Professional Documents

Culture Documents

Violin Luthier

Violin Luthier

Uploaded by

Andi NurafniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Violin Luthier

Violin Luthier

Uploaded by

Andi NurafniCopyright:

Available Formats

Fiddle Kit

#5342 Assembly Instructions

www.stewmac.com

Coloring the varnish 12

More fnish coats 12

Level sanding 13

Attach the fngerboard 13

Final-fnish the neck 14

Re-install the tailgut saddle 14

Fitting the tuning pegs 14

Slot the nut 15

Install the soundpost 15

Fit the bridge 16

Install the tailgut 17

Install the fne tuner 17

Install the chinrest 18

String the fddle 18

Kit parts list 2

Recommended tools and supplies 2

Install the purfings 3

Install the bass bar 4

Attach the top 5

Prepare the neck 6

Fit the neck 7

Cutting the mortise 9

Glue the neck 9

Install tailgut saddle 10

Install the endpin 11

Wood and fnish preparation 11

Applying varnish 11

Apply the frst two fnish coats 12

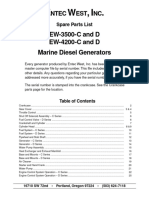

Table of contents

important for you to dry run the ftting, gluing, clamping

and fnishing operations before trying them for real

Youll need a fat work surface, approximately 2' x 4' or big

enough for your fddle

Be safe when using tools, glues, and fnishes. Wear eye

protection and gloves when needed, and always use

proper ventilation.

Welcome to the world of fddle building! The fddle youre

about to build has a quality spruce top with curly maple sides

and back This kit is designed for the beginner and intermedi-

ate builder, with enough of the diffcult work already done

to give you a great head start The fne handwork is left to

you, with the help of these instructions

Please read these instructions before starting on your fddle,

so youll understand the process and how the parts ft Its

Fiddle Kit Instructions

stewmac.com

Please make sure you have all these parts before assembling

your kit Its important to completely rehearse all ftting

and clamping operations before applying glue or fnishing

materials

1 Spruce bass bar

2 Carved maple neck, tuning pegs, fngerboard and nut

3 Carved spruce top with pre-cut F-holes

4 Carved maple back and side assembly

5 Strings

6 Endpin

7 Purfing

8 Fine tuner

9 S-shaped soundpost setter

10 Pre-shaped boxwood tailpiece

11 Pre-shaped boxwood chinrest

12 Tailgut saddle

13 Maple bridge

14 Soundpost blank

15 Tailgut

16 Chinrest mounting bracket

17 Cork

Not pictured: rubber binding band

Kit parts list

Supplies

Pencil

Binding tape (#0677)

Titebond wood glue (#0620) or

hide glue (#0669) and glue pot (#0668)

3M Gold Fre-Cut Sandpaper 150, 220, 320, 400, 800-grit

Micro Finishing Paper 1500-grit

(#5562 Sandpaper/Finishing Sampler Package)

Quality paint brush

Lint-free cloth and cotton

Behlen Violin Varnish (#0747)

Behkol solvent (#0774)

ColorTone Concentrated Liquid Stains (optional)

medium brown (#5033), vintage amber (#5030)

Tung oil (#0624)

Fiddle LiteCase (#1498)

Violin bow, cherrywood (#4275), brazilwood (#4277)

Reference

Violin Setup DVD (#5622)

The following tools and supplies are recommended to

assemble your kit Most of these tools are standard wood-

working items, though a few specialty tools are also shown

Where applicable, item numbers for ordering from Stewart-

MacDonald are included

Tools

Steel rule with millimeters (#4894), or at least 1/64" scale

Chisels: variety of micro chisels (#1628)

brace chisel (#1629)

X-acto knife, several blades

Clamps: variety of C-clamps (#3721) or

small spool clamps (#0683) or

violin clamps (#3713)

Drill with 1/16" and 1/8" (or 15mm) drill bit

Feeler gauge (#1811)

Scraper blade with curved end (#0628)

Violin Neck Angle Gauge (#0349)

Files: miscellaneous sizes; round, fat, and curved shapes

nut slotting fles 010", 020", 032" (#0821, 0828, 0831)

Razor saw (#3598)

Tapered violin reamer, #0344

Soundpost gauge (#0389)

Recommended tools, supplies and reference materials

1

2

3

4

5

6

7

8

9

10 11 12 13 14

15 16

17

2

stewmac.com

The top and back are routed for body purfings, but you will

need to complete the points of the channels, connect the

channels at the neck end, and clean out any burrs left dur-

ing manufacture Use an X-acto knife and small micro-chisel

to cut the points, clean up the corners, shape the channel

and clean the bottom (top photo) The tang of a small fle

can be ground so that its sharp on all edges creating a

handy micro-chisel You can also smooth rough spots on the

channel walls by using a small thin blade with sandpaper

stuck to it

On the back of the fddle, theres a gap in the purfing chan-

nel near the neck joint This blank area gives you the option

of creating a decorative purfing design, which some builders

prefer In these instructions, well simply connect the ends

of the channel at this point

Create a template by drawing a 6" radius (1524mm radius)

onto stiff cardboard or plastic, and lay it on the back to trace

a curved line connecting the channel ends (middle photos)

Using your template as a guide, cut lightly with a sharp knife

Slowly make your cuts deeper until you can chisel out the

wood with your small micro-chisel

When cutting the purfing to ft, you can get sharp corner

joints by cutting with an X-acto knife or a sharp chisel (bot-

tom photo) To help you visualize the angle youre cutting,

heres a tip: cut the corner points with a sharp chisel whose

fat side has been polished to a mirror shine As you hold

the chisel on the purfing, it will refect itself in the chisel to

show you how the joint will look By cutting carefully, the

laminations of the purfing will meet evenly at the miter

joints without a gap

Be careful when bending the purfing: overbending will

cause it to crack or break To keep the purfing from break-

ing while ftting it to the channels, use a rag dipped in warm

water and wipe the purfing in the areas where you need to

make a tight bend Dont immerse the purfing in water it

will delaminate! Too much water will cause purfing to swell

bigger than the channel

Install the purfings

3

stewmac.com

The bass bar is glued under the top, beneath the bass side

of the bridge A pattern is supplied for shaping the bass

bar First, cut the rough bar stock to the sizes indicated on

the Bass bar template (next page): 10-1/2" (267mm) long,

7/16" (11mm) tall, and 7/32" (55mm) wide Next, cut out the

paper template and glue it to the side of the bass bar and

cut the bar to shape

Fit the bass bar to the top You can shape the bottom of the

bar to the template by a plane, scraper, chisel, or sander

After the initial shaping, test-ft the bar to the top The thick-

est portion of the bass bar is located toward the butt of the

instrument A feeler gauge will show you the gaps in the ft

of the bar (photo)

By taping a piece of sandpaper to the top, you can form-ft

the bass bar by carefully working it back and forth in short

Install the bass bar

(Traditional violin makers use heated Hide Glue, but its dif-

fcult to use because it cools and sets very quickly For these

instructions we use Titebond, a better choice for frst-time

builders)

When the glue has dried, trim and scrape the purfing to

lower its height so that its fush with the top and back sur-

faces Dont overwork it at this stage Youll fnal-sand and

smooth these purfings later, after the top is glued on

For the tight curves, create your own bending iron using a

piece of copper plumbing pipe and a propane torch (above

photo) Heat the pipe, keeping the temperature low, and

bend the damp purfing against the copper

The dampened purfing is left to dry in its curved shape

While one joint is drying, you can work on another area

(photo right) Remove the dry-fit purflings, handling

them gently Glue the pieces in place with Titebond glue

l3/l6"

(20.5mm)

5/8"

(l6mm)

! "

!"

7/32"

(5.5mm)

l0-l/2"

(267mm)

centerline

cross-wise strokes (photo) This will remove any small gaps

between the top and bar Once it fts, remove the template

and sand the bass bar smooth

4

stewmac.com

the rims to get a consistent measurement around the entire

circumference Dont remove too much wood Work slowly

and measure often

Inspect all the surfaces of the top, back, and rims, both in-

side and outside Pay special attention to the rims: theyre

much easier to work while the top is off Spend lots of time

scraping and/or sanding the outside of the rims Scraping

produces a cleaner fnished look; you may want to sand frst,

then scrape Now is also the time to clean off excess glue,

pencil marks, etc

By carving or fling, put a rounded edge on the underside of

the top and back where they overhang the rims This job is

much easier to do now than later when the tops on

Check the gluing surface of the top to be sure its fat before

gluing to the sides Mark all around the outer edge with

pencil, then sand the marks away on your sanding board

When the pencil marks are gone, the edge is fat and ready

for gluing

Hold the top in place, centering it on the neck block and

tail block Check the overhang of the top, and position it to

get a relatively even overhang all around (Aligning for an

even overhang all around may mean that the top doesnt

center exactly over the neck and tail blocks, but it will be

close enough that it doesnt matter)

Before you glue the top on the fddle, make sure that the

upper edge of the back/sides assembly is fat and true

Take several measurements all the way around to be sure

the sides are parallel If there are variations in the measure-

ments, mark the highest areas by scribbling on them with a

pencil (photo) As you sand the edges smooth, these pencil

marks will disappear

Sand the top surface of the back/sides assembly on a full

sheet of 150-grit sandpaper applied to a fat board or table

top (be sure it is very fat check it with a straightedge)

You can use double-stick tape, contact cement, or spray

adhesive to apply the sandpaper to your workboard Sand

Heres a neat trick used by many builders Clamp the bass bar

in place above the curved top, then roll a fat washer along

the top with a pencil point drawing the line of the curve onto

the bass bar (photo left) Do this on both sides of the bar,

and youll have a very accurate line to follow

A good way to support the top when working on the inside

surface is to clamp it upside down on the open rims of the

body (photo right) Put wedges below each end before

clamping in place

Once you feel sure of your alignment, clamp the bass bar in

place without gluing it With a pencil, lightly mark its location

on the top Remove the clamps, apply glue to the bass bar,

and re-clamp Three clamps should do the job: one in the

middle, and one at each end Be gentle dont distort the

shape of the top when you glue in the bass bar!

When the glue has dried, you can fnish sanding the bass bar

and feather the ends, thinning them down to a taper

Attach the top

5

stewmac.com

instrument is fnished

Before ftting the neck to the body, shape the neck, including

its heel and scroll (photos) Good tools for this work include

chisels, fles (both round and fat), sandpaper, and scrapers

A good tool for tight areas is sandpaper wrapped around

dowels The small abrasive belts of the Sand-Stick tool make

great scroll sanders

When youve done a dry run and are comfortable with your

clamping plan, spread Titebond glue onto the rims and

clamp the top on for real

Clamp the top in place and drill a small hole (approx

1/8"/3175mm) through the top into the neck block (photo

above) Drill a second hole through the top into the tail

block At the butt end, drill the hole within the area where

the saddle will be notched into the top later (see "Install

the tailgut saddle") Use these as alignment holes during

glue-up: insert two small brads as alignment pins to quickly

reposition the top while the glue is wet

If youre going to attach a label, nows the time, before the

top goes on! (photo, top right)

Using spool clamps or cam clamps (photo right), practice

clamping the top onto the back/sides assembly without

glue If you have a limited number of clamps, you can

supplement them by also using string and/or rubber bind-

ing bands (which are wrapped around the fddle) If you use

string, also use pieces of cardboard to protect the edges

from being crushed

For this step, the fngerboard and nut need to be temporarily

spot-glued to the neck, with just a drop or two of glue to

hold them in position Your kit may have arrived with the

fngerboard and nut already spot-glued; if theyre loose, use

a drop or two of glue to temporarily join them to the neck

for this step The wall of the pegbox aligns with the nut

After ftting the neck to the body, the fngerboard will be

removed for fnishing, then permanently installed after the

Prepare the neck

6

stewmac.com

Insert the endpin temporarily, and tie a rubber band to it

Wrap the rubber band around the fddle rims a couple of

times from end to end, and tie it off Stretch out the rubber

band and set the neck in place The rubber will clamp the

neck against the body This way, its easy to take the neck

in and out during ftting Clamp the neck down into the

neck joint using a small clamp that wont get in the way of

2OUNDOFFTHESHARPEDGES

In ftting the neck to the body, the measurements shown in

the diagram are critical Double-check these points:

The centerline of the neck and fngerboard must align with

the bodys centerline

The angle of the necks fngerboard gluing surface parallels

the plane of the top

At the neck joint, the height of the fngerboard over the

body is 15/64" (6mm)

A straightedge laid on top of the fngerboard, and extend-

ing over the top of the instrument, should measure 1-1/16"

(27mm) above the top at the bridge location

The bottom of the heel and the back of the neck must

mate perfectly with the neck mortise and neck heel cap

extension of the back

The nut/fngerboard joint is 5-1/8" (130mm) from the front

edge of the top

Put white pencil marks on each narrow side of the fn-

gerboard at 5-1/8" (130mm) from where the nut joins the

fngerboard These marks will be used later as a reference

point when ftting the neck to the body

A simple tool for ftting the neck is a Violin Neck Angle Gauge

which makes it easy to see when the neck is at the proper

angle and height above the top (photos) Make one out of

scrap wood:

The neck-set stick is 13-1/4" x 3/4" (337mm x 19mm), with

one very straight edge placed along the center of the fn-

gerboard Butted against the nut, the stick reaches over the

bridge area A smaller stick, 1-1/16" (27mm) long, is glued to

the main stick at an angle so its end is square to the top This

end rests squarely on the top at the bridge position A small

clamp will press the neck downward toward the body

Neck heel cap extension

These |oints must mate perfectly

l5/64"

(6mm)

l-l/l6"

(27mm)

5-l/8"

(l30mm)

Fit the neck

The fngerboard edges are already good straight lines, so

shape the neck to match these edges where the two meet

However, the fngerboard may need to be shaped to ft

the neck if it is wider and its edges overhang Smooth the

neck/fngerboard so their edges are fush

The fngerboard edges are sharply machined round them

off for comfortable playing

7

stewmac.com

the fddle body (This is not the line you will cut on it is

only recording the proper angle)

Next, draw a line indicating how much wood to take off

the bottom of the heel where it will meet the heel cap

Keep in mind that indicates a 15/64" (6mm) gap between

the fngerboard and the top (see diagram, previous page)

You want to reduce enough wood from the heel to lower

the fngerboard to this height (5/32" (4mm) in the case of

the fddle in these photos)

Before unclamping, trace along both sides of the heel with

pencil to draw the shape of the heel onto the fddle body

This marks the area where you will cut a mortise, or pocket,

for insetting the heel into the body

Remove the neck and mark the wood to be cut away from

the heel The white marks you made on the fngerboard

indicate where the heel will be fush with the sides You will

be insetting approximately 3/16" of wood (about 5mm) into

the mortise you make in the body, so leave that much wood

for the neck joint Staying parallel to the angle line you traced

onto the heel, mark the wood to be cut away from the heel

Also mark the wood to be cut away from the base of the heel,

where it meets the end cap (5/32" (4mm) in our case)

In the photo below, the pencil-darkened area marks the

wood to be cut away Remove the wood from the heel with a

thin saw or with chisels and fles (Removing the fngerboard

at this stage makes the cutting easier)

the neck-set stick (which must remain on center) A wedge

of wood placed under the fngerboard will allow you to

change the neck angle Slide the wedge in or out to tip the

neck if needed

The neck pictured above needs to be lowered by about

5/32" (4mm) at the heel and also at the bridge position This

means were dropping the neck down onto the body

With the rubber bands holding the neck in place, align the

neck so that it centers on the tops centerline A feeler gauge

placed under the bass or treble side of the neck heel may be

handy for making fne adjustments in the neck angle (photo

below) The neck needs to be very accurately aligned for

the next step

At this point, the neck is nicely aligned, but its heel isnt fush

against the sides it will be glued to (its resting against the

overhanging edges of the top and back) The next step is

to draw a line on the heel of the neck that is parallel to the

sides of the fddle Place a small block of wood or Plexiglas

(about 3/16" (48mm) thick) on the fddle next to the neck

heel and use it as a straightedge to trace a pencil line onto

the neck (photo top right) This line records the angle that

youll follow when you trim the end of the neck heel to match

8

stewmac.com

The heel of the neck will be glued into a mortise cut into

the body Cut this mortise following the marks you made by

tracing the shape of the neck heel onto the body Cut inside

the lines; its easy to enlarge the mortise, but you dont want

it to be oversize

The depth of the neck mortise is approximately 3/16" (5mm)

The depth is less critical than the shape: you need a good,

snug ft, and the surfaces should be fat and smooth, to

match the shape of the neck heel

A small razor saw is good for starting the cuts and deepen-

ing the walls of the mortise, followed by sharp chisels Stay

inside your pencil lines while cutting, and carefully increase

the size until the neck ft is perfect

As you create the mortise, keep your chisels sharp and keep

the mortise shape fat and smooth This is tricky cutting, but

take your time and remove only a little bit with each cut Slow

and careful will give you great results The neck joint must

be snug, but not too tight If its too tight it will put undue

stress on the surrounding wood when clamped for gluing,

and that could split the wood holding the neck

Refer to your pencil line marking the angle of the neck set

Keep this line parallel to the sides of the fddle If its not

parallel, remove tiny amounts of wood to adjust the angle

of the neck Check your progress often

When the neck ft is correct, you are ready to glue the neck in

place (you may wish to spot-glue the fngerboard back on in

order to test the centerline alignment again) As always, dry-

clamp the glue joint to perfect your clamping methods before

actually using glue Make sure you have enough time to ft

everything together and apply clamping pressure (especially

important with hide glue, which sets quickly) A well-rehearsed

clamping procedure will give you accurate results

The neck can be clamped with a single C-clamp contacting

the heel cap and the top of the fngerboard In the photos

below weve made a clamping caul that allows the neck-set

Glue the neck

Cutting the mortise

stick to stay on during the clamping This isnt necessary,

but its a good way to keep an eye on maintaining the neck

angle during this procedure

To make this caul, cut two pieces of wood that will stand

slightly taller than the neck-set stick Shape them to match

the curve of the fngerboard, and glue them onto the sides

of the stick A bridge of wood across the tops of these two

pieces will give you a clamping surface that allows the

neck-set stick to stay on during gluing While gluing, you

can check the neck angle with the neck-set sticks 1-1/16"

(27mm) fnger

9

stewmac.com

The tailgut saddle supports the plastic tailpiece fastener and

keeps it from damaging the softer wood of the fddles top

Professional makers dont cut and ft the saddle until the

fddle is fnished and buffed, but we recommend that you

do it now After fnishing the fddle, youll glue the saddle

into the notch you create now

To install the tailgut saddle youll need to cut a small notch

into the top above the endpin hole This notch should be

3/16" (5mm) wide, 1-3/8" (35mm) long, and 1/8" (3mm)

deep

The saddle is 1-3/8" (35mm) long x 5/16" (8mm) high and

needs to be shaped so that a ridge rises along the center of

one side This ridge is 3/4" (19mm) wide, and will stand 3/16"

(5mm) above the fddles spruce top

Square-up the saddle blank on a fat surface covered with

100-grit sandpaper Make sure the bottom and one side are

square to each other these are your gluing surfaces, and

this is the side which will have the ridge described above Cut

and square the sides of the saddle to match the dimensions

of the diagram Mark Top on the top edge to keep track of

which end is up while youre working

Use a small fle, a chisel or plane, and sandpaper to shape

the saddle blank, keeping your squared edges clean and

ready for gluing

When the saddle blank is the right size, hold it frmly on

center above the endpin hole and on each side make a

clean, sharp cut in the spruce top using an X-acto knife (top

photos) Deepen these cuts with the knife, and then use the

knife and chisels to cut the mortise the notch that the

saddle will glue into after fnishing

Compare the saddle to the mortise often as you work When

the ft is good, hold the saddle blank in place and mark

around it with a pencil to show where the top surface meets

it Using this mark and the dimensions in the diagram above

as a guide, shape the saddle

Install the tailgut saddle

l-3/8"

(35mm)

3/4"

(l9mm)

5/l6"

(8mm)

3/l6" (5mm)

above violin's

top

10

stewmac.com

lin reamer makes this easy) Dont ream much! Test often!

When the endpin fts, remove it until after the fnish has

been applied

Now youre ready for fnishing!

The endpin mounting hole is pre-drilled, but will need to

be reamed to accept the endpin It wont take much to

shape the hole to ft the peg; you can do this with a bit of

sandpaper wrapped around the tip of the peg itself (a vio-

Install the endpin

When the wood is dry, scrape or sand it again, smoothing

away the fbers that are raised by dampening the wood

Mask off the notch you cut for the tailgut saddle, to keep it

free of fnish (for a good glue joint later)

Many makers remove the fngerboard and spot-glue on

a temporary dummy board that stops at the end of the

neck heel (tape can be used to mask it off) This protects the

necks gluing surface during fnishing, and the absence of

the fngerboards overhang makes fnishing the top easy

The fddle is now in the white and ready for careful wood

preparation before fnishing Prepping a fddle is enjoyable,

and involves scraping, fling, sanding, and more scraping

Final-scraping leaves a smooth surface without the scratches

of sandpaper, and it exposes the wood grain nicely for

fnishing Scraping takes some practice, and your scraper

must be sharp

Shape the overhang of the top and back using a fle, knife,

scraper, and sandpaper (photo) Use these same tools to

remove all scratches from the sides, top, and back After

thoroughly prepping the surfaces, dampen the wood with

a rag dipped in hot water and well squeezed-out to raise

the grain (dampen the wood, dont wet it)

Wood and fnish preparation

You can also stain the wood or tint the varnish to achieve a

specifc color or shade using Stewart-MacDonalds ColorTone

concentrated liquid stains In the fnish steps shown here, we

tint the varnish For a frst-time builder, however, the best

fnishing plan is the simplest, so if this is your frst fnishing

project we recommend that you apply uncolored varnish

We recommend Behlen Violin Varnish, a traditional fnish

that can be sprayed, brushed, or rubbed onto the instru-

ment Varnish is a good choice for a frst-time fddle builder;

its easy to apply, builds quickly, and dries to a hard luster It

has a slight amber tint that is typical for fddles

Its important to clean and dust your fnishing room before

applying varnish This is to avoid raising dust that can settle

on the surface while the varnish is curing (varnish is a slow-

curing fnish)

Applying varnish

varnish into the wood using circular, fgure-eight motions

Watch for wet areas, and wipe them up with the tampon

Never stop moving with the varnish-wet rag, or it will stick

You will end up using very little fnish, and the wood will be

Thin the varnish with denatured alcohol such as Behlens

Behkol to make a 4:1 mixture (4 parts varnish and 1 part

Behkol) Apply the varnish with a tampon made of a lint-

free cloth wrapped tightly around a cotton ball Rub the

Seal the wood

To hold the saddle for carving, use a scrap of wood with

a raised stop on one end that you can butt the saddle

against This will keep your fngers safely away from the

cutting tools

Once the saddle is shaped and fts the notch well, set it aside

It will be glued in after fnishing the violin

11

stewmac.com

If you have professional spray equipment, you can spray the

coats of varnish With spraying, its easier to achieve an even

coverage than with brushing You can also spray coloring

stain on the instrument in the frst coats, without the blotchy

look of hand-staining unfnished wood

well sealed Even with no color added, the varnish brings out

a great color in the wood

After your sealer coat is dry, use a light touch to remove any

lint or dust with 400-grit sandpaper (we prefer 3M Gold Fre-

Cut Sandpaper) Dont actually sand the wood just kiss

the surface, leaving your sealer coat intact

Apply the frst coat of varnish using a quality brush On the

fddle top, brush only lengthwise along grain lines of the

spruce The maple back can be brushed both crosswise and

lengthwise The varnish is amber-hued, so each coat adds

more richness and color

Clean your brushes well after every use, and hang them in a

glass jar with a bit of thinner (Behkol) in it Keep a dust-proof

cover on the jars, and suspend the brushes by their handles

so the bristles dont touch the bottom

colored or uncolored varnish Unfnished varnish gives a rich

honey amber color Weve decided to tint our varnish to get

a richer, reddish color

If youre coloring the varnish, follow the steps in the next

section If youre using uncolored varnish, skip the Coloring

step and resume with More fnish coats below

Apply two coats of varnish, one coat a day, and let the last

coat dry for at least two days After its thoroughly dry,

lightly sand the instrument with 220-grit or 320-grit gold

sandpaper to remove ONLY high spots in the fnish (dont

sand through the thinner parts of the fnish)

The next step will be to apply two more coats of varnish,

but here is where you need to decide whether youre using

Apply the frst two fnish coats

For transparent color, use ColorTone stains added to a little

unthinned varnish We used a mix of medium brown and

vintage amber Pour the colored varnish into a fat bowl and

dip your fnish tampon lightly into it to pick up color Work

the colored varnish into the fnish where you choose, build-

ing the color toward the edges to create a subtle sunburst

effect Use a small brush to apply color to the surfaces of

the scroll

Applying color to bare wood is tricky and it streaks easily,

but now that you have two coats of varnish applied, you can

add color to the next two coats and its easier to get good

results In this step, youll add color to your varnish and rub

it onto the existing fnish Youll fnd that you can highlight

areas and create a subtle sunburst effect near the edges of

the fddle

Coloring the varnish

If you have professional spray equipment, you can spray

the coats of varnish

At this point, youve applied four coats of varnish (you

may or may not have added color between coats 2 and 3)

Give the fnish time to cure, 2 days or more If the varnish

imprints easily with a thumbprint, it is not dry enough to

sand or spray

Brush two more coats of varnish, one coat per day Brush

in long straight strokes that slightly overlap Begin and end

your brush stroke off the instrument, like an airplane gliding

onto the surface Dont stop a stroke in the middle of the in-

strument continue moving off the edge Use a light touch:

brushing over color can lift the color and cause streaks

More fnish coats

12

stewmac.com

After the varnish has cured, sand the fnish to a satin sheen

with 1200-grit, or polish it to a high gloss, whichever you

prefer Use a power buffer if you own one, but be careful:

a buffng wheel can easily heat the varnish and pull or

streak it Hand-buffng with medium and fne grit polishing

compounds is safer

When the last coat of varnish applied is dry, carefully level

it with 320- and/or 400-grit sandpaper The high parts of

the fnish will be fattened by the sanding, and become

dull That leaves the low areas which are still shiny (shown

in the photo) Sand until you start removing some of these

low spots, but not all of them They will be flled in with the

next fnish coats

After sanding, apply a coat of varnish and let it dry overnight

If the fnish has cured perfectly level and smooth, with the

sheen youre looking for, youre done fnishing Its more

likely that the varnish will have flled in most of the low

spots, but not all

If it has a smooth surface with only a few low spots, youre

probably done applying varnish You wont know until you

try sanding the coat smooth Start with 800-grit Fre-Cut

paper and graduate to 1200-grit Micro-Finishing paper If

you still have some low spots in the fnish, and are unsure

whether they would disappear when buffng the fnish, its

a good idea to add another coat of varnish

Set the fddle aside to cure for one to three weeks before

ftting the parts

Level-sanding

Use a sharp knife to remove the tape or dummy fngerboard

from the neck Clean the glue remnants from the surface of

the neck and fngerboard before gluing the fngerboard to

the neck

Align the fngerboard carefully, keeping in mind the 5-1/8"

(130mm) measurement from the edge of the nut to the

edge of the fddle top (see diagram page 7) Do a dry-run

of your clamping procedure to be sure of your positioning,

then apply the glue and clamp

Spread the glue in a thin layer to avoid excess squeeze-out,

and wrap the fngerboard to the neck using the rubber band

provided Rubber band clamping gives you a chance to clean

away glue squeeze-out, and move the fngerboard to align it

during the frst few wraps of the band Once youve wrapped

the neck from end to end, youll have a very strong clamp

holding the fngerboard in place Let it dry overnight

Attach the fngerboard

13

stewmac.com

fnishing, now is the time for that step (see Install the tailgut

saddle)

Traditionally, the color of the fddle covers the peghead and

heel of the neck, but feathers away to an almost-bare playing

surface on the back of the neck By sanding and scraping,

feather the fnish at the heel and peghead creating a quick,

smooth transition blend from the fnish to bare wood

Scrape and sand the maple smooth, then add a light stain

for a traditional look Practice on a scrap piece of maple

to fnd the color you want We used ColorTone Amber and

Medium Brown, in tiny amounts, added to Behkol solvent

until we got the look we liked

Then we stained the real thing Allow the stain to dry, then

rub the neck with a clean rag to burnish it Wipe on a coat or

two of Tung Oil for a fnal fnish that has a bare wood feel

Remove the mask from the mortise you cut for the saddle

A little careful cleanup will probably be needed Glue the

saddle in place If you chose to cut and ft the saddle after

D

G

L

A

about l/2"

(l2-l4mm)

centerline

Re-install the tailgut saddle

The pegholes are tapered to accept the tuning pegs, but

youll need to refne this shape with a violin peg reamer for

a good ft A few careful turns should be all thats needed

Check the ft after every twist of the reamer The diagram

shows that the band around the tapered shaft is generally

1/2" (12 to 14 mm) from the side of the pegbox Try to make

all four pegs extend the same distance

When each peg is properly seated and operating smoothly,

mark the ends of the pegs with a pencil to show where

the excess wood needs to be cut away Remove the pegs

and trim them to length, then smooth the cut ends with

sandpaper

Put the trimmed pegs back in their respective holes, and

mark the location of the string hole in each peg The string

hole should be slightly off-center (as measured within the

pegbox), toward the knob side of each peg Use an awl to

make a start for the hole to be drilled

Carefully drill a 1/16" (15mm) hole through each peg, then

smooth the sharp edges of the hole, for less stress on the

string When drilling, hold the peg down frmly on a hard

wood surface so that when the drill bit comes through the

other side it doesnt blow-out wood

Fit the tuning pegs

Final-fnish the neck

14

stewmac.com

"RIDGE

3OUNDPOST

Without a soundpost gauge: Look through the endpin

hole to see the curve of the top and back Trim the soundpost

bottom to approximate the back curve Stand the soundpost

in the F-hole Mark the angle of the fddle top onto the

soundpost in pencil Use this line as a guide and trim the

post to length, approximating the angle of the surface the

post will rest against Try ftting the post and remove wood

if necessary to get a good ft Remove only small amounts

of wood, test-ftting often

Use the S-shaped soundpost setter to position the

soundpost The sharp end of the setter is poked into the

side of the soundpost and inserted through the treble side

F-hole You can sight the position of the soundpost through

the endpin hole and the treble F-hole

When the soundpost has the proper length and shape,

install it in the fddle Moistening the ends of the post will

help it stay in place

The nut blank comes roughly shaped to the correct size Be

sure the bottom is fat, as well as the front wall that glues

to the fngerboard If necessary, square it up on your fat

sanding board

String spacing at the nut should be 41/64" (163mm) be-

tween the two outside strings With the two inner slots

added, the space between string slots should be 7/32"

(543mm)

Slot the nut

The bottom of each string slot should be 1/64" (03mm)

above the fngerboard (slightly less than the thickness of a

business card) The depth of the slot should be about 1/3 of

the strings diameter Use a triangular fle to start the slots,

and fnish them with small round fles that match the string

diameters Nut slotting fles work well for this

File the nut to its fnal shape, smooth its surfaces and make

sure its not wider than the neck You might want to remove

it for this work and glue it back on afterward

Be very careful and precise when ftting the soundpost since

it determines the overall volume and tone of the fddle

The soundpost is ftted inside the instrument, between the

top and back Its installed about 1/8"(3mm) behind the

bridges treble foot (see diagram) with its grain or annual

rings perpendicular to that of the top and back Dont use

glue to secure the soundpost The ft should be snug, but

doesnt need to be tight, since pressure from the strings will

provide additional clamping force

Carefully cut the soundpost to roughly the proper length

(described below) It may take several attempts to get it

right, so consider making one or two practice posts from

scrap Be patient and do not remove wood too quickly The

soundpost ends are not parallel They must be carved to

conform to the inner shapes of the bodys top and back As

you get close to fnal size, dampen the end of the soundpost

this will raise the grain and allow you to trim off a very

thin shaving of wood as you approach the fnal ft

Two ways to rough-in the length of the soundpost:

With a soundpost gauge: Insert the soundpost marking

gauge through the treble f-hole, and hold it in the soundpost

location (photos) Set the gauge and transfer its measure-

ment to the post, using a pencil to mark the approximate

angle of the curve of the top and back Trim the post to

length, trimming the ends to match the angles of the sur-

faces they will rest against

Install the soundpost

15

stewmac.com

mately 3/64" (13mm) thick at the top and 5/32" (4mm) at the

base The back of the bridge (towards the tailpiece) should

remain fat and perpendicular to the top when installed

The front side of the bridge should taper or curve inward

slightly just above the feet Sand the bridge to thickness or

use a chisel, fle, or knife

In the photo below, the bridge has been fitted to the

top, trimmed to height, and shaped round on the front It

rests squarely on its feet, and is ready to be smoothed of

scratches

The bridges taller side is for the bass strings, with the treble

strings sitting slightly lower and closer to the fngerboard

The bridge will need fnal height adjustment and ftting

Flatten the bridge by sanding it on a fat surface Do this

sanding on the back of the bridge Scribble with pencil on

this side, then sand until the pencil marks are gone The

disappearing marks will show whether youre sanding the

whole surface evenly

The feet of the bridge must conform to the curved top of

the fddle Set the bridge in place and trace the curve of the

top onto it using a half pencil (a pencil sanded fat on one

side) (above photo) Trim the feet to this shape, leaving

the pencil line showing (this leaves wood to work with in

shaping the feet)

Trim the feet so that the bridge sits square to the top (above

photo) Carving the feet accurately can be diffcult A good

method is to put a small piece of 120-grit sandpaper on

the top in the bridge location and sand the feet with short

strokes until they match the tops curve Be careful to keep

the bridge standing up straight, perpendicular to the top

With a pencil, mark the locations for the two outer strings (G

and E) 1-5/16" (335mm) apart and centered Mark the two

remaining strings (D and A) at 7/16" (113mm) apart

To check the height of the bridge, lay a straightedge on

the fngerboard Extend this straightedge to the bridge,

and make a pencil mark showing this height at the G string

position Make another mark at the E string position (these

are the two outer strings)

These two marks indicate the fngerboard line extended to

the bridge Next, make a second pair of marks above these

two, indicating a higher point for shaping the top of the

bridge Raise the G string mark by 9/32" (7mm) on the bass

side, and raise the E string mark by 7/32" (55mm) on the

treble side Draw a curve between these two marks using the

bridge template (see "Prepare the neck" cut out page)

The E-string slot should be 3/32" (25 - 3mm) above the fn-

gerboard line, and the G-string should be 11/64" (45mm) If

only a small adjustment is required (less than 1/64" (1mm)),

remove material from the feet by sanding If more must be

removed, take the material from the top rather than the

feet The feet should remain between 5/64" (19mm) to 1/8"

(25mm) thick

If the bridge is too heavy it will affect the fddles tone, so it

will need to be thinned and shaped It should be approxi-

Fit the bridge

16

stewmac.com

The bridge can be further reduced in weight by beveling the

sides and the edges of the cutaway holes, and thinning the

feet if they are too thick Raising the bottom arch between

the feet reduces mass, and looks good, too

The string notches will be cut later, when the strings are

on The bridge is held in place by the string tension, and

no glue is used

Insert the endpin into the fddle Secure the tailgut to the

tailpiece, installing it as in the photo Remove the thumb-

screws, push each threaded end through the tailpiece holes,

and thread the thumbscrews back on When attached to the

instrument, the end of the tailpiece should be almost touch-

ing the front edge of the tailgut saddle Adjust the tailguts

length, using the thumbscrews, to locate the tailpiece at

that point Trim excess material from the tailgut, and set

the tailpiece aside

Install the tailgut

The fne tuner installs from underneath the tailpiece It

should be tight If for any reason the fne tuner is touching

the fddle top, it will need to be inset up into the tailpiece

by chiseling a pocket for it

Install the fne tuner

Before

After

17

stewmac.com

justing bars To tighten or loosen the bracket, rotate both

turnbuckles the same number of turns

Glue the cork to the bottom of the chinrest and onto the

metal bracket where it contacts the fddle body Double-stick

tape will keep the cork in place, but a glue such as Goop

is more permanent

Attach the chinrest to the fddle The holes in the turnbuckles

allow you to tighten them with a thin tool

The bracket spans the notched area of the chinrest that fts

over the tailpiece Set the chinrest over the tailpiece with

clearance on both sides Find and mark its center, then

locate the bracket holes equally from center and drill them

with a 1/8" bit Disassemble the metal bracket and thread

the L-shaped pieces into the holes (they will cut their own

threads) You may want to use a small amount of glue so

that they dont come loose

The chinrest bracket has two turnbuckles that work as ad-

Install the chinrest

Before stringing, put a little graphite into the string slots at

the nut by rubbing pencil lead in them

Protect the top by placing a cloth under the tailpiece, then

install the tailpiece Insert the strings into the tailpiece and

run them up to the pegbox, installing them loosely before

placing the bridge

Push approximately 1/4" (6mm) of string through each peg

hole and wind it once or twice onto the side away from the

peg knob Continue winding, crossing over the hole, toward

the peg knob

Set the bridge in position, locating the strings over your

pencil marks for string spacing Measure the string spac-

ing again to check for accuracy Outside strings are 1-5/16"

(335mm) apart, with equally spaced strings between Cut

notches for the strings with a sharp knife and smooth the

edges of these notches with a fle or sandpaper

String to pitch, recheck the bridge alignment, and youre

ready to play your fddle!

String the fddle

18

21 N. Shafer St Athens, Ohio 45701 USA

USA & Canada call toll-free: 800-848-2273

9am-6pm weekdays Eastern time

24-hour fax: 740-593-7922

www.stewmac.com

i-5342

01/08

You might also like

- Violin Templates and The Form PDFDocument9 pagesViolin Templates and The Form PDFAndrés Medina100% (1)

- Lutherie - Making A ViolinDocument68 pagesLutherie - Making A Violinanon-620705100% (26)

- How To Make A Violin PDFDocument176 pagesHow To Make A Violin PDFOmarInfante78% (18)

- Controlling Arch ShapeDocument9 pagesControlling Arch Shapenostromo1979100% (1)

- Del Gesu Table of MeasurementsDocument1 pageDel Gesu Table of MeasurementsCarl100% (1)

- Power Up Level 2 FlashcardsDocument180 pagesPower Up Level 2 FlashcardsRoberto BekembauerNo ratings yet

- Learn Violin-Making With Dmitry BadiarovDocument12 pagesLearn Violin-Making With Dmitry BadiarovDmitry Badiarov75% (4)

- Violin MakingDocument69 pagesViolin MakingJeffrey Grosser88% (8)

- A Dictionary of Violin MakersDocument116 pagesA Dictionary of Violin MakersFernando Coton Luthier100% (6)

- The History and Design of the Violin Bridge - A Selection of Classic Articles on the Development and Properties of the Violin Bridge (Violin Series)From EverandThe History and Design of the Violin Bridge - A Selection of Classic Articles on the Development and Properties of the Violin Bridge (Violin Series)No ratings yet

- Making The Violin Geometric Arching Shape - KopiaDocument24 pagesMaking The Violin Geometric Arching Shape - Kopianostromo1979100% (1)

- Area Tuning The ViolinDocument10 pagesArea Tuning The ViolinRotar Razvan100% (1)

- Facts About Violin Making - Tiegton - 1904Document29 pagesFacts About Violin Making - Tiegton - 1904Christopher WardNo ratings yet

- Varnish ViolinDocument15 pagesVarnish ViolinMassimiliano Giacalone100% (1)

- Violin Varnish and How To Make ItDocument54 pagesViolin Varnish and How To Make ItMatt Hartwell100% (5)

- Violin Making, Second Edition Revised and Expanded: An Illustrated Guide for the AmateurFrom EverandViolin Making, Second Edition Revised and Expanded: An Illustrated Guide for the AmateurRating: 4.5 out of 5 stars4.5/5 (2)

- The Art of Violin Playing for Players and TeachersFrom EverandThe Art of Violin Playing for Players and TeachersRating: 4.5 out of 5 stars4.5/5 (3)

- The Violin Maker: A Search for the Secrets of Craftsmanship, Sound, and StradivariFrom EverandThe Violin Maker: A Search for the Secrets of Craftsmanship, Sound, and StradivariRating: 4 out of 5 stars4/5 (9)

- The Art of Violin Playing - How to Achieve SuccessFrom EverandThe Art of Violin Playing - How to Achieve SuccessRating: 5 out of 5 stars5/5 (1)

- ViolinDocument24 pagesViolinPriscilla Satie Aono Hipolito100% (1)

- Making A New Violin BridgeDocument9 pagesMaking A New Violin BridgefuyberNo ratings yet

- Designrr - Cello-RepairsDocument56 pagesDesignrr - Cello-RepairsRuukie Chen100% (2)

- Making The Violin ManualDocument73 pagesMaking The Violin ManualFldksk100% (2)

- How To Make A Violin, J. Broadhouse, Rev. Ed.Document139 pagesHow To Make A Violin, J. Broadhouse, Rev. Ed.Beray Selen100% (10)

- Cello BridgeDocument11 pagesCello Bridgefrancisco Javier CaballeroNo ratings yet

- How To Make A Violin 1900Document178 pagesHow To Make A Violin 1900als36violi100% (3)

- Empirical Tools in Contemporary Violin Making: Part I. Analysis of Design, Materials, Varnish, and Normal ModesDocument15 pagesEmpirical Tools in Contemporary Violin Making: Part I. Analysis of Design, Materials, Varnish, and Normal ModesFábio Daniel HadadNo ratings yet

- Bridge Wood Removal RodgersDocument5 pagesBridge Wood Removal RodgersCristian TorricoNo ratings yet

- Shaping Violin or Viola CornersDocument19 pagesShaping Violin or Viola CornersJairo Duarte100% (2)

- Guarneri AndreaDocument163 pagesGuarneri AndreaViolin Ttpc100% (1)

- Violin Repair and RestorationDocument148 pagesViolin Repair and RestorationMichael Mayson100% (3)

- How To Make Varnish: Adele BeardsmoreDocument3 pagesHow To Make Varnish: Adele Beardsmoremarcellomorrone100% (1)

- Bok InstrumentDocument27 pagesBok InstrumentAmeli ChanNo ratings yet

- Carving A Scroll Using Angular TemplatesDocument3 pagesCarving A Scroll Using Angular TemplatesDeaferrantNo ratings yet

- Violin Construction PDFDocument43 pagesViolin Construction PDFNóra RajcsányiNo ratings yet

- Strad Tap TonesDocument5 pagesStrad Tap TonesAlfstrad100% (3)

- Retuning The Plates of A - Cello - CASDocument1 pageRetuning The Plates of A - Cello - CASAnonymous K8QLiP0% (1)

- Violin Tone and Violin Makers, by Hidalgo Moya (1916)Document302 pagesViolin Tone and Violin Makers, by Hidalgo Moya (1916)jruivo100% (2)

- Working Methods Guarneri Del GesùDocument10 pagesWorking Methods Guarneri Del GesùhorozimbuNo ratings yet

- Subject To ChangeDocument7 pagesSubject To Changenostromo1979100% (1)

- Violin PDFDocument44 pagesViolin PDFblancofrank545No ratings yet

- The Identification of Cremonese Violins Part 1Document8 pagesThe Identification of Cremonese Violins Part 1PHilNam100% (1)

- A Note On Practical Bridge Tuning For The Violin Maker Carleen M. HutchinsDocument4 pagesA Note On Practical Bridge Tuning For The Violin Maker Carleen M. HutchinsNikolai BuerginNo ratings yet

- Edge WorkDocument16 pagesEdge Worknostromo1979100% (1)

- 10 Easy Steps To Make Your Own CelloDocument10 pages10 Easy Steps To Make Your Own CelloRamses MalonyNo ratings yet

- George Gemünder's Progress in Violin Making: With Interesting Facts Concerning the Art and Its Critics in GeneralFrom EverandGeorge Gemünder's Progress in Violin Making: With Interesting Facts Concerning the Art and Its Critics in GeneralNo ratings yet

- Violins and Violin Makers Biographical Dictionary of the Great Italian Artistes, their Followers and Imitators, to the present time. With Essays on Important Subjects Connected with the Violin.From EverandViolins and Violin Makers Biographical Dictionary of the Great Italian Artistes, their Followers and Imitators, to the present time. With Essays on Important Subjects Connected with the Violin.No ratings yet

- Violin-Making: A Historical and Practical GuideFrom EverandViolin-Making: A Historical and Practical GuideRating: 4.5 out of 5 stars4.5/5 (4)

- The Bow, Its History, Manufacture and Use 'The Strad' Library, No. III.From EverandThe Bow, Its History, Manufacture and Use 'The Strad' Library, No. III.Rating: 5 out of 5 stars5/5 (1)

- Violins and Violin Makers: Biographical Dictionary of the Great Italian Artistes, their Followers and Imitators, to the present time. With Essays on Important Subjects Connected with the ViolinFrom EverandViolins and Violin Makers: Biographical Dictionary of the Great Italian Artistes, their Followers and Imitators, to the present time. With Essays on Important Subjects Connected with the ViolinNo ratings yet

- Violin Technique - Some Difficulties and Their SolutionFrom EverandViolin Technique - Some Difficulties and Their SolutionRating: 5 out of 5 stars5/5 (6)

- A Guide to Violin Varnish - A Selection of Classic Articles on the Development and Qualities of Different Violin Varnishes (Violin Series)From EverandA Guide to Violin Varnish - A Selection of Classic Articles on the Development and Qualities of Different Violin Varnishes (Violin Series)No ratings yet

- The Violin: Some Account of That Leading Instrument and Its Most Eminent Professors, from Its Earliest Date to the Present Time; with Hints to Amateurs, Anecdotes, etcFrom EverandThe Violin: Some Account of That Leading Instrument and Its Most Eminent Professors, from Its Earliest Date to the Present Time; with Hints to Amateurs, Anecdotes, etcNo ratings yet

- Modeling and Simulation of A Distillation Column Using MatlabDocument15 pagesModeling and Simulation of A Distillation Column Using Matlabrajtharun48No ratings yet

- Wan Bao Construction Company: Register of Environmental AspectsDocument43 pagesWan Bao Construction Company: Register of Environmental AspectsJusnie Erwine EdwardNo ratings yet

- 2 Changing Our Vision From Material Outlook To Spiritual Outlook PDFDocument4 pages2 Changing Our Vision From Material Outlook To Spiritual Outlook PDFvarun7salunkheNo ratings yet

- Site Installation Standard - Ver 20200706Document179 pagesSite Installation Standard - Ver 20200706Kyaw Kyaw WinNo ratings yet

- My Business PlanDocument7 pagesMy Business Planadeoye sheyiNo ratings yet

- PIIS1098360021012478Document13 pagesPIIS1098360021012478Opale PapaleNo ratings yet

- T.E. (2019 Pattern) Insem Exam. Timetable For March-April-2024Document13 pagesT.E. (2019 Pattern) Insem Exam. Timetable For March-April-2024rauthrishikesh009No ratings yet

- EW-3500-C and D EW-4200-C and D Marine Diesel Generators: Ntec EST NCDocument27 pagesEW-3500-C and D EW-4200-C and D Marine Diesel Generators: Ntec EST NCGeorgiNo ratings yet

- Using Geophysics To Characterize The Subsurface: The PrinciplesDocument152 pagesUsing Geophysics To Characterize The Subsurface: The PrinciplesMasahiro Galang SusantoNo ratings yet

- 2bhk Sell in Casa Rio Palava City 909sqf PDFDocument54 pages2bhk Sell in Casa Rio Palava City 909sqf PDFDailydiegestNo ratings yet

- # Sample Quotation Copy For Go Kart SparesDocument3 pages# Sample Quotation Copy For Go Kart SparessaqibNo ratings yet

- 3 Most Dangerous Pressure PointsDocument4 pages3 Most Dangerous Pressure PointsNano ZetaNo ratings yet

- Powerpoint Presentation PetrophysicsDocument18 pagesPowerpoint Presentation PetrophysicsgregNo ratings yet

- Transistor-Transistor Logic (TTL or T L) : ExerciseDocument10 pagesTransistor-Transistor Logic (TTL or T L) : ExerciseHassan allaNo ratings yet

- TAD531GE: Volvo Penta Genset EngineDocument2 pagesTAD531GE: Volvo Penta Genset EngineMATS DIVISIONNo ratings yet

- 5596 EN SKF Microlog MX SeriesDocument4 pages5596 EN SKF Microlog MX SerieskarthimeenaNo ratings yet

- Alternador AVK - DSG DIG Instalacion Servicio y MantenimientoDocument595 pagesAlternador AVK - DSG DIG Instalacion Servicio y MantenimientoMartin FloresNo ratings yet

- DO10 ValveDocument6 pagesDO10 ValvetunradotNo ratings yet

- The New India Assurance Co. LTDDocument3 pagesThe New India Assurance Co. LTDsarath potnuriNo ratings yet

- Study of Reweighting Methods Using Single Histogram MethodDocument3 pagesStudy of Reweighting Methods Using Single Histogram Methodt_sairamNo ratings yet

- Fault CodesDocument6 pagesFault CodesAnonymous zF4syKOrJNo ratings yet

- Anti-Inflammatory and Analgesic Activities of Flavonoid and Saponin Fractions From Zizyphus Lotus (L.) LamDocument5 pagesAnti-Inflammatory and Analgesic Activities of Flavonoid and Saponin Fractions From Zizyphus Lotus (L.) LamDaris UntoroNo ratings yet

- Quanta G31a Dag31amb6d0 Y61x-6l Rev 1aDocument49 pagesQuanta G31a Dag31amb6d0 Y61x-6l Rev 1aKrystian PalaciosNo ratings yet

- Standard Moisture Regain and Moisture Content of FibersDocument3 pagesStandard Moisture Regain and Moisture Content of Fibersff fixNo ratings yet

- Keratin TreatmentDocument2 pagesKeratin TreatmentDilinika PriyadarshaniNo ratings yet

- Spirited Away - Film of The Fantastic and Evolving Japanese Folk SymbolsDocument25 pagesSpirited Away - Film of The Fantastic and Evolving Japanese Folk Symbolscv JunksNo ratings yet

- IPE Section PropertiesDocument2 pagesIPE Section Propertiesmajkil1988No ratings yet

- Package FaultsDocument6 pagesPackage FaultsArunraj Arumugam100% (1)

- Chapter 12 BIO 1510Document34 pagesChapter 12 BIO 1510Chachi CNo ratings yet