware of the relationship of arc blow to weldment fixturing. Steel fixtures may effect the magnetic field around the arc, and may become magnetized over time. Usually, fixturing wont cause problems when SMA-welding if weld current does not exceed 250 amps. Fixtures used with higher currents and mechanized welding should be designed to minimize arcblow-promoting situations. Here are some fixture-design tips: Design fixtures for welding the longitudinal seam of cylinders with a minimum of 1-in. clearance between the supporting beam and the work. Use nonmagnetic clamping fingers or workholding bars. Do not attach the workpiece cable to the copper backup bar make the work connection directly to the workpiece. Fabricate the fixture from low-carbon steel to prevent buildup of permanent magnetism in the fixture. Weld toward the closed end of horn-type fixtures to reduce back blow. Design the fixture long enough so that end tabs can be used. Do not use a copper strip inserted in a steel bar for a backing. The steel part of the backup bar will increase arc blow. Provide for continuous or close clamping of parts to be seam welded. Wide, intermittent clamping may cause seams to gap between clamping points, causing arc blow over the gaps. Do not build into the fixture large masses of steel on one side of the seam only; counterbalance with a similar mass on the opposite side of the fixture.

Fig. 4Flux due to the welding current returning to the workpiece connection is behind the arc in (a) and ahead of the arc in (b).

(a)

Travel

(b)

Fig. 5In (a), magnetic blow at the finished end of a joint is reduced because the two flux fields tend to offset each other. In (b), the two fields combine to cause a strong back blow.

Problem Areas

Arc blow is especially problematic in the corners of fillet welds and in weld joints that use deep weld preparations. Here, the cause of arc blow is the same as when welding a straight seamflux concentration and the movement of the arc to relieve it. Figs. 6 and 7 illustrate where arc blow, when using DC current, is problematic. Using low welding current produces less arc blow than using high current because a higher current causes a more intense magnetic field. Usually, serious arc-blow problems do not occur when SMAwelding with DC under 250 amps, although joint fitup and geometry play a role. The use of AC current markedly reduces the likelihood of arc blow. The rapid reversal of the AC current induces eddy currents in the base metal, and the fields created by the eddy currents greatly reduce the strength of the magnetic fields that cause arc blow. Some materials, such as nine-percent nickel steels, are easily magnetized by external magnetic fields, such as those from power lines. These materials are difficult to weld due to arc blow

www.metalforming.com

produced by magnetic fields in the material. Hand-held Gauss meters easily detect and measure these fields. Fields higher than 20 Gauss can cause arc blow in these nickel steels.

Thermal Arc Blow

Thermal arc blow occurs because an electric arc requires hot zones on the electrode and workpiece plate to maintain a continuous flow of current in the arc stream. As the electrode advances along the work, the arc tends to lag behind, caused by reluctance of the arc to move to the colder plate. The ionized space between the end of the electrode and the hot surface of the molten crater creates a more conductive path than from the electrode to the colder

Fig. 6Arcblow difficulties abound when high-amp DC welding in deep-groove joints. Switching to AC current can alleviate this. Fig. 7Expect considerable arc blow when placing the inside fillet using DC current. Again, switching to AC current can help. MetalForming/May 2001

44

Prevent Arc Blow When Welding

c Fig. 8Multiple-arc welding, when the two arcs are located close together, may cause magnetic arc blow. When the arcs are of different polarity (a), the magnetic fields combine to blow arcs outward. If the arcs are of the same polarity (b), magnetic fields oppose each other and the arcs blow inward. With one arc powered by DC current and the other by AC current (c), little or no arc blow occurs.

plate. During manual welding, a small amount of thermal back blow due to arc lag is not detrimental, but becomes problematic at higher welding speeds, as occurring in automatic welding. Thermal arc blow sometimes may combine with magnetic back blow, leading to quality problems.

Arc Blow with Multiple-Arc Welding

Welding with multiple arcs, for high speed and increased productiv46

ity, can cause arc-blow problems, especially when two arcs are locat(a) (b) ed close together. If these two arcs have opposite polarities (Fig. 8a), magnetic fields between the arcs cause the arcs to Arc blow Blow reduced deflect away from each other. If polarity is identical (Fig. 8b), magnetic Fig. 9Arc blow (a) may be corrected fields between by angling the electrode (b). the arcs oppose each other, resulting in a Bead sequence weaker field between the arcs and causing the arcs to deflect Direction of welding toward each Weld both sides other. When using Fig. 10The direction of welding and the sequence of two arcs, one beads is illustrated for the back-step technique. Note the may be DC, the tabs on each end of the seamthey should be of the other AC (Fig. same thickness as the workpiece. 8c). Here, the AC-arc flux field Reduce the welding current. completely reverses for each cycle, which barely affects the DC field and This may require an arc-speed reduction. results in very little arc blow. Angle the electrode with the When using two AC arcs, a common arrangement, arc-blow interfer- work opposite to the direction of arc ence is avoided mainly by phase- blow (Fig. 9). Make a heavy tack weld on shifting the current of one arc 80 to 90 deg. from the other arc. With a both ends of the seam; apply frephase shift, the current and magnet- quent tack welds along the seam, esic fields of one arc reach a maximum pecially if fitup is loose. Weld toward a heavy tack weld when the current and magnetic fields of the other arc are at or near or toward a previously made weld. Use a backstep welding techminimum, resulting in very little, if nique (Fig. 10). any, arc blow. Weld away from the workpiece How to Reduce Arc Blow connection to reduce back blow, Not all arc blow is detrimental. In and weld toward the workpiece fact, a small amount helps form the connection to reduce forward blow. bead shape, control molten slag and If welding produces heavy slag, control penetration. But arc blow a small amount of back blow is demust be controlled when it con- sirable, and is attained by welding tributes to defects such as undercut, toward the workpiece connection. inconsistent penetration, crooked Wrap the work cable around beads, beads of irregular width, the workpiece so that the current reporosity, wavy beads and excessive turning to the power supply passes spatter. Possible corrective measures through it in such a direction that include the following: the magnetic field setup neutralizes If DC current is being used with the magnetic field causing the arc the SMAW processespecially at blow. MF welding current greater than 250 ampschange to AC current. Information for this article was Hold as short an arc as possible supplied by The Lincoln Electric Co., to help arc force counteract arc Cleveland, OH; tel. 216/481-8100; blow. www.lincolnelectric.com.

www.metalforming.com MetalForming/May 2001

You might also like

- 1 - SINCRO - 7a - EN - DESCRIPTION AND TECHNICAL FEATURESDocument45 pages1 - SINCRO - 7a - EN - DESCRIPTION AND TECHNICAL FEATURESBoldsaikhan Tavkhai100% (1)

- Fire Resistant Cables CatalogueDocument7 pagesFire Resistant Cables CatalogueSathis Kumar Naidu Thasnamoothy100% (2)

- Astm C-42 Core TestDocument5 pagesAstm C-42 Core TestPapaDaplisNo ratings yet

- Silver Bridge Collapse Research PaperDocument5 pagesSilver Bridge Collapse Research Paperzoraiz shahidNo ratings yet

- Cisco Advanced IPSec With FlexVPNDocument91 pagesCisco Advanced IPSec With FlexVPNSrdjan MilenkovicNo ratings yet

- N28 - AS0715 - S003 - 2010-03-22 BoschDocument4 pagesN28 - AS0715 - S003 - 2010-03-22 BoschjoaopedrosousaNo ratings yet

- Database EvolutionDocument8 pagesDatabase EvolutionKrissa VillanuevaNo ratings yet

- Assignment 2Document5 pagesAssignment 2tilahun Mersha50% (2)

- Corriente Continua PDFDocument44 pagesCorriente Continua PDFGeraldynne SierraNo ratings yet

- Waves Program Feb 2023Document56 pagesWaves Program Feb 2023mohgana ponnampalamNo ratings yet

- Cover Concrete: Effectively Confined Section B-B Cover Concrete (Spalls Off) - Q-Ra Ineffectively Confined Core S/sDocument1 pageCover Concrete: Effectively Confined Section B-B Cover Concrete (Spalls Off) - Q-Ra Ineffectively Confined Core S/sRonal J Clavijo RNo ratings yet

- Notes-Api Exams-Prathap DhasDocument7 pagesNotes-Api Exams-Prathap DhasAnonymous 4e7GNjzGWNo ratings yet

- Figure 9Document1 pageFigure 9suryansh guptaNo ratings yet

- Iso 9600Document19 pagesIso 9600Chinh PhamNo ratings yet

- How To Prevent Arc BlowDocument12 pagesHow To Prevent Arc BlowFelix GomintongNo ratings yet

- Arc BlowDocument8 pagesArc BlowAnonymous 4e7GNjzGWNo ratings yet

- 1987_Mawardi_Armature reaction in a flux pumpDocument4 pages1987_Mawardi_Armature reaction in a flux pumpLaukik DesaiNo ratings yet

- Polarity of Power Inductor An-E 0 ROHMDocument11 pagesPolarity of Power Inductor An-E 0 ROHMcyo3fffNo ratings yet

- Adobe Scan 22 May 2024Document1 pageAdobe Scan 22 May 2024subhabuddy0No ratings yet

- V-8120 DWG CommentsDocument1 pageV-8120 DWG CommentsSulist N Wahyudie100% (1)

- Deflection of Beams and Shafts: The Elastic CurveDocument13 pagesDeflection of Beams and Shafts: The Elastic CurveNoermansyar SikandeNo ratings yet

- Switch Nozzle Position As Per Latest Dwg. (Mirrored), See Below CaptureDocument1 pageSwitch Nozzle Position As Per Latest Dwg. (Mirrored), See Below CaptureSulist N WahyudieNo ratings yet

- Seminar - Active Magnetic BearingsDocument14 pagesSeminar - Active Magnetic BearingskichupadiyathNo ratings yet

- Bending of BeamDocument4 pagesBending of BeamsvpNo ratings yet

- CE Board Nov 2020 - RCD - Set 8 and 9Document6 pagesCE Board Nov 2020 - RCD - Set 8 and 9Dale MalazzabNo ratings yet

- Electromagnetic Waves 2022Document12 pagesElectromagnetic Waves 2022ADITYA MAHECHANo ratings yet

- VBNJLKJHGDocument1 pageVBNJLKJHGAli MahamedNo ratings yet

- IMG - 0032 PSME Code 2008 21Document1 pageIMG - 0032 PSME Code 2008 21Arwyn BermasNo ratings yet

- Dae Hep Poster2Document2 pagesDae Hep Poster2Random PersonNo ratings yet

- Sample Exam 2Document3 pagesSample Exam 2DiexNo ratings yet

- Electrical Machines IIDocument6 pagesElectrical Machines IIsuryaprakash001No ratings yet

- Preparing To Weld: Unit 11Document3 pagesPreparing To Weld: Unit 11ahmedNo ratings yet

- HysteresisDocument8 pagesHysteresiscidadedoconcretoeacoNo ratings yet

- PH34 7.0 Physics Exam Cheat Sheet BorderDocument2 pagesPH34 7.0 Physics Exam Cheat Sheet BorderBatza BatsakisNo ratings yet

- Electrostatics + Magnetostatic + CurrentDocument1 pageElectrostatics + Magnetostatic + Currentrudraveer2805No ratings yet

- DeepLay-eks-2022-183 - Distributed Buoyancy Module For Lazy WaveDocument13 pagesDeepLay-eks-2022-183 - Distributed Buoyancy Module For Lazy WaveGunawan SuwarnoNo ratings yet

- Scan0055 PDFDocument1 pageScan0055 PDFJayson Jonson AraojoNo ratings yet

- RRTC Sept.05 G Caronno Fired Heaters PresentationJH Final 1 AnimatedDocument21 pagesRRTC Sept.05 G Caronno Fired Heaters PresentationJH Final 1 AnimatedAhmed J Al-Terkait0% (1)

- Short Circuit Design 9.8.22Document51 pagesShort Circuit Design 9.8.22jackthonetNo ratings yet

- Wave Optics Class - 1 (Notes)Document21 pagesWave Optics Class - 1 (Notes)Krishna GuptaNo ratings yet

- 15.3 Open Coiled Helical Springs: To and MeanDocument19 pages15.3 Open Coiled Helical Springs: To and MeanBiswadeep Roy ChoudhuryNo ratings yet

- Numerical Investigation of Oblique Shock Wave/vortex Interaction.Document14 pagesNumerical Investigation of Oblique Shock Wave/vortex Interaction.alvaro737max10No ratings yet

- Unit 9 PDFDocument20 pagesUnit 9 PDFpoojaNo ratings yet

- Def Fen Baugh 1946Document4 pagesDef Fen Baugh 1946Kevin Fachrul Razi LubisNo ratings yet

- Relativistic Pendulum and The Weak Equivalence PriDocument11 pagesRelativistic Pendulum and The Weak Equivalence PriVatsalNo ratings yet

- A Study of The Initial Surge Distribution inDocument17 pagesA Study of The Initial Surge Distribution inibrahimNo ratings yet

- Linear Theory With Snell'S: Wave Transformation ACES Technical ReferenceDocument18 pagesLinear Theory With Snell'S: Wave Transformation ACES Technical ReferenceSamirNo ratings yet

- TwoStep Linkage SSP9028 v10Document1 pageTwoStep Linkage SSP9028 v10David BriggsNo ratings yet

- Light Lenses EM SpectrumDocument25 pagesLight Lenses EM SpectrumSYED MUHAMMAD UZAIRNo ratings yet

- Useof DescartesfoliumequationDocument13 pagesUseof Descartesfoliumequationموسى حسنNo ratings yet

- Lecture 3 Sem 2 2020 PDFDocument8 pagesLecture 3 Sem 2 2020 PDFMohamadNo ratings yet

- AP Physc em Electromagnetic Problem Solving Techniques 2020-03-20Document64 pagesAP Physc em Electromagnetic Problem Solving Techniques 2020-03-20Armored SumanNo ratings yet

- BHA AnalysisDocument15 pagesBHA Analysismfazaeli40No ratings yet

- 24 PDFDocument21 pages24 PDFJasdeepSinghNo ratings yet

- HFBV Viaduct - IdeaDocument1 pageHFBV Viaduct - Ideastavros stergiopoulosNo ratings yet

- Vogel PaperDocument7 pagesVogel PaperRanjith BhoopalNo ratings yet

- KMC EE 2022 JuneDocument10 pagesKMC EE 2022 JuneDIPNo ratings yet

- Ae2 Comp Insta Guide Na enDocument2 pagesAe2 Comp Insta Guide Na enAnonymous rrD8UKYNXNo ratings yet

- Equipotential Surfaces For Uniformly Charged Symmetric Polyhedral ConductorsDocument7 pagesEquipotential Surfaces For Uniformly Charged Symmetric Polyhedral ConductorsNizwan AhammadNo ratings yet

- Appendix IDocument5 pagesAppendix ISƠN NGUYỄN NGỌC TRƯỜNGNo ratings yet

- Matirial ThingsDocument1 pageMatirial ThingshongNo ratings yet

- De MagnetizationDocument9 pagesDe Magnetization322399mk7086No ratings yet

- A Coneccion SD PastillasDocument1 pageA Coneccion SD PastillasCarlos NarvaezNo ratings yet

- Pages From Smith & Hendy 2009 6Document1 pagePages From Smith & Hendy 2009 6Napong SubanpongNo ratings yet

- Harman Kardon Omni 50 PLDocument30 pagesHarman Kardon Omni 50 PLApostolie IulianNo ratings yet

- Guidance On Bolted JointsDocument54 pagesGuidance On Bolted JointsGerman ToledoNo ratings yet

- Cranes Inspection ChecklistDocument4 pagesCranes Inspection ChecklistApostolie IulianNo ratings yet

- Laggan-Tormore Project: TOTAL E&P UK LimitedDocument2 pagesLaggan-Tormore Project: TOTAL E&P UK LimitedApostolie IulianNo ratings yet

- Design Model of Automation Washer For Two Tubes Aperture (Twin Tube Top Loader) Microcontroller Based Atmega32Document11 pagesDesign Model of Automation Washer For Two Tubes Aperture (Twin Tube Top Loader) Microcontroller Based Atmega32Intan ArdinaNo ratings yet

- Oracle Secondary Ledger Set UpDocument20 pagesOracle Secondary Ledger Set UpPraveen KsNo ratings yet

- Collapse of The World Trade CentreDocument15 pagesCollapse of The World Trade CentrePiyush KumarNo ratings yet

- Kerala's Baby Steps Toward Sanitation - The Vilappilasala PlantDocument5 pagesKerala's Baby Steps Toward Sanitation - The Vilappilasala PlantDr.Thrivikramji.K.P.No ratings yet

- Manual Silver Crest SFB 10.1 A1 10-In-1 Remote ControlDocument111 pagesManual Silver Crest SFB 10.1 A1 10-In-1 Remote ControlDragos DragoshNo ratings yet

- Selection of Eag (Van, Lui Luong)Document9 pagesSelection of Eag (Van, Lui Luong)ntt_121987No ratings yet

- NemaDocument4 pagesNemaMohamed ElfekyNo ratings yet

- QR1207 Preact SysDocument1 pageQR1207 Preact SysLe DucNo ratings yet

- Metalclad PlusDocument12 pagesMetalclad PlusAbdullah JavedNo ratings yet

- Late Torque Converter PartsDocument60 pagesLate Torque Converter Partseduardo100% (1)

- IC Contractor Progress Payment Template 8531 V1Document6 pagesIC Contractor Progress Payment Template 8531 V1elbaraniNo ratings yet

- 2023 01 Gasket-HandbookDocument216 pages2023 01 Gasket-Handbookrbnotosagoro100% (1)

- Grease 2Document4 pagesGrease 2arunNo ratings yet

- Pipe ThicknessDocument8 pagesPipe ThicknessvijayunityNo ratings yet

- Kromatografi KolomDocument20 pagesKromatografi KolomRista Siti MaarniNo ratings yet

- Surdial Service ManualDocument130 pagesSurdial Service Manualdjayriddler67% (3)

- Interface Qos: Security LevelDocument6 pagesInterface Qos: Security Levelmafasa_2005No ratings yet

- 50-Applicable Codes and StandardsDocument48 pages50-Applicable Codes and StandardsmohsenNo ratings yet

- Calculate % Voltage Regulation of Line (1.1.17)Document17 pagesCalculate % Voltage Regulation of Line (1.1.17)Raheleh JavidNo ratings yet

- Quantification Methodology For The Use of Sulphur Concrete in Precast Applications (First Assessment Version) - 0Document33 pagesQuantification Methodology For The Use of Sulphur Concrete in Precast Applications (First Assessment Version) - 0Verma NverNo ratings yet

- BuildingSMART IFC4 What Is NewDocument25 pagesBuildingSMART IFC4 What Is Newlaurenssen0% (1)

- H 99 Sec 8 D 1 App 1Document9 pagesH 99 Sec 8 D 1 App 1Benjamin Enmanuel Mango DNo ratings yet