Professional Documents

Culture Documents

G-SPC A SHFT 03 April

G-SPC A SHFT 03 April

Uploaded by

abhisheksikka17Copyright:

Available Formats

You might also like

- Process Potential Failure Mode & Effects AnalysisDocument12 pagesProcess Potential Failure Mode & Effects Analysisankit kumar100% (1)

- 5R55S Pinpoint TestsDocument21 pages5R55S Pinpoint TestsJason Wolfe100% (3)

- 2-2-14 Tier 4i Engine Troubleshooting Cheat SheetDocument8 pages2-2-14 Tier 4i Engine Troubleshooting Cheat SheetKevine Khaled100% (3)

- SMT Generic Control PlanDocument3 pagesSMT Generic Control PlanPedro Lopez Rodriguez100% (1)

- PFMEA Reference CardDocument2 pagesPFMEA Reference Cardkeyoor_pat100% (2)

- Design FMEADocument10 pagesDesign FMEAAbu AzkhaNo ratings yet

- TQM PolaroidDocument36 pagesTQM Polaroiduttam.nift100% (1)

- GP-12 Check SheetsDocument2 pagesGP-12 Check SheetsLam Nguyen100% (4)

- Copia de FORMATO AmefDocument2 pagesCopia de FORMATO AmefDavid SaucedoNo ratings yet

- Fmea Process TemplateDocument20 pagesFmea Process TemplateLazarasBenny IsprithiyoneNo ratings yet

- Amef - Risk AnalysisDocument8 pagesAmef - Risk AnalysisUSUIENo ratings yet

- PFMEADocument10 pagesPFMEAsmallik3100% (1)

- Dynamic Test Report of DECR-S Excitation Devices: ExperimenterDocument14 pagesDynamic Test Report of DECR-S Excitation Devices: ExperimenterSalmanEjazNo ratings yet

- FMEADocument7 pagesFMEAnishuNo ratings yet

- SAA ReportDocument54 pagesSAA ReportSonny AguilarNo ratings yet

- PFMEA TemplateDocument19 pagesPFMEA Templatejcruz909100% (1)

- 0.1 Pre Test Question Paper Core ToolsDocument16 pages0.1 Pre Test Question Paper Core Toolsnikhalesh123No ratings yet

- confC101E 20230823Document1 pageconfC101E 20230823SPORTS SPIRITNo ratings yet

- Suggested Pfmea Evaluation CriteriaDocument2 pagesSuggested Pfmea Evaluation Criteriatrfcprop100% (1)

- WORK INSTRUCTION For Calibration of Pressure GuagesDocument6 pagesWORK INSTRUCTION For Calibration of Pressure GuagesRakesh Ranjan100% (1)

- Failure Mode and Effect AnalysisDocument25 pagesFailure Mode and Effect AnalysislokelooksNo ratings yet

- Test Scenario No. Q10 Quality Management PlaybacksDocument2 pagesTest Scenario No. Q10 Quality Management PlaybacksashumovNo ratings yet

- Final Review Reza 19 June 2014 PDFDocument1 pageFinal Review Reza 19 June 2014 PDFReza RahmaputraNo ratings yet

- confCEB 20230823Document1 pageconfCEB 20230823SPORTS SPIRITNo ratings yet

- Kurrawa Replacement Project INC LB TMA FaultDocument13 pagesKurrawa Replacement Project INC LB TMA FaultSaravana EthirajNo ratings yet

- Making Sense of Pump Testing Standards - How Understanding Standards Can Impact The Bottom Line PDFDocument24 pagesMaking Sense of Pump Testing Standards - How Understanding Standards Can Impact The Bottom Line PDF1sympatyagaNo ratings yet

- Qualification Rest Risk Based Approach EvaluationDocument4 pagesQualification Rest Risk Based Approach EvaluationApoloTrevino100% (1)

- SUPPLI 4 JDocument69 pagesSUPPLI 4 JkvasudevinK123No ratings yet

- CPPP Self Assessment Spot Welding (QHB037G) 1Document28 pagesCPPP Self Assessment Spot Welding (QHB037G) 1broNo ratings yet

- Feedforward and Ratio Control: Isa Mentor Program Presentation By: Gregory K. McmillanDocument24 pagesFeedforward and Ratio Control: Isa Mentor Program Presentation By: Gregory K. McmillanJosé Diogo ForteNo ratings yet

- Practical No.:: Aim: ApparatusDocument5 pagesPractical No.:: Aim: ApparatusDREAM11 protipsNo ratings yet

- Teaching An Old FMEA New TricksDocument21 pagesTeaching An Old FMEA New TricksJossie FuentesNo ratings yet

- AMEF Entrenamiento 1st StageDocument41 pagesAMEF Entrenamiento 1st StagevictorvillegasNo ratings yet

- Severity Ranking (Sev) : Score Criteria 10 9 8 7 6 5 4 3 2 1Document2 pagesSeverity Ranking (Sev) : Score Criteria 10 9 8 7 6 5 4 3 2 1Sushil Kr ChaurasiaNo ratings yet

- 6sigma - Control PhaseDocument130 pages6sigma - Control Phasesathya_145No ratings yet

- 1 Outage From Last Overhaul: SL - No. Description Weightag e (A) Marks Obtained (B) CriteriaDocument3 pages1 Outage From Last Overhaul: SL - No. Description Weightag e (A) Marks Obtained (B) CriteriaVIBHAVNo ratings yet

- Performance ValidationDocument1 pagePerformance ValidationJohnmar AquinoNo ratings yet

- Performance Validation PDFDocument1 pagePerformance Validation PDFJohnmar AquinoNo ratings yet

- ZERO Defect MachineDocument3 pagesZERO Defect MachinenasikroadNo ratings yet

- Test Case (Black Box) Design Techniques Ol AugDocument7 pagesTest Case (Black Box) Design Techniques Ol Aug000rajeshNo ratings yet

- Fire Alarm Inspection Report: Testing Performed in Accordance With Applicable Nfpa StandardsDocument8 pagesFire Alarm Inspection Report: Testing Performed in Accordance With Applicable Nfpa StandardsByamba BimbaNo ratings yet

- Complete Final Assembly / Sub Assembly / Rubber Parts From BIN That Are Going Into Final Assembly With SC CC Characteristics Table - 1 Issued byDocument1 pageComplete Final Assembly / Sub Assembly / Rubber Parts From BIN That Are Going Into Final Assembly With SC CC Characteristics Table - 1 Issued byKarthiNo ratings yet

- FMEA Memory JoggerDocument33 pagesFMEA Memory JoggeripatoffNo ratings yet

- D6R Track-Type Tractor 2YN00001-UP (MACHINE) POWننERED BY 3306 Engine (SEBP2615 - 58) - Document StructureDocument2 pagesD6R Track-Type Tractor 2YN00001-UP (MACHINE) POWننERED BY 3306 Engine (SEBP2615 - 58) - Document StructureBasem ElhosanyNo ratings yet

- Testring Installation and Commissioning of LT MetersDocument40 pagesTestring Installation and Commissioning of LT Meterskajale_shrikant2325No ratings yet

- SuperDos 20 Rev F - en - 76Document76 pagesSuperDos 20 Rev F - en - 76Renis Paulo CardosoNo ratings yet

- 2006 File 15Document63 pages2006 File 15eurospeed2No ratings yet

- DTC P0101 - 00 (Skyactiv-D 2.2)Document2 pagesDTC P0101 - 00 (Skyactiv-D 2.2)Roberto Hidalgo CalvillaNo ratings yet

- 23 Automatic TransmissionDocument45 pages23 Automatic Transmissionossoski100% (1)

- Troubleshooting Control Loops - Cairo UniversityDocument27 pagesTroubleshooting Control Loops - Cairo UniversityMartín StirparoNo ratings yet

- Fmea & CP FormsDocument16 pagesFmea & CP FormswebtecnicaNo ratings yet

- ISC Termination SheetDocument1 pageISC Termination SheetAjayChaudharyNo ratings yet

- confCC13 20230823Document1 pageconfCC13 20230823SPORTS SPIRITNo ratings yet

- Process Flow Diagram: 10-12-2011 Part NameDocument4 pagesProcess Flow Diagram: 10-12-2011 Part NameVenu Gopal RaoNo ratings yet

- 1.3 Kaizen ModulesDocument9 pages1.3 Kaizen ModulesBalakrishnanRangasamyNo ratings yet

- I Have A Similar Problem Right Now With A cb534d Not Moving Front or Back. Have Done The Handle Calibration WithDocument19 pagesI Have A Similar Problem Right Now With A cb534d Not Moving Front or Back. Have Done The Handle Calibration Withabdelbagi ibrahimNo ratings yet

- Forensic Systems Engineering: Evaluating Operations by DiscoveryFrom EverandForensic Systems Engineering: Evaluating Operations by DiscoveryNo ratings yet

G-SPC A SHFT 03 April

G-SPC A SHFT 03 April

Uploaded by

abhisheksikka17Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G-SPC A SHFT 03 April

G-SPC A SHFT 03 April

Uploaded by

abhisheksikka17Copyright:

Available Formats

Process wise Defect Hanadling Rate

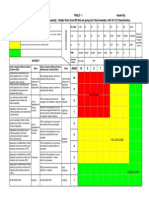

W06 GOOD NG N/A No.of Inspection line Handling Rate MAIN 13 11 6 30 54% PBA 9 13 8 30 41%

If defect rate decreases more than 50% on the worst line +1shift, it is r

If there is no same model porduction +1shift or minumum amount of p

ore than 50% on the worst line +1shift, it is regarded as Good. Otherwise, NG.

porduction +1shift or minumum amount of production does not proceed, N/A

PBA Monitoring and Handling Rate Check List

1. Dashboard Failure status (Standard:Production) 2. Check on 2 hours after A shift commencement 3.Check Worst 10 from lines with defect rate 3% / defect quantity 10ea (If less than 10, check the quantity only) 4. If defect rate decreases 50% compared to the rate on 3 hours after work commencement, it is regarded as GOOD. If there is no production or less than 200ea(50), N/A 5. shift : A 08:00~19:59 C 20:00~07:59 GOOD Handling Rate NG

0%

N/A

Daily Handling Status

NO WEEK SHIFT DATE PROCESS Line MODEL INSPECTION TIMES NG Q'TY DEFECT RATE DETAILS HANDLING STATUS REMARKS

0

Inspection Q'ty

5

+1 shift Defect Q'ty

0

Defect Rate Result

W13 Ashift

3/4

PBA FT

PBA 06

1232

200

10

5.00%

SMD FUNCTION SKIP

TRUE FAIL , feedback given to Process quality.

NO IMAGE

757

34

4.49%

NG

W13 Ashift

3/4

PBA FT

PBA 16

1200

400

1.50%

GSM RSSI 25 Ch Fail

The Jigs & progarm is faulty , feedback already given to R&D & Process

1,508

20

1.33%

NG

W13 Ashift

3/4

PBA FT

PBA 11

6102

150

4.00%

CAMERA ON Fail

TRUE FAIL , feedback given to Process quality.

519

18

3.47%

NG

W13 Ashift

3/4

PBA FT

PBA 05

5380

175

2.86%

FMR Left Freq.

3.5 mm ear jack & zendar was found faulty so changed it.

554

17

3.07%

NG

W13 Ashift

3/4

PBA FT

PBA 14

1200

350

0.86%

GSM RSSI 25 Ch Fail

The Jigs & progarm is faulty , feedback already given to R&D & Process

1,566

12

0.77%

NG

You might also like

- Process Potential Failure Mode & Effects AnalysisDocument12 pagesProcess Potential Failure Mode & Effects Analysisankit kumar100% (1)

- 5R55S Pinpoint TestsDocument21 pages5R55S Pinpoint TestsJason Wolfe100% (3)

- 2-2-14 Tier 4i Engine Troubleshooting Cheat SheetDocument8 pages2-2-14 Tier 4i Engine Troubleshooting Cheat SheetKevine Khaled100% (3)

- SMT Generic Control PlanDocument3 pagesSMT Generic Control PlanPedro Lopez Rodriguez100% (1)

- PFMEA Reference CardDocument2 pagesPFMEA Reference Cardkeyoor_pat100% (2)

- Design FMEADocument10 pagesDesign FMEAAbu AzkhaNo ratings yet

- TQM PolaroidDocument36 pagesTQM Polaroiduttam.nift100% (1)

- GP-12 Check SheetsDocument2 pagesGP-12 Check SheetsLam Nguyen100% (4)

- Copia de FORMATO AmefDocument2 pagesCopia de FORMATO AmefDavid SaucedoNo ratings yet

- Fmea Process TemplateDocument20 pagesFmea Process TemplateLazarasBenny IsprithiyoneNo ratings yet

- Amef - Risk AnalysisDocument8 pagesAmef - Risk AnalysisUSUIENo ratings yet

- PFMEADocument10 pagesPFMEAsmallik3100% (1)

- Dynamic Test Report of DECR-S Excitation Devices: ExperimenterDocument14 pagesDynamic Test Report of DECR-S Excitation Devices: ExperimenterSalmanEjazNo ratings yet

- FMEADocument7 pagesFMEAnishuNo ratings yet

- SAA ReportDocument54 pagesSAA ReportSonny AguilarNo ratings yet

- PFMEA TemplateDocument19 pagesPFMEA Templatejcruz909100% (1)

- 0.1 Pre Test Question Paper Core ToolsDocument16 pages0.1 Pre Test Question Paper Core Toolsnikhalesh123No ratings yet

- confC101E 20230823Document1 pageconfC101E 20230823SPORTS SPIRITNo ratings yet

- Suggested Pfmea Evaluation CriteriaDocument2 pagesSuggested Pfmea Evaluation Criteriatrfcprop100% (1)

- WORK INSTRUCTION For Calibration of Pressure GuagesDocument6 pagesWORK INSTRUCTION For Calibration of Pressure GuagesRakesh Ranjan100% (1)

- Failure Mode and Effect AnalysisDocument25 pagesFailure Mode and Effect AnalysislokelooksNo ratings yet

- Test Scenario No. Q10 Quality Management PlaybacksDocument2 pagesTest Scenario No. Q10 Quality Management PlaybacksashumovNo ratings yet

- Final Review Reza 19 June 2014 PDFDocument1 pageFinal Review Reza 19 June 2014 PDFReza RahmaputraNo ratings yet

- confCEB 20230823Document1 pageconfCEB 20230823SPORTS SPIRITNo ratings yet

- Kurrawa Replacement Project INC LB TMA FaultDocument13 pagesKurrawa Replacement Project INC LB TMA FaultSaravana EthirajNo ratings yet

- Making Sense of Pump Testing Standards - How Understanding Standards Can Impact The Bottom Line PDFDocument24 pagesMaking Sense of Pump Testing Standards - How Understanding Standards Can Impact The Bottom Line PDF1sympatyagaNo ratings yet

- Qualification Rest Risk Based Approach EvaluationDocument4 pagesQualification Rest Risk Based Approach EvaluationApoloTrevino100% (1)

- SUPPLI 4 JDocument69 pagesSUPPLI 4 JkvasudevinK123No ratings yet

- CPPP Self Assessment Spot Welding (QHB037G) 1Document28 pagesCPPP Self Assessment Spot Welding (QHB037G) 1broNo ratings yet

- Feedforward and Ratio Control: Isa Mentor Program Presentation By: Gregory K. McmillanDocument24 pagesFeedforward and Ratio Control: Isa Mentor Program Presentation By: Gregory K. McmillanJosé Diogo ForteNo ratings yet

- Practical No.:: Aim: ApparatusDocument5 pagesPractical No.:: Aim: ApparatusDREAM11 protipsNo ratings yet

- Teaching An Old FMEA New TricksDocument21 pagesTeaching An Old FMEA New TricksJossie FuentesNo ratings yet

- AMEF Entrenamiento 1st StageDocument41 pagesAMEF Entrenamiento 1st StagevictorvillegasNo ratings yet

- Severity Ranking (Sev) : Score Criteria 10 9 8 7 6 5 4 3 2 1Document2 pagesSeverity Ranking (Sev) : Score Criteria 10 9 8 7 6 5 4 3 2 1Sushil Kr ChaurasiaNo ratings yet

- 6sigma - Control PhaseDocument130 pages6sigma - Control Phasesathya_145No ratings yet

- 1 Outage From Last Overhaul: SL - No. Description Weightag e (A) Marks Obtained (B) CriteriaDocument3 pages1 Outage From Last Overhaul: SL - No. Description Weightag e (A) Marks Obtained (B) CriteriaVIBHAVNo ratings yet

- Performance ValidationDocument1 pagePerformance ValidationJohnmar AquinoNo ratings yet

- Performance Validation PDFDocument1 pagePerformance Validation PDFJohnmar AquinoNo ratings yet

- ZERO Defect MachineDocument3 pagesZERO Defect MachinenasikroadNo ratings yet

- Test Case (Black Box) Design Techniques Ol AugDocument7 pagesTest Case (Black Box) Design Techniques Ol Aug000rajeshNo ratings yet

- Fire Alarm Inspection Report: Testing Performed in Accordance With Applicable Nfpa StandardsDocument8 pagesFire Alarm Inspection Report: Testing Performed in Accordance With Applicable Nfpa StandardsByamba BimbaNo ratings yet

- Complete Final Assembly / Sub Assembly / Rubber Parts From BIN That Are Going Into Final Assembly With SC CC Characteristics Table - 1 Issued byDocument1 pageComplete Final Assembly / Sub Assembly / Rubber Parts From BIN That Are Going Into Final Assembly With SC CC Characteristics Table - 1 Issued byKarthiNo ratings yet

- FMEA Memory JoggerDocument33 pagesFMEA Memory JoggeripatoffNo ratings yet

- D6R Track-Type Tractor 2YN00001-UP (MACHINE) POWننERED BY 3306 Engine (SEBP2615 - 58) - Document StructureDocument2 pagesD6R Track-Type Tractor 2YN00001-UP (MACHINE) POWننERED BY 3306 Engine (SEBP2615 - 58) - Document StructureBasem ElhosanyNo ratings yet

- Testring Installation and Commissioning of LT MetersDocument40 pagesTestring Installation and Commissioning of LT Meterskajale_shrikant2325No ratings yet

- SuperDos 20 Rev F - en - 76Document76 pagesSuperDos 20 Rev F - en - 76Renis Paulo CardosoNo ratings yet

- 2006 File 15Document63 pages2006 File 15eurospeed2No ratings yet

- DTC P0101 - 00 (Skyactiv-D 2.2)Document2 pagesDTC P0101 - 00 (Skyactiv-D 2.2)Roberto Hidalgo CalvillaNo ratings yet

- 23 Automatic TransmissionDocument45 pages23 Automatic Transmissionossoski100% (1)

- Troubleshooting Control Loops - Cairo UniversityDocument27 pagesTroubleshooting Control Loops - Cairo UniversityMartín StirparoNo ratings yet

- Fmea & CP FormsDocument16 pagesFmea & CP FormswebtecnicaNo ratings yet

- ISC Termination SheetDocument1 pageISC Termination SheetAjayChaudharyNo ratings yet

- confCC13 20230823Document1 pageconfCC13 20230823SPORTS SPIRITNo ratings yet

- Process Flow Diagram: 10-12-2011 Part NameDocument4 pagesProcess Flow Diagram: 10-12-2011 Part NameVenu Gopal RaoNo ratings yet

- 1.3 Kaizen ModulesDocument9 pages1.3 Kaizen ModulesBalakrishnanRangasamyNo ratings yet

- I Have A Similar Problem Right Now With A cb534d Not Moving Front or Back. Have Done The Handle Calibration WithDocument19 pagesI Have A Similar Problem Right Now With A cb534d Not Moving Front or Back. Have Done The Handle Calibration Withabdelbagi ibrahimNo ratings yet

- Forensic Systems Engineering: Evaluating Operations by DiscoveryFrom EverandForensic Systems Engineering: Evaluating Operations by DiscoveryNo ratings yet