Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

48 viewsFailure Analysis Report of TCM Cut Failure in Stand

Failure Analysis Report of TCM Cut Failure in Stand

Uploaded by

Saurav SinghThe failure analysis report summarizes a cut failure that occurred in TCM #3 stand on 16/03/09. Observations found that the flame was improper and not cutting the billet. The main reasons for failure were identified as a clogged electrical solenoid valve, clogged safety valves on the cutting, preheating, and propen lines, and a damaged pressure regulator. Upon changing these components, foreign particles were found in the valves and a damaged strainer was found in the pressure regulator. It is recommended that pressure regulators be checked and cleaned during every shutdown.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You might also like

- Package Question List: UPT Periode Exam Code Level Package CodeDocument5 pagesPackage Question List: UPT Periode Exam Code Level Package CodeYoga Heru NNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- BHEL 600 MW Soot BlowerDocument279 pagesBHEL 600 MW Soot BlowerAmit Biswas75% (8)

- P5 Kia+carnival+07+2.7+gazDocument106 pagesP5 Kia+carnival+07+2.7+gazĐức Hòang50% (2)

- Section - 1: Meo Class 4 - Electrical Oral Questions With AnswersDocument81 pagesSection - 1: Meo Class 4 - Electrical Oral Questions With Answersbaba maachoNo ratings yet

- Transformer FailureDocument66 pagesTransformer FailureLammie Sing Yew Lam100% (1)

- CBA Example Application 2012Document38 pagesCBA Example Application 2012Manuel FernizaNo ratings yet

- Scope of Work For Cranes: Utility & Power HouseDocument2 pagesScope of Work For Cranes: Utility & Power HouseRana ImtiazNo ratings yet

- MEP Objective March 2013Document49 pagesMEP Objective March 2013lazyreaderr100% (1)

- B. The Type of Message They Send or ReceiveDocument7 pagesB. The Type of Message They Send or ReceiveLee Matthew BorlagdanNo ratings yet

- Circuit Breaker TestingDocument17 pagesCircuit Breaker Testingtibetanlama100% (1)

- Duo Therm TroubleshooterDocument9 pagesDuo Therm TroubleshooterDale LewisNo ratings yet

- Inrd Ea09008 38753PDocument263 pagesInrd Ea09008 38753PCarlos CisnerosNo ratings yet

- UntitledDocument88 pagesUntitledGaurav GairolaNo ratings yet

- Horton Toubleshooting GuideDocument1 pageHorton Toubleshooting GuideGabriel Castillo MuñozNo ratings yet

- Repair ManualDocument5 pagesRepair ManualAzhar Ibrahim50% (4)

- Feed Water UnitDocument2 pagesFeed Water UnitEslam ElsayedNo ratings yet

- Fouress Valve DrawingsDocument3 pagesFouress Valve DrawingsNaveen NagisettiNo ratings yet

- Incident Report PDFDocument2 pagesIncident Report PDFParekh KarNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0031Document10 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0031Elmer PerezNo ratings yet

- Part 5 Fan ControlsDocument10 pagesPart 5 Fan Controlsmuhammad nazirNo ratings yet

- Pre Test - TransformerDocument4 pagesPre Test - TransformerخالدNo ratings yet

- Marine Engineering PracticeDocument159 pagesMarine Engineering PracticeRemisius Corera100% (1)

- ATT III - 8. Maintenance and Repair of Electrical and Electronic EquipmentDocument8 pagesATT III - 8. Maintenance and Repair of Electrical and Electronic EquipmentGideon TariganNo ratings yet

- Industrial Training Seminar ON "Transformer Construction" ATDocument27 pagesIndustrial Training Seminar ON "Transformer Construction" ATbhattparthivNo ratings yet

- Transformer Failure InvestigationDocument5 pagesTransformer Failure InvestigationVishal Mahire100% (2)

- GR00004300B 13aDocument274 pagesGR00004300B 13aEduardo Enrique Rojas Valenzuela100% (1)

- 220kV SF6 Circuit BreakerDocument24 pages220kV SF6 Circuit BreakerHusein Okhonov100% (1)

- Answers (1) (2) (1) (1) (1) (1) 1Document3 pagesAnswers (1) (2) (1) (1) (1) (1) 1tirunehdefaru1No ratings yet

- .:: Astrill Error ::. &NBSP Connection To WWW - Scribd.com:80 Failed (Socket Error # 11002 )Document67 pages.:: Astrill Error ::. &NBSP Connection To WWW - Scribd.com:80 Failed (Socket Error # 11002 )Hamed GeramiNo ratings yet

- 2011 Sept 26th Class IVDocument3 pages2011 Sept 26th Class IVNabi Jan ChoohanNo ratings yet

- Interview Questions On Transformer ProtectionDocument3 pagesInterview Questions On Transformer ProtectionM Moarraf Naeem100% (2)

- CSTPS 4 - 09 11 2013Document2 pagesCSTPS 4 - 09 11 2013SE ESTNo ratings yet

- Injection Molding Machine's Error Codes and Troubleshooting SolutionsDocument5 pagesInjection Molding Machine's Error Codes and Troubleshooting SolutionsarijitoNo ratings yet

- AuditDocument3 pagesAuditswapnil majeeNo ratings yet

- Maint. SchedulesDocument109 pagesMaint. SchedulesShahriyar Kabir RistaNo ratings yet

- Tube Deterioration in Fired HeatersDocument7 pagesTube Deterioration in Fired HeatersChem.EnggNo ratings yet

- Inspection Procedure 24 Ignition Circuit SystemDocument7 pagesInspection Procedure 24 Ignition Circuit SystemMortada AlsonniNo ratings yet

- 2nd TA Modification Work List Rev1Document71 pages2nd TA Modification Work List Rev1Vy NguyenNo ratings yet

- HDT Job List For AUG '08Document3 pagesHDT Job List For AUG '08Alex LeeNo ratings yet

- Failures Analyzing and SolutionDocument10 pagesFailures Analyzing and SolutionAam AadmiNo ratings yet

- As68rc ElectricalDocument2 pagesAs68rc Electricalruben casiqueNo ratings yet

- Rioc - Diesel Hydrant Pump-6aDocument3 pagesRioc - Diesel Hydrant Pump-6aeeeeaNo ratings yet

- Q and A Part1Document56 pagesQ and A Part1Subramanian VenkatNo ratings yet

- CHE EP - Troubleshooting Tube-Deteriorration Mechanisms in Direct-FiredHeaters - May 2015Document11 pagesCHE EP - Troubleshooting Tube-Deteriorration Mechanisms in Direct-FiredHeaters - May 2015John UrdanetaNo ratings yet

- Special Topics - Industrial Elex and Medical ElexDocument5 pagesSpecial Topics - Industrial Elex and Medical ElexGepel OntanillasNo ratings yet

- Tep 0066Document7 pagesTep 0066RAMKUMARNo ratings yet

- Special Topics - Industrial ElexDocument5 pagesSpecial Topics - Industrial ElexGepel OntanillasNo ratings yet

- PRS Lab Manual 2020 1 R FinalDocument22 pagesPRS Lab Manual 2020 1 R Finalstephan dsilvaNo ratings yet

- Section - 1: Meo Class 4 - Electrical Oral Questions With AnswersDocument81 pagesSection - 1: Meo Class 4 - Electrical Oral Questions With AnswersHelna joseph JOSENo ratings yet

- Ccad-Aed-Meters and Gauges For Hvac PipingDocument5 pagesCcad-Aed-Meters and Gauges For Hvac PipingArun UdayabhanuNo ratings yet

- Operating SequencesDocument2 pagesOperating SequencesDC VashistNo ratings yet

- 09-03-20 B - ShiftDocument13 pages09-03-20 B - Shiftneha khanNo ratings yet

- Section 21 05 23Document6 pagesSection 21 05 23Ismail MohammadNo ratings yet

- Q&A For Instrument TechnicianDocument15 pagesQ&A For Instrument Technicianworkt1me100% (3)

- Manual Trident Klasik 200 - CompressDocument12 pagesManual Trident Klasik 200 - CompressAleš FejglNo ratings yet

- SMP - O2 AnalyserDocument5 pagesSMP - O2 AnalyserPragneshNo ratings yet

- How Many Fire/overheat Detectors Does The Engine Fire/overheat Detection System Comprise Of? (Level 2)Document33 pagesHow Many Fire/overheat Detectors Does The Engine Fire/overheat Detection System Comprise Of? (Level 2)Phạm Hà TiếnNo ratings yet

- Samsung Rl23-25-28 Dats Datw Service ManualDocument28 pagesSamsung Rl23-25-28 Dats Datw Service ManualKonstantinas OtNo ratings yet

Failure Analysis Report of TCM Cut Failure in Stand

Failure Analysis Report of TCM Cut Failure in Stand

Uploaded by

Saurav Singh0 ratings0% found this document useful (0 votes)

48 views1 pageThe failure analysis report summarizes a cut failure that occurred in TCM #3 stand on 16/03/09. Observations found that the flame was improper and not cutting the billet. The main reasons for failure were identified as a clogged electrical solenoid valve, clogged safety valves on the cutting, preheating, and propen lines, and a damaged pressure regulator. Upon changing these components, foreign particles were found in the valves and a damaged strainer was found in the pressure regulator. It is recommended that pressure regulators be checked and cleaned during every shutdown.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe failure analysis report summarizes a cut failure that occurred in TCM #3 stand on 16/03/09. Observations found that the flame was improper and not cutting the billet. The main reasons for failure were identified as a clogged electrical solenoid valve, clogged safety valves on the cutting, preheating, and propen lines, and a damaged pressure regulator. Upon changing these components, foreign particles were found in the valves and a damaged strainer was found in the pressure regulator. It is recommended that pressure regulators be checked and cleaned during every shutdown.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

48 views1 pageFailure Analysis Report of TCM Cut Failure in Stand

Failure Analysis Report of TCM Cut Failure in Stand

Uploaded by

Saurav SinghThe failure analysis report summarizes a cut failure that occurred in TCM #3 stand on 16/03/09. Observations found that the flame was improper and not cutting the billet. The main reasons for failure were identified as a clogged electrical solenoid valve, clogged safety valves on the cutting, preheating, and propen lines, and a damaged pressure regulator. Upon changing these components, foreign particles were found in the valves and a damaged strainer was found in the pressure regulator. It is recommended that pressure regulators be checked and cleaned during every shutdown.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 1

31/01/2012 00:14:52

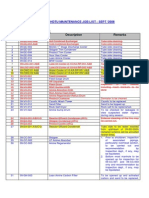

Failure analysis report of TCM cut failure in stand#3

1. DESCRIPTION------ Regular cut failure in TCM#3 from 16/03/09 2. OBSERVATION-----During observation I found that flame is not proper and not Cutting the billet. 3.REASON OF FAILURE---- There are many possibilities listed here (A) Due to electrical sylonide valve clogged (B) Due to safety valve clogging (cutting line, preheating line, propen line. (C) Due to pressure regulator damaged. (D) Due to cutting nozzle jam. (E) Leakage in line. (F) Due to edge correction value. (G) Due to initial slow region. 4.FINDINGS----- First of all we changed the electrical sylonide valve and then we open The valve and got there are some foreign particle in it. Secondly we changed the cutting line safety valve and we got the Same foreign particles are there. Thirdly we changed the pressure regulator and we got that Regulators strainer was damaged. 5. RECOMMANDATION-------In every shut down pressure regulator should be checked And clean.

NAME MAHESH KUMAR P.NO - 503734

You might also like

- Package Question List: UPT Periode Exam Code Level Package CodeDocument5 pagesPackage Question List: UPT Periode Exam Code Level Package CodeYoga Heru NNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- BHEL 600 MW Soot BlowerDocument279 pagesBHEL 600 MW Soot BlowerAmit Biswas75% (8)

- P5 Kia+carnival+07+2.7+gazDocument106 pagesP5 Kia+carnival+07+2.7+gazĐức Hòang50% (2)

- Section - 1: Meo Class 4 - Electrical Oral Questions With AnswersDocument81 pagesSection - 1: Meo Class 4 - Electrical Oral Questions With Answersbaba maachoNo ratings yet

- Transformer FailureDocument66 pagesTransformer FailureLammie Sing Yew Lam100% (1)

- CBA Example Application 2012Document38 pagesCBA Example Application 2012Manuel FernizaNo ratings yet

- Scope of Work For Cranes: Utility & Power HouseDocument2 pagesScope of Work For Cranes: Utility & Power HouseRana ImtiazNo ratings yet

- MEP Objective March 2013Document49 pagesMEP Objective March 2013lazyreaderr100% (1)

- B. The Type of Message They Send or ReceiveDocument7 pagesB. The Type of Message They Send or ReceiveLee Matthew BorlagdanNo ratings yet

- Circuit Breaker TestingDocument17 pagesCircuit Breaker Testingtibetanlama100% (1)

- Duo Therm TroubleshooterDocument9 pagesDuo Therm TroubleshooterDale LewisNo ratings yet

- Inrd Ea09008 38753PDocument263 pagesInrd Ea09008 38753PCarlos CisnerosNo ratings yet

- UntitledDocument88 pagesUntitledGaurav GairolaNo ratings yet

- Horton Toubleshooting GuideDocument1 pageHorton Toubleshooting GuideGabriel Castillo MuñozNo ratings yet

- Repair ManualDocument5 pagesRepair ManualAzhar Ibrahim50% (4)

- Feed Water UnitDocument2 pagesFeed Water UnitEslam ElsayedNo ratings yet

- Fouress Valve DrawingsDocument3 pagesFouress Valve DrawingsNaveen NagisettiNo ratings yet

- Incident Report PDFDocument2 pagesIncident Report PDFParekh KarNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0031Document10 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0031Elmer PerezNo ratings yet

- Part 5 Fan ControlsDocument10 pagesPart 5 Fan Controlsmuhammad nazirNo ratings yet

- Pre Test - TransformerDocument4 pagesPre Test - TransformerخالدNo ratings yet

- Marine Engineering PracticeDocument159 pagesMarine Engineering PracticeRemisius Corera100% (1)

- ATT III - 8. Maintenance and Repair of Electrical and Electronic EquipmentDocument8 pagesATT III - 8. Maintenance and Repair of Electrical and Electronic EquipmentGideon TariganNo ratings yet

- Industrial Training Seminar ON "Transformer Construction" ATDocument27 pagesIndustrial Training Seminar ON "Transformer Construction" ATbhattparthivNo ratings yet

- Transformer Failure InvestigationDocument5 pagesTransformer Failure InvestigationVishal Mahire100% (2)

- GR00004300B 13aDocument274 pagesGR00004300B 13aEduardo Enrique Rojas Valenzuela100% (1)

- 220kV SF6 Circuit BreakerDocument24 pages220kV SF6 Circuit BreakerHusein Okhonov100% (1)

- Answers (1) (2) (1) (1) (1) (1) 1Document3 pagesAnswers (1) (2) (1) (1) (1) (1) 1tirunehdefaru1No ratings yet

- .:: Astrill Error ::. &NBSP Connection To WWW - Scribd.com:80 Failed (Socket Error # 11002 )Document67 pages.:: Astrill Error ::. &NBSP Connection To WWW - Scribd.com:80 Failed (Socket Error # 11002 )Hamed GeramiNo ratings yet

- 2011 Sept 26th Class IVDocument3 pages2011 Sept 26th Class IVNabi Jan ChoohanNo ratings yet

- Interview Questions On Transformer ProtectionDocument3 pagesInterview Questions On Transformer ProtectionM Moarraf Naeem100% (2)

- CSTPS 4 - 09 11 2013Document2 pagesCSTPS 4 - 09 11 2013SE ESTNo ratings yet

- Injection Molding Machine's Error Codes and Troubleshooting SolutionsDocument5 pagesInjection Molding Machine's Error Codes and Troubleshooting SolutionsarijitoNo ratings yet

- AuditDocument3 pagesAuditswapnil majeeNo ratings yet

- Maint. SchedulesDocument109 pagesMaint. SchedulesShahriyar Kabir RistaNo ratings yet

- Tube Deterioration in Fired HeatersDocument7 pagesTube Deterioration in Fired HeatersChem.EnggNo ratings yet

- Inspection Procedure 24 Ignition Circuit SystemDocument7 pagesInspection Procedure 24 Ignition Circuit SystemMortada AlsonniNo ratings yet

- 2nd TA Modification Work List Rev1Document71 pages2nd TA Modification Work List Rev1Vy NguyenNo ratings yet

- HDT Job List For AUG '08Document3 pagesHDT Job List For AUG '08Alex LeeNo ratings yet

- Failures Analyzing and SolutionDocument10 pagesFailures Analyzing and SolutionAam AadmiNo ratings yet

- As68rc ElectricalDocument2 pagesAs68rc Electricalruben casiqueNo ratings yet

- Rioc - Diesel Hydrant Pump-6aDocument3 pagesRioc - Diesel Hydrant Pump-6aeeeeaNo ratings yet

- Q and A Part1Document56 pagesQ and A Part1Subramanian VenkatNo ratings yet

- CHE EP - Troubleshooting Tube-Deteriorration Mechanisms in Direct-FiredHeaters - May 2015Document11 pagesCHE EP - Troubleshooting Tube-Deteriorration Mechanisms in Direct-FiredHeaters - May 2015John UrdanetaNo ratings yet

- Special Topics - Industrial Elex and Medical ElexDocument5 pagesSpecial Topics - Industrial Elex and Medical ElexGepel OntanillasNo ratings yet

- Tep 0066Document7 pagesTep 0066RAMKUMARNo ratings yet

- Special Topics - Industrial ElexDocument5 pagesSpecial Topics - Industrial ElexGepel OntanillasNo ratings yet

- PRS Lab Manual 2020 1 R FinalDocument22 pagesPRS Lab Manual 2020 1 R Finalstephan dsilvaNo ratings yet

- Section - 1: Meo Class 4 - Electrical Oral Questions With AnswersDocument81 pagesSection - 1: Meo Class 4 - Electrical Oral Questions With AnswersHelna joseph JOSENo ratings yet

- Ccad-Aed-Meters and Gauges For Hvac PipingDocument5 pagesCcad-Aed-Meters and Gauges For Hvac PipingArun UdayabhanuNo ratings yet

- Operating SequencesDocument2 pagesOperating SequencesDC VashistNo ratings yet

- 09-03-20 B - ShiftDocument13 pages09-03-20 B - Shiftneha khanNo ratings yet

- Section 21 05 23Document6 pagesSection 21 05 23Ismail MohammadNo ratings yet

- Q&A For Instrument TechnicianDocument15 pagesQ&A For Instrument Technicianworkt1me100% (3)

- Manual Trident Klasik 200 - CompressDocument12 pagesManual Trident Klasik 200 - CompressAleš FejglNo ratings yet

- SMP - O2 AnalyserDocument5 pagesSMP - O2 AnalyserPragneshNo ratings yet

- How Many Fire/overheat Detectors Does The Engine Fire/overheat Detection System Comprise Of? (Level 2)Document33 pagesHow Many Fire/overheat Detectors Does The Engine Fire/overheat Detection System Comprise Of? (Level 2)Phạm Hà TiếnNo ratings yet

- Samsung Rl23-25-28 Dats Datw Service ManualDocument28 pagesSamsung Rl23-25-28 Dats Datw Service ManualKonstantinas OtNo ratings yet