Professional Documents

Culture Documents

90322710ADOBROVICESCU pp336-345

90322710ADOBROVICESCU pp336-345

Uploaded by

Livia NedelkovskiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

90322710ADOBROVICESCU pp336-345

90322710ADOBROVICESCU pp336-345

Uploaded by

Livia NedelkovskiCopyright:

Available Formats

Thermotechnique et thermonergtique

THERMOECONOMIC OPTIMIZATION OF ENERGETIC

SYSTEMS BASED ON THE MARGINAL COST CONCEPT

ALEXANDRU DOBROVICESCU,

1

DORIN STANCIU,

1

TUDOR PRISECARU,

1

MLINA PRISECARU,

1

CAMELIA PETRE,

1

GEORGIANA TRC-DRAGOMIRESCU

1

Key words: Exergetic analysis, Thermoeconomics, Optimization, Marginal cost.

The target of the paper is to bring an argument on behalf of the use of exergy in the

analysis of the operating and optimization of complex energetic systems. For a system

with more than one product, the proper cost assessment for each one of them requires,

besides the global economic balance, some supplementary assumptions. The exergetic

equivalence succeeds in giving the true value of utilization for different types of energy

products; the cost assessment based on exergetic analysis is close to reality. For a single

product system the optimization procedure based on the first law of thermodynamics

only, implies complicated calculus. The use of the marginal cost concept in the

optimization analysis based on Lagranges multipliers gives the direction to follow for

the optimum solution field search.

1. INTRODUCTION

The union between the thermodynamics of irreversible processes and

economics, known as exergoeconomics, currently represents the most important

instrument for analyzing and optimizing complex energy systems [1, 2]. Also, the

optimal power flow method may be used for the operating costs minimization of

exergy consumer networks [3]. Nevertheless exergoeconomics is the only method

that points out the correlation between the cost of the useful energy destruction and

the capital investment cost leading to the estimation of the minimum total cost

given by the sum between the operating and investment cost.

2. OPERATING COST ASSESSING

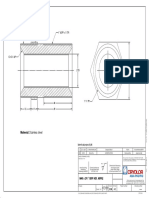

Fig. 1 shows a cogeneration system producing work (electricity) and heat

(thermal energy), represented by a steam turbine plant with backpressure.

1

University Politehnica of Bucharest, adobrovicescu@yahoo.com

Rev. Roum. Sci. Techn. lectrotechn. et nerg., 56, 3, p. 336346, Bucarest, 2011

2 Alexandru Dobrovicescu et al. 337

a b

Fig. 1 Cogeneration steam turbine system: a flow diagram; b T-s diagram.

The question that arises is to find out the proper cost of each one of the two

products. For simplicity only the operating cost is considered.

F W Q

C C C = +

. (1)

Equation (1) containes two variables the cost of the mechanical

power

W

C

and the cost of the heat flow

Q

C

suplied to the costumer.

To specify the numerical values of the two variables a second condition is

required.

2.1. ENERGETIC EQUIVALENCE

Taking into account only the First Law of Thermodynamics one can consider

the mechanical work (electricity) and heat as equivalent.

The unitary energy cost of each one of the two products becomes:

eur

s

MJ energy

s

F

e

C

c

Q W

(

(

=

(

+

(

eur

MJ energy

(

(

, (2)

and therefore

e

W e

C c W =

eur

s

(

(

and

e

Q e

C c Q =

eur

s

(

(

. (3)

338 Thermoeconomic optimization through marginal cost concept 3

2.2. EXERGETIC EQUIVALENCE

Keenan (1932) [4] is considered to be the first who proposed the use of

thermodynamic equivalence (based on both the First and Second Law of

Thermodynamics, called later exergetic equivalence).

Whithin the thermodynamic (exergetic) equivalence conditions the exergetic

unitary cost of each one of the two products becomes:

eur

s

MJ exergy

s

F

ex

Q

C

c

Ex W

(

(

=

(

+

(

eur

MJ exergy

(

(

. (4)

The costs of the two products are calculated as follows:

ex

W ex

C c W =

and

0

1

ex

Q ex

T

C c Q

T

| |

=

|

\ .

eur

.

s

(

(

(5)

2.3. CASE STUDY

The case of the cogeneration steam turbine system, analysed above, is

considered to evaluate the consequences of using the energetic or exergetic

equivalence. The characteristics of the system are: p

1

= 100 bar,

1

t = 500

o

C,

st

0.8 = ,

gen

0.9 = . The variation of the exergetic and energetic unitary costs

function of the the condensation temperature (pressure) are shown in Fig. 2.

Fig. 2 Variation of the energy and exergy costs function of the condensation temperature.

4 Alexandru Dobrovicescu et al. 339

Fig. 2 shows that when using the energetic equivalence the unitary cost

e

c of

the energy produced is constant and it is not influenced by the temperature level at

which heat is provided.

The equation of energy balance for the global system gives:

gen f

Q Q W = +

, (6)

and when written on economic bases

gen gen

( )

f f f f

c Q C c Q W = = +

. (7)

Equation (7) gives:

f f

e

gen

C c

c

Q W

= =

+

eur

MJ energy

(

(

. (8)

Relationship (8) shows clearly that when the costs of different products of the

same system are attributed based on the energetic equivalence (First Law of

Thermodynamics) the temperature level (quality) at which heat is supplied and the

turbine isentropic efficiency are ignored. The energetic cost accounts only for

external energy losses in this case the energetic efficiency of the steam generator.

For the cogeneration system shown in Fig. 1, relationship (4) that gives the

unitary exergetic cost becomes:

ex

0 2 3

gen

1 3

1

( ) ( )

1

( )

f

st

c

c

T h h T

T h h T

=

eur

MJ exergy

(

(

. (9)

The exergetic unitary cost depends not only on the external losses of the

steam generator

( )

gen

but also, directly, and implicitly on the temperature level

T of the heat source supplied to the customer and on the internal exergy destruction

in the turbine.

This analysis shows clearly that in the case of a system with several products,

only the exergetic equivalence manages to bring at the same denominator different

types of energy accounting not only for their quantity but also for their quality in

correlation with the intensive parametes of their physical environment [57].

The example of the steam turbine system cogenerating mechanical energy

and heat has maybe convinced us to become supporters of the exergetic analysis

applied to systems with multiple products. But things are much more complex than

they appear at first sight.

340 Thermoeconomic optimization through marginal cost concept 5

3. THERMOECONOMIC OPTIMIZATION OF A GAS TURBINE SYSTEM

3.1. THERMOECONOMIC MODEL OF GAS TURBINE SYSTEM

The case of a simple gas turbine plant (Fig. 3) whose only product is

mechanical energy is considered.

The investor specifies the effective mechanical power

e

W

(the product) and

indicates the location of the system, thus providing information about the

parameters of physical and economical environment. In these conditions the

imposed parameters of the system are:

{ } { }

1 1

, , , , ,

fix e p

x p T W R c =

.

The remaining parameters can be divided into two categories: independent

(decisional) parameters and dependent ones.

Denoting with

i

x the decisional parameters and with

k

y those of state

(dependent), they become:

{ } { }

3

, , , ,

i sc cc st

x p m = and { } { }

cb

Q T p

t

W

cp

W T p

k

y

,

3

,

4

, , ,

2

,

2

= .

Fig. 3 Gas turbine system.

The optimal solution is obtained by minimizing the objective function that

expresses the annual cost given by the sum between the amortization rate of the

investment cost and the operating (fuel) cost.

( )

Min

cp cc t f f

C Z Z Z c Q = + + +

eur

s

(

(

. (10)

The annual amortization cost

( )

, ,

;

j i j k j

Z x y

of each piece of equipment is

expressed function of the local (j) decisional and state parameters [8].

6 Alexandru Dobrovicescu et al. 341

The thermodynamic model of the system is based on energy balance

equations and relations for calculating the state parameters. For example, for the

compressor the relationships for calculating the dependent parameters are:

3

2 1 3

( , )

cc

cc

p

p g p = =

, (11)

1

2

2 1 2 1 1 2

1

1

1 1 ( , , , )

k

k

sc

sc

p

T T g T p p

p

(

| |

(

= + =

` |

(

\ .

(

)

, (12)

2 1 3 1 2

( ) ( , , )

cp p

W m c T T g T m T = =

. (13)

The economic model is given by the economic correlations for calculating

the purchase cost of each piece of equipment to which the fuel cost is added [5, 9].

3.2. THERMOECONOMIC OPTIMIZATION OF THE GAS TURBINE SYSTEM

The optimum solution from the design and operating point of view is given

by the minimization of the total (capital investment and operating) cost under

specific constraints

1 1

Min ( ,... ,... , ,... ,... )

i n k m

C x x x y y y

, (14)

in the restrictive conditions

0 ) ,...

1

,

1

,...

1

, ,... ,...

1

( =

+

=

k

y

m

y

k

y

k

y y

n

x

i

x x

k

g

k

. (15)

The Lagrange function [9] attached to the mathematical model becomes:

=

+ =

m

k

k k

C L

1

(16)

and the conditions for extreme are given by the system :

0

1

=

=

+

m

k

i

x

k

k

i

x

C

i

x

L

, (i=1, , n) (17a)

0

1

=

=

+

m

k

k

y

k

k

k

y

C

k

y

L

, (k = 1, , m) (17b)

342 Thermoeconomic optimization through marginal cost concept 7

k

y

m

x

k

y

k

y y

n

x

i

x x

k

g

k

k

L

+

= =

) ...,

, 1

,

1

,...,

1

, ,... ,...,

1

( , (k = 1,, m). (17c)

Actually solving the system is extremely difficult. The success of the

mathematical procedure depends on finding a viable initial operating and design

point, close to optimum.

To simplify the calculation procedure one observes that according to

equations of type (1113), the value of the Lagrangian L and of the objective

functionC

are the same. Under these conditions the vector of the derivatives in the

space of decision variables ( )

i

x :

m

i

k

k

i i

x x

C

x

L

1

, show the sensitivity of

the objective function C

when the decision variable changes. These derivatives are

denoted by

i

CM and play the role of marginal costs [10, 11].

i

x

L

i

CM

=

(i = 1n). (18)

The thermoeconomic optimization strategy consists in breaking down the

problem and solving successively and in the order the three groups of equations

defined by system (17).

In the first stage the initial solution for the n independent variables of

decision (vector

i

x ) is estimated and the dependent variables (the state variables)

k

y (i = 1 m) and the values of Lagranges multipliers (

k

) are determined.

Finally, the partial derivatives of the Lagrangian

i

x L are calculated with

respect to the independent decision variables. The set of values of marginal costs

indicate the sense in which the size of decision variables should be changed to

reach an optimal solution.

3.3. CASE STUDY

A simple gas turbine system whose functional scheme is shown in Fig. 5 is

considered. The characteristics of the system are

e

W

= 65 MW,

1 0

1.013 bar p p = = ,

1 0

300 T T K = = ,

5

10 bar p = ,

5

300 K T = ,

| |

6

8.4 10 eur/kJ

f

c

= . The fuel is

CH

4

.

The annual amortization cost of each piece of equipment, which includes

operating cost, maintenance and taxes was considered to be 50% higher than

purchase cost [5].

The number of annual working hours for the system is considered to be: N =

= 8 000 hours/year.

8 Alexandru Dobrovicescu et al. 343

In the optimization procedure based on the Lagranges multipliers method

and the concept of marginal cost, as starting point, the following set of decision

variables (estimated) was considered:

est

3

{ 0.8; 0.95; 0.87; 10 bar; 400 kg/s}

i sc cc st

x p m = = = = = = .

Marginal cost values and the sense they indicate in order to change the size of

a decision parameter in the search procedure for reaching the optimal solution are

presented in Table 1.

Table 1

Marginal costs for the gas turbine system for the decision variables set:

kg/s 400 ; 10 ; 87 . 0 ; 95 . 0 ; 8 . 0

3

= = = = = m p

st cc sc

) (

1 sc

CM

eur

s

(

(

) (

2 cc

CM

eur

s

(

(

) (

3 st

CM

eur

s

(

(

)

3

(

4

p CM

eur

s bar

(

(

) (

5

m CM

eur

kg

(

(

1.191

) (

sc

1.093

(

cc

)

3.54

(

st

)

0.03406 (

3

p )

0.00358

( m )

The cost of the product of the global system is: C

= 2.785 eur/s.

Negative values of the marginal costs indicate a need to increase the

corresponding decision parameters, and positive values to reduce them.

In the optimization procedure the decision parameters are modified following

indications given by the marginal cost. The results of the first iterations are given

in Table 2.

Table 2

Iteration 1 Marginal costs of the gas turbine system for the decision variables set:

kg/s 270 ; bar 8 ; 856 . 0 ; 97 . 0 ; 778 . 0

3

= = = = = m p

st cc sc

) (

1 sc

CM

eur

s

(

(

) (

2 cc

CM

eur

s

(

(

) (

3 st

CM

eur

s

(

(

)

3

(

4

p CM

eur

s bar

(

(

) (

5

m CM

eur

kg

(

(

1.943

( )

sc

0.04564

(

cc

)

2.705

(

st

)

0.02031

(

3

p )

0.000013

( m )

The cost of the product of the global system is: C

= 2.33 eur/s.

A marginal price gives the tangent at the L-x graph.

344 Thermoeconomic optimization through marginal cost concept 9

After two iterations the values of the marginal prices approach zero leading

to the conclusion that the optimum solution is practically reached for

819 . 0 =

sc

kg/s 247 ; bar 61 . 8 ; 87 . 0 ; 97 . 0 ;

3

= = = = m p

st cc

. The minimum

cost of the product of the global system is: C

= 2.281 eur/s.

4. CONCLUSIONS

For a system with several products of different energetical nature, using only

the energy balance in the procedure of finding the cost of each product can lead to

totally erroneous results.

The exergetic analysis finds the real cost to each product pointing out the

internal inefficiency of the system.

For systems with a single product, the optimal operating and design solution,

at least theoretically, can be obtained without recourse to the Second Law of

Thermodynamics and the concept of exergy. In this last case the optimization

procedure of the overall system leads to slow calculations, making use of many

simplifying analysis.

The use of the concept of marginal cost in the optimization procedure based

on the Lagranges multipliers method makes possible to indicate the sense the

decision parameters should be modified in the search for the optimum solution.

NOMENCLATURE

C cost [eur]

c unitary cost [eur/(kJ energy /

exergy)]

C

cost per time unit [eur/s]

Cc combustion chamber

Cp compressor

p

c specific heat [kJ/(kg K)]

CM marginal cost

Ex

exergy current [kJ/s]

F fuel

G steam generator

g mathematical function

(eqs. 1113)

h specific enthalpy [kJ/kg]

HE heat exchanger

k adiabatic exponent

L Lagrangian

m mass flow rate [kg/s]

p pressure [N/m

2

]

R particular gas constant

[kJ/(kg K)]

Q

heat flux [kW]

T temperature [K], turbine

x decision parameter

y state parameter

Z

capital amortization rate

[eur/s]

W

mechanical power [kW]

Indice

cc combustion chamber

cp compressor

ex exergetic

f fuel

0 ambient parameters

10 Alexandru Dobrovicescu et al. 345

Q heat

t turbine

Superscript

e energetical

est estimated

ex exergetic

Greek letters

restrictive condition

gen

energy efficiency of steam

generator

sc

isentropic compressor efficiency

st

isentropic turbine efficiency

Lagrange multiplier, unit cost

cc

3 2

p p =

N operation time (hours/year)

AKNOWLEDGEMENTS

This work was supported by CNCSIS-UEFISCU, project number PNII-IDEI-

1719/2009.

Received on 31 August 2010

REFERENCES

1. A. Dobrovicescu, Exergetic and thermoeconomic analysis of refrigerating and cryogenic systems

(in Romanian), AGIR, Bucharest, 2000.

2. A. Dobrovicescu, Principles of exergoeconomic analysis (in Romanian), Politehnica Press,

Bucharest, 2007.

3. Younes, M., Rahli, M., Abid, M., Kandouci, M., Oprimisation decoulement des puissances par

algorithms inteligents, Rev. Roum. Sci. Techn. Electrotechn. et Energ., 52, 1, pp. 3-12, 2007.

4. J.H. Keenan, A Steam Chart for Second Law Analysis, Mechanical Engineering, Trans. ASME,

54, 195, pp. 195-204, 1932.

5. A. Bejan A., G. Tsatsaronis, M.J. Moran, Optimization and thermal design, Willey, 1996

6. R.A. Gaggioli, Y.M. El-Sayed, 1987, Critical Review of Second-Law Costing Methods, ASME

Book, 100236, pp. 59-73, 1987.

7. M.A. Lozano, Termoeconomia, Universidad de Zaragoza, 1992.

8. C.A Frangopoulos, Application of the Thermoeconomic Functional Approach to the CGAM

Problem, Energy, 19, 3, 323-342, 1994.

9. Y.M. El-Sayed, M.Tribus, The Strategic Use of Thermoeconomic Analysis for Process

Improvement, in: Efficiency and Costing Second Law Analysis of Processes, Ed. Gaggioli R.,

ACS Symposium, Series 235, Washington, 1983.

10. Barnett, R.A., Ziegler, M. R., Byleen, K.E., Applied Mathematics for Business, Economics, Life

Sciences and Social Sciences, Prentice Hall, 2002.

11. McConnell, C., Brue, S., Flynn, S., Macroeconomics, McGraw-Hill/Irwin, 2008.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DBMS Lab Manual With ER DiagramsDocument53 pagesDBMS Lab Manual With ER Diagramssuhas67% (3)

- Ijert Ijert: "Frequency Control of Smart Grid - MATLAB/SIMULINK Approach"Document7 pagesIjert Ijert: "Frequency Control of Smart Grid - MATLAB/SIMULINK Approach"Mohan KrishnaNo ratings yet

- Customer Satisfaction Tata MotorsDocument92 pagesCustomer Satisfaction Tata MotorsRK SinghNo ratings yet

- Catalog 21Document77 pagesCatalog 21tasingenieriaNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Karthik ReddyNo ratings yet

- Akinlade ThesisDocument298 pagesAkinlade Thesis16mariusNo ratings yet

- m40 2p BSPP Nex NippleDocument1 pagem40 2p BSPP Nex NippleAravind VIJAYANNo ratings yet

- Using A BIRT Editor To Create or Modify Web Reports-V2-20190131 - 1014 PDFDocument36 pagesUsing A BIRT Editor To Create or Modify Web Reports-V2-20190131 - 1014 PDFrodianlupuNo ratings yet

- Introduction To SAP BWDocument43 pagesIntroduction To SAP BWHardy SimNo ratings yet

- FMDocument2 pagesFMSen HuNo ratings yet

- Paint IndiaDocument18 pagesPaint IndiaNikhil RaiNo ratings yet

- The Key Factors of New Car Models DevelopmentDocument12 pagesThe Key Factors of New Car Models DevelopmentJohnm MINo ratings yet

- 14 - Operations SchedulingDocument11 pages14 - Operations SchedulingmanjuNo ratings yet

- Distillation Operation, Control, Design and Troubleshooting Course For Maintenance PersonnelDocument8 pagesDistillation Operation, Control, Design and Troubleshooting Course For Maintenance PersonnelBadiuzzama AzmiNo ratings yet

- Bolt Pocket Formers Plates v.5Document4 pagesBolt Pocket Formers Plates v.5Ankush JainNo ratings yet

- 42 Rules For Building A High-Velocity Inside Sales TeamDocument25 pages42 Rules For Building A High-Velocity Inside Sales TeamHappyAbout0% (2)

- Caa (Approved Training Organisations) Regulations, 2022Document93 pagesCaa (Approved Training Organisations) Regulations, 2022GeoffLNo ratings yet

- 2.materials and WeldingDocument44 pages2.materials and WeldingAlina NastasaNo ratings yet

- Brochure SPLISETDocument4 pagesBrochure SPLISETsav17No ratings yet

- Water Tunnel Flow VisualizationDocument40 pagesWater Tunnel Flow VisualizationvictoriaNo ratings yet

- Anna University: Courses Ug CoursesDocument7 pagesAnna University: Courses Ug Coursesbasheersmiles100% (5)

- Gear Pumps / Motors: Series PGP / PGM Fixed Displacement Pumps, Cast-Iron and Aluminium DesignsDocument6 pagesGear Pumps / Motors: Series PGP / PGM Fixed Displacement Pumps, Cast-Iron and Aluminium DesignsKristijan HorvatNo ratings yet

- Managing Supply Chain Risks To Dod Systems and Networks: Thomas Barth, Michelle Albert, and Elizabeth McdanielDocument5 pagesManaging Supply Chain Risks To Dod Systems and Networks: Thomas Barth, Michelle Albert, and Elizabeth McdanieljrudzzNo ratings yet

- Cast Iron Soil Pipe Fit HandbookDocument218 pagesCast Iron Soil Pipe Fit HandbookMajho CanilangNo ratings yet

- Mark Fitzgerald-Licensed Architect ResumeDocument3 pagesMark Fitzgerald-Licensed Architect Resumemark_fitzgerald61100% (1)

- E747 97 Wire IQIDocument14 pagesE747 97 Wire IQIayubali009No ratings yet

- Kabaad Se JugaadDocument2 pagesKabaad Se JugaadIshaNo ratings yet

- Journal 02 10 eDocument88 pagesJournal 02 10 eWasif KhanNo ratings yet

- Manufacturing PlantDocument37 pagesManufacturing Plantanuragmishra2112No ratings yet

- Rolamentos Vedados SKFDocument28 pagesRolamentos Vedados SKFJose GomesNo ratings yet