Professional Documents

Culture Documents

Bayat 2

Bayat 2

Uploaded by

ali11111Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bayat 2

Bayat 2

Uploaded by

ali11111Copyright:

Available Formats

Topping Plant: An alternative approach for asphaltenic heavy crude oil processing

Mahmoud Bayat *,a, Sattarin Manzara, Teymouri Mohammada. Modarresi Hassanb

a

Research Institute of Petroleum Industry,. P.O. Box: 14665-137, Tehran, Iran b Topsoe Fuel Cell Nymoellevej 66 DK-2800 Kgs. Lyngby Denmark (* corresponding author: bayatm@ripi.ir)

Generally, more than 50% of heavy oil (API<20) feed stock, in crude distillation unit, remains as residue, requiring upgrading process to be converted to valuable products. However, residue upgrading units often utilise catalysts, which could be easily poisoned by heavy metals of these types of residue. Alternatively, since residue from asphaltenic heavy crude oil is naturally good pitch, it would be advantageous if the crude is directly split into several lumped distillates and pitch cut, in a topping plant. We found that high quality pitch having an excellent viscosity (350 cP at 130 C) and adhesion property could be obtained, for a typical Iranian extra-heavy crude oil. Based on this, in this paper, an innovative conceptual design following by a comprehensive economical feasibility study of a topping plant is presented for the mentioned crude oil. The fixed capital investment of a topping plant is about 2000 3000 $/bbl, with an high annually rate of return on capital, i.e. 50%.rate.

You might also like

- Gas Lift Presentation 1Document242 pagesGas Lift Presentation 1Hadi Bapir SlemanNo ratings yet

- 03 Vertical Pump Test ANSI HI 2.6 2000Document48 pages03 Vertical Pump Test ANSI HI 2.6 2000Benny RivasNo ratings yet

- Petroleum Refining ProcessesDocument21 pagesPetroleum Refining ProcessesJimNo ratings yet

- DownstreamDocument62 pagesDownstreamKhairul IrfanNo ratings yet

- Vocational Training Report I.O.C.L Haldia Refinary: Jadavpur UniversityDocument54 pagesVocational Training Report I.O.C.L Haldia Refinary: Jadavpur Universityrahul aseriNo ratings yet

- GBPummus Crude To chemicaGBPs Part 1 The Basic Concept of CrudesDocument6 pagesGBPummus Crude To chemicaGBPs Part 1 The Basic Concept of CrudesKemkengNo ratings yet

- Mini RefineryDocument12 pagesMini RefinerySaraAwad100% (1)

- ChE499 Design Project - Brief Project Descriptions Miri 2011Document8 pagesChE499 Design Project - Brief Project Descriptions Miri 2011Norman ChinNo ratings yet

- Tank Vessel HandbookDocument57 pagesTank Vessel HandbookRahulNo ratings yet

- 6 PDFDocument6 pages6 PDFKevin LealNo ratings yet

- Key Terms DefinitionDocument6 pagesKey Terms DefinitionHammad HashmiNo ratings yet

- Case Study - Fuel OilDocument34 pagesCase Study - Fuel OilironiteNo ratings yet

- Processing Biomass in Conventional Oil RefineriesDocument10 pagesProcessing Biomass in Conventional Oil RefineriesSpafiu Paula RalucaNo ratings yet

- AMP BrochureDocument8 pagesAMP BrochureDavid GNo ratings yet

- 6 Refining: 6.1 Fractional DistillationDocument10 pages6 Refining: 6.1 Fractional Distillationaldi gufroniNo ratings yet

- Classification of Crude OilDocument6 pagesClassification of Crude OilSultana AlmansooriNo ratings yet

- BRICC中低温煤焦油非均相悬浮床加氢技术Document5 pagesBRICC中低温煤焦油非均相悬浮床加氢技术董芳儒No ratings yet

- Purifier Maintenance 1Document54 pagesPurifier Maintenance 1Noel Nico FernandoNo ratings yet

- Artículo Sobre PetróleoDocument4 pagesArtículo Sobre PetróleoAlejandra Portinari BiceNo ratings yet

- HBU I FinaleDocument40 pagesHBU I FinaleEm Niax100% (1)

- Presentation of Gasoline (Petroleum Refinery)Document17 pagesPresentation of Gasoline (Petroleum Refinery)hayder alaliNo ratings yet

- Petroleum IndustryDocument39 pagesPetroleum IndustryQuenie Rose RontalNo ratings yet

- RefiningDocument105 pagesRefiningLuis AcidNo ratings yet

- For Indian Oil HaldiaDocument42 pagesFor Indian Oil Haldiamohit0% (1)

- Oil Rifinery and Processing PlantDocument34 pagesOil Rifinery and Processing PlantFemi ErinleNo ratings yet

- Petroleum Refining Process Control and RT OptimizationDocument11 pagesPetroleum Refining Process Control and RT Optimizationdemos2011No ratings yet

- Introduction To RefineryDocument6 pagesIntroduction To RefinerydyarNo ratings yet

- Session 4 Refining Notes 2012 PDFDocument17 pagesSession 4 Refining Notes 2012 PDFWon JangNo ratings yet

- Fundamentals of Oil RefineryDocument12 pagesFundamentals of Oil RefineryMarie SaundersNo ratings yet

- UntitledDocument11 pagesUntitledapi-256504985No ratings yet

- A Study of Residual Oils Recovered From Spent Bleaching Earth: Their Characteristics and ApplicationsDocument6 pagesA Study of Residual Oils Recovered From Spent Bleaching Earth: Their Characteristics and Applicationsfatiya rizkiyaniNo ratings yet

- Chapter 3 Stripping at The Wellhead An in Gathering StationsDocument22 pagesChapter 3 Stripping at The Wellhead An in Gathering Stationsali AbbasNo ratings yet

- CrackingDocument32 pagesCrackingMuhammad HAmAd QureshiNo ratings yet

- Fundamentals of Oil RefineryDocument12 pagesFundamentals of Oil Refineryvenkatrangan2003No ratings yet

- Selection of Processing Steps, Catalyst and Downstream Process IntegrationDocument4 pagesSelection of Processing Steps, Catalyst and Downstream Process IntegrationAmr El SaeedNo ratings yet

- Petroleum RefineryDocument3 pagesPetroleum RefinerySaba JavedNo ratings yet

- CrackingDocument28 pagesCrackingzaraNo ratings yet

- Petroleum Refining Process Control and Real-Time OptimizationDocument11 pagesPetroleum Refining Process Control and Real-Time OptimizationLuís Roberto Cavalcanti da SilvaNo ratings yet

- Can Be Used in SI-engines, To Increase The Resistance To Knock Not Suitable For CI-engines DueDocument21 pagesCan Be Used in SI-engines, To Increase The Resistance To Knock Not Suitable For CI-engines Duesagar shinkarNo ratings yet

- NaphthaDocument10 pagesNaphthaShagun Bhardwaj0% (1)

- Petroleum Naphtha - Wikipedia PDFDocument4 pagesPetroleum Naphtha - Wikipedia PDFSauptik DattaNo ratings yet

- WPC 20 2866Document8 pagesWPC 20 2866annasitNo ratings yet

- Oil-Degassing:: 1-SeparationDocument34 pagesOil-Degassing:: 1-SeparationAhmed AbdullaNo ratings yet

- PetroluemDocument37 pagesPetroluemAhmed AbdullaNo ratings yet

- Unit 4-Lecture 3-Liquid Fuel, Gaseous Fuel & Alternative FuelsDocument24 pagesUnit 4-Lecture 3-Liquid Fuel, Gaseous Fuel & Alternative FuelsLadliNo ratings yet

- Energy Optimization and Performance Improvement For Crude Distillation Unit Using Pre Flash SystemDocument13 pagesEnergy Optimization and Performance Improvement For Crude Distillation Unit Using Pre Flash SystemVAIBHAV FACHARANo ratings yet

- IOCL, Mathura Refinery Training ReportDocument26 pagesIOCL, Mathura Refinery Training ReportNamishaAgarwalNo ratings yet

- Crude Oil. The Process of Refining Involves The Following StepsDocument4 pagesCrude Oil. The Process of Refining Involves The Following StepsSai Ram MotupalliNo ratings yet

- Aizaz Home Work 1Document4 pagesAizaz Home Work 1Aizaz MuhammadNo ratings yet

- Catalytic ReformingDocument9 pagesCatalytic ReformingAjay TulpuleNo ratings yet

- Isomerization Process, Reactions, Effects of Process Variables. IsomerizationDocument6 pagesIsomerization Process, Reactions, Effects of Process Variables. IsomerizationAlaa El-sherbinNo ratings yet

- Indian Oil Corporation LTDDocument11 pagesIndian Oil Corporation LTDsaz786chemicalNo ratings yet

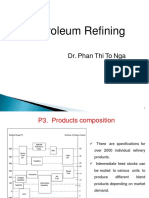

- P3. Products CBDDocument14 pagesP3. Products CBDChiến NguyễnNo ratings yet

- 03 Road Map Presentation ItalyDocument26 pages03 Road Map Presentation ItalyKURAF MUHENDISLIK AŞ.No ratings yet

- Petroleum Refining NotesDocument4 pagesPetroleum Refining Notesapi-304149645No ratings yet

- FuelsDocument44 pagesFuelsfirst lastNo ratings yet

- Paper Nr101Document6 pagesPaper Nr101SterlingNo ratings yet

- Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingFrom EverandDeactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingNo ratings yet

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- 199 Department of Civil EngineeringDocument6 pages199 Department of Civil EngineeringMARSDEN RONNYNo ratings yet

- Answers To Assignment 5 Continuity, Bernouilli and Energy EquationDocument4 pagesAnswers To Assignment 5 Continuity, Bernouilli and Energy EquationAbhinandan RamkrishnanNo ratings yet

- Water ConservationDocument29 pagesWater ConservationsurekhakcNo ratings yet

- Extended EssayDocument10 pagesExtended EssayManjula DasyamNo ratings yet

- Hydraulic Analysis of Ductile Iron PipeDocument8 pagesHydraulic Analysis of Ductile Iron PipemartjnNo ratings yet

- Texaco Oil EquivalentsDocument32 pagesTexaco Oil EquivalentsMustafa100% (2)

- Hydraulics - Graphic Symbols ValvesDocument1 pageHydraulics - Graphic Symbols ValvesJairoHernanLoperaNo ratings yet

- MYP Unit Planner - 3, G8Document5 pagesMYP Unit Planner - 3, G8Likisha RaffyNo ratings yet

- Body Valve PicantoDocument7 pagesBody Valve PicantoadinxNo ratings yet

- Project Performance Records As of 4th Quarter of 2012Document9 pagesProject Performance Records As of 4th Quarter of 2012Ki Ho ChungNo ratings yet

- Amt 1201 - Midterm - Module 2 - DelgadoDocument7 pagesAmt 1201 - Midterm - Module 2 - DelgadoBrendan Lewis DelgadoNo ratings yet

- A JCB Gyári Kenőanyagainak Átváltó Segédlete A KenőanyagokraDocument4 pagesA JCB Gyári Kenőanyagainak Átváltó Segédlete A KenőanyagokrakotvasilevNo ratings yet

- 104T4691 - A Liquid FuelDocument3 pages104T4691 - A Liquid FuelseshatsNo ratings yet

- Opposition - FBDocument37 pagesOpposition - FBRomulo UrciaNo ratings yet

- Goal Plot 1Document56 pagesGoal Plot 1jaelani sidikNo ratings yet

- Donaldson LPG Filter Data SheetDocument2 pagesDonaldson LPG Filter Data Sheetronald mudimuNo ratings yet

- CVE 372 HYDROMECHANICS - 2 Flow in Closed Conduits 2 PDFDocument54 pagesCVE 372 HYDROMECHANICS - 2 Flow in Closed Conduits 2 PDFabhilibra14No ratings yet

- Design of Oil Water Separator - API 420Document17 pagesDesign of Oil Water Separator - API 420melpomenne100% (1)

- Pump - Suction Side System DesignDocument9 pagesPump - Suction Side System Designashumishra007100% (1)

- High-Cycle Thermal Fatigue in Mixing Tees. Large-Eddy Simulations Compared To A New Validation ExperimentDocument21 pagesHigh-Cycle Thermal Fatigue in Mixing Tees. Large-Eddy Simulations Compared To A New Validation ExperimentdidoNo ratings yet

- FUCHS RENOLIN B SeriesDocument1 pageFUCHS RENOLIN B SeriesAnonymous srwHCpANo ratings yet

- Energy Dissipators and Hydraulic Jump by Willi H. Hager (Auth.)Document298 pagesEnergy Dissipators and Hydraulic Jump by Willi H. Hager (Auth.)Cecilia GalvezNo ratings yet

- MJ2429 Part I PDFDocument74 pagesMJ2429 Part I PDFmailsk123No ratings yet

- 1800 Pcs Screens Performance ChartsDocument1 page1800 Pcs Screens Performance ChartsJorge BarrazaNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement and Mixing Intensity CalculationWael Abdel-MageedNo ratings yet

- Absorbers: About AbsorptionDocument18 pagesAbsorbers: About AbsorptionLorraineNo ratings yet

- Uenr Uenr: Flow Regimes in The ReservoirDocument12 pagesUenr Uenr: Flow Regimes in The ReservoirOdonkor NicholasNo ratings yet

- Week 4Document7 pagesWeek 4shmyeNo ratings yet